STANDARD RECOMMENDED PROCEDURE 003-1072-AEN | ISSUE 2 | MARCH 2021 | PAGE 3 OF 11

3. Storage and Transportation

The shipping container and its contents must be stored indoors in a vertical position in the

original packaging. A forklift or hand truck capable of lifting approximately 250 pounds is

required to unload or transport the product in its shipping container prior to unpacking. Observe

all local safety precautions when moving the container. Do not double stack shipping containers.

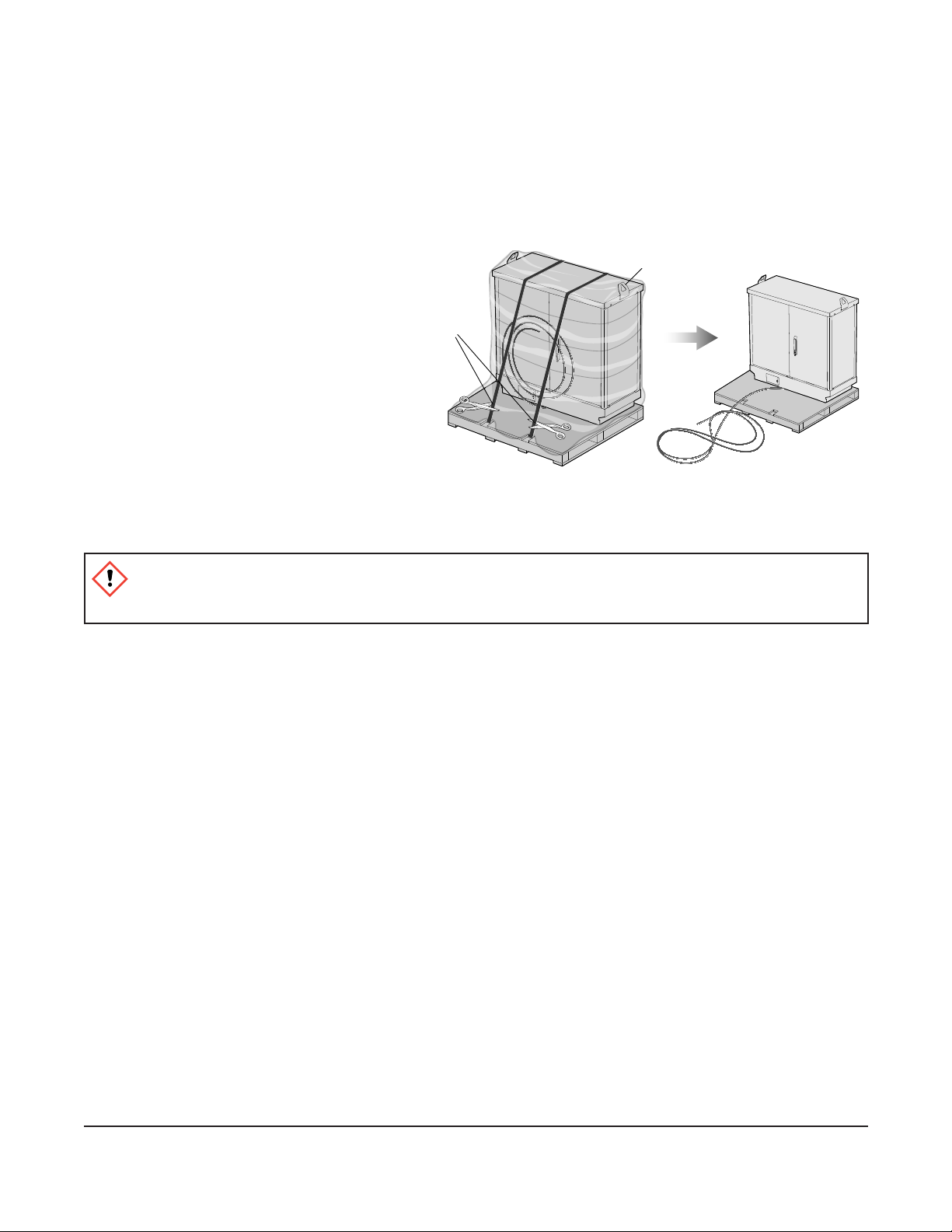

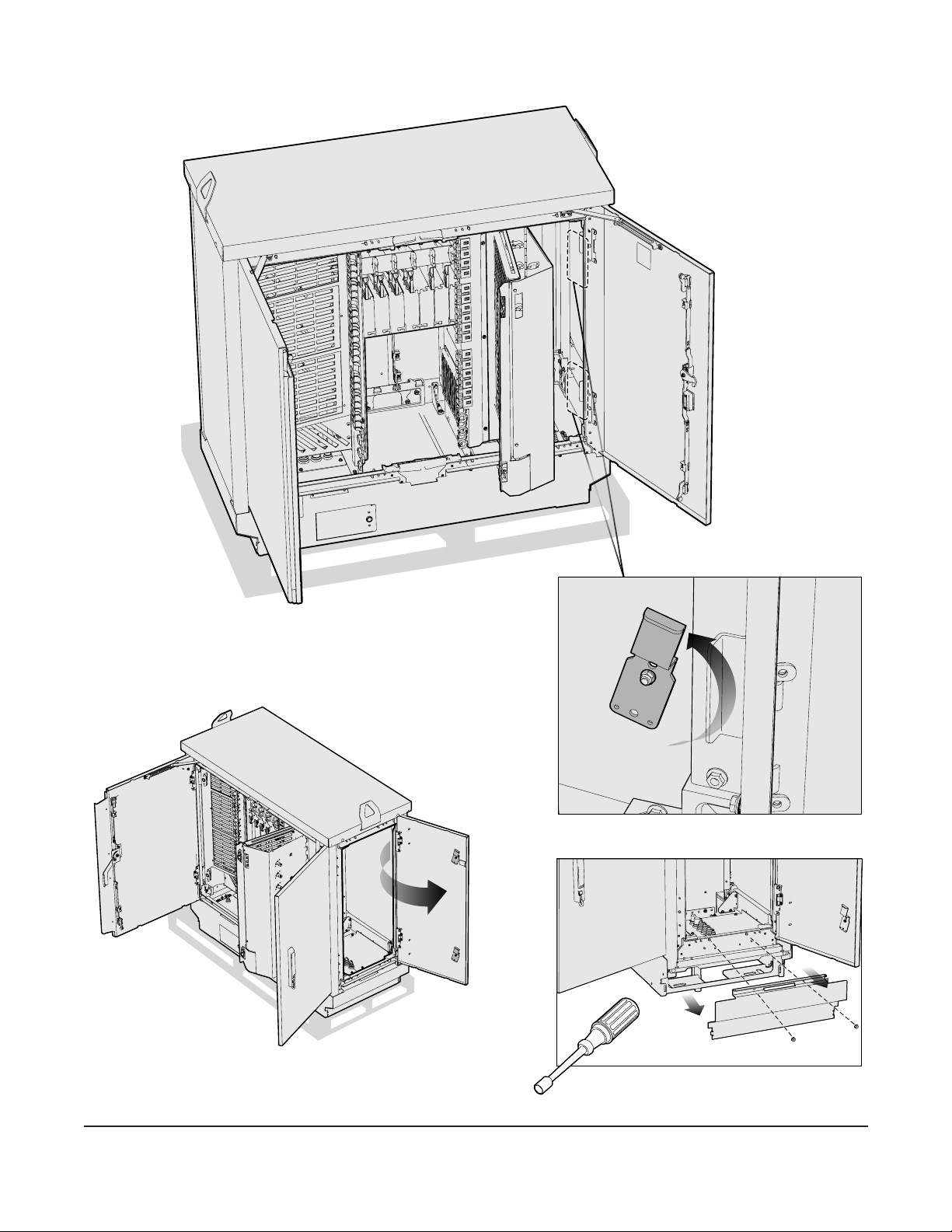

4. Unpacking the Cabinet and Components

Step 1: Place the container

near the site prepared

for installation of the

cabinet.

Step 2: Cut the bands holding

the cabinet to the pallet.

Step 3: Remove the

shrinkwrapping from

around the cabinet

(Figure 2).

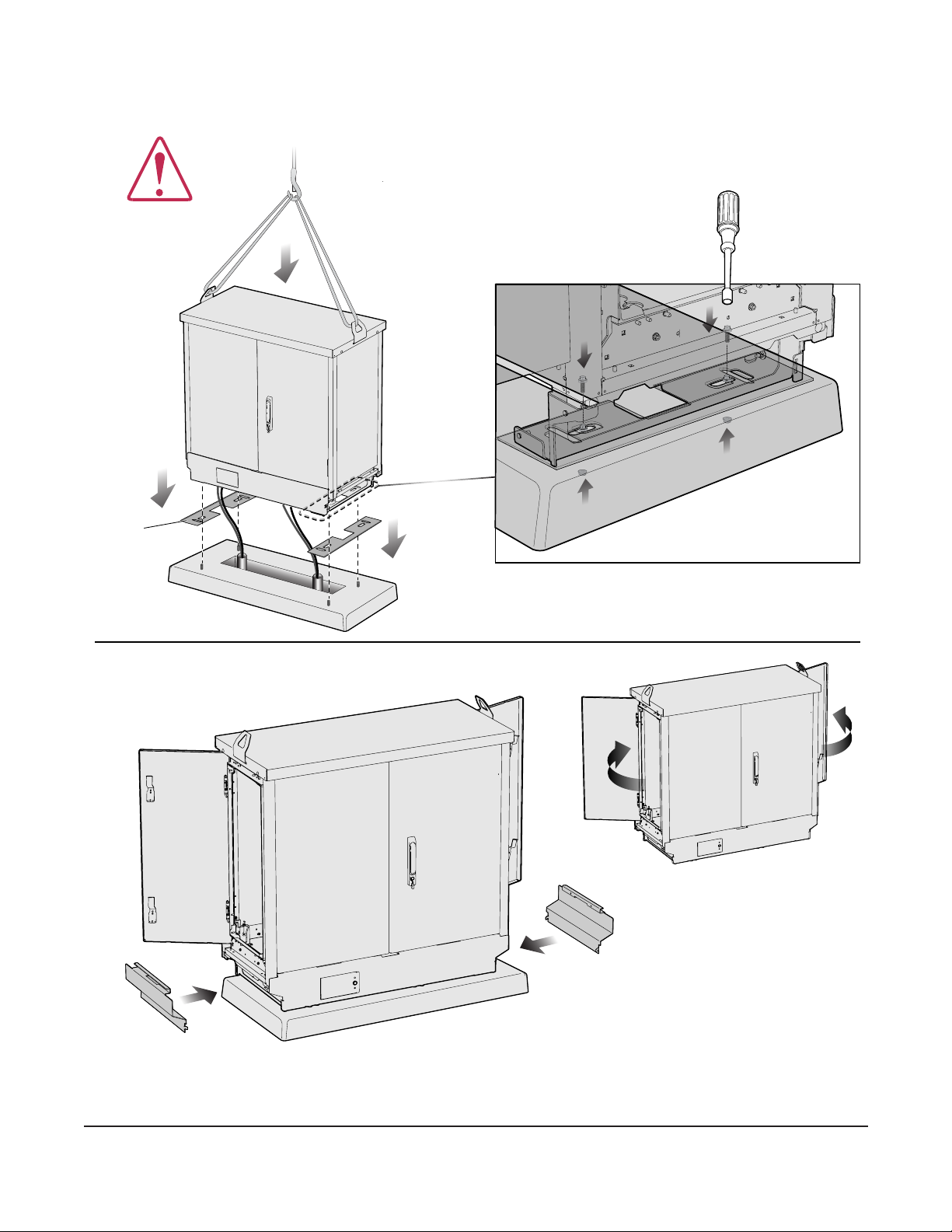

5. Installing the Cabinet on a Pad

DANGER: Only certied operators should operate the crane. Ensure that stabilizers are

extended and rmly positioned before lifting. Avoid overhead obstructions or power lines when

lifting.

IMPORTANT: Ensure that a lifting device, such as a hoist or crane, capable of lifting at least 250

pounds is available to lift the cabinet into position. The cabinet is heavy and requires two

people to maneuver it. Observe all safety precautions while using the cable hoist. Make

sure the door is locked in the closed position. Failure to do so may result in personal

injury or damage to the cabinet or cables.

5.1 On a pad

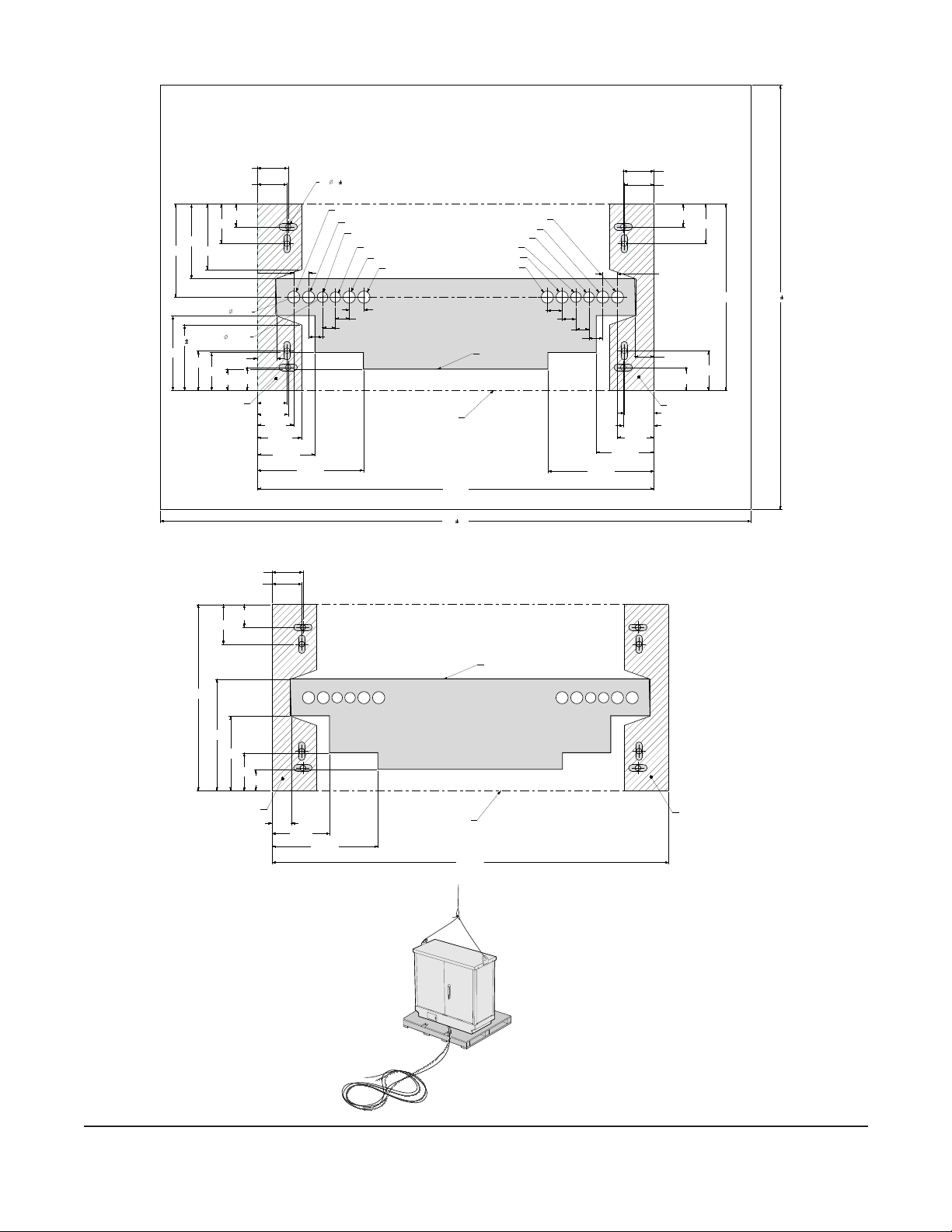

Step 1: If not using a precast pad with mounting hardware installed, use the provided

template to mark the location for the mounting bolts (Page 5). Drill holes for 0.5-inch

bolt anchors in the poured pad and insert the mounting bolts (0.5-inch diameter). Or

use an anchor assembly kit (FDH-LS-ANCHOR-432 or FDH-LS-ANCHOR-864).

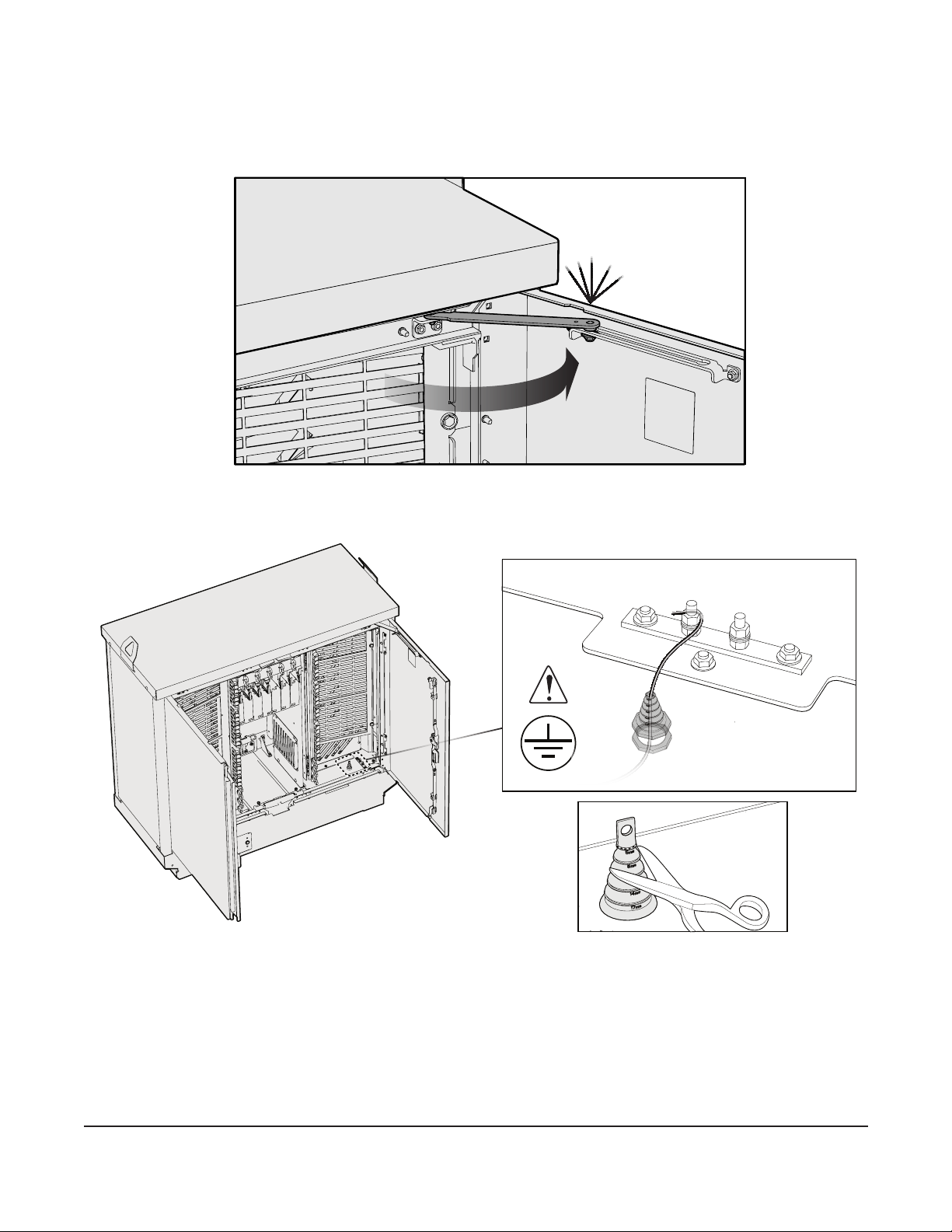

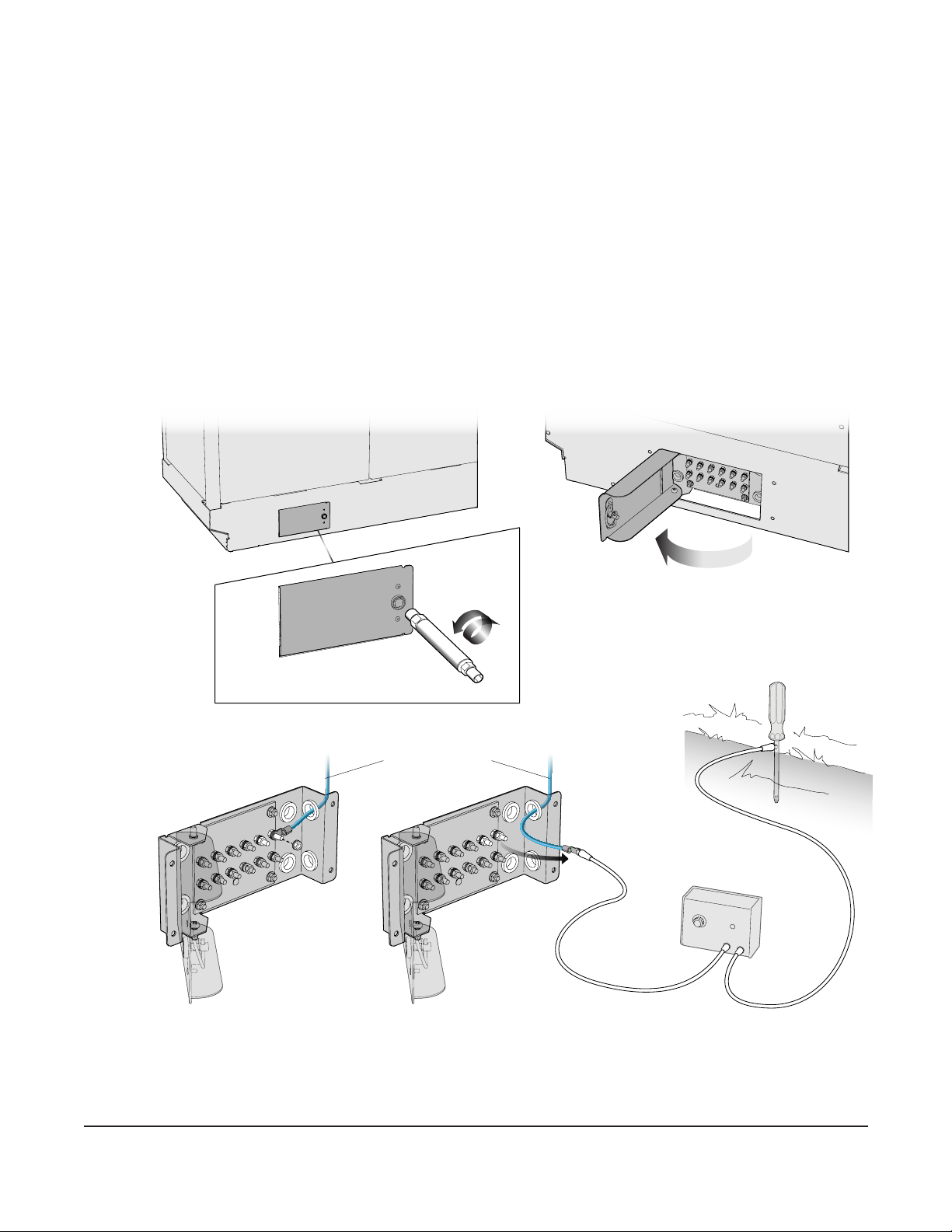

Step 2: Clip the ties from the cables. Roll out the cables when removing them from the

packaging to avoid putting twists into the cable. Then loop the cables in a “Figure-8”

pattern next to the mounting location before placing the cabinet (Figure 2).

IMPORTANT: Fiber optic cable is sensitive to excessive pulling, bending and crushing forces. Do not

exceed 200 pounds of pulling force on the cable. Do not bend the cable more sharply

than the minimum recommended bend radius (typically 9 inches). Do not crush the cable

or allow it to kink. Doing so may alter the transmission characteristics of the cable.

Cut bands

here

Lifting eye

safety loop

TPA-6657

Figure 2

Note: Side panels may be packaged separately