2

1. Introduction

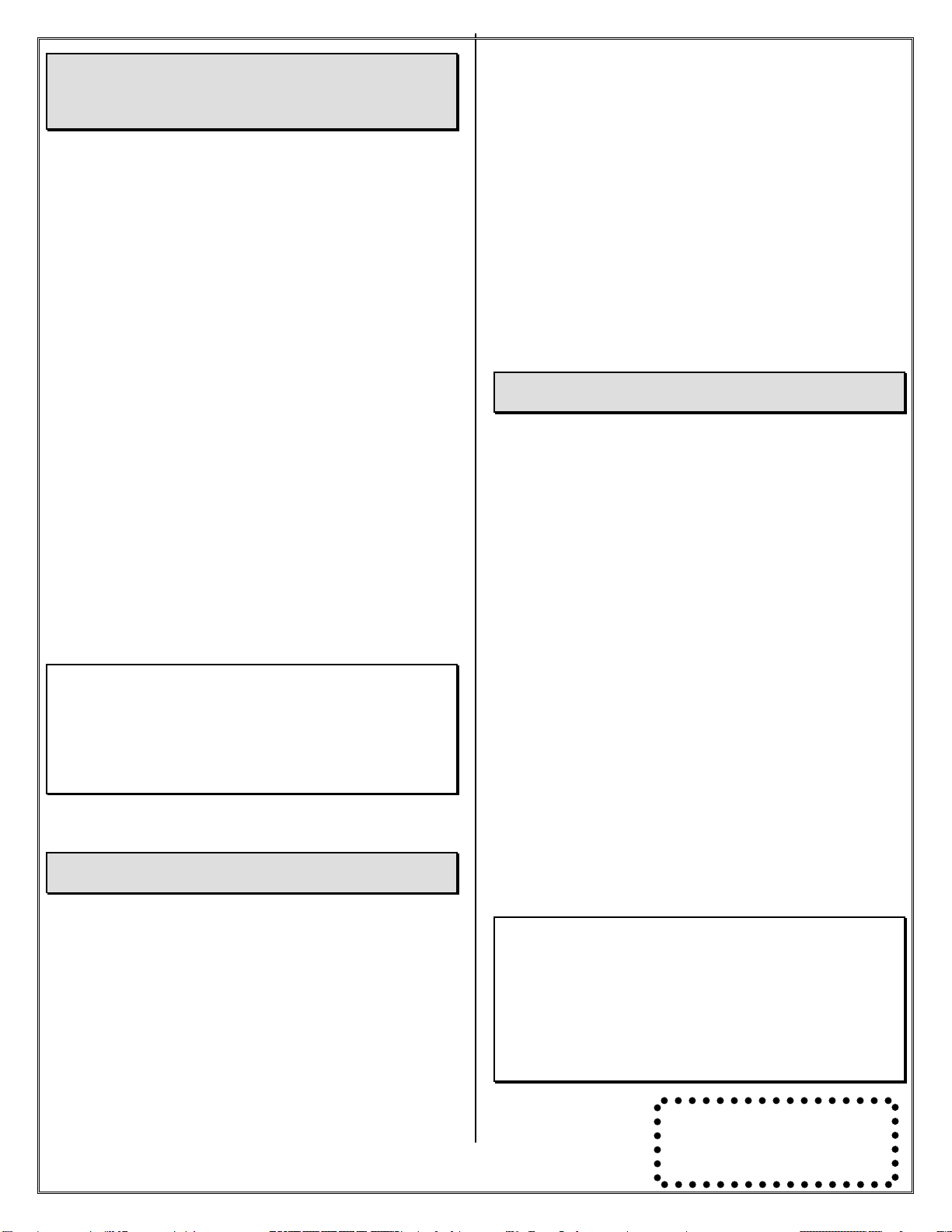

This manual contains information for the proper

installation, and operation of w.Cooper Inc.

sand filters. Your w.Cooper Inc. sand filter is

designed and manufactured to provide many years of

trouble free operation, when installed, operated

and maintained as outlined in this owner's manual.

2. How Your Sand Filter Works

Special filter sand removes dirt and debris particles

from your pool water. Following instructions (as

outlined in this manual) filter sand is loaded into the

filter tank, the pool water is pumped through the piping

system, then directed by the 6 position dial valve into the

filter. As the water is pumped through the sand bed, the

particles of dirt and debris are removed leaving clean

water. The clean water is returned to the pool through

the bottom of the filter, the 6 position valve, and through

the return piping to your swimming pool.

After the filter has been in use for a period of time, the

accumulation of dirt and debris particles in the sand bed

will cause the pressure in the filter to rise. This indicates

it is time to backwash (clean) the filter. With the 6

position valve in the backwash position, the flow will

reverse direction in the filter. The water will enter the

sand through the bottom of the filter, flow up through

the sand bed removing the accumulated dirt and debris,

through the 6 position valve, and out the waste line.

Once the filter has been cleaned, the 6 position valve

should be set to rinse and then back to filter. The system

now resumes normal filtering.

3. Installation

Hand tools are all that is required to install your new

filter. Screwdrivers, wrenches and Teflon tape

(to seal threads).

3. A: Place the filter so that the piping, 6 position dial

valve, and winterizing drain plug are readily accessible

for service, operation and winterizing.

4. Loading the Filter Sand

Filter sand is loaded through the top of filter tank.

4. A: Cover the stand pipe in the filter with the clear

plastic sand disc provided with the filter. Check the

winter drain is tight.

4. B: Fill the filter tank 1/2 full with water. This helps

prevent damage to the laterals when the sand is added.

4. C: Very slowly pour in the filter sand. Only add the

recommended amount of sand as outlined in the

specifications in this manual. Ensure standpipe does not

move when adding sand. Remove the clear plastic sand

disc, and level the sand bed after all the sand has been

added.

5. Install 6 Position Dial Valve

5. A: Unpack dial valve, you should have 2 nuts,

2 bolts, one clamp ( 2 half sections ), one pressure

gauge, one large o-ring, and the valve itself.

5. B: Place valve on top of filter tank with large o-ring

in the groove on the underside of the valve flange. Push

valve down on the stand pipe gently. Be sure the large

o-ring is seated between tank flange and valve.

5. C: Once the dial valve is on top of filter tank,

carefully rotate valve until the desired location for

installing the plumbing is reached.

5. D: Place both halves of valve clamp around filter

valve flange, press both halves as close together as you

can. Place the nut in the recessed side of the clamp, and

the screw in the other, and snug down. DO NOT

COMPLETELY TIGHTEN.

5. E: Wrap pressure gauge with Teflon tape. One or

two wraps is all you need. Carefully screw pressure

gauge into 1/4" NPT opening (located at the front of the

valve down from the filter label).

!!!! DO NOT OVER-TIGHTEN PRESSURE

GAUGE INTO VALVE BODY

5. F: Make your pump connection to the port labeled

"pump" on the dial valve. When making

connections to valve ports, only wrap the threaded fitting

once or twice with Teflon tape, hand tighten and then a

quarter turn with a wrench. Hand tighten then a quarter

turn with wrench

!!!! DO NOT OVER-TIGHTEN ANY

CONNECTION IN TO THE 6 POSITION DIAL

VALVE

5. G: After the dial valve has been plumbed in, tighten

the valve clamp with your screwdriver until both sides

are close together.

6. Finish all other connections, return to pool from

return port on dial valve, suction line to the pump, and

waste line from waste port on valve.

7. Run electrical connections to pump and

install as outlined in the pump owner's manual.

8. Start Up Of The Filtration System.

To avoid any water losses check all connections to dial

valve and pump. Make sure all connections are tight and

secure

!!!! ALWAYS DEPRESS VALVE HANDLE THEN

ROTATE WHEN CHANGING VALVE

POSITIONS

!!!! NEVER CHANGE DIAL VALVE POSITIONS

WITH THE PUMP RUNNING