7

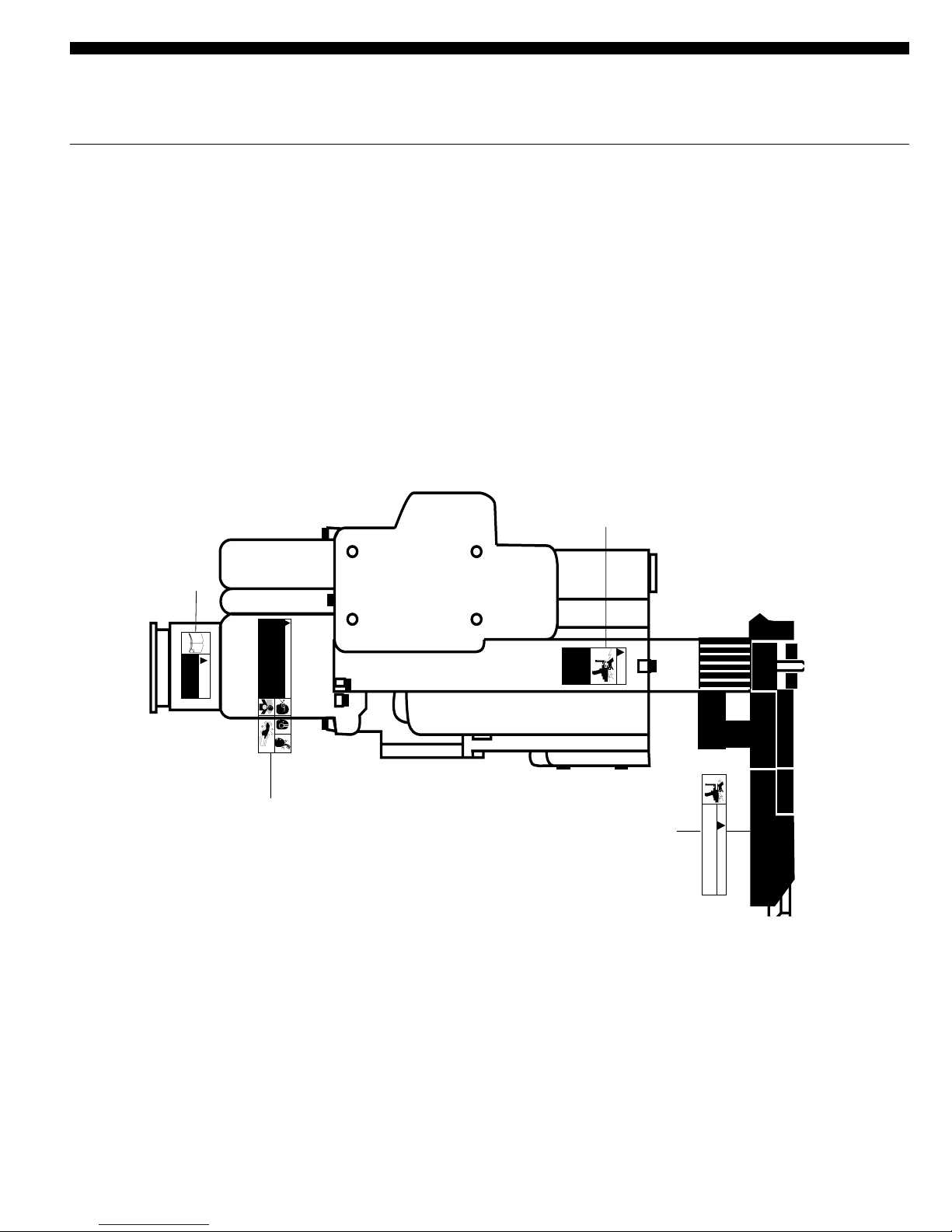

The180SC-225 isair operated,hydraulically controlled tool

thatautomaticallyclamps tothe material, drillsand counter-

sinks close tolerance holes in one operation. The 180S will

produce high quality holes in aluminum, steel, titanium and

petroleum hybrid materials primarily found in the aircraft/

aerospaceindustries.The180Sself-colletingdrillmotorhas

been designed using state-of-the-art technology that pro-

vides maximum power,minimum weight and the highest

degreeofaccuracyfordemandingholepreparationrequire-

ments.

Technical Data

Feed Stroke: Feed stroke of the 180SC-225 is 2.25 inches

to drill and countersink in 2 inch stacked material. The feed

stroke is unaffected by the collet stroke.

Collet Stroke: The 180SC-225 will clamp throughout its

.875 inch stroke. Feed stroke is unaffected by collet stroke.

Spindle Adjustment: The spindle adjustment of .375 inch

allows for drill length variations. See Spindle Adjustment

information on page 25.

Countersink Depth Control: A micrometer adjustment

provides for countersink stop repeatability within .001 inch.

Cutter Sizes: The 180SC-225 will accommodate .500 di-

ameter drills and.875 countersink diameter.

FeedRate:Anadjustabledrillfeedratemechanismenables

the 180SC-225 to drill from 5 seconds per inch to 1 minute

perinch.SeeFeedRateAdjustmentinformationonpage25.

Cutter to Collet Spacing: The cutter to collet distance is

adjustable between 1.00 inch minimum to 3.50 inch maxi-

mum.

Coolant:The180SC-225hasadrillpointcoolantportinthe

pressure foot. A coolant mist lubricator is available (See

Accessories Page 32-38)

Air Motor: The air motor for the 180SC-225 is rated at 1.8

horsepower nominal when supplied with air at 90 p.s.i.

AirConsumption:Airconsumptionofthe180SC-225is68

c.f.m. at 90 p.s.i. dynamic.

Weight:180SC-225weightwiththealuminumpressurefoot

is 14.9 pounds.

Spindle Speeds: Eleven geared spindle speeds are avail-

able with the 180S: 240, 420, 650, 850,1050, 2000, 3100,

4900, 6300, 12500 and 21000 RPM. See pages 31 and 32

for gear set assembly configurations.

TriggerLock:Atriggerlockisprovidedwhichallowsthetool

to be locked in the "Operate" position. With the lock acti-

vated, the tool will run through the clamp, feed and retract

cycles, but it will not unclamp or stop the motor until the

trigger lock is manually released.

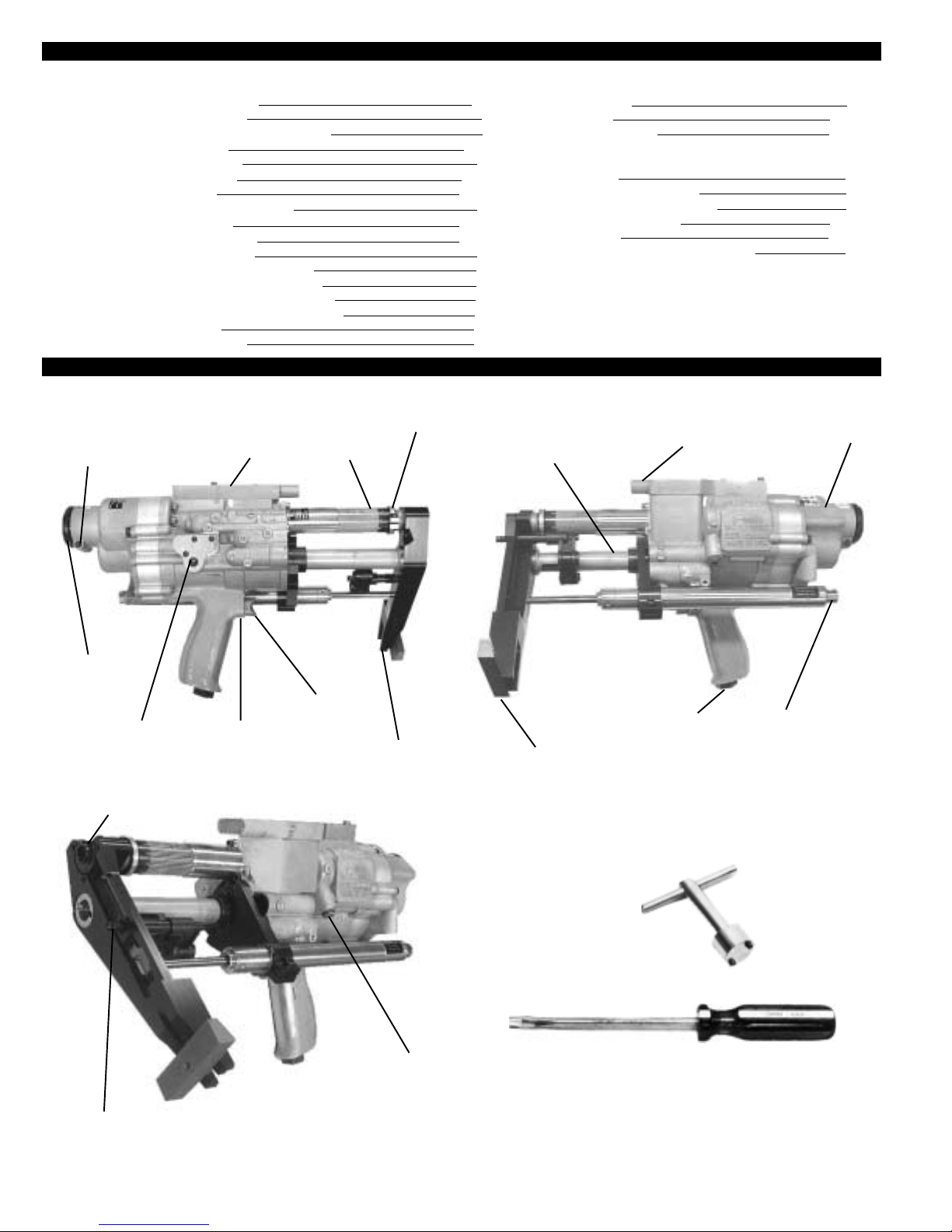

Tool Start-Up

The180SC-225 drill isshipped from the factory equipped to

the customer's specifications: spindle RPM, spindle to ac-

commodate cutter type desired, pressure foot type, collet

guide to accommodate collet desired and optional booster

pump (if required).

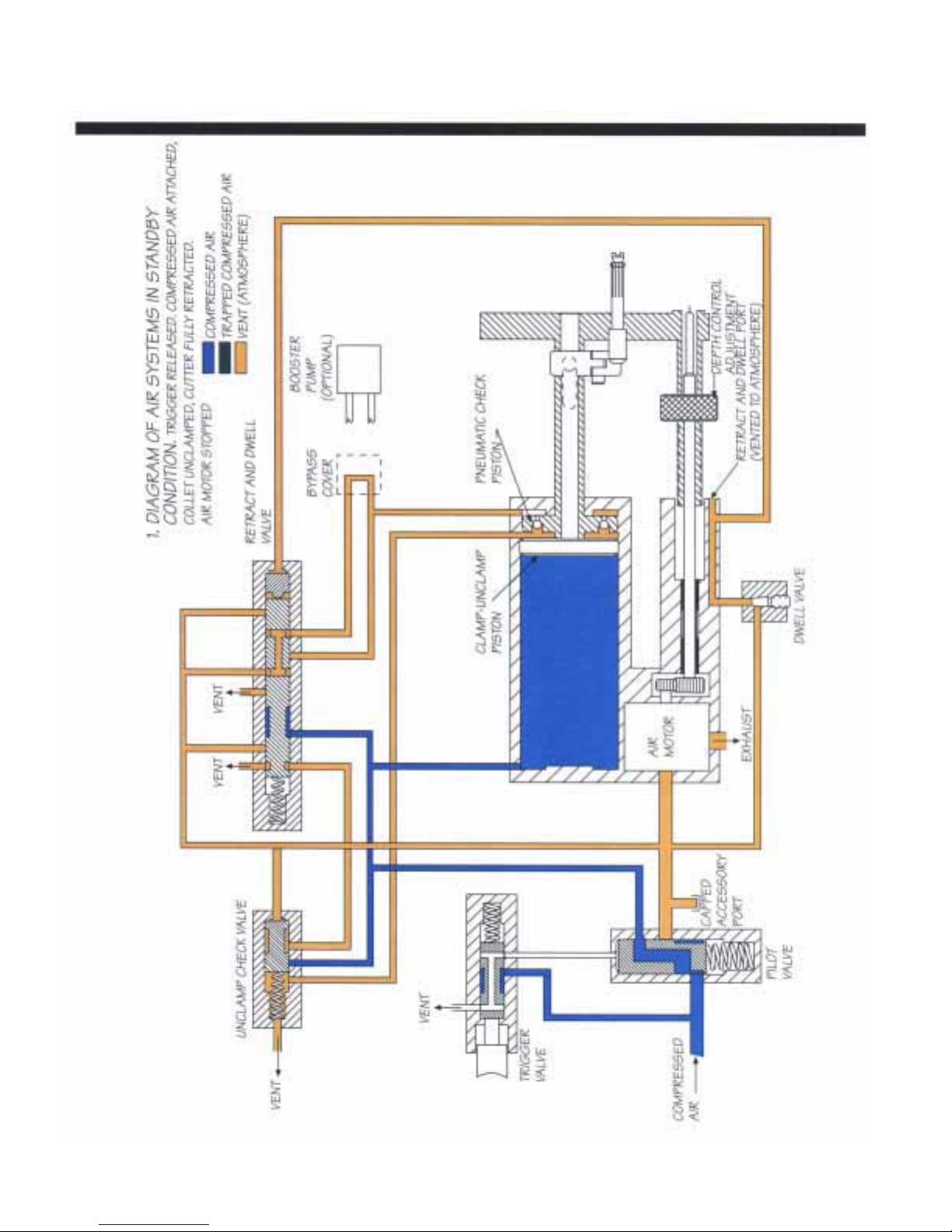

After unpacking, examine the customer-specified equip-

ment on the 180SC-225 tool to verify type and speed of

components. Attach air line to 3/8-18 NPT inlet bushing. If

quick disconnect fittings are used, 3/8 in. ID are minimum.

The 180SC-225 drill requires a supply of clean 90-100 PSI

air. Air consumption is 45 CFM at 90 PSI. The use of the in-

line lubricator will provide the proper lubrication for the air

motorand willsignificantly increasethe tool life expectancy.

Because O-rings are extensively used to seal systems

within the tool, the elimination of foreign particles and other

contaminants will reduce the possibility of damage to these

parts. Always inspect O-rings for damage or wear and

replace as required. The use of silicone O-ring lubricant is

strongly recommended during reassembly. The addition of

oilintheairlinewillalsoincreasemotorandvalvelifeaswell

asthelifeoftheO-rings.Avoidtheuseofsyntheticlubricants

to prevent damage to O-rings and seals.

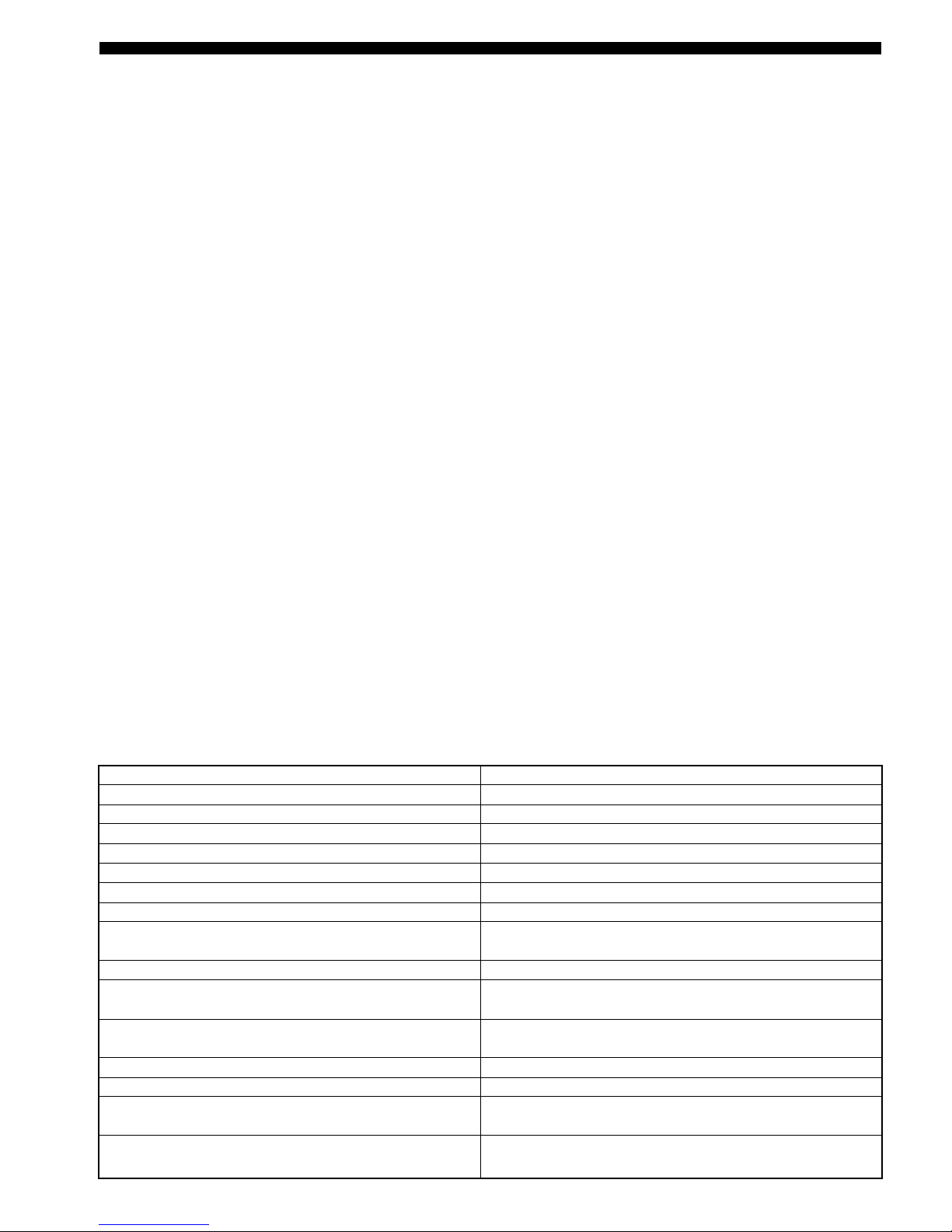

Introduction and General Information

WEIGHT

AIR CONSUMPTION

HORSE POWER

O/A LENGTH

STROKE

COLLET STROKE

COUNTERSINK

FEED RATE

SPINDLESPEEDS

DRILLING THRUST

CLAMPFORCE

SPINDLEADJUSTMENT

MAX. DRILL SIZES

COLLET FOOT SPACING

SPINDLE

COOLANT

180SC-225-14.0 LBS. MAX. W/ALUMINUM FOOT

68 C.F.M. @ 90 P.S.I. DYNAMIC

APPROX. 180S-1.4 @ 90 P.S.I.

180S-15.28 IN. MAX AT FULL EXTENSION

2.225 IN. (DRILL & C/SINK 2 IN. STACK)

.875 IN. (NO LOSS OF FEED STROKE)

COUNTERSINK STOP REPEATS WITHIN .001 IN.

MIN. 5 SEC. PER INCH, MAX 1 MIN. PER INCH

240, 420, 650, 850, 1050, 2000, 3100,

4900,6300,12500,21000

300 LBS. MAX. (WITHOUT BOOSTER PUMP)

548 LBS. START CLAMP STROKE (UNREGULATED AIR)

460 LBS. FULL CLAMP STROKE (UNREGULATED AIR)

.375 IN. ADJUSTMENT TO ALLOW FOR DRILL LENGTH

VARIATIONS

.500DRILL/.875C/SINK

1.00 IN. MIN. - 3.50 IN. MAX.

.500 IN. DIA. W1/4-28 & 3/8-16 O.D. THD OR 1/4-28 I.D. THD

THREAD TYPE DRILLS OR 1/4-28 TAPER-LOK TYPE DRILLS.

AIR BLAST PORT & DRILL POINT PORT IN TEMPLATE STD.,

COOLANT MIST LUBRICATOR AVAILABLE.

180SC-225 DRILL SPECIFICIATIONS