Revised 05/15/20 3

WARNING – TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCTWORK.

CAUTION – To reduce the risk of fire and to properly exhaust air, be sure to duct air outside –

Do not vent exhaust air into spaces within walls, ceilings, cabinets or into attics, crawl spaces, or garages.

CAUTION – To reduce the risk of fire and electric shock, install this (range hood) only with

models rated maximum 5 amps.

CONTENTS:

Part 1 - Planning The Installation Part 2 - Securing The Liner

Part 3 - Use & Care Part 4 - Electrical Connection (Give copy of these 2 pages to electrician.)

PART 1 Planning the Installation

CopperSmith® Liners are designed for installation inside custom hood canopies. Proper installation of the liner is

directly related to the material from which the custom canopy is constructed. A qualified person must complete

the installation of this unit. Because of the large size and weight of this hood / liner, two installers are recommend-

ed. Plan the installation so that all minimum clearances are met or exceeded. Dimensions shown provide minimum

clearances, unless otherwise specified. Important: You must provide structural framing and tight backing in the

areas in which you are securing the liner inside your custom canopy. Failure to do so could distort and damage the

liner and void the warranty.

It is important to locate the remote blower in a preferably easily accessible location. This will ensure that any

service that may be required in the future may be performed on the blower without damaging the range hood, walls

or ceiling.

For best and quietest performance with In-Line Blower installations, the blower should be installed in the attic, near

or slightly beyond the mid-point of the duct system. In installations requiring the blower be in a chase or wood-type

hood over the range (e.g., no attic above the kitchen), the duct silencer will not be as effective in absorbing motor

noise. In addition, there will likely be motor sound transmitted through the walls of the chase, bypassing the duct

silencer.

Given the high performance of CopperSmith® Remote Blowers, it is highly recommended that the blower NOT

be attached directly to the liner or in a chase immediately above the liner unless a CopperSmith® brand duct

silencer is installed between the blower and liner and neoprene lined FC Clamps are used. FC Clamps are

available from CopperSmith®. Ask for model numbers CS-C6 (6”), CS-C8 (8”) or CS-C10 (10”), 2 per box.

CopperSmith® Ventilators, Duct Silencers, Dampers, and Ducting

CopperSmith® Liners (non-internal motor models) are also designed for use with “in-line” and “remote-mount”

ventilators. When planning for installations using these products, please refer to the Installation Instructions

provided with the ventilator. CopperSmith® Duct Silencers are available from your CopperSmith® dealer. When

planning for installation using a duct silencer, please refer to the Installation Instructions provided with the duct

silencer.

Given that most installations are different, a back-draft damper is not provided with this unit. CopperSmith®

back draft dampers are also available from your CopperSmith® dealer. Always install ventilation products with

an approved wall or roof cap. Duct performance is improved by using round, smooth metal duct work instead of

rectangular. If multiple elbows must be used, ensure that there is a minimum of 24” of straight duct between any

two elbows. Avoid “S” or back to back configurations caused by adjacent elbows. Do not rely on duct tape alone

to seal duct joints. Use sheet metal screws as required to support the duct.

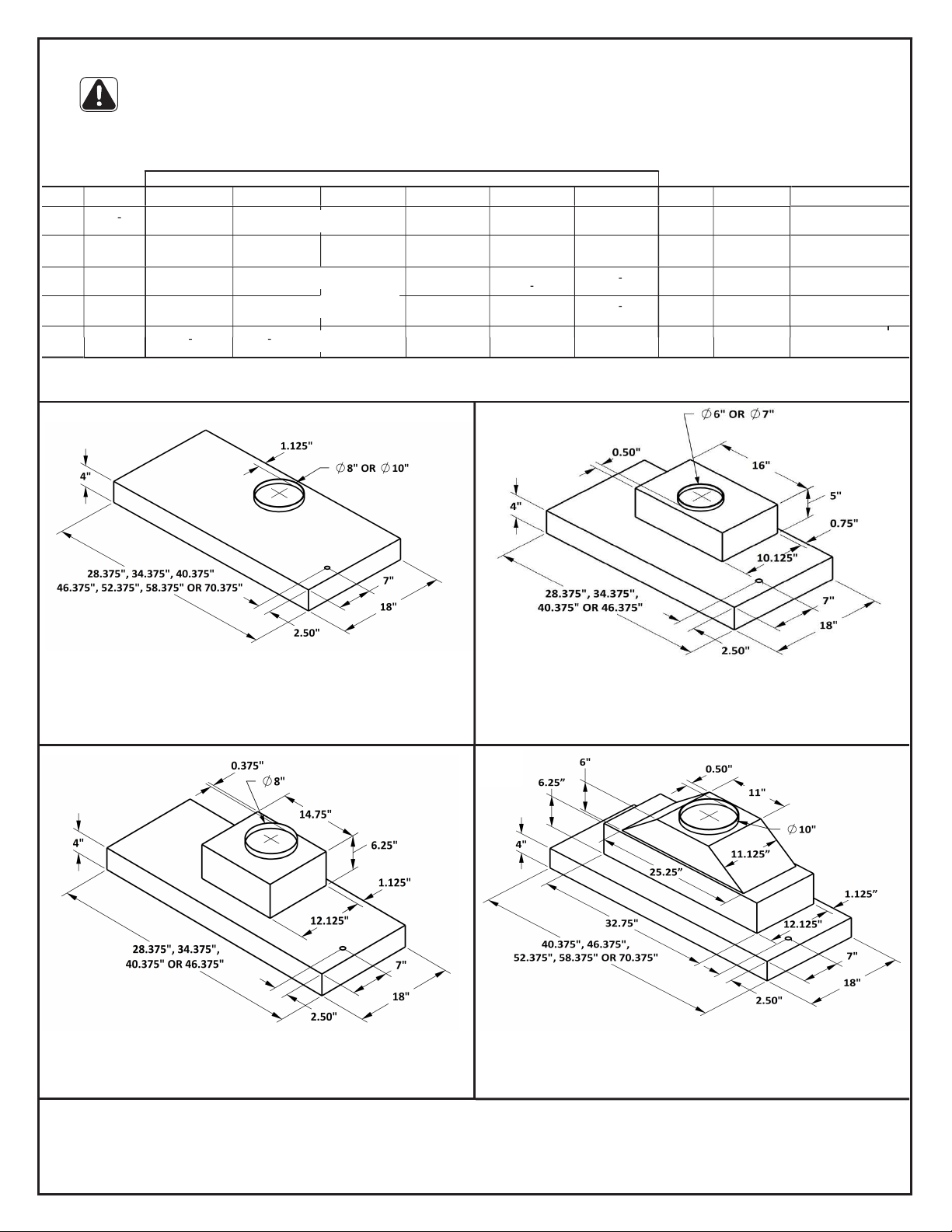

WARNING! For maximum ventilation performance, the bottom of the hood or liner should be 30 -

inches (76.2 - 91.4 cm) above the cooking surface (minimum is 24”). This would typically result in the

bottom of the hood being 66 - 72 inches (167.6 - 182.9 cm) above the floor. These dimensions provide

for safe and efficient operation of the hood. Always observe local building codes.