P/N 003-991-AEN

Issue 5

Standard Recommended Procedure 003-991-AEN | Issue 5 | January 2021 | Page 1 of 8

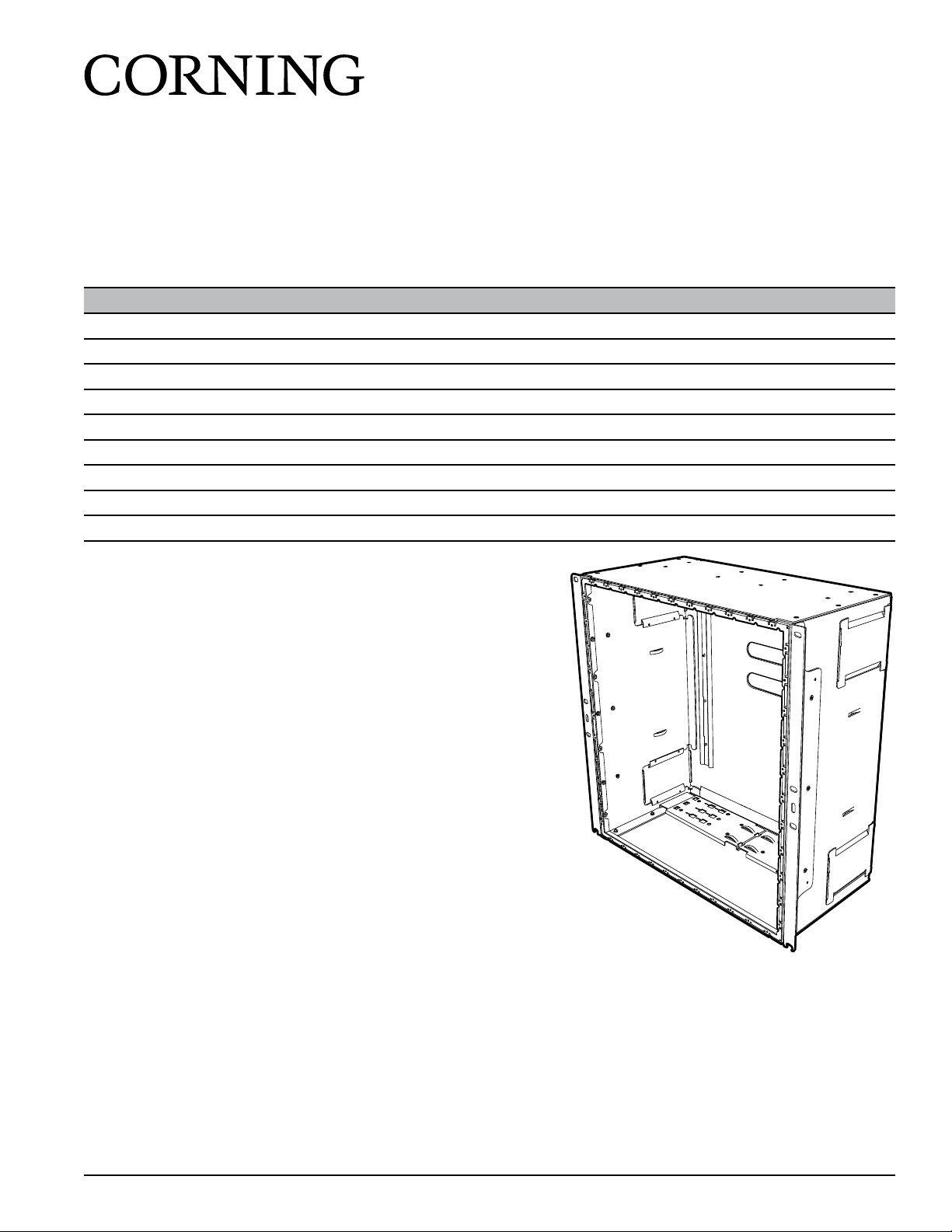

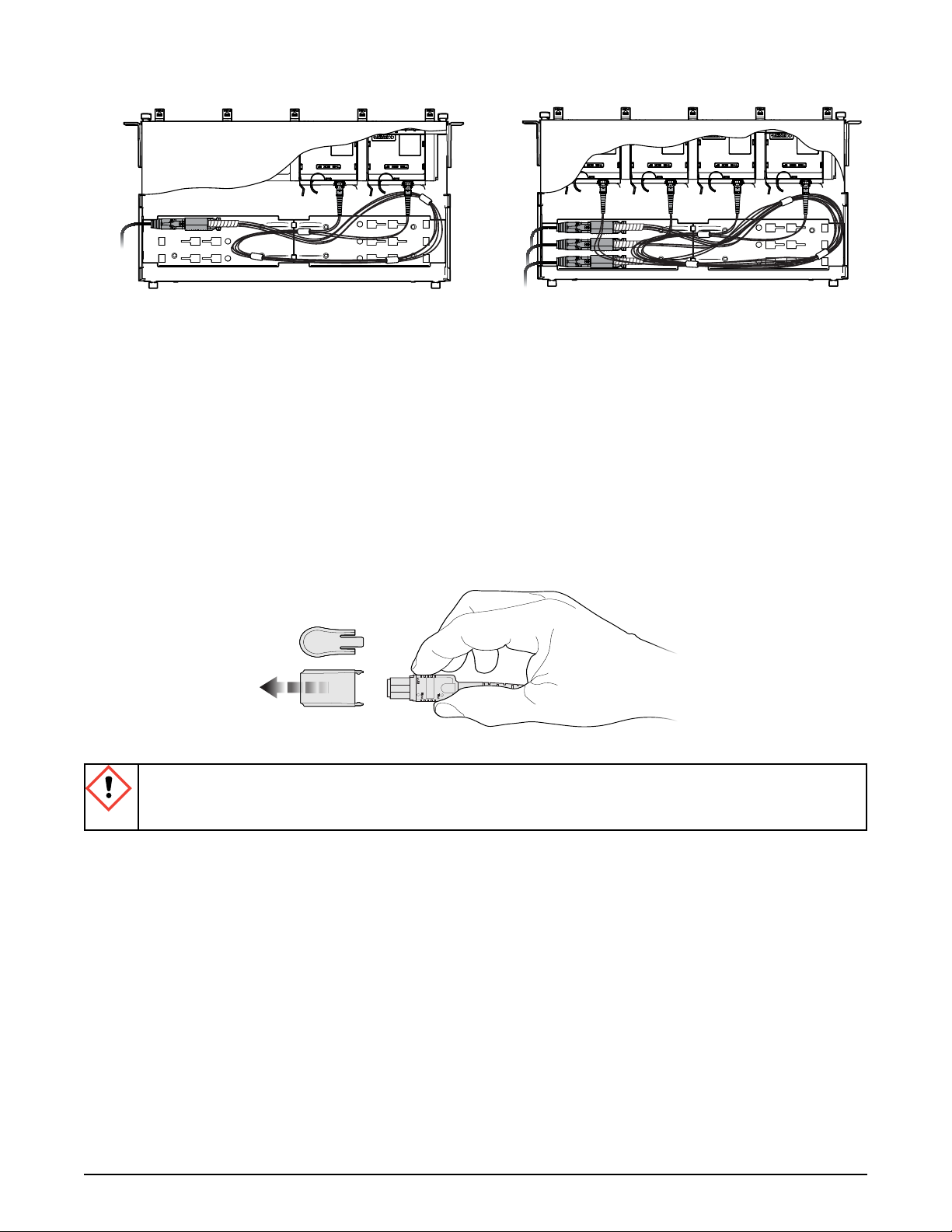

EDGE™ Port Replication Housing

1. Carton Contents

• EDGE™ port replication housing

(EDGE-10U-PRH) (Figure 1)

• #12-24 x 0.5-in mounting screws (6)

2. Tools and Materials

2.1 Standard Installation

• Phillips screwdriver

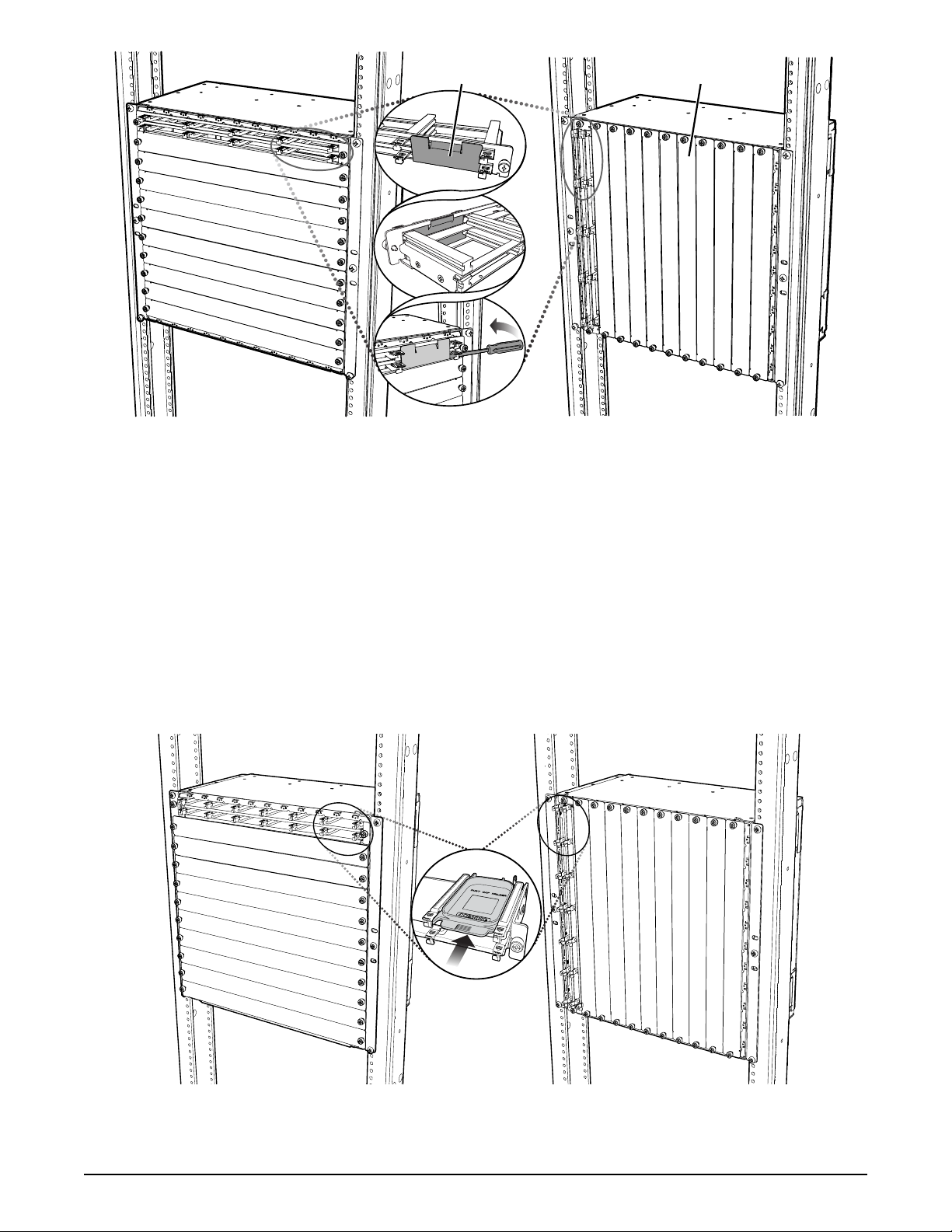

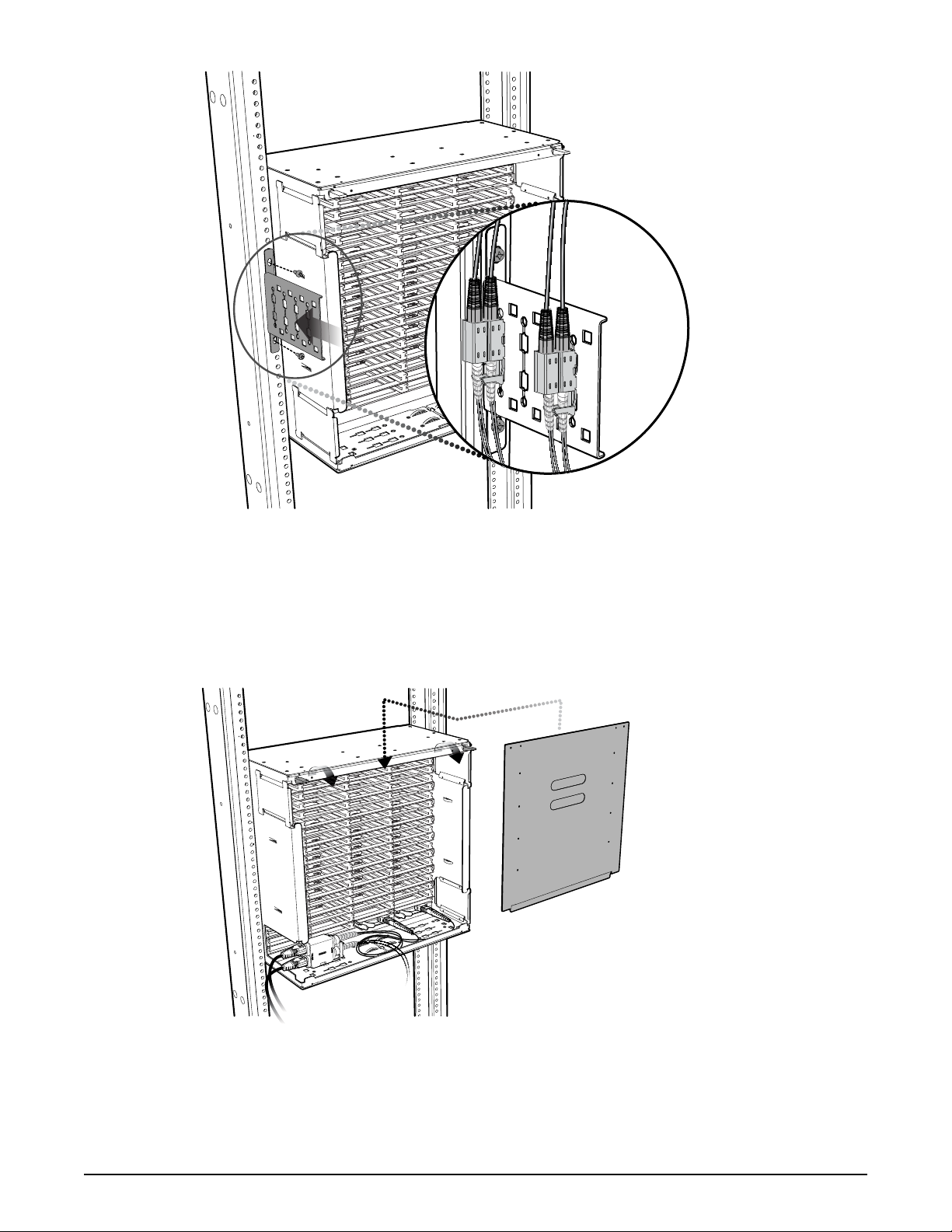

• Double-stack EDGE furcation plug cradles

(quantity one ships with each EDGE trunk)

2.2 Additional Solution Components

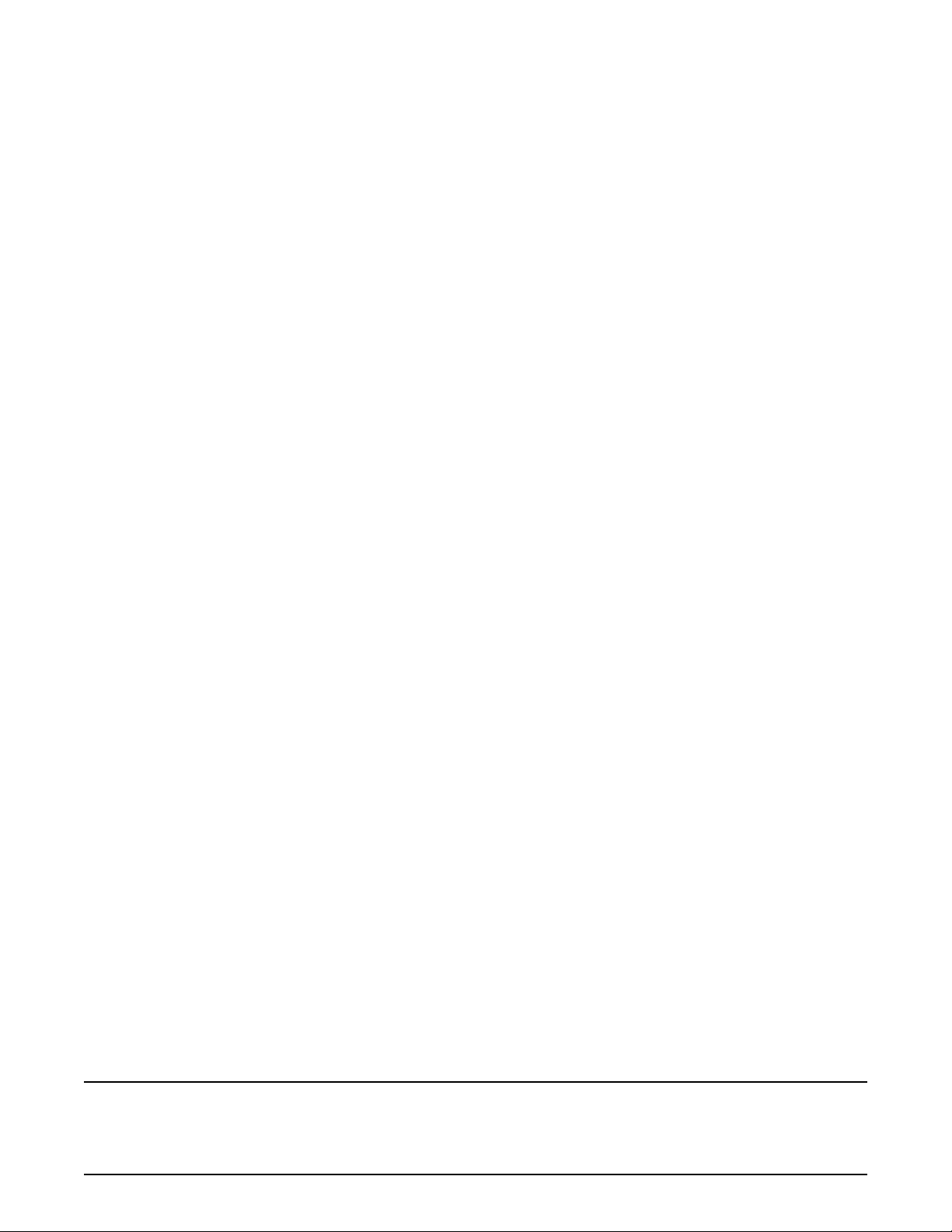

2.2.1 EDGE Solution

• EDGE panel (EDGE-CP8B-PRH), up to 11 per

housing with up to eight EDGE modules per

panel

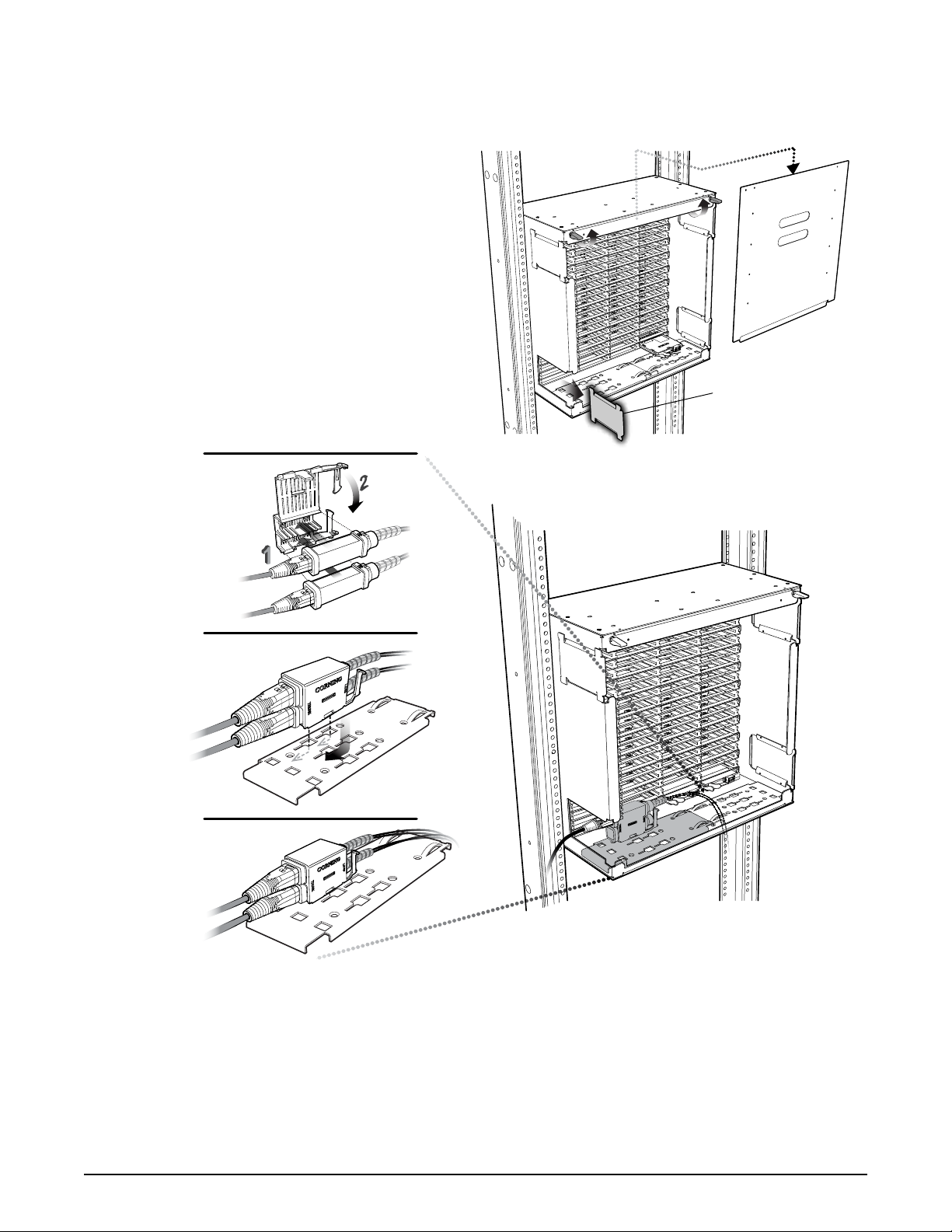

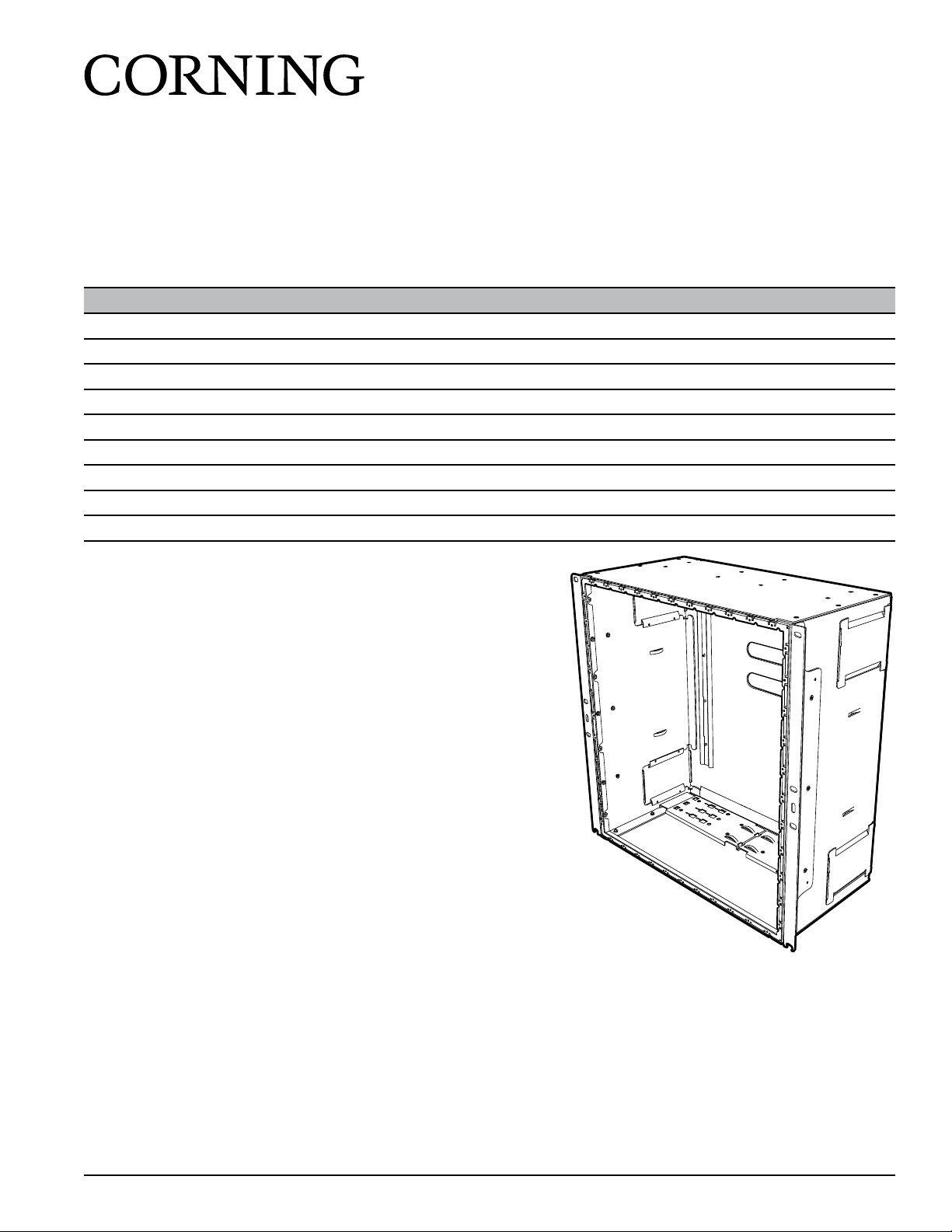

• (Optional) Blank panel cover (EDGE-BLNK-PRH)

• (Optional) Blank module cover (EDGE-CPCVR-PRH)

• (Optional) LC adapter panel, aqua (EDGE-CP96-AD-PRH)

• (Optional) LC adapter panel, blue (EDGE-CP96-AE-PRH)

related literature | Search www.corning.com/opcomm. Click on “Resources.”

003-794-AEN EDGE™Solution

003-888-AEN EDGE Solution with 1U/2U/4U Fixed Trays

000-276-AEN EDGE Secure Solutions FTTD Module

003-825-AEN EDGE and EDGE8®Fiber Zone Boxes

003-892-AEN EDGE and EDGE8 Solution Single Module Housing

003-1049-AEN EDGE Solution Single Module Housing for Splicing

000-274-AEN EDGE Splice Cassette EDGE Field-Terminated Cassette

003-885-AEN EDGE Solution Modules in an Enhanced Management Frame

006-407-QSG-AEN Field Tool for MTP®PRO Connectors Quick Start Guide

Figure 1