Ionizing Blower Maunal

9 10

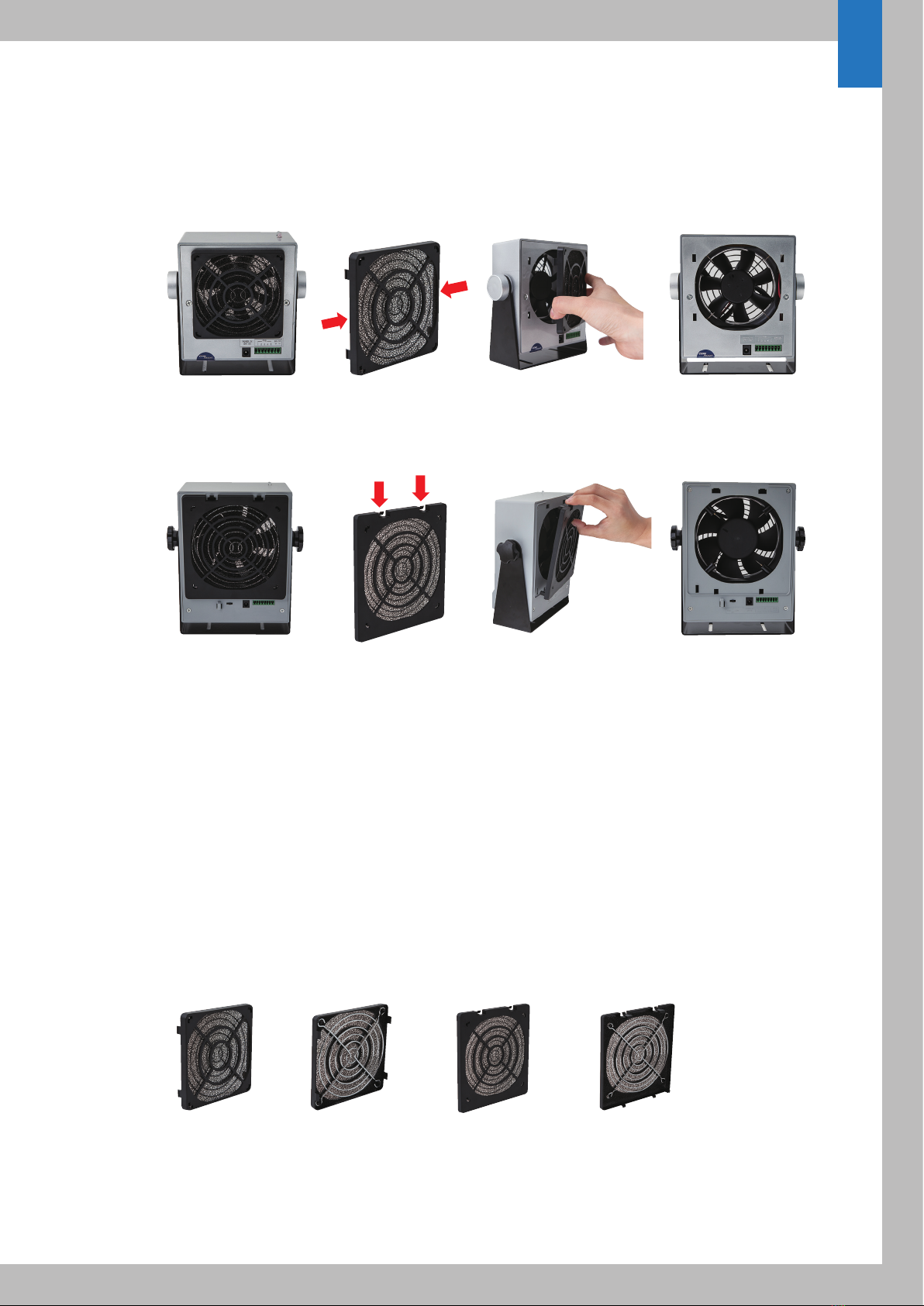

4-4. Emitter Replacement

Cleaning emitter points are varying based on operating environment. Recommended cleaning cycle will be

once in a month or every quarter. Emitter point life cycles are also varying based on operating environment

and performance trade off. Normally, emitter points will requires replace it in every year or second year. If there

is any damage on emitter point, highly recommend replace it. It is very easy to place by user due to pogo pin

and socket design.

5. Ionizer Status

(Model 310 only allow front panel LED indicator)

5-1. LED

Topside LED gives better indication of ionizer operation and alarm status.

5-2. Audio Alarm

Audible buzzer alarm gives better recognition for user or operator

6. Specification

Model 310

Model 310A(S)

Input Voltage 24V DC, 6W (Maximum)

Ion Emission Steady-State DC Technology

Balance < ±20V

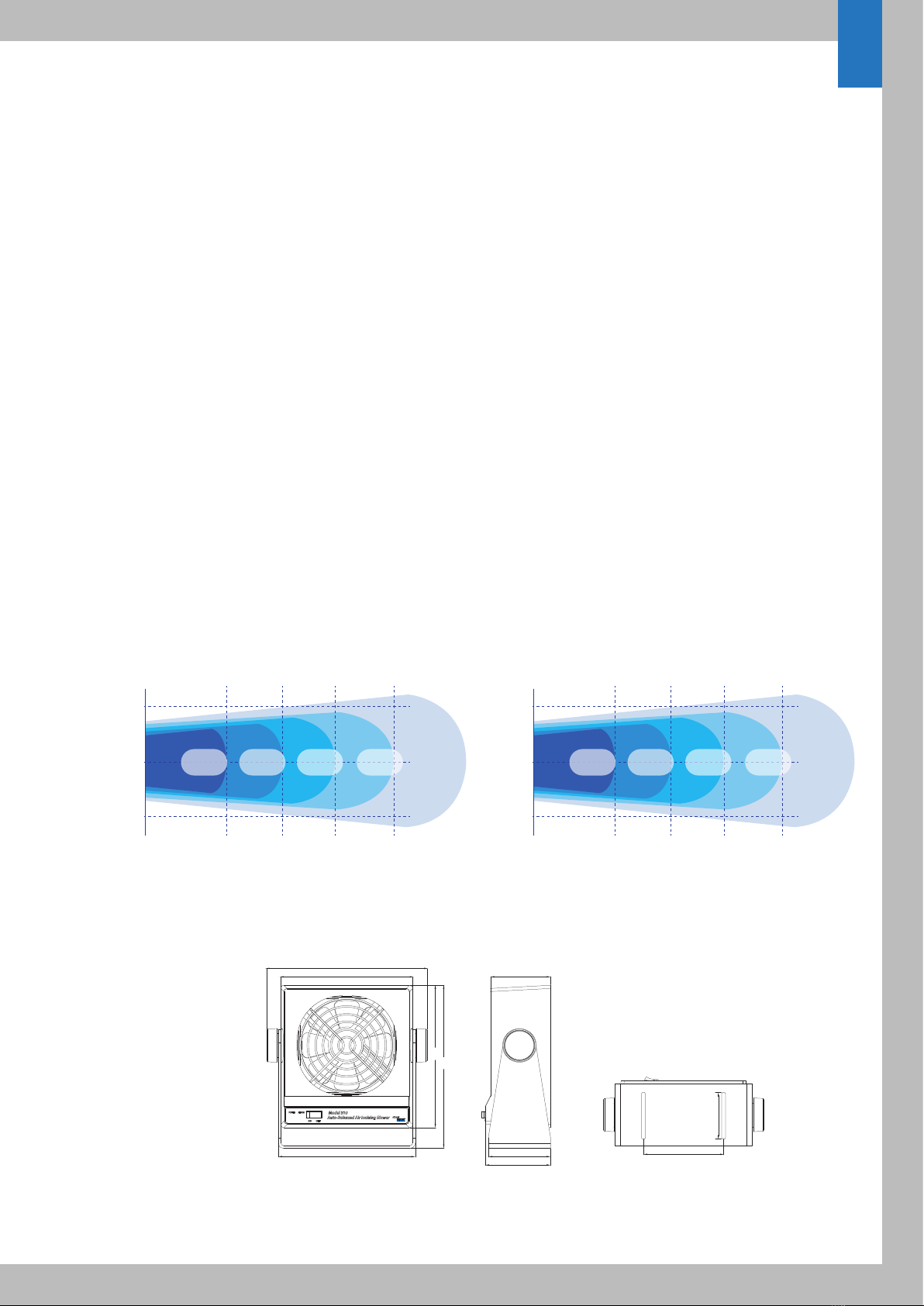

Discharge ±1000V to ±100V less than 2 seconds at 30cm

±1000V to ±100V less than 5 seconds at 60cm

Air ow 59.91 CFM

Emitter Point Tungsten 99.99%

Alarm Function Visual(LED)-HV Power fail

Output Monitoring FMS Interface

Materia Ionizer body- ABS (Gray) Bracket- Aluminum

Operating Environment

Temperature: 15~35℃, Humidity: 35~85% RH

Dimensions 125x135x62mm

(WxHxD) (with bracket 152x154.5x69.5mm)

Weight 507g (with bracket)

Input Voltage 24V DC, 7.2W (Maximum)

Ion Emission Steady-State DC Technology

Balance < ±20V

Discharge ±1000V to ±100V less than 2 seconds at 30cm

±1000V to ±100V less than 5 seconds at 60cm

Air ow 100 CFM

Emitter Point Tungsten 99.99%

Alarm Function Visual(LED), Audio(Buzzer) / HV Power fail

Output Monitoring FMS Interface

Material Ionizer body- ABS (UV Silver pearl coating)

Filter cover- ABS (Black) Bracket- Aluminum

Operating Environment Temperature : 15~35℃, Humidity : 35~85% RH

Dimensions(WxHxD) 125x135x69.5mm (with bracket 152x154.5x69.5mm)

Weight 571g (with bracket)