5

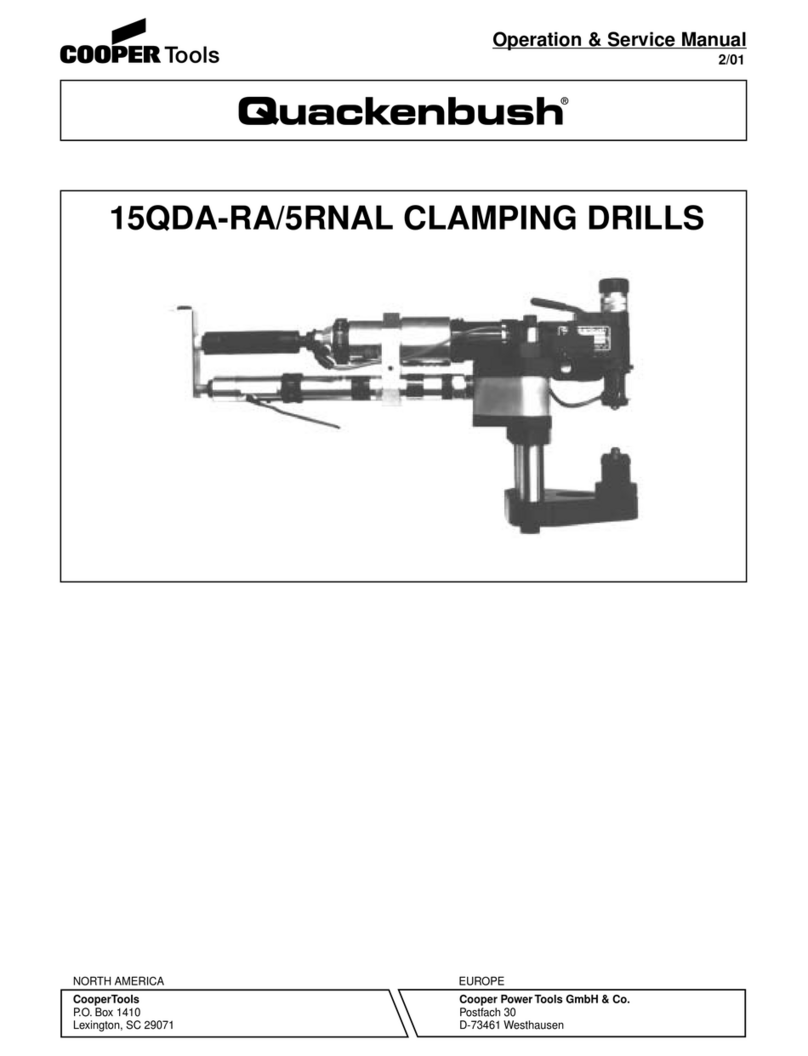

The 120SC-112 drill is an air operated, hydraulically con-

trolledtoolthatautomaticallyclampstothematerial,drillsand

countersinks close tolerance holes in one operation.

The120SC-112 will producehigh qualityholes in aluminum,

steel,titaniumandcompositematerialsprimarilyfoundinthe

aircraft/aerospace industries. The 120SC-112 has been de-

signed using state-of-the-art technology that provides maxi-

mum power, minimum weight and the highest degree of

accuracy for demanding hole preparation requirements.

Technical Data

FeedStroke: Feedstroke of the120SC-112 is1.1inchesto

drill and countersink in 1 inch stacked material. The feed

stroke is unaffected by the collet stroke.

Collet Stroke: The 120SC-112 will clamp throughout its .5

inch stroke. Collet stroke is unaffected by feed stroke.

SpindleAdjustment: Thespindleadjustmentof.375inch

allows for drill length variations. See Spindle Adjustment

information on page 24.

CountersinkDepthControl:Amicrometeradjustmentpro-

vides for countersink stop repeatability within .001 inch.

CutterSizes:The120SC-112willaccommodate.375diam-

eter drills without countersink and .328 diameter drills with

.625 countersink diameter.

FeedRate: Anadjustable drillfeedratemechanismenables

the 120SC-112 to drill from 5 seconds per inch to 1 minute

perinch.SeeFeedRateAdjustmentinformationonpage22.

Cutter to Collet Spacing: The cutter to collet distance is

adjustable between .875 inch minimum to 3.50 inch maxi-

mum.

Coolant: The 120SC-112 has a drill point coolant port in the

pressure foot. A coolant mist generator is available. (See

Accessories Page 36)

Air Motor: The air motor develops 1.2 horsepower when

supplied with air at 90 p.s.i.

Air Consumption: Air consumption of the 120SC-112 is 45

c.f.m. at 90 p.s.i. dynamic.

Introduction and General Information

Weight: Tool weight with the steel pressure foot is 12

pounds.

Spindle Speeds: Ten geared spindle speeds are available:

270, 470, 700, 900, 1150, 2200,3500, 5500, 7000,14,000 &

23,500 RPM. See pages 33 and 34 for gear set assembly.

Configurations. Any gear set can be used with the 120SC-

112toolTriggerLock:Atriggerlockisprovidedwhichallows

the tool to be locked in the "Operate" position. With the lock

activated,thetoolwillrunthroughtheclamp,feedandretract

cycles,butitwillnotunclamporstopthemotoruntilthetrigger

lock is manually released.

Tool Start-Up

The 120SC-112 is shipped from the factory equipped to the

customer's specifications: spindle RPM, spindle to accom-

modatecuttertypedesired,pressurefoottype,colletguideto

accommodate collet desired, and optional booster pump (if

required).

Afterunpacking,examinethecustomer-specifiedequipment

on the 120SC-112 tool to verify type and speed of compo-

nents.

Attachairlineto3/8-18NPTinletbushing.Ifquickdisconnect

fittings are used, 3/8 in. ID are minimum. The 120SC-112

requiresa supply ofclean 90-100PSIair. Airconsumption is

45CFMat90PSI.Theuseofthein-linelubricatorwillprovide

the proper lubrication for the air motor and will significantly

increase the tool life expectancy.

BecauseO-ringsareextensivelyusedtosealsystemswithin

the tool, the elimination of foreign particles and other con-

taminantswillreducethepossibilityofdamagetotheseparts.

Always inspect O-rings for damage or wear and replace as

required. The use of silicone O-ring lubricant is strongly

recommended during reassembly. The addition of oil in the

air line will also increase motor and valve life as well as the

life of the O-rings. Avoid the use of synthetic lubricants to

prevent damage to O-rings and seals.

WEIGHT

AIR CONSUMPTION

HORSE POWER

O/A LENGTH

STROKE

COLLET STROKE

COUNTERSINK

FEED RATE

SPINDLE SPEEDS

DRILLING THRUST

CLAMP FORCE

(W ASSIST SPRING)

(W ASSIST SPRING)

(W/O ASSIST SPRING)

SPINDLE ADJUSTMENT

MAX. DRILL SIZES

COLLET FOOT SPACING

SPINDLE

COOLANT

120SC-112 SELF-COLLETING DRILL SPECIFICATIONS

12 LBS. MAX. W/STEEL FOOT

45 C.F M. @ 90 P.S.I. DYNAMIC

APPROX.1.2 @ 90 P.S.I.

13.04 IN. MAX WITH SPINDLE ADJUST AT FULL EXTENSION

1.1 IN. (DRILL &C/SINK 1 IN. STACK)

.5 IN. (NO LOSS OF FEED STROKE)

COUNTERSINK STOP REPEATS WITHIN .001 IN.

MIN. 5 SEC. PER INCH & MAX. 1 MIN. PER INCH

270, 470, 700, 900, 1150, 2200,3500, 5500, 7000,14,000 & 23,500 RPM

234 LBS. MAX. (UNREGULATED AIR)

548 LBS. START CLAMP STROKE (UNREGULATED AIR)

460 LBS. FULL CLAMP STROKE (UNREGULATED AIR)

290 LBS. (UNREGULATED AIR)

.375 IN. ADJUSTMENT TO ALLOW FOR DRILL LENGTH VARIATIONS

.375 (NO C/SINK), .328 (.625 C/SINK DIA.)

.875 IN. MIN.—3.50 IN. MAX.

.500 IN. DIA: TUBE W/1/4-28 & 3/8-16 IN. THD. FOR l.D.

THREAD TYPE DRILLS OR 1/4-28 TAPER-LOK TYPE DRILLS.

AIR BLAST PORT & DRILL POINT PORT IN TEMPLATE STD.,

COOLANT MIST GENERATOR AVAILABLE.