CORNING OptiTect SRP 000-245 User manual

003-737, Issue 4

STANDARD RECOMMENDED PROCEDURE 003-737 | ISSUE 4 | MAY 2015 | PAGE 1 OF 25

OptiTect®Indoor Local

Convergence Point

Enclosure

related literature | Search www.corning.com/opcomm. Click on “Resources.”

SRP 000-245 Instruction, Splitter Modules

EVO-707-EN Product Specications for OptiTect™ Indoor MDU Local Convergence Cabinet

Table of Contents

1. General .................................................................... 2

1.1 Use and Application ...................................................... 2

1.2 Planning ............................................................... 3

2. Materials and Tools Required ................................................... 4

2.1 Materials ............................................................... 4

2.2 Tools .................................................................. 4

2.3 Auxiliary Equipment ...................................................... 4

3. Components and Shipping Container Contents ..................................... 4

4. Storage and Transportation ..................................................... 6

5. Unpackaging the Enclosure and Components ...................................... 6

6. Installing the Enclosure ........................................................ 7

6.1 Mount the Enclosure on a Wall .............................................. 7

6.2 Mount the Enclosure into a Rack ............................................ 8

6.3 Mount the Enclosure on the Floor............................................ 8

7. Accessing the Enclosure ...................................................... 10

8. Grounding the Enclosure...................................................... 10

9. Managing Fiber ..............................................................11

9.1 Field-installed Unconnectorized Feeder and Distribution Cable Option ...............11

9.2 Preinstalled Connectorized Feeder And Distribution Cable Option ..................11

10. Installing Unconnectorized Cable ................................................11

10.1 Feed Cable into Enclosure ................................................ 12

10.2 Prepare Cable.......................................................... 14

10.2.1 Install Braided Tubing .............................................. 15

10.2.2 Install Grounding Hardware to Armored Cable ........................... 17

10.2.3 Secure Metallic Strength Members .................................... 17

10.2.4 Install Strain-relief Hardware......................................... 18

10.2.5 Ground Cable .................................................... 19

11. Splicing ................................................................... 19

12. Installing Splitter Modules ..................................................... 21

13. Connecting Splitter Input Fibers to Feeder Cable ................................... 21

14. Connecting Splitter Output Fibers ............................................... 23

14.1 Route Splitter Output Fibers to be Connected Now ............................. 23

14.2 Route and Store Splitter Output Fibers to be Connected Later .................... 23

15. Connector Care and Cleaning .................................................. 24

STANDARD RECOMMENDED PROCEDURE 003-737 | ISSUE 4 | MAY 2015 | PAGE 2 OF 25

1. General

The OptiTect™ GEN III Local Convergence Point Enclosure (LCP) serves as an interface

between a telecommunication provider’s network and individual customer connections. The

enclosure provides mechanical and environmental protection for the splices and connector

interfaces while providing easy access for the service provider. It also provides a management

system for optical ber connectors, and splitter modules and a test access point to verify the

integrity of the network. There are several sizes of enclosures available from a 144-ber version

up to an 864-ber capacity unit.

1.1 Use and Application

The OptiTect GEN III LCP is used in an indoor environment, either mounted on a wall, 23-in

equipment rack or pedestal. The enclosure design allows front access to the bers, connectors,

and splitter modules for management, testing, and maintenance by the craft persons.

The interior is accessible through a hinged front door secured with a single-point pawl latch.

The door can be locked with a 216B tool and padlock. The standard conguration is one

connectorized distribution and one connectorized feeder cable preinstalled and attached to the

internal housings.

144-ber Cabinet 288-ber Cabinet 432-ber Cabinet

Distribution 144 288 432

Feeder Maximum 24 bers

(10 are connectorized)

Maximum 48 bers

(18 are connectorized)

Maximum 48 bers

(28 are connectorized))

Splitter Modules (1x32,

1x16)

3/5 9/18 14/28

Parking (Storage) 96 128 192

Table 1: Cabinet Capacity

• Preconnectorized distribution and feeder cables are routed into the enclosure and

terminated on the back side of the connector adapter elds. The front side of each adapter is

ready to receive the connectorized bers from the splitter modules.

• Splitter modules (purchased separately) are installed into the splitter storage area.

Refer to Table 1 for the maximum number of splitter modules for each size of enclosure.

Preconnectorized output bers from the splitter modules can be connected at the time of

installation in the distribution eld or routed to and stored in a connector storage/parking

panel for connection later.

16. Securing the Enclosure ....................................................... 25

17. Maintenance ............................................................... 25

18. Testing .................................................................... 25

18.1 Provisioning Tests ....................................................... 25

18.2 Troubleshooting Tests.................................................... 25

STANDARD RECOMMENDED PROCEDURE 003-737 | ISSUE 4 | MAY 2015 | PAGE 3 OF 25

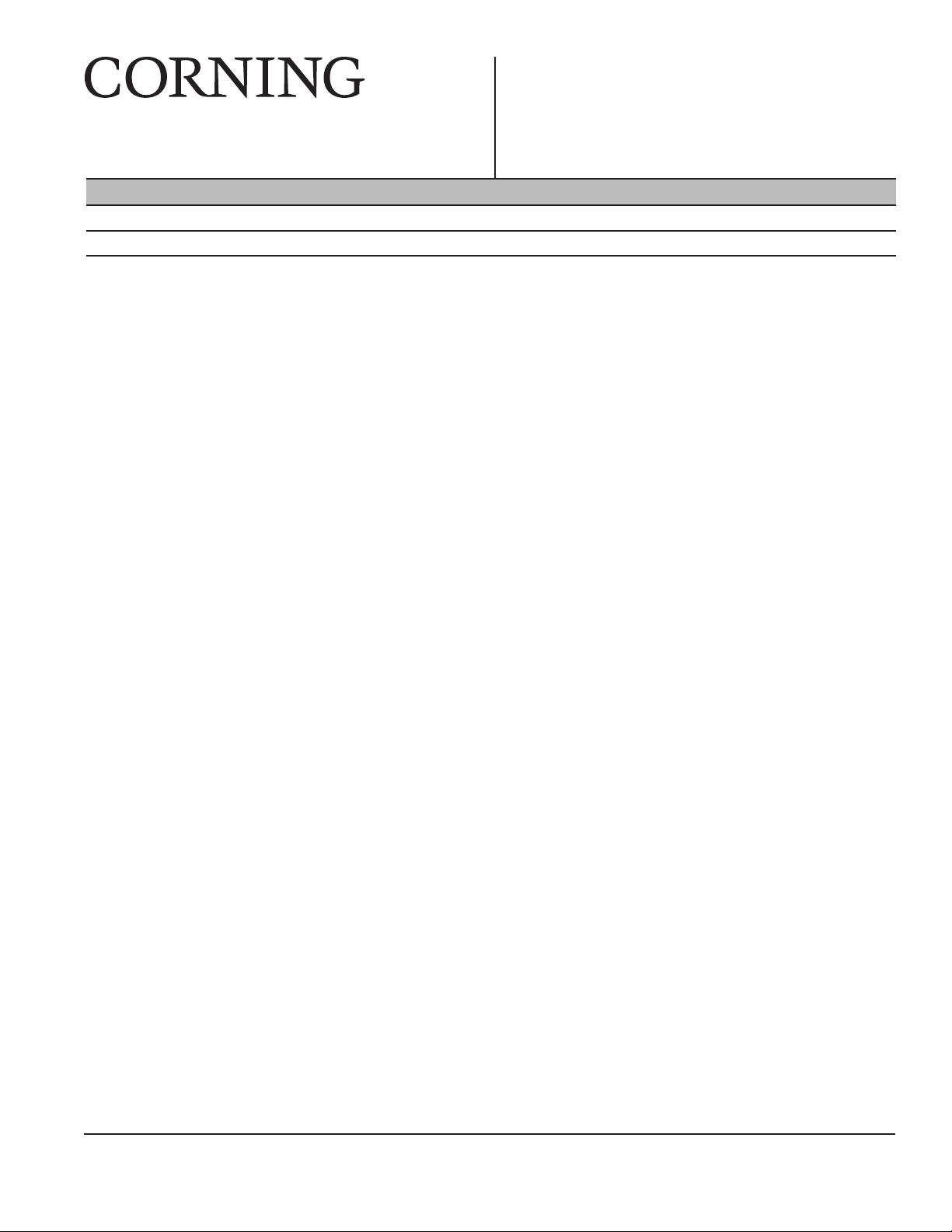

1.2 Planning

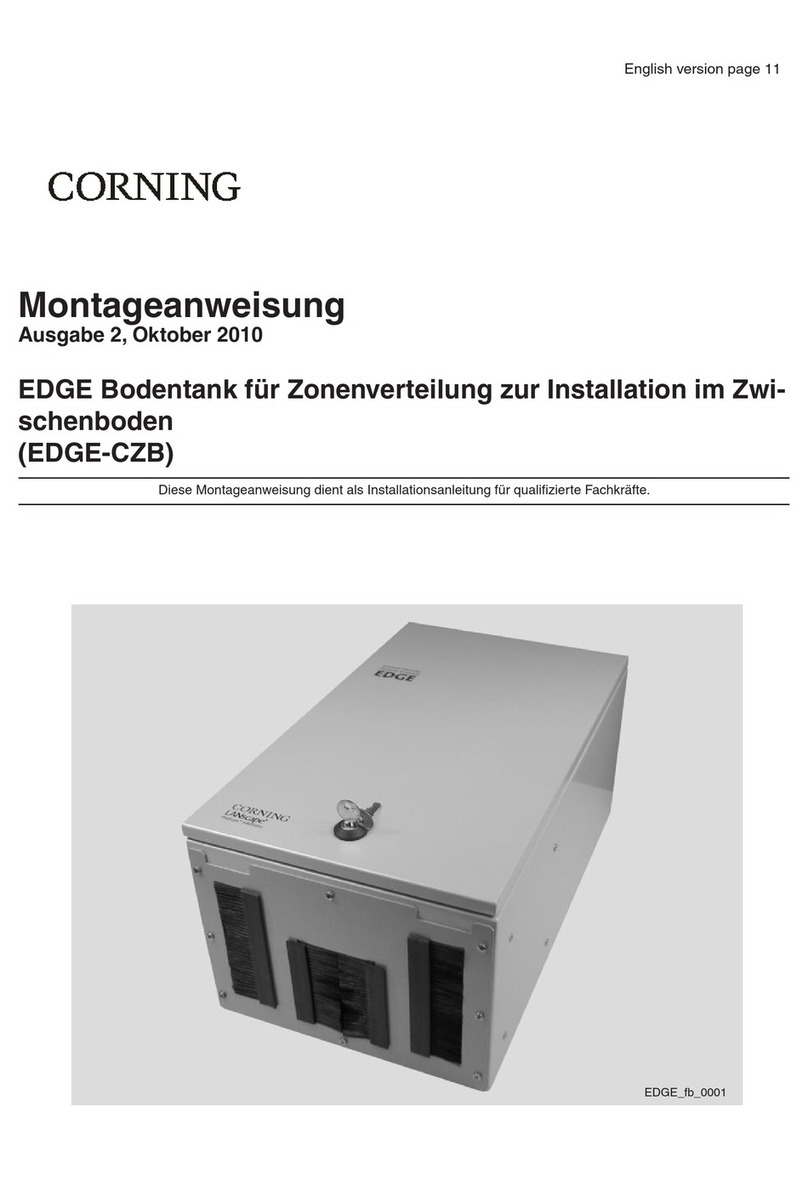

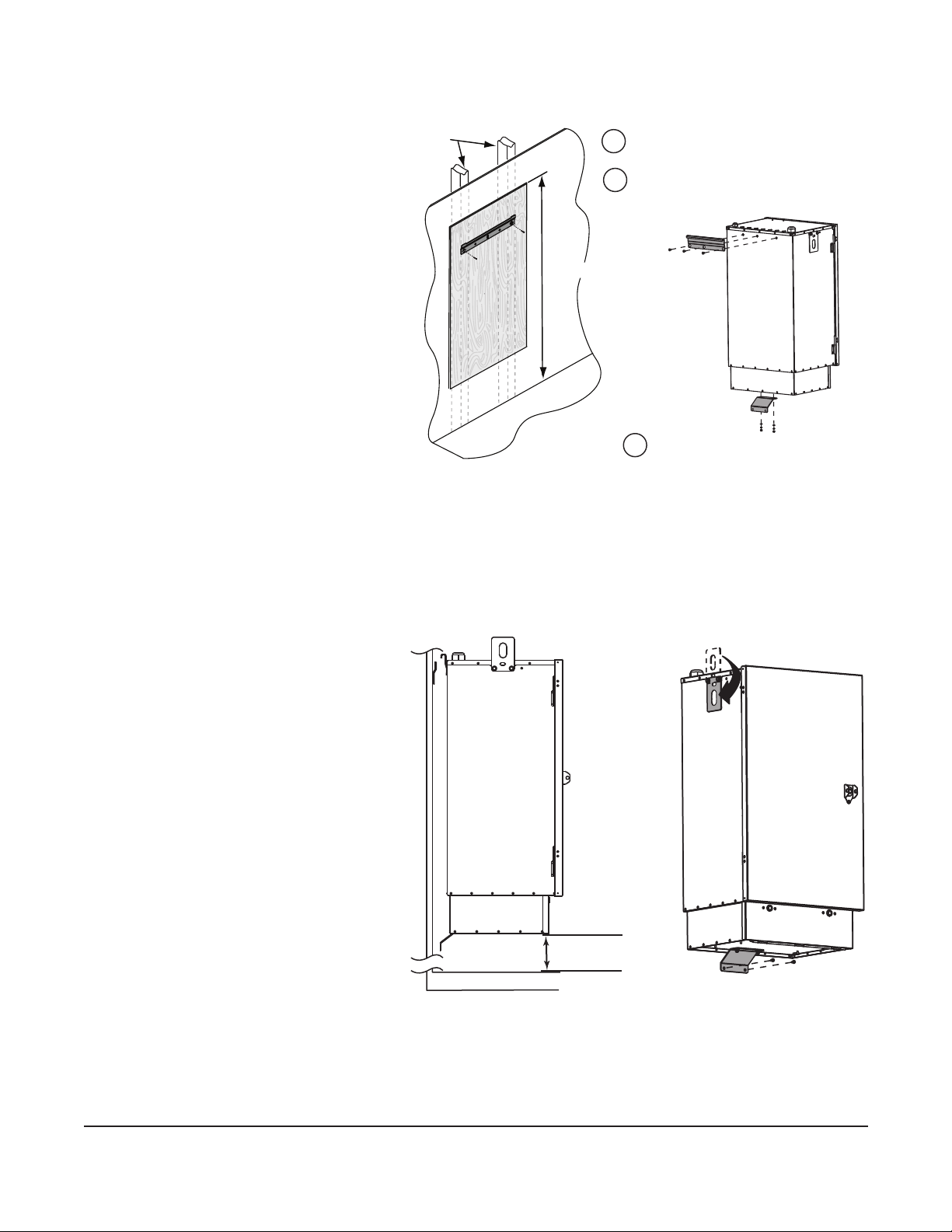

Figure 1

Contact a Corning customer care representative to place an order for this product in the

conguration required by your network installation plan.

• The dimensions for each of the enclosure sizes are shown in Figure 1. Ensure that sufcient

space is available at the installation site to accommodate the enclosure. Allow 19 in in front

and 10 in on each side of the enclosure to enable the door to open fully.

• The installing company should obtain rights-of-way from property owners and permits or

other approvals from public authorities prior to installation of the enclosure.

KPA-0887

Weight (Empty)

Depth (inches)

Width (inches)

Height (inches)

Number of Top Ports

Distribution Splice Trays

Feeder Splice Trays

PARAMETER ILCP - 72/144 ILCP - 288 ILCP - 432

6

60 lbs

9

2

1

9

1

70 lbs

19.5

17.3

9

4

1

80 lbs

19.5

17.3

ILCP Cabinet with

Optional Splice Housing

ILCP Cabinet with

Stubbed Cables

46.7 (31.5 w/o splice hsg) 52.5 (37.3 w/o splice hsg)

22.9 (16.2 w/o splice hsg)

19.5

17.3

STANDARD RECOMMENDED PROCEDURE 003-737 | ISSUE 4 | MAY 2015 | PAGE 4 OF 25

• Select an appropriate site per your design plan and follow standard local practices for

installation of the enclosure. The mounting location should be able to withstand the weight of

a fully loaded enclosure.

2. Materials and Tools Required

2.1 Materials

Mounting hardware to attach the enclosure to the wall is not provided. The hardware used is

dependent upon the surface to which the enclosure is being installed; the appropriate hardware

may be purchased from a local hardware store.

2.2 Tools

To install the enclosure, the following tools may be required:

• Hoist or lifting device capable of lifting at least 150 pounds (largest enclosure’s weight,

including packaging)

• Forklift or handtruck

• 216B tool or a 7/16-in nutdriver (for entry into the interior of the enclosure)

• Crescent wrench

• 9/16-in nut driver or socket

• 3/4-in nut driver or socket

• Phillips-head screwdriver

• Dry-process connector cleaning supplies

Depending upon the ber and splicing congurations required for your application, the following

tools may be required to install the enclosure:

• Drill and drill bits

• Lint-free wipes

• Appropriate hardware (if wall mounting) for the wall-mount surface material

• Isopropyl alcohol

• Flat-tipped screwdriver

• Fiber stripping tools

• Splicing equipment and supplies

2.3 Auxiliary Equipment

There is no auxiliary equipment required to install the enclosure. If the enclosure is not full

to capacity, additional products may be installed to expand the customer connections. Refer

to the section, Growth, for details on expanding the capacity. Contact a Corning customer

service representative to order additional products in the conguration required by your network

installation plan.

3. Components and Shipping Container Contents

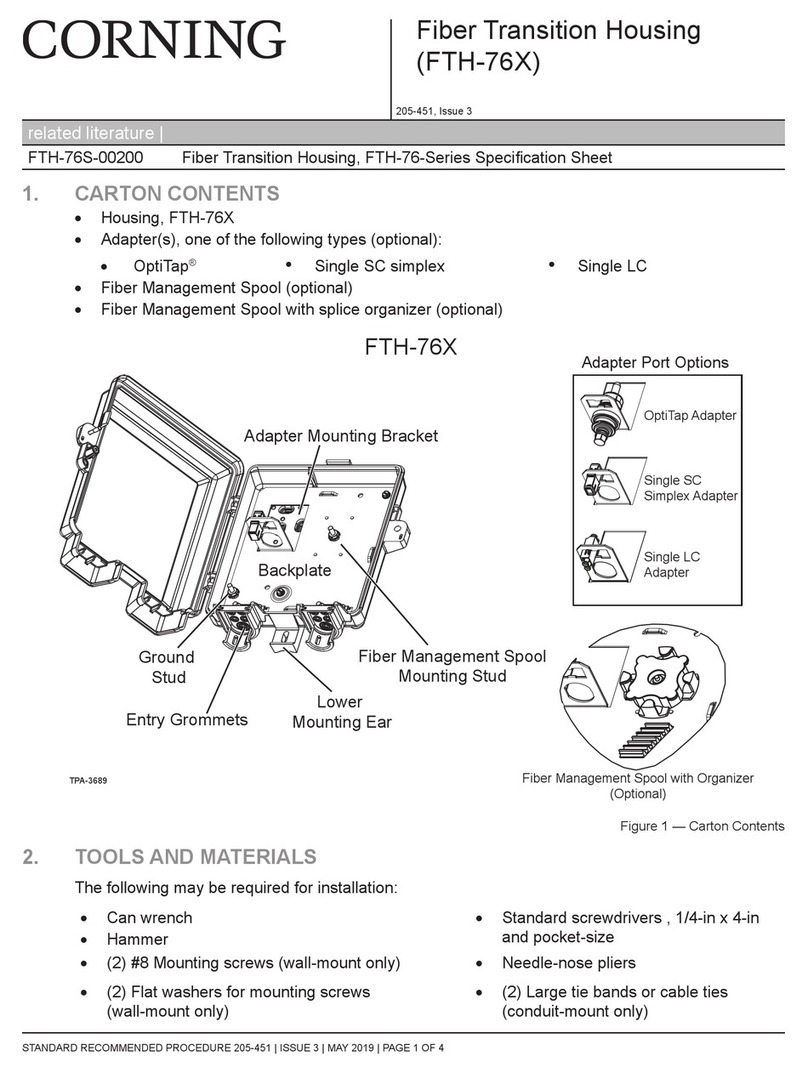

Figure 2 provides a pictorial description of the enclosure and its components.

• Packing List of Shipping Container Contents:

• (1) OptiTect™ GEN III Local Convergence Point enclosure, prestubbed with distribution

and feeder cables in lengths specied by the customer (other congurations available)

• (1) Installation instruction (SRP 003-737)

• (1) Bag with extra adapter and connector dust caps

• Wallmount kit (p/n 07-000867-001) including mounting brackets and hardware

STANDARD RECOMMENDED PROCEDURE 003-737 | ISSUE 4 | MAY 2015 | PAGE 5 OF 25

• Grounding kit (installed) (p/n FDH-GRND-KIT)

• Rackmount kit (p/n 07-000876-001) to mount in racks with EIA/TIA or WECO hole

spacing

• Feeder and distribution cable installation kit

• Feeder and distribution cable strain-relief kit

• Additional Container Contents for Field-splice Applications:

• Splice trays (number of trays included depends upon conguration)

Figure 2

Cable Entry Ports

Slack Storage

Radius Guides

Panel Latch

Splitter Module

Input Fiber Field

Splice Housing

(Optional)

Removable Door

216B Tool

Pawl Latch

(Optional

Padlock)

Storage / Parking

Panel for Unmated

Connectors

KPA-0732

Lifting Eye

Stored position of lifting eyes

STANDARD RECOMMENDED PROCEDURE 003-737 | ISSUE 4 | MAY 2015 | PAGE 6 OF 25

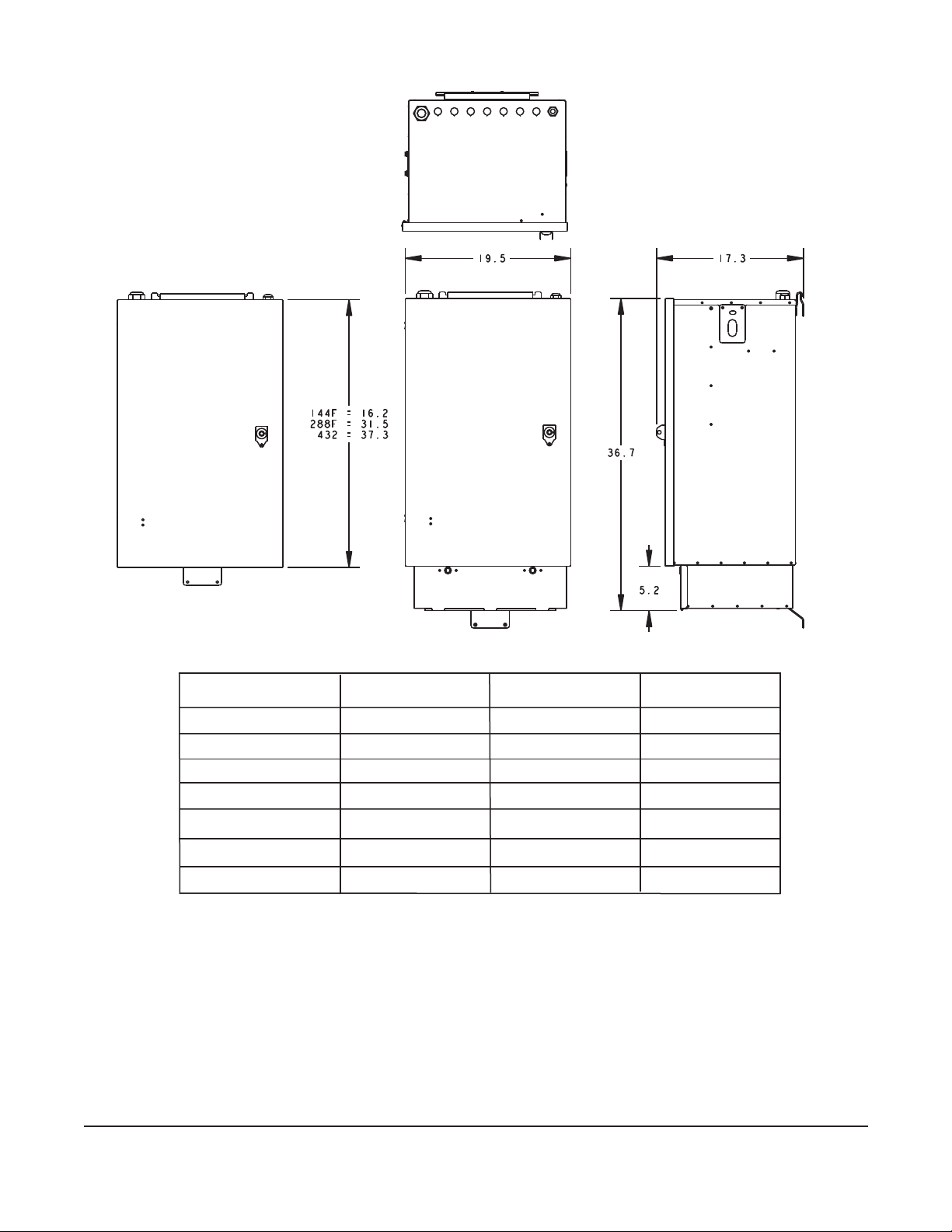

4. Storage and Transportation

The shipping container and its contents must be stored

indoors in a vertical position in the original packaging. A

forklift or handtruck capable of lifting approximately 150

pounds is required to unload or transport the product in

its shipping container prior to unpacking. Observe all local

safety precautions when moving the container. Do not

double-stack shipping containers.

5. Unpackaging the Enclosure and

Components

Step 1: Place the container near the site prepared

for installation of the enclosure. Remove the

installation instruction.

Step 2: Remove the shrinkwrapping from around the

enclosure (Figure 3).

Step 3: Cut the bands holding the enclosure to the pallet.

Step 4: Ensure that a lifting device, such as a hoist or crane, capable of lifting at least 150

pounds (largest enclosure’s weight) is available to lift the enclosure into position.

WARNING: Only certied operators should operate the crane. Ensure that the stabilizers are

extended and rmly positioned before Lifting. Avoid overhead obstructions or power lines

when lifting.

WARNING: The enclosure is heavy and requires two people to maneuver it. Observe all safety

precautions while using Make sure the door is locked in the closed position. Failure to do so

may result in personal injury or damage to the enclosure or cables.

CAUTION: Fiber optic cable is sensitive to excessive pulling, bending, and crushing forces.

Consult the cable specication sheet for the cable you are installing. Do not bend the cable

more sharply than the minimum recommended bend radius. Do not apply more pulling force

to the cable than specied. Do not crush the cable or allow it to kink. Doing so may cause

damage that can alter the transmission characteristics of the cable; the cable may have to be

replaced.

Step 5: If the unit shipped with cables preinstalled, clip

the ties from the cables. Roll out the cables

when removing them from the packaging to

avoid putting twists into the cable. Then loop

the cables in a “Figure-8” pattern next to the

mounting location as shown in Figure 4 before

placing the unit.

Figure 4

KPA-0733

Lifting

Eye

Cut

Bands

Here

Figure 3

KPA-0731

Lift

Cabinet

STANDARD RECOMMENDED PROCEDURE 003-737 | ISSUE 4 | MAY 2015 | PAGE 7 OF 25

6. Installing the Enclosure

6.1 Mount the Enclosure on a Wall

Step 1: For standard

installation of the

LCP enclosure on a

wall, secure a 4-foot

by 8-foot by 1/2-in

sheet of plywood

to the studs of the

wall in the mounting

location, with the top

edge of the plywood

approximately 80

in above the oor

(Figure 5), at the

height specied in

your standard local

procedures.

Step 2: Using appropriate hardware (not provided), attach the mounting bracket to the

plywood approximately 75 in above the oor. Ensure the bracket is level and secured

to the wall to support the weight of the enclosure.

Step 3: Attach the wallmount mounting brackets to the rear of the enclosure as shown in

Figure 5.

Step 4: Using the hoist or

lifting device, lift

the enclosure and

hook the mounting

bracket over the

bracket on the wall.

IMPORTANT: Lower edge of the

enclosure or splice

chamber should be

located approximately

36 in above the oor.

Step 5: Screw the bottom

bracket into the

plywood and move

the lifting eyes to

their stored position

(Figure 6).

KPA-1783

Attach mounting brackets to cabinet.

Attach mounting bracket to plywood.

Attach plywood to wall.

1

2

3

Floor

Plywood

Wall Studs

Sheetrock

80 inches

Figure 5

KPA-0057

Floor

36 inches

Figure 6

STANDARD RECOMMENDED PROCEDURE 003-737 | ISSUE 4 | MAY 2015 | PAGE 8 OF 25

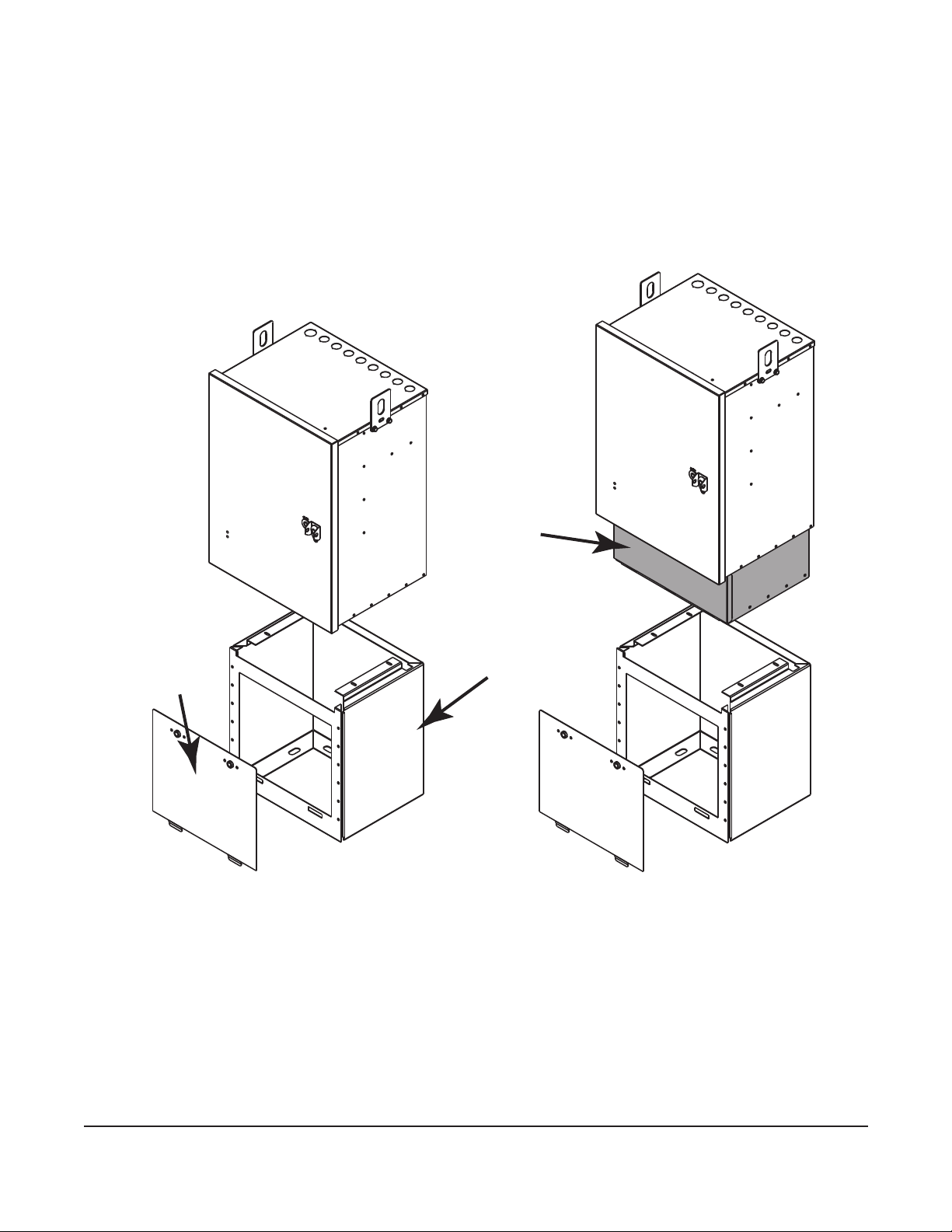

6.2 Mount the Enclosure into a Rack

Step 1: Install the rack-mount brackets to each

side of the enclosure as shown in

Figure 7.

Step 2: Using a hoist or lifting device, lift the

enclosure, position it within the rack

and secure the enclosure to the rack.

6.3 Mount the Enclosure on the Floor

IMPORTANT: Pedestal must be used when oor

mounting the cabinet. The pedestal may be

attached to the cabinet with or without the

splice housing.

Pedestal Kit (p/n:IFDH-G3-PEDESTAL) comes

with:

• (1) Pedestal Assembly

• (4) #10 Washers (for securing the cabinet to

the pedestal)

• (4) #10-32 Self-locking nuts (for securing the

cabinet to the pedestal)

• (1) Isolation pad (installed between pedestal base and oor)

• (1) Ground wire

Step 1: Determine the cabinet location in your application per the installation plan.

Step 2: Determine the type of installation for oor mounting the pedestal. You will need to

order one of the following kits applicable to your type of installation:

• For mounting by drilling and installing wedge anchors, order p/n FDH-MTNG-KIT-

DRLAN

• For mounting to

precast inserts,

order p/n FDH-

MTNG-KIT-TDIN

• For mounting to

precast studs,

order p/n FDH-

MTNG-KIT-TDST

Step 3: Use the base of

the pedestal as a

mounting template

as shown in Figure

8 to determine

the location of the

mounting holes.

Remove the front

access cover and

mark the holes

shown by the shaded

locations in Figure 8.

KPA-0738

Figure 7

KPA-1343

44.58 cm

(17.55 inch)

24.92 cm

(9.81 inches)

3.81 cm

(1.5 inch)

10.16 cm

(4 inches) 24.26 cm

(9.55 inches)

32.54 cm

(12.81 inches)

Figure 8

STANDARD RECOMMENDED PROCEDURE 003-737 | ISSUE 4 | MAY 2015 | PAGE 9 OF 25

Step 4: Prepare the oor per the installation type and remove excess debris when complete.

Step 5: Position the isolation pad between the pedestal and the oor and secure the

pedestal to the oor (Figure 9) using the hardware for your application.

Step 6: Assemble the cabinet to the pedestal by fully securing the four #10 washers and self-

locking nuts provided.

Step 7: Reattach the front access panel.

Step 8: Replace grounding wire supplied with the cabinet with the grounding wire supplied in

the pedestal kit. It provides additional length allowing the wires to be attached to the

building ground according to standard local codes and practices.

Figure 9

Optional

Splice

Housing

Pedestal

KPA-0740

Front Access

Cover

STANDARD RECOMMENDED PROCEDURE 003-737 | ISSUE 4 | MAY 2015 | PAGE 10 OF 25

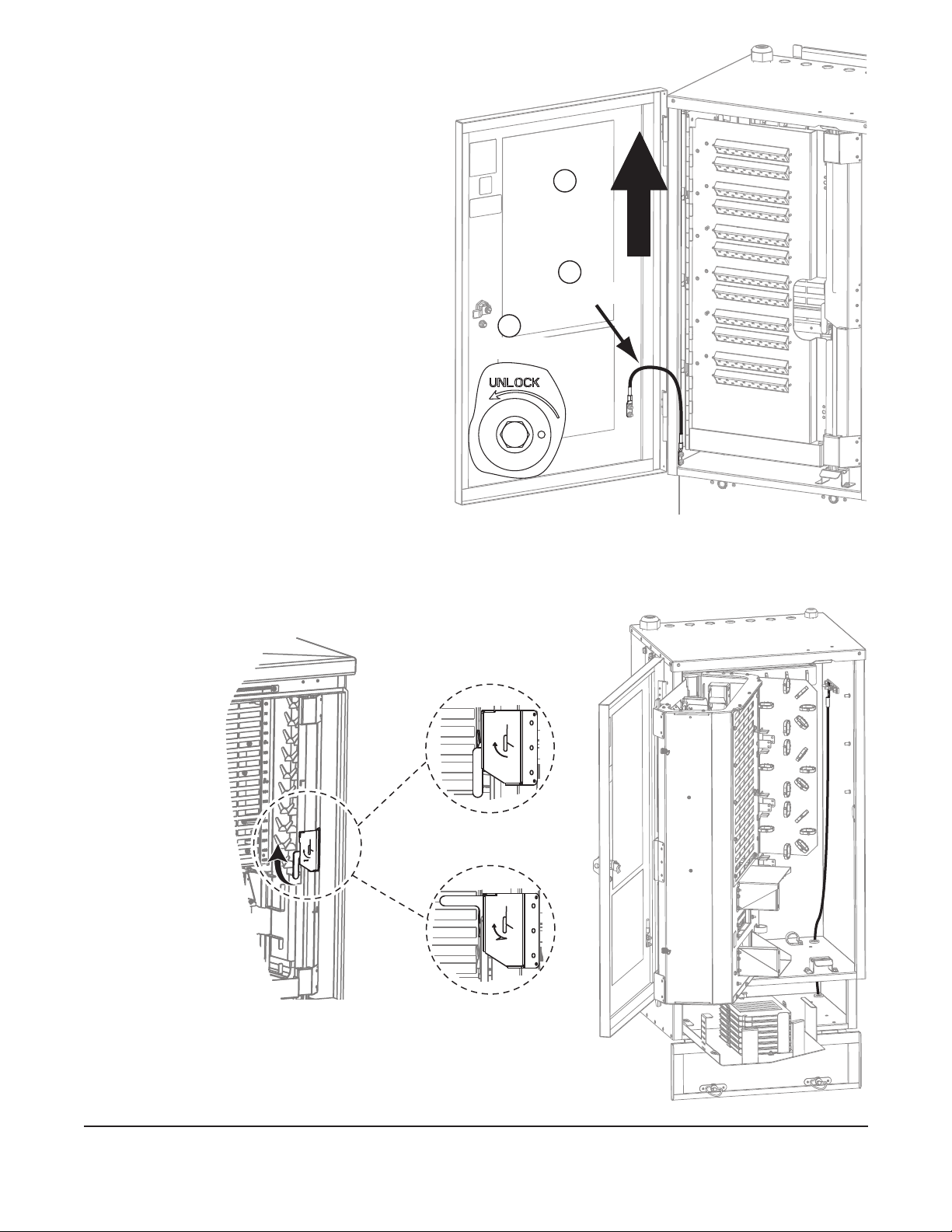

7. Accessing the Enclosure

If the enclosure door is closed, use a

216B tool or a 7/16-in nutdriver on the

latch to open it as shown by the inset in

Figure 10. To facilitate work operations

inside the enclosure, the exterior door

may be removed.

Step 1: Remove ground strap at

the bottom of the door

by removing the two nuts

securing the ground lug to

the door. Replace the two

nuts on the stud to prevent

misplacing them during the

rest of the work operations.

Step 2: After removing the ground

strap, lift the door free of the

hinges. Set the door aside.

Step 3: When work operations are

complete, reverse these

steps to replace the door

and ground strap.

8. Grounding the Enclosure

Step 1: Open the panel door (Figure 11) inside the enclosure to access the ground bar in the

upper right side of the enclosure.

Step 2: Open the splice housing door and pedestal skirt

door, if the enclosure is equipped with these

items. Bring the ground cable up through the

KPA-0739

Remove Strap

1

Unlock Door

2

3

Lift Door

Off Hinges

Figure 10

KPA-0699

OPEN

OPEN

Open

Closed

Figure 11

KPA-0734

Figure 12

This manual suits for next models

1

Table of contents

Other CORNING Enclosure manuals