For iOptron Internal Use Only

7

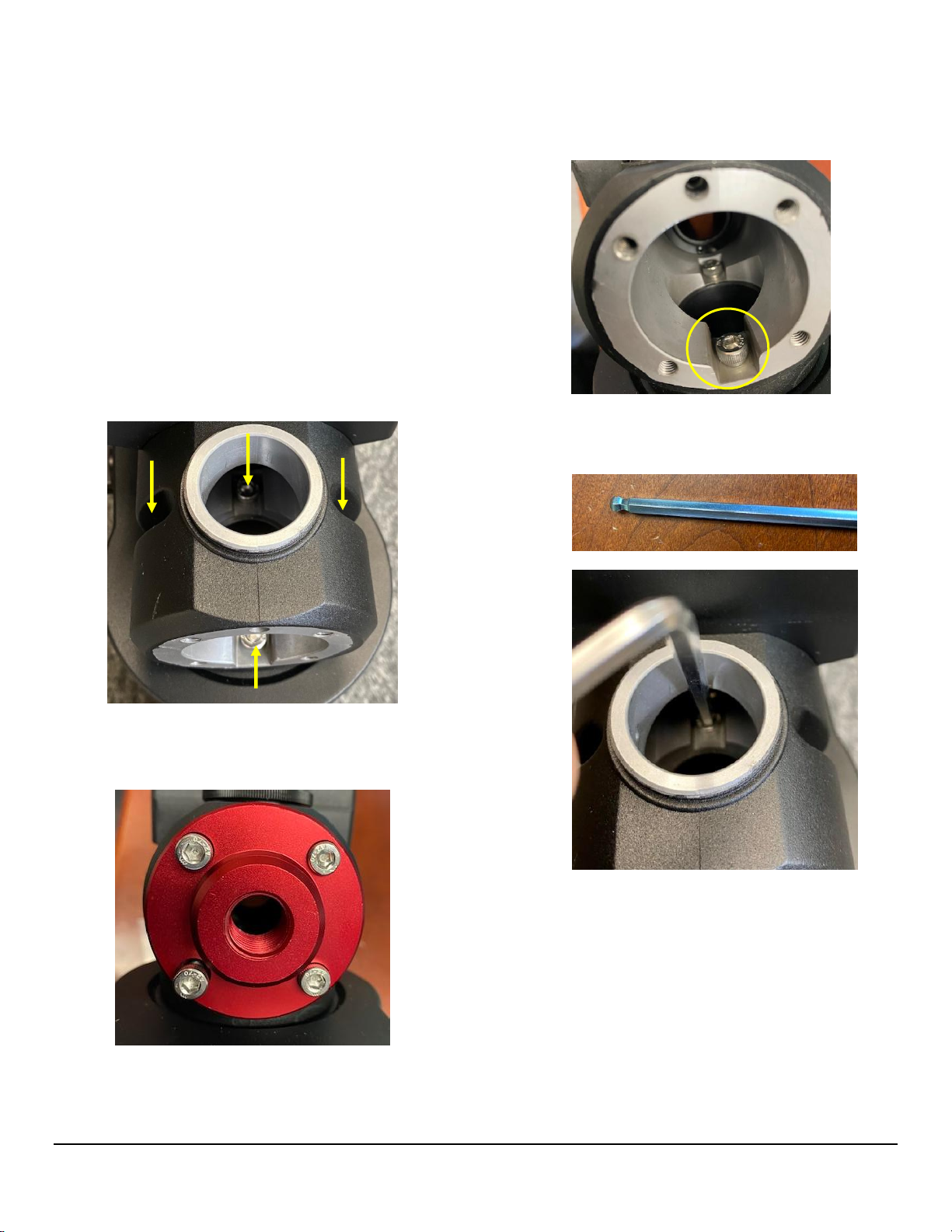

21. Release worm end cap set screw a little.

Tighten the brass end cap by using a pair of

nose pliers or a pair of strong tweezers. Back

out the end cap 1/16-1/8 turn. Turn the worm

shaft with fingers. There should be no stiffness.

Check if the lateral free movement is eliminated.

Tighten the set screw. Check the worm

smoothness again. If there is any stiffness

exists, you need to readjust the worm end cap.

Until there is no lateral play, or worm stiffness.

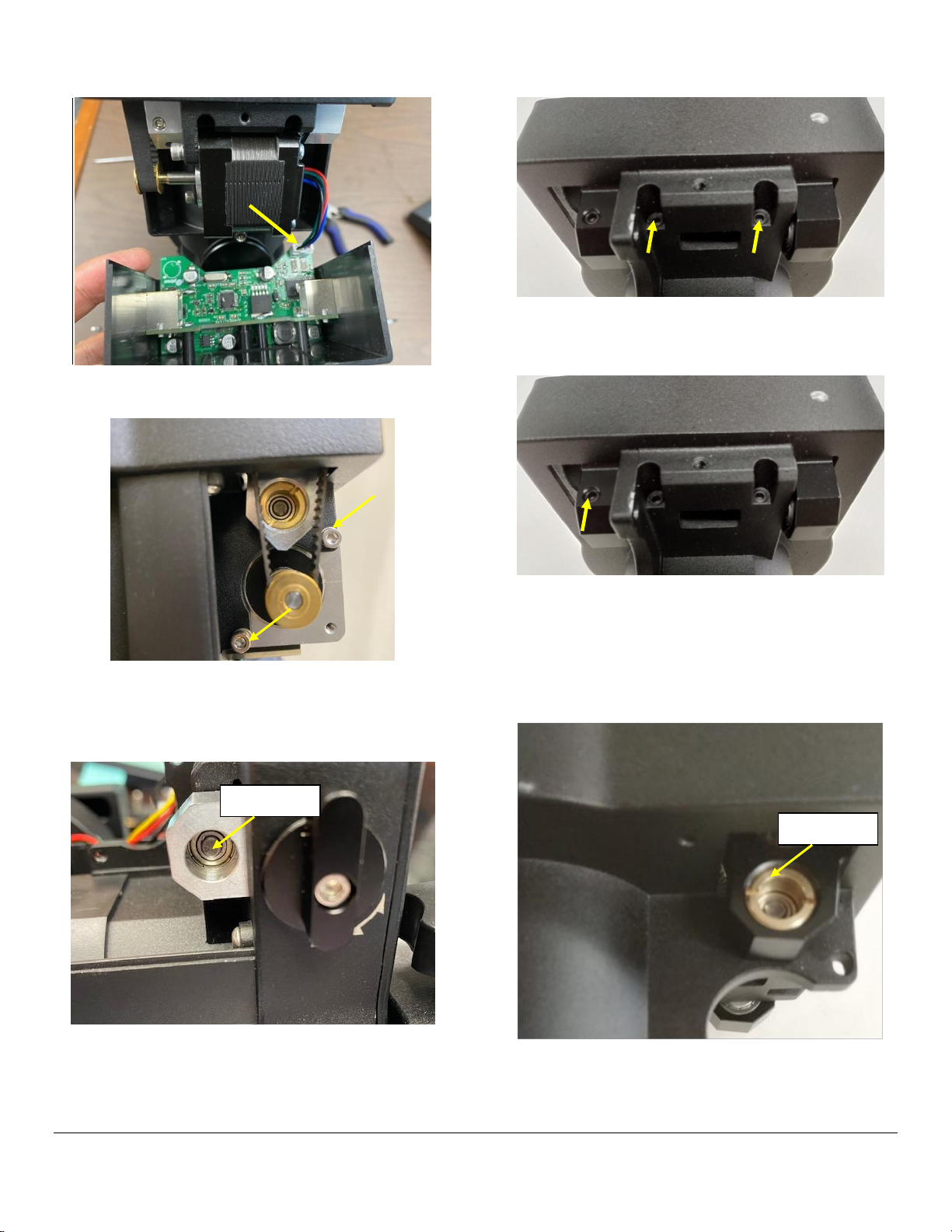

22. Put the worm pulley back on to the worm shaft.

Locate the flat surface on the shaft and tighten

the set screw onto it. Make sure that the worm

shaft end if aligned flash to the pulley surface.

23. Before install the worm assembly, insert one

hinge bearing into the bearing housing without

the locking end cap.

24. Wrap the belt over the worm pulley and insert

the worm assembly back into the ring gear

compartment. You may rotate the mount head

90 degree so the worm pulley and open-ended

hinge pin bearing house is on top.

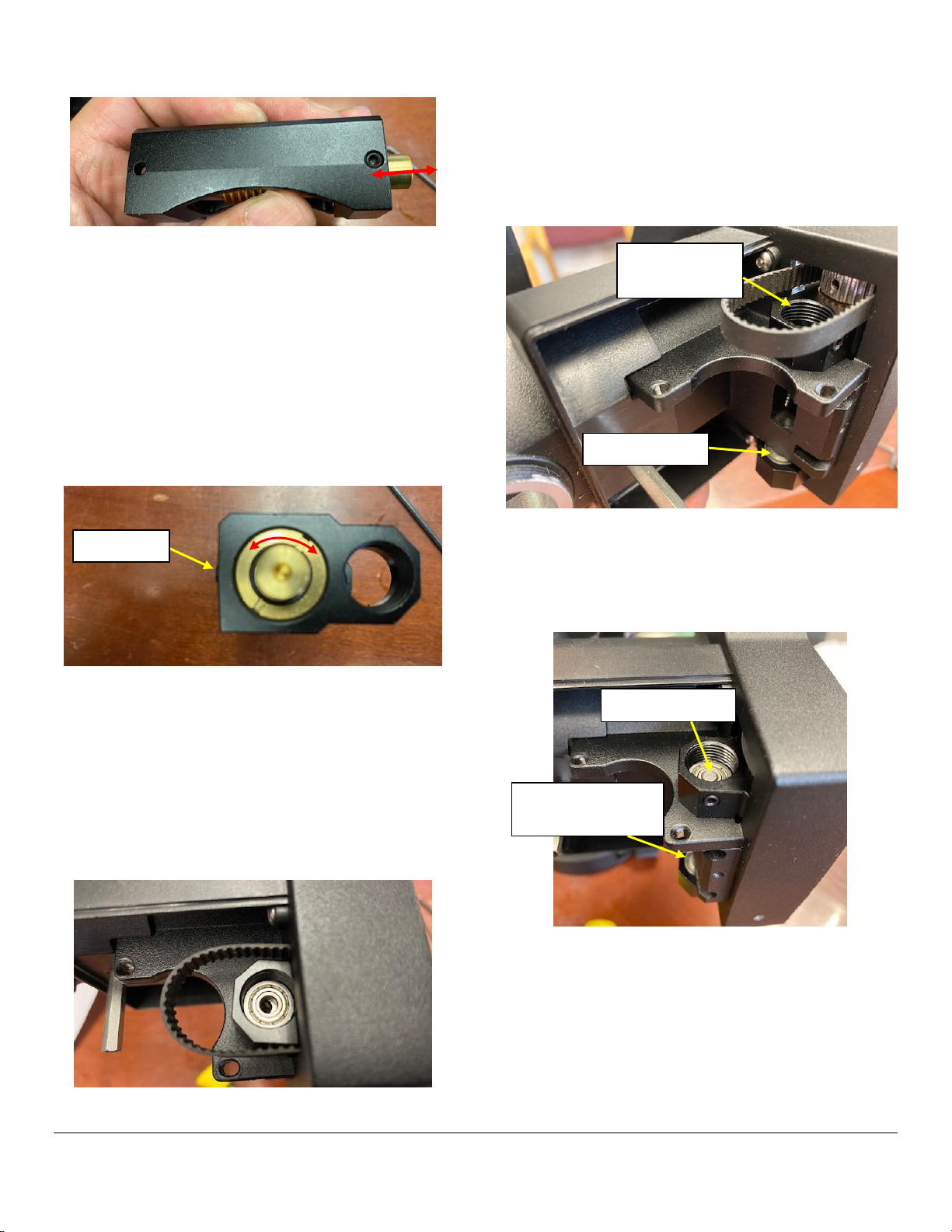

25. Insert hinge pins while insert the washer

between the bearing and worm assembly body.

Tap the hinge pin inward to make sure its end

flash with the bearing surface.

26. Lock hinge pin by tightening the locking set

screws.

Hinge bearing

and end cap

Washer goes next

to bearing