Printed in U.S.A. 1

These instructions do not claim to cover all details or variations in the equipment, procedure, or process described, nor to provide

directions for meeting every contingency during installation, operation, or maintenance. When additional information is desired to

satisfy a problem not covered sufficiently for the user’s purpose, please contact your Cooper Power Systems sales engineer.

CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

GENERAL APPLICATION RECOMMENDATIONS . . .1

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Base or Foundation Mounting . . . . . . . . . . . . . . . .2

Bracket or Structure Mounting . . . . . . . . . . . . . . .2

Suspension Mounting . . . . . . . . . . . . . . . . . . . . . . .2

ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . .2

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

GENERAL

VariSTAR AZE station class surge arresters incorporate

the latest in metal oxide varistor (MOV) technology.

These arresters are totally gapless and are constructed

of a single series column of MOV disks. The arrester is

designed and tested to the requirements of standard

ANSI/IEEE C62.11 and is available in ratings suitable for

the overvoltage protection of high-voltage systems

through 345 kV.

GENERAL APPLICATION

RECOMMENDATIONS

Cooper Power Systems application engineers are

available to make specific application recommendations.

INSPECTION

The factory takes special precautions to ship arresters

in well designed containers that reduce the possibility of

damage which may occur during transit. Carefully

inspect the porcelain for chips or cracks. In case of

improper handling or shipping damage, immediately file

a claim with the carrier, and promptly notify Cooper

Power Systems or your local representative.

IDENTIFICATION

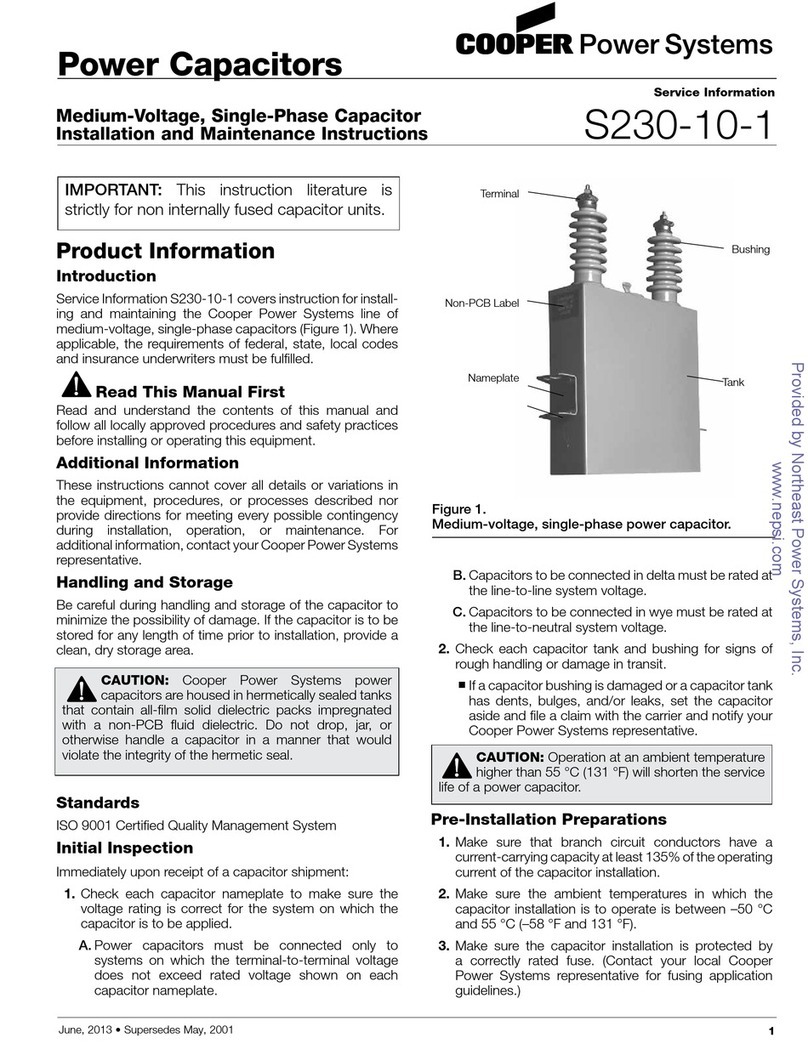

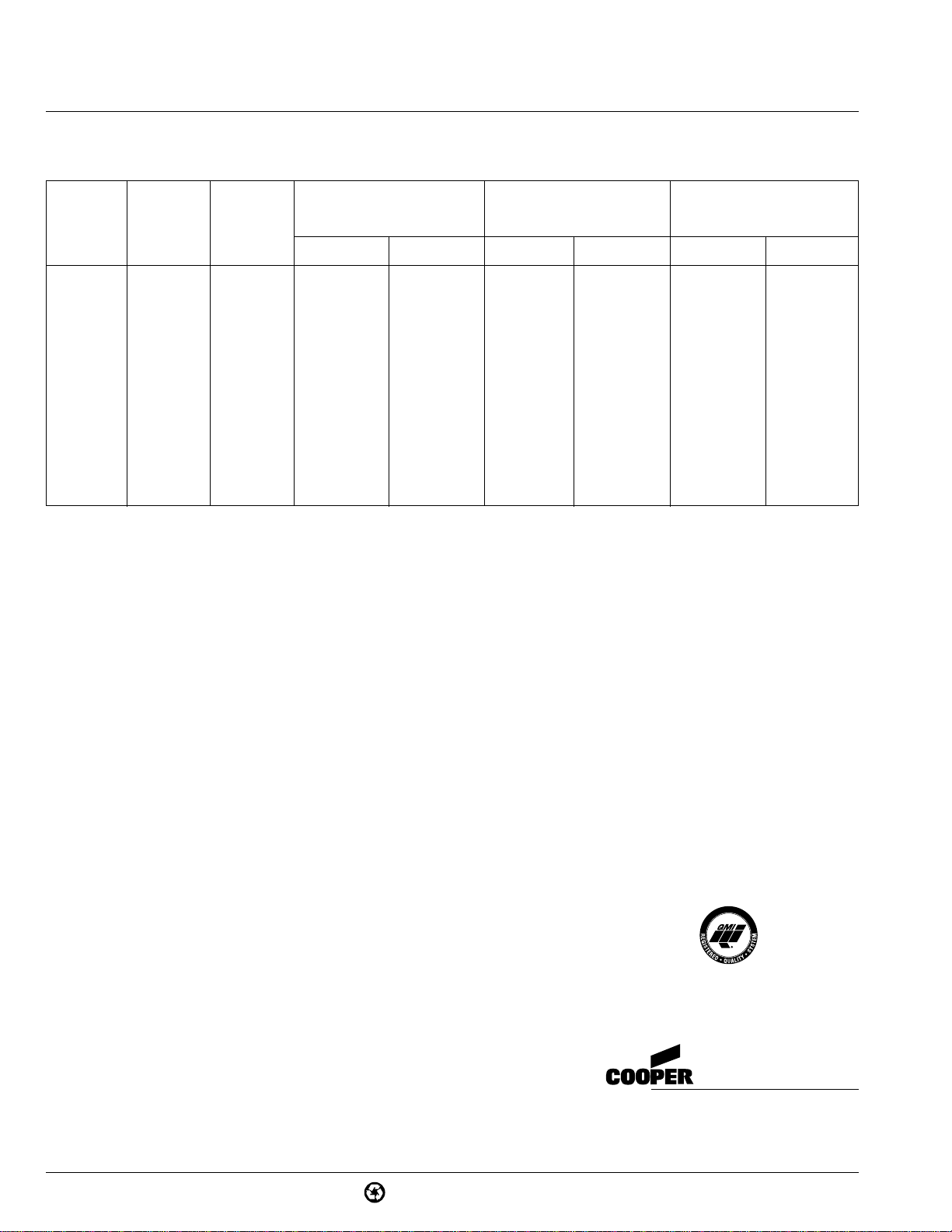

A nameplate attached to the base casting of each

VariSTAR arrester indicates its catalog number, voltage

rating, maximum continuous operating voltage (MCOV),

rated frequency, pressure-relief current rating, class,

reference to the type test standard, altitude range, serial

number, and year of manufacture.

For multiple unit arresters, a nameplate attached to

the top casting of each unit indicates the catalog number

and serial number of the complete arrester of which the

unit forms a part. The unit nameplate also indicates the

total number of units comprising the complete arrester

and references the position of this unit in the complete

assembly.

ASSEMBLY

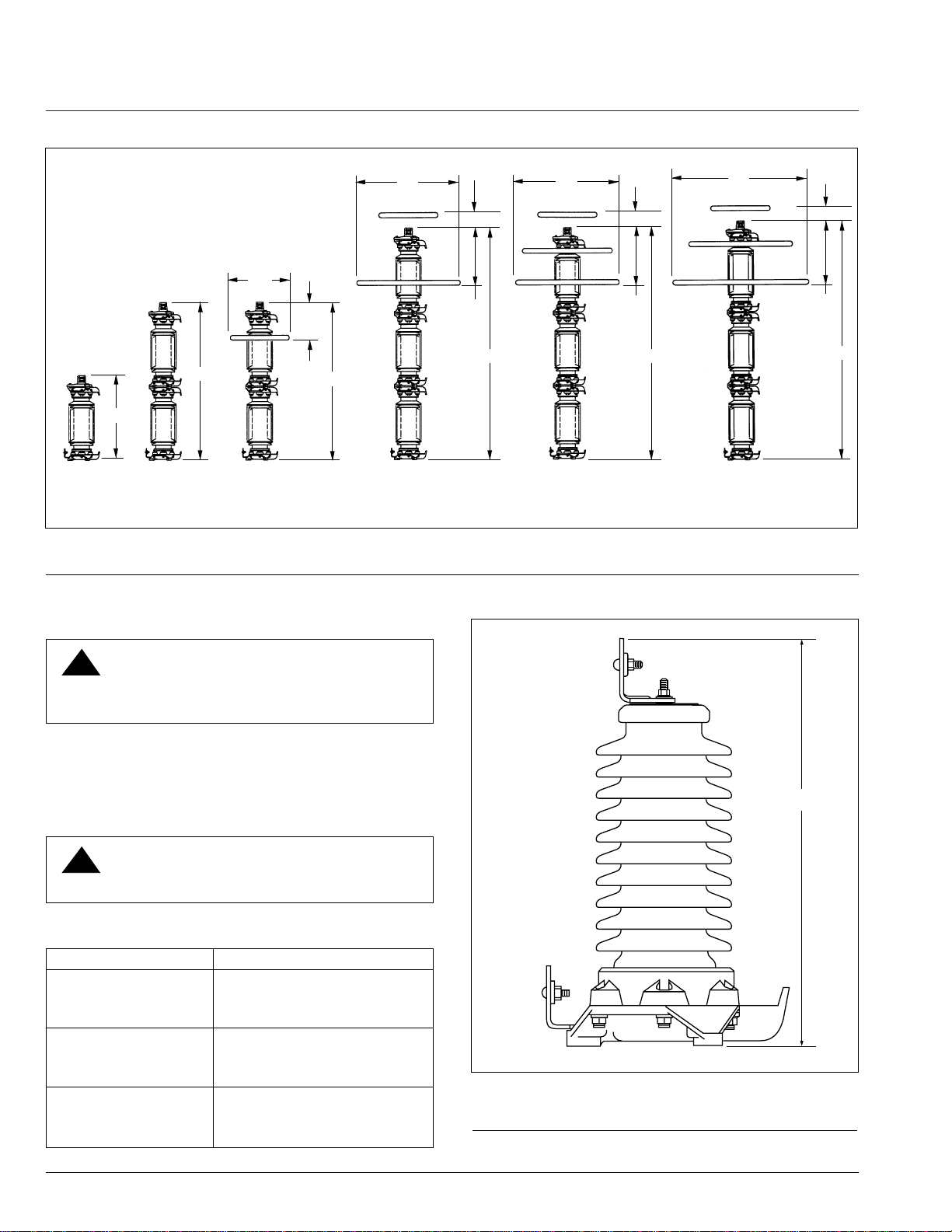

VariSTAR Type AZE arresters rated 3 through 120 kV

are shipped ready for installation. The 132 through 360 kV

standard arresters require the assembly of multiple units

stacked in series. A grading ring is supplied for arresters

rated 172 through 360 kV. Some lower voltage ratings

having extra creepage housings may require multi-units

stacked in series and grading rings. Grading ring

assembly instructions are shown in Figure 6.

Choose a permanent location so that the arresters will

be installed as close as possible (electrically) to the

equipment being protected. Minimum clearance distances

between any line potential surface to an arrester and to

any ground plane are listed in Tables 2 and 3. Figures 1

and 2 show minimum phase-to-ground and minimum

phase-to-phase clearances. See Tables 2 and 3 and

Figures 7 and 8 for standard arrester dimension and

weight information.

Surge Arresters

VariSTAR®Type AZE Station Class Surge Arresters

Installation and Maintenance Instructions S235-87-1

Service Information

August 1997 • New Issue • © 1997 Cooper Power Systems, Inc.

CAUTION: The Cooper Power Systems

VariSTAR Type AZE surge arrester is

designed to be operated in accordance with safe

operating procedures. These instructions are not

intended to supersede or replace proper safety and

operating procedures. Read all instructions before

installing the arrester.

Surge arresters should be installed and serviced only

by personnel familiar with good safety practice and

the handling of high-voltage electrical equipment.