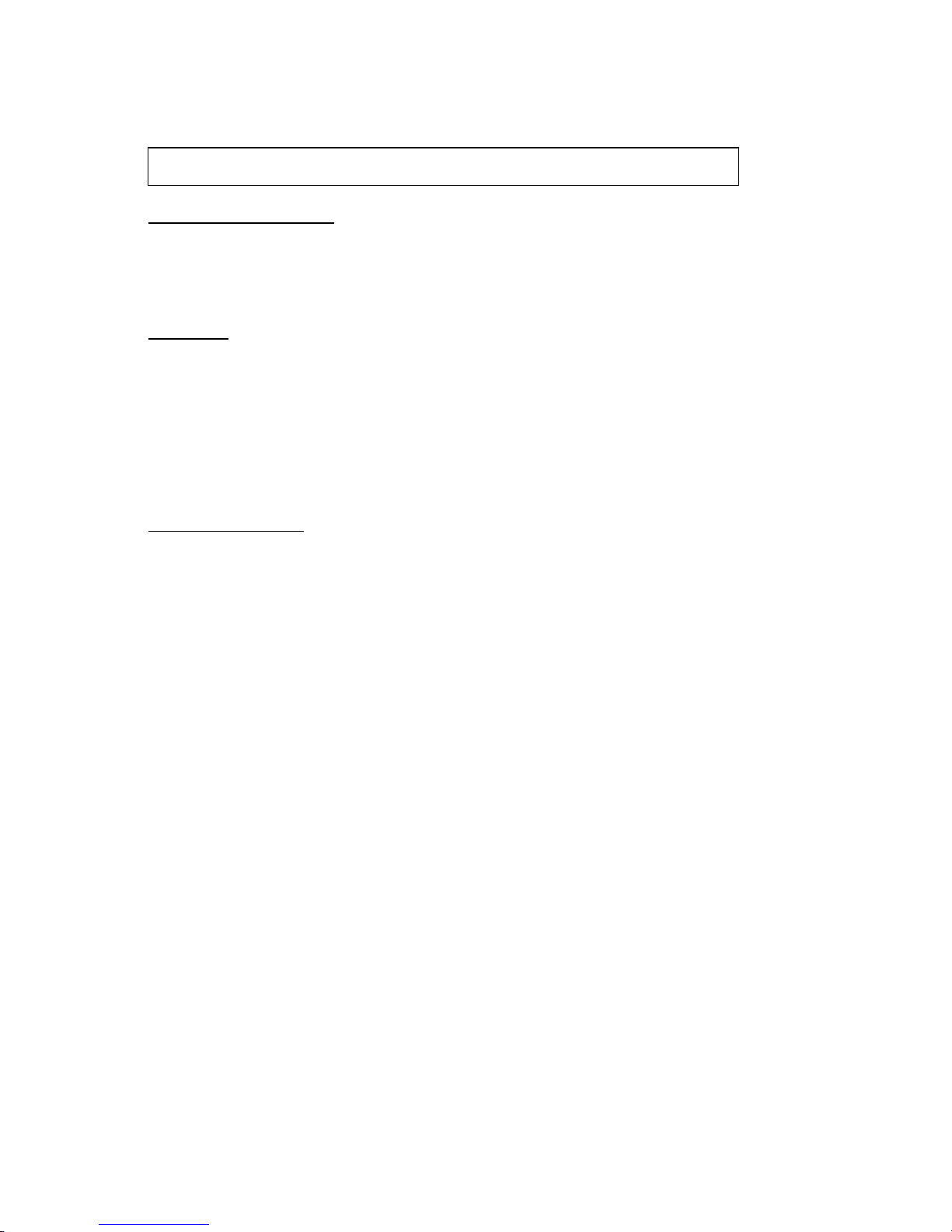

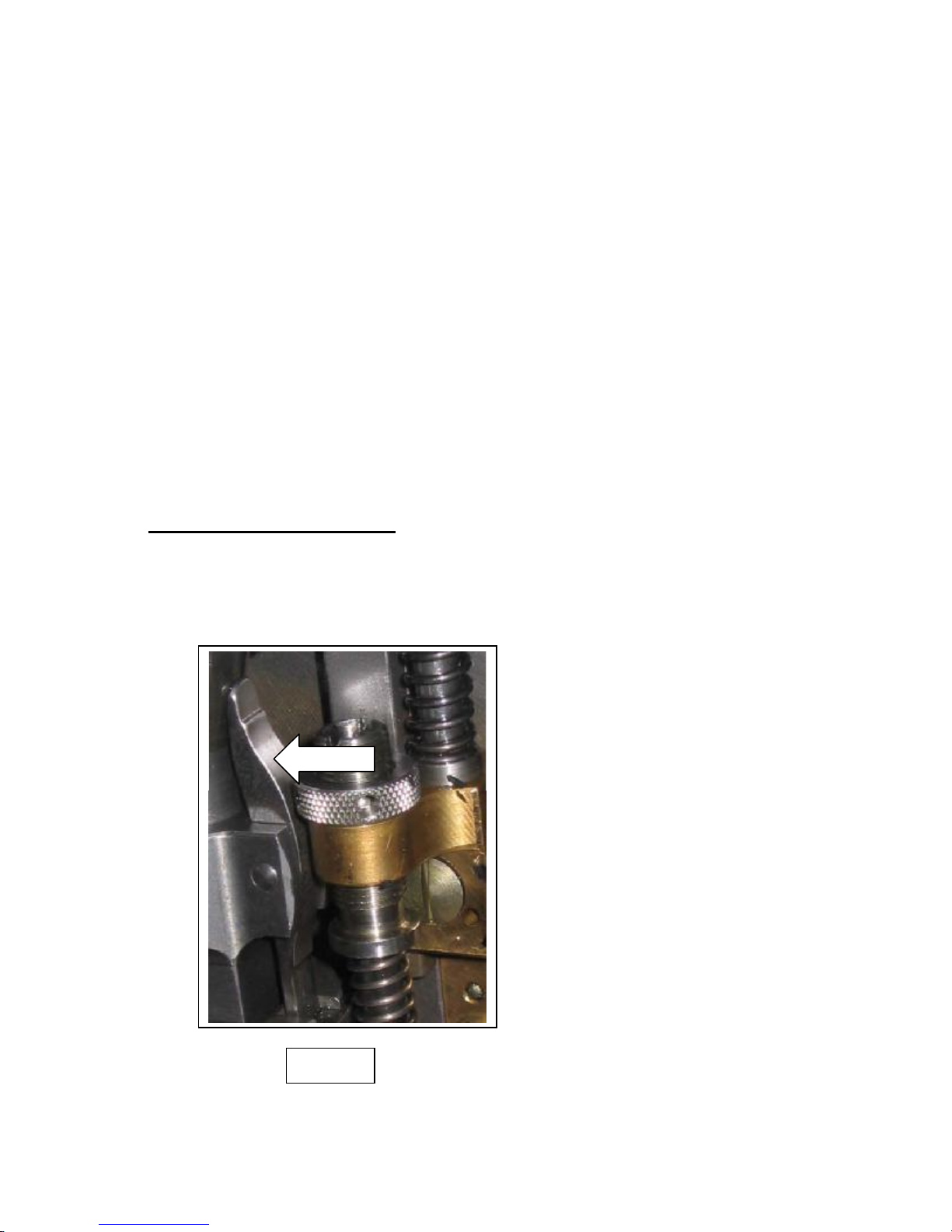

Raisethe pad,C.00093 (Fig.6) insertthe spool on the shaftand adjust nutscrew

C.13295V. Pull the thread through the eyeofthe tensionspring C.00945.The

thread mustcomefrombelowthe spool.

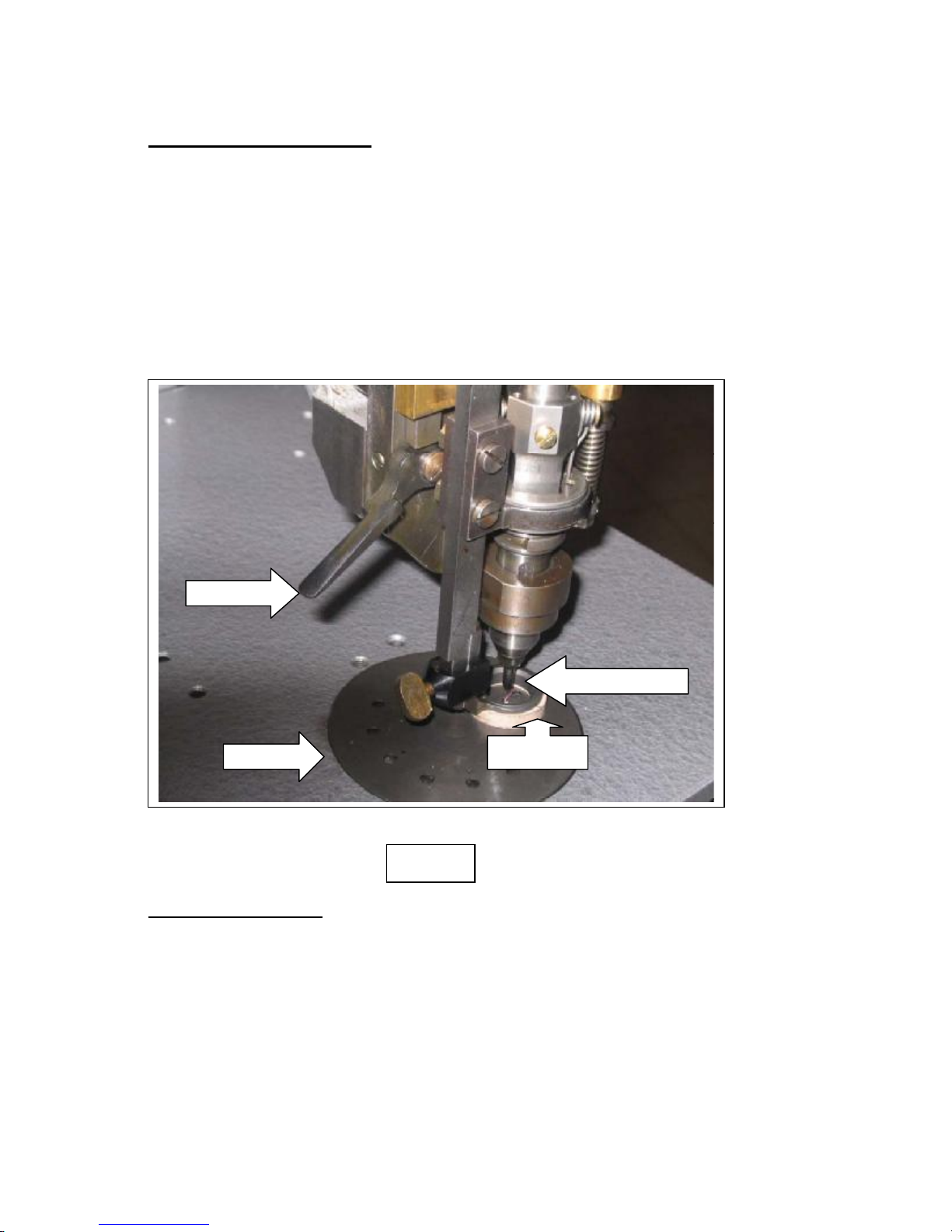

Passthe thread hookC.01305 through the bighole ofthe needleplateC.01707

whichisin frontofthe needle hole.

Catchthe thread and pull itup under the needleplateC.01707.

Passthe threadunder footC.00946Awhichhasbeen raised beforehand.

The thread mustbe laying towardsyou.

Startthe motor while holding the thread on the table withyour lefthand as

instructedabovejustthetimetodo onestitchsothattheneedle catchesthe thread

and letitpassthrough the plate.

Now,removethe thread fromthe needle withthe curvedknifeand laythe thread

on the table.

The thread tension isadjustedbypad pressure.

The spool tension can be regulated byraising the lever C.00094 (Fig.6) or lower

the lever C.00094.

b.The machine threading withaconical spoolholder isthe following :

C.00945

E

C

25764 D

FIG.7

Putthe conicalBobbin on the spoolholderA.,(Fig.8),putthe yarn through the eye

B(Fig.8),passthrough eyeC(Fig.7)between thetension disc D

(Fig.7) then passthrough the eyeEtopass afterwardsthrough the tensionspring

C.00945.

Follownowthe instruction asfor the cylindrical spoolholder.

From the Library of Superior Sewing Machine & Supply LLC