2

For your safety and the safety of others, read and understand the

safety recommendations and operating instructions before operat-

ing a drill.

Always wear protective equipment:

For additional information on eye protection and face protection,

refer to Federal OSHA Regulations, 29 Code of Federal Regula-

tions, Section 1910.133., Eye and Face Protection, and American

National Standards Institute, ANSI Z87.1, Occupational and Educa-

tional Eye and Face Protection. Z87.1 is available from the American

National Standards Institute, Inc., 11 West 42nd Street, New York,

NY 10036.

Hearing protection is recommended in high noise areas 85 dBA or

greater. The operation of other tools and equipment in the area,

reflective surfaces, process noises and resonant structures can

substantially contribute to, and increase the noise level in the area.

Excessive air pressure above 90 PSIG or worn motor components

can also increase sound level emitted by tool. Proper hearing

conservation measures, including annual audiograms and training

in the use and fit of hearing protection devices may be necessary.

For additional information on hearing protection, refer to Federal

Regulations, Section 1910.95, Occupational Noise Exposure, and

American National Standards Institute, ANSI S12.6, Hearing Protec-

tors.

Drilling operations may produce

hazardous fumes and/or dust.

To avoid adverse health effects

utilize adequate ventilation and/

or wear a respirator. Respira-

tors should be selected, fitted,

used and maintained in accor-

dance with Occupational Safety

and Health Administration and

other applicable regulations.

Read the material safety data

sheet of any cutting fluids or

materials involved in the drilling

process.

Safety Recommendations

WARNING

!

Wear respirator where

necessary.

!

Do not wear loose fitting clothes,

long hair, gloves, ties or jewelry.

WARNING

CAUTION!

Personal hearing protection is

recommended when operating

or working near this tool.

WARNING!

Impact resistant eye protection

must be worn while operating

or working near this tool.

CAUTION!

Follow good machine shop practices. Rotating shafts and moving

components can entangle and entrap, and can result in serious

injuries. Never wear long hair, loose-fitting clothes, gloves, ties, or

jewelry when working with or near a drill of any type.

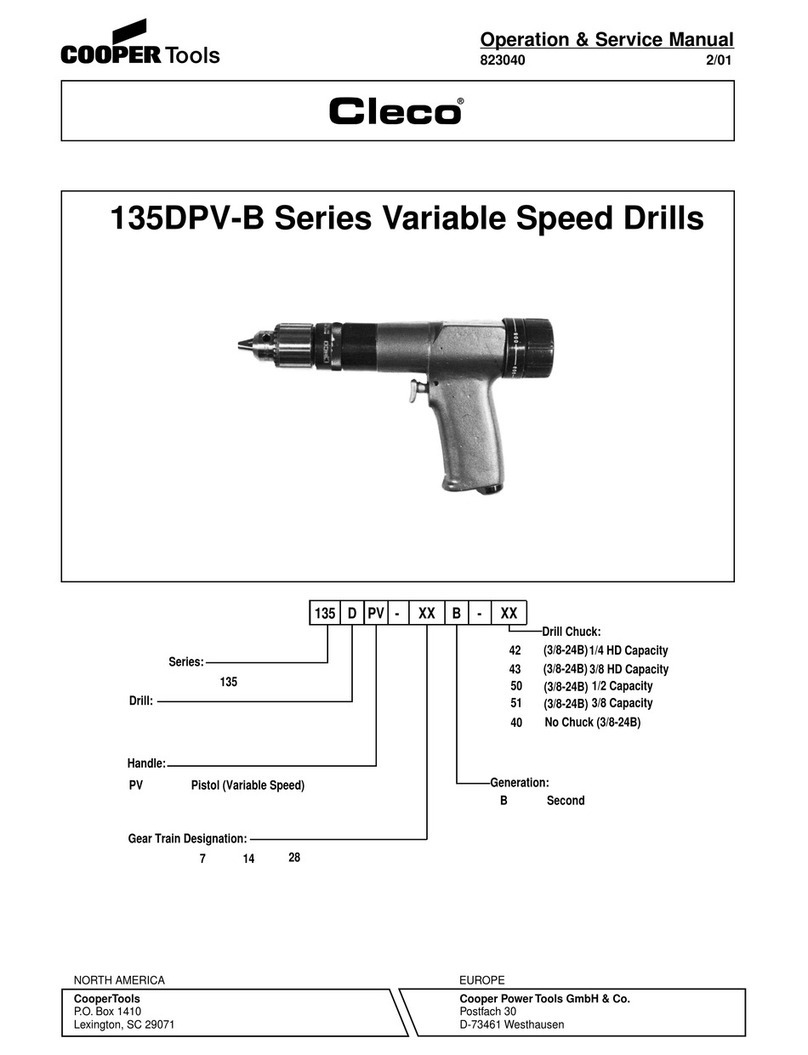

Cleco drills are designed to operate on 90 psig

(6.2 bar) maximum air pressure. If the tool is

properly sized and applied, higher air pressure is unnecessary.

Excessive air pressure increases the loads and stresses on the tool

parts and may result in breakage. Installation of a filter-regulator-

lubricator in the air supply line ahead of the tool is recommended.

Before the tool is connected to the air supply, check the throttle for

proper operation (i. e., throttle moves freely and returns to closed

position). Being careful not to endanger adjacent personnel, clear

the air hose of accumulated dust and moisture. Before removing a

tool from service or changing a drill bit, tap, reamer, or any accessory

make sure the air line is shut off and drained of air. This will prevent

the tool from operating if the throttle is accidently engaged.

Sudden and high reaction torque may be experienced with any drill

if:

• Drill motor stalls by excessive load being applied to drill bit or drill

bit snags on material being drilled.

• on break-through when the drill bit passes through the material

being drilled. User must be prepared to resist torque.

• Drill bits are sharp. Handle them carefully to avoid injury.

• Cutting tool maximum speed rating must equal or exceed rated

speed of tool.

• Drill bits or accessories not centered properly in the chuck can

cause excessive wobble or vibration.

• Use appropriately sized chuck key to securely tighten drill bit, tap,

or reamer in drill chuck. Always remove chuck key before starting

tool.

• Use care when drilling because of the possibility of the cutting tool

bending or breaking.

Tools equipped with chuck capacity over 1/4" should have at least

one handle offset at a right angle to drill axis to counteract torque

developed by tool. If tool is equipped with a chuck over 3/8" capacity,

two handles at right angles to the drill axis should be used. One

handle should contain the tool throttle, such as pistol grip or offset

handle models. Always use a dead handle with low RPM — high

torque tools.

Some individuals

may be susceptible

to disorders of the

hands and arms

when performing

tasks consisting of

highlyrepetitivemo-

tions and/or expo-

sure to extended vi-

bration. Cumulative

trauma disorders such as carpal tunnel syndrome and tendonitis can

be caused or aggravated by repetitious, forceful exertions of the

hands and arms. Vibration may contribute to a condition called

Raynaud's Syndrome. These disorders develop gradually over

periods of weeks, months, and years. It is presently unknown to what

extent exposure to vibrations or repetitive motions may contribute to

the disorders. Hereditary factors, vasculatory or circulatory prob-

Repetitive work motions and/or vibration

may cause injury to hands and arms.

Use minimum hand grip force consistent

with proper control and safe operation.

Keep body and hands warm and dry.

Avoid anything that inhibits blood circulation.

Avoid continuous vibration exposure.

Keep wrists straight.

WARNING

!

Avoid repeated bending of wrists and hands.