Contents

1 About this document........................................................................ 4

1.1 Information on the operating instructions.............................................. 4

1.2 Target group.............................................................................................. 4

1.3 Further information................................................................................... 4

1.4 Related applicable documents................................................................ 4

1.5 Symbols and document conventions...................................................... 4

2 Safety information............................................................................ 6

2.1 Basic safety notes..................................................................................... 6

2.2 Intended use............................................................................................. 6

2.3 Improper use............................................................................................. 7

2.4 Qualification of personnel........................................................................ 7

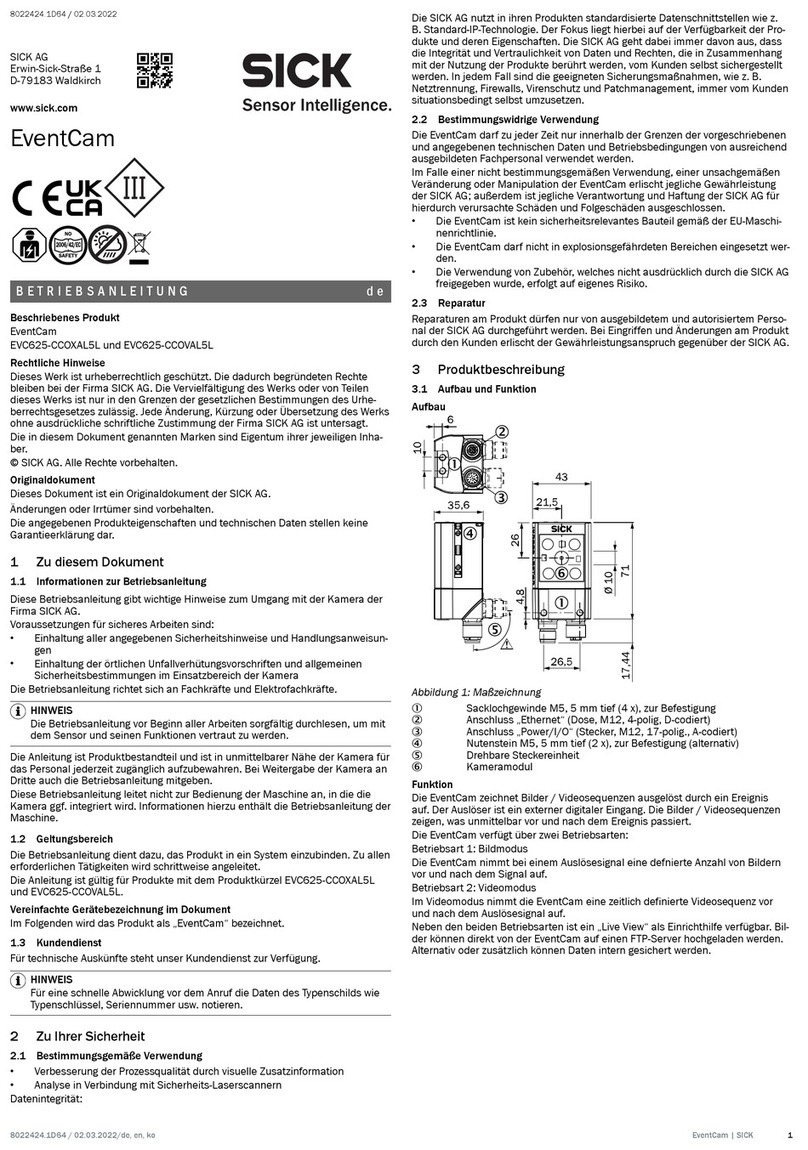

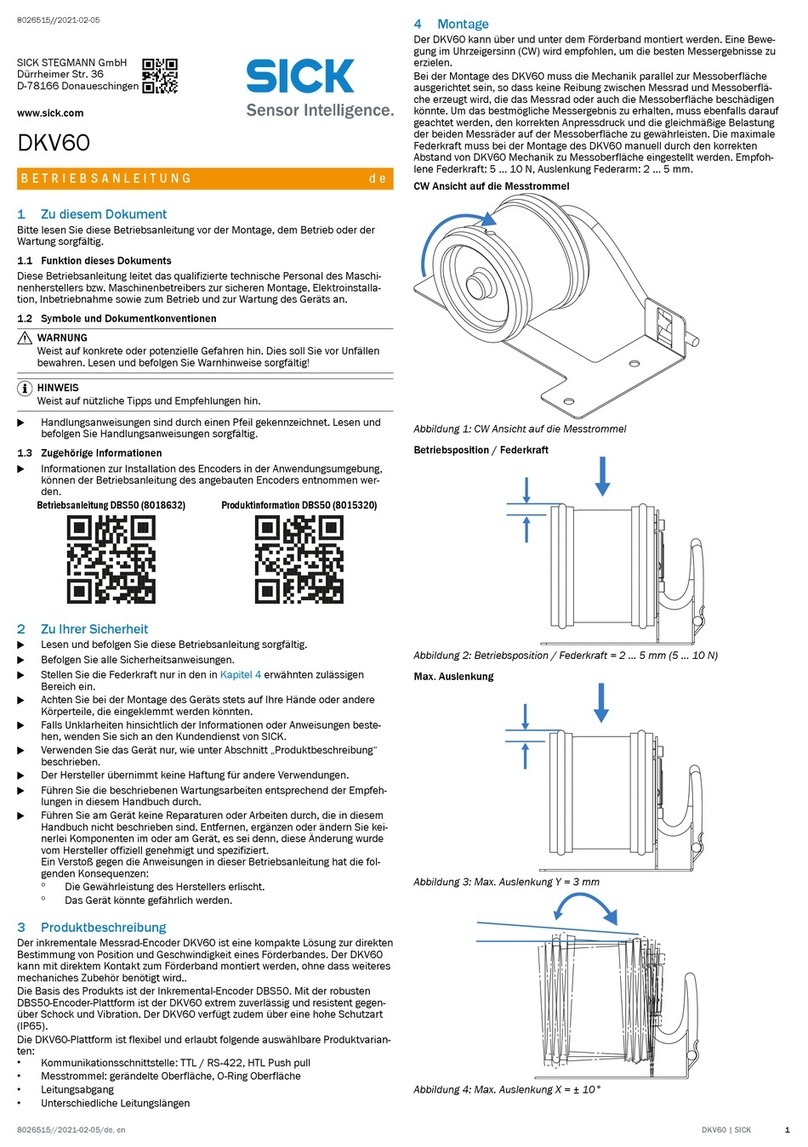

3 Product description........................................................................... 8

3.1 Scope of delivery....................................................................................... 8

3.2 System components................................................................................. 8

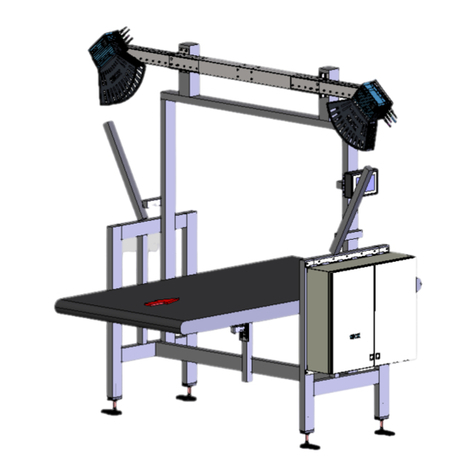

3.3 System setup............................................................................................ 9

3.4 Functionality.............................................................................................. 11

4 Maintenance...................................................................................... 13

4.1 Maintenance............................................................................................. 13

4.2 Maintenance............................................................................................. 13

4.2.1 Visual inspection of the photoelectric retro-reflective sen‐

sor............................................................................................. 13

4.2.2 Visual inspection of measuring wheel encoder..................... 13

4.2.3 Visual inspection of the cables............................................... 14

4.3 Replacing components............................................................................. 14

5 Troubleshooting................................................................................. 15

5.1 Important information.............................................................................. 15

5.2 Fault indications of the components....................................................... 15

5.3 Troubleshooting the controller................................................................. 15

5.4 Faults during operation............................................................................ 16

5.5 Detailed fault analysis.............................................................................. 16

5.6 Status log.................................................................................................. 16

6 Decommissioning............................................................................. 17

7 Technical data.................................................................................... 18

7.1 RFID system data sheet........................................................................... 18

7.2 Modules data sheet.................................................................................. 18

7.3 Antenna data sheet.................................................................................. 18

CONTENTS

8028460/2023-08-08 | SICK O P E R A T I N G I N S T R U C T I O N S | RFCS-HP 3

Subject to change without notice