CountyLine RBRC402CL User manual

For more information and questions, please contact

Customer Service: 1-844-338-8721

OPERATION AND ASSEMBLY MANUAL

RBRC402CL, RBRC502CL, RBRC602CL

ROTARY CUTTER

2

INTRODUCTION

TO THE OWNER:

Read this manual before operating your implement. Keep this manual handy for reference.

Require all operators to read this manual carefully and become acquainted with all

adjustments and operating procedures before attempting to operate the equipment.

READ THIS MANUAL BEFORE ASSEMBLING OR OPERATING YOUR IMPLEMENT.

REQUIRE ALL OPERATORS TO READ THIS MANUAL.

OBSERVE ALL SAFETY INFORMATION IN THIS MANUAL AND SAFETY DECALS ON THE

IMPLEMENT.

The equipment you have purchased has been carefully engineered and manufactured

to provide dependable and satisfactory use. Like all mechanical products, it will require

cleaning and upkeep. Lubricate the unit as specified. Please observe all safety information

in this manual and safety decals on the equipment. Use only genuine service parts.

Substitute parts will void the warranty and may not meet standards required for safe and

satisfactory operation.

For more information and questions, please contact:

1-844-338-8721

CUSTOMER INFORMATION

Name___________________________________________________

Purchased From__________________________________________

DatePurchased___________________________________________

Model__________________________________________________

Serial #_________________________________________________

PREPARATION CHECKLIST

Verify the following before operating your Rotary Cutter

1. implement is completely assembled.

2. Gearbox is filled with oil and checked for

possible leaks.

3. All fittings are lubricated.

4. All shields in place and in good condition.

5. All fasteners torqued to specifications in

torque chart. (Pg. 36)

6. Check PTO driveline. Make sure it is the

correct length to operate Rotary Cutter

with intended tractor.

7. Check front of input gearbox shaft and make

sure that snap ring is properly installed.

8. Check shear/retaining bolt for proper grade

and installation.

9. All decals in place and legible.

10. Overall condition good (i.e. paint, welds)

11. Operator’s manual has been given to owner

and the owner has been instructed on the

safe and proper use of the Rotary Cutter.

3

INTRODUCTION

GENERAL DESCRIPTION

Your Rotary Cutter has been carefully designed for cutting grass and small brush. This

manual is provided to give you the necessary operation and maintenance instructions

for keeping your rotary tiller in excellent operating condition. Please read this manual

thoroughly. Understand the purpose of the controls and how to use them. Observe all

safety precautions on the machine and as noted throughout this manual. If any assistance

or additional information is needed, contact us at 1-844-338-8721.

NOTICE

All information, illustrations, and specifications in this manual are based on the latest information

available at the time of publication. Because we are always striving to improve our products, the

images could differ slightly from actual equipment. Specifications are subject to change without

notice. We also reserve the right to make changes at any time without notice.

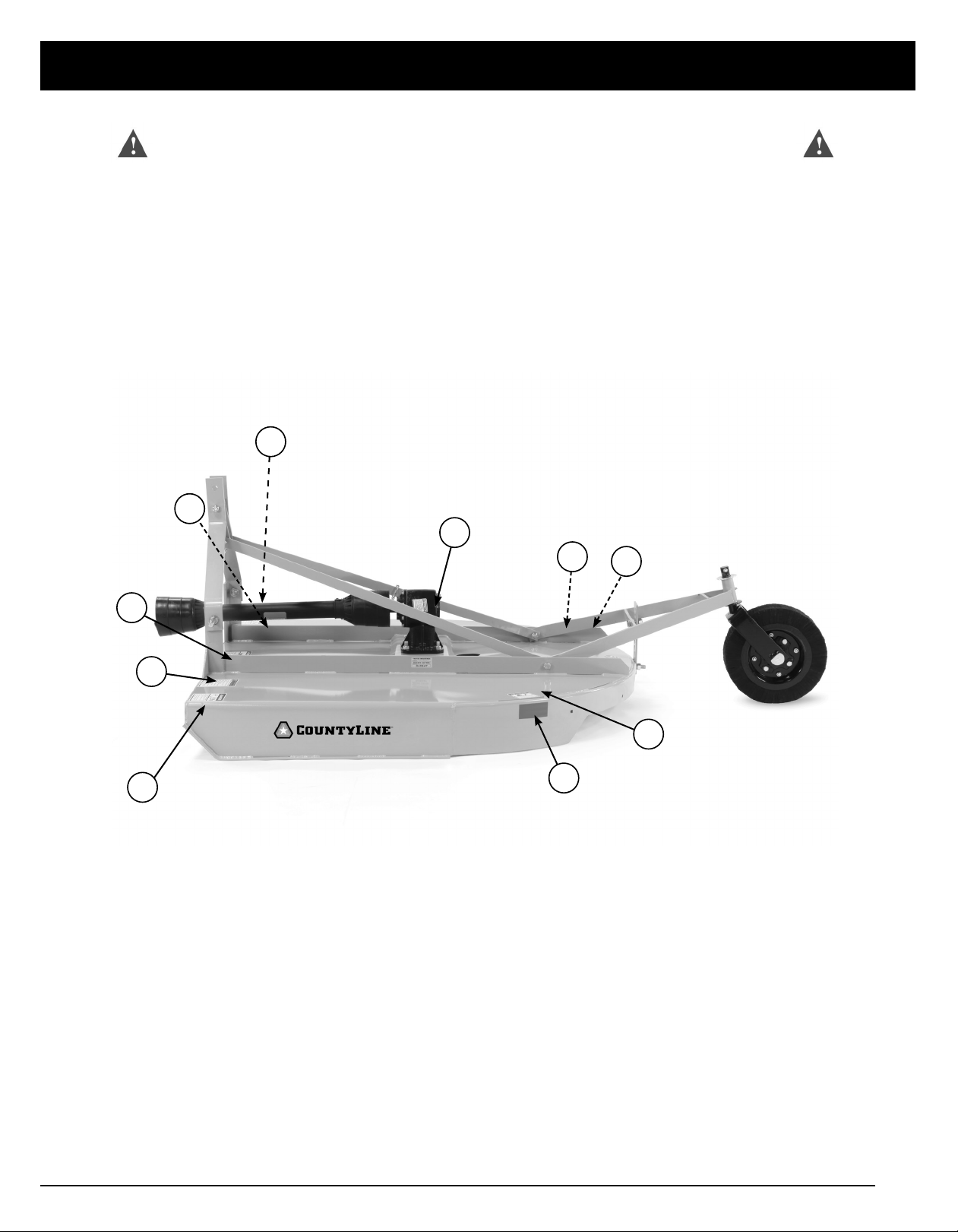

Major components

Gearbox

Tail wheel

Driveline Deck

A-Frame

4

TABLE OF CONTENTS

Safety..............................................................................................................................................................................5

Safety Description and Decals.............................................................................................................................7

Assembly......................................................................................................................................................................13

Attaching....................................................................................................................................................................18

Modify PTO Driveline.............................................................................................................................................. 19

Operation...................................................................................................................................................................22

Lubrication/Maintenance......................................................................................................................................24

Service..........................................................................................................................................................................26

Detaching/Storage................................................................................................................................................ .31

ProductSpecifications............................................................................................................................................32

Parts..............................................................................................................................................................................33

Torque Specifications.............................................................................................................................................36

Trouble Shooting............................................................................................................................................... ......37

Warranty......................................................................................................................................................................38

TABLE OF CONTENTS

5

SAFETY

Rotary Cutter Manufacturer Product Council

Safety is a primary concern in the design, manufacture,

sale, and use of Rotary Cutters. As manufacturers

of Rotary Cutters, we want to conrm to you, our

customers, our concern for safety. We also want to

remind you about the simple, basic, and common sense

rules of safety when using a Rotary Cutter. Failure to

follow these rules can result in severe injury or death to

operators or bystanders.

It is essential that everyone involved in the assembly,

operation, transport, maintenance, and storage of this

equipment be aware, concerned, prudent, and properly

trained in safety. The majority of accidents involve

entanglement on the driveline or thrown objects. These

risks become greater when you do not use proper

shielding specied by the manufacturer.

Our current production machines include, as standard

equipment, guards or shields for drivelines and input

shafts, safety signs and operators manuals. If you have

an older machine which does not have current standard

safety equipment, please contact your dealer about

bringing your machine up to the current level of safety.

Below are some of the most important safety rules to

be understood and followed by anyone who works

with Rotary Cutters:

SAFETY

IMPORTANT SAFETY MESSAGE FOR OWNERS/OPERATORS OF

ROTARY CUTTERS

From members of the Farm Equipment Manufacturers Association

Before operating a Rotary Cutter, an operator must

read and understand all the information in the owner’s

manual and in the safety signs attached to the product.

A person who has not read or understood the owner’s

manual and safety signs is not qualied to operate

the cutter. Accidents occur often on machines that

are loaned or rented to someone who has not read

the owner’s manual and is not familiar with a Rotary

Cutter. If you do not have an owner’s manual or current

production safety signs, contact the manufacturer or

your dealer immediately.

Rotary cutters are designed for one-man operation.

Never operate the cutter with anyone near, or in contact

with, any part of the implement or PTO driveline. Be

sure no one else, including bystanders, is near you when

you operate this product

If operation of a Rotary Cutter around bystanders,

animals, or property that may sustain damage (such as

highway, park, or airport) is absolutely necessary, use

safety guarding recommended by the manufacturer for

thrown object prevention.

Following these simple, basic safety rules, as well

as others identied in the owner’s manual and in

product safety signs, will help minimize the possibility

of accidents and increase your productivity in using

this product. Be careful and make sure that everyone

who operates the cutter knows and understands that

it is a very powerful piece of machinery, and if used

improperly, serious injury or death may result. The nal

responsibility for safety rests with the operator of this

machine.

Phone: 314.878.2304

E-mail: staff@FarmEquip.org

A safety manual for Rotary Cutters is

available through the FEMA ofce.

6

THE BEST SAFETY DEVICE IS AN INFORMED, CAREFUL OPERATOR.

WE ASK YOU TO BE THAT KIND OF OPERATOR.

YOUR SAFETY is our concern. We design and manufacture our implements with this in mind. Our design

can’t eliminate an operator’s careless actions. Hazard control and accident prevention are dependent

upon the awareness, concern, judgment, and proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

CALIFORNIA PROPOSITION 65

WARNING: Cancer and reproductive harm - www.P65Warnings.ca.gov

Throughout this manual, the term IMPORTANT is used to indicate that failure to observe

procedures can cause damage to equipment. The terms CAUTION, WARNING and DANGER

are used in conjunction with the Safety-Alert Symbol, (a triangle with an exclamation mark),

to indicate the degree of hazard for items of personal safety.

This Safety-Alert Symbol indicates a hazard and means ATTENTION!

BECOME ALERT! YOUR SAFETY IS INVOLVED!

Indicates an imminently hazardous situation that, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, could

result in death or serious injury, and includes hazards that are exposed when

guards are removed.

Indicates a potentially hazardous situation that, if not avoided, may

result in minor or moderate injury.

Indicates that failure to observe can cause damage to equipment.

Indicates helpful information.

WARNING

CAUTION

IMPORTANT

NOTE

SAFETY

7

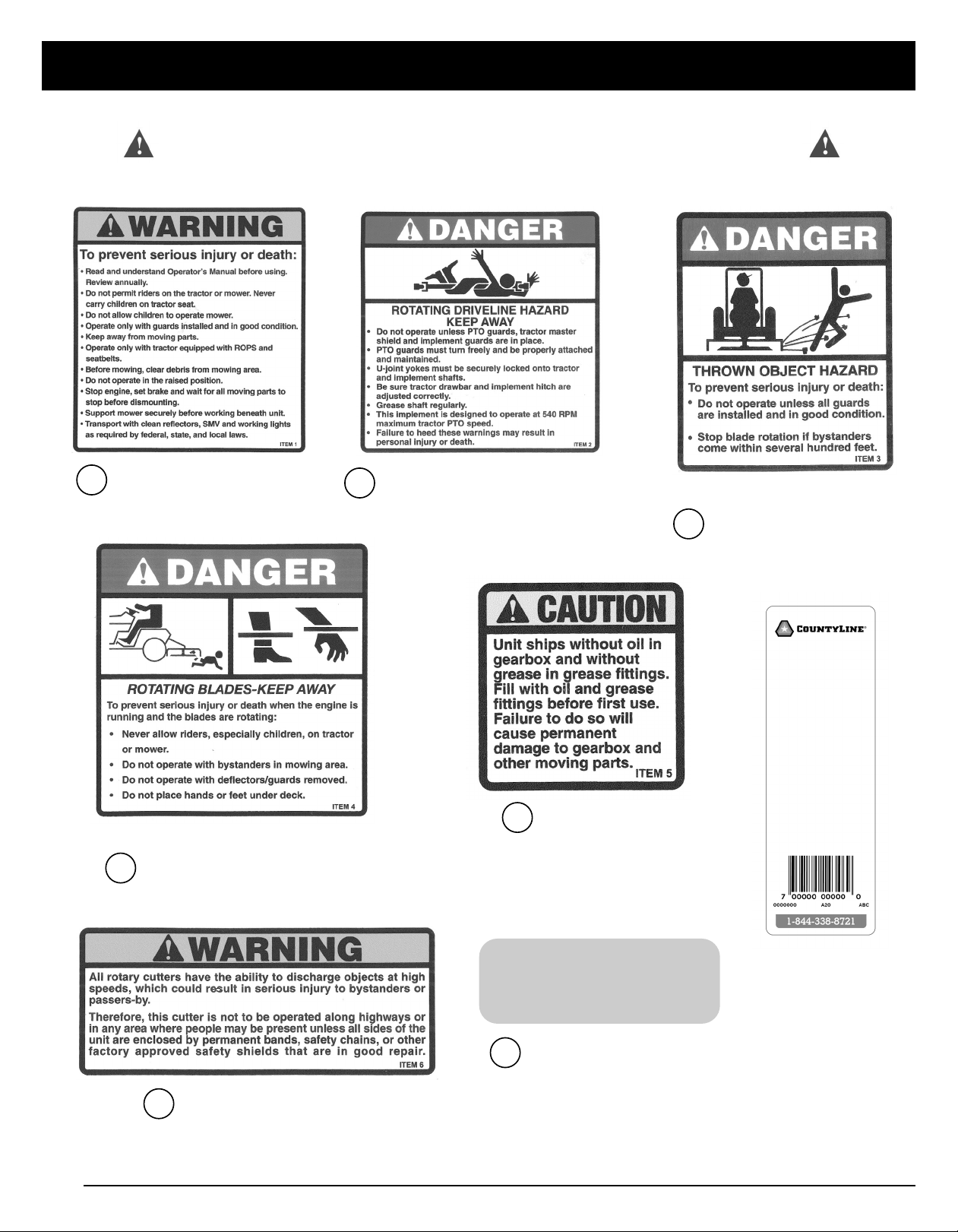

SAFETY AND INSTRUCTION DECALS

4

1

4

6

2

5

7

3

7

3

SAFETY and INSTRUCTIONAL DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately if Damaged!

8

1SERIOUS

INJURY

2ROTATING

DRIVELINE THROWN

OBJECT

3

(2 needed)

RED

REFLECTOR

(2 Needed)

7RED REFLECTOR

Warning Label Sheet - Reorder Part #’s

Decals 1-6 (part # RC-DECALS) & Decal 7 (part #

FT4003)

4ROTATING

BLADES

5NEEDS OIL

UPC LABEL

6THROWN

OBJECT

(2 needed)

SAFETY

SAFETY and INSTRUCTIONAL DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately if Damaged!

9

SAFETY

SAFETY GUIDELINES

Most accidents can be avoided by a few seconds

of thought and a careful approach to handling

equipment. You, the operator, can avoid many

accidents by observing the following precautions

and insist those working with you follow them too.

If you need assistance or a replacement manual and

safety decals call 1-844-338-8721.

PLEASE READ YOUR TRACTOR/AUV/UTV

(POWER UNIT) MANUAL BEFORE ASSEMBLING

OR OPERATING YOUR IMPLEMENT.

In order to provide a better view, certain

photographs or illustrations in this manual may

show an assembly with a safety shield removed.

However, an implement should never be operated

in this condition. Keep all shields in place. If shield

removal becomes necessary for repairs, replace the

shield prior to use.

Replace any safety decal that is illegible or missing.

Location of such safety decals are indicated in this

manual.

Never use alcoholic beverages or drugs that can

hinder alertness or coordination while operating

the power unit or the implement. Consult your

doctor about operating this machine while taking

prescription medications.

Under no circumstances should children under

the age of 18 be allowed to operate the power

unit or the implement. Do not allow persons to

operate or assemble the implement until they have

read this manual and have developed a thorough

understanding of the safety precautions and how it

works. Review the safety instructions with all users

annually.

This implement can be dangerous to children and

persons unfamiliar with its operation. The operator

should be a responsible, properly trained and

physically able person familiar with farm machinery

and trained in this implement’s operations.

Always use a power unit equipped with a Roll Over

Protective System and seat belts(ROPS). Keep

your seat belt securely fastened because falling

o can result in your death from being run over or

crushed. Always keep a foldable ROPS system in

the “locked up” position at all times.

Never exceed the limits of any piece of machinery,

whether the power unit of the implement. If its

ability to perform a job safely is in question DO

NOT TRY IT.

Do not modify the implement in any way.

Unauthorized modification could result in serious

injury or death and may impair the function and life

of the implement.

In addition to the design of this implement,

including safety signs and safety equipment,

hazard control and accident prevention are

dependent upon the awareness, concern, prudence,

and proper training of personnel involved in the

operation, transport, maintenance and storage of

the implement. Refer also to safety messages and

operation instruction in each of the appropriate

sections of the power unit and implement manuals.

Heed the safety signs axed to both the power

unit and implement.

Follow all safety rules and safety decal information.

Your implement is attached to a power unit. You

must know the controls of your power unit and

how to stop the engine and implement quickly in

an emergency. All operators must be capable to

safely operate the power unit, its attachments, and

all controls.

PREPARATION

Always wear relatively tight and belted clothing

to avoid getting caught in any moving part. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, ears, and head.

Wear respirator or filter mask when appropriate.

Before using the implement, check all driveline

guards for damage and replace any damaged

DANGER: Failure to follow instructions or

safety rules can result in serious injury or

death.

DANGER: DO NOT allow anyone to operate

the power unit or the implement without

proper instruction.

10

SAFETY

guards. Make sure all guards rotate freely on all

drivelines. Inspect chain or rubber guards before

each use and replace any that are damaged.

Check that all hardware is properly installed.

Always tighten to torque chart specifications unless

instructed otherwise in this manual.

Make sure the implement is properly secured,

adjusted and in good operating condition.

Before using the implement, check and adjust

PTO driveline length as instructed in this manual.

The driveline must not bottom out or pull apart

throughout the full range of the tractor hitch.

Make sure PTO driveline shield safety chain is

attached as shown in this manual and replace if

damaged or broken. Make sure collar slides freely

and is seated firmly in tractor PTO spline groove.

A minimum of 20% of tractor weight must be on

the tractor’s front wheels when implements are

in use. Without this weight, the tractor could tip

over, causing personal injury or death. The weight

may be attained with a loader, front wheel weights,

ballast in tires or front tractor weights. Weigh the

tractor and implement. DO NOT ESTIMATE.

STARTING AND STOPPING

Check the implement master shield over the PTO

(power take o) stub shaft. Make sure it is in good

condition and fastened securely to the power unit.

Purchase a new shield if old shield is damaged or

missing.

All power units that are not equipped with a “live”

power takeo (PTO) must be equipped with an

over-running PTO clutch. These are available

through most farm equipment stores.

The implement is operated from power supplied

from the power unit PTO. Refer to the power unit

manual for PTO engagement and disengagement

instructions.

Understand how to stop the power unit and

implement quickly in case of an emergency.

When engaging the PTO, the engine RPM should

always be at idle speed. Once engaged and ready

to start, raise PTO speed to 540-RPM and maintain

throughout operation.

TRANSPORTATION

Never transport the power unit or the implement

while under the influence of alcohol or drugs.

Always comply with all federal, state and local

laws regarding lighting, marking requirements

and transportation of farm equipment on a public

roadway.

Transport only in daylight or satisfactory artificial

light.

Be aware of overhead utility lines.

Never allow riders on the power unit or implement.

Do not operate PTO during transport.

Watch for hidden hazards on the terrain during

transport.

Do not operate or transport on steep slopes.

Do not stop, start or change directions suddenly on

slopes.

Use extreme care and reduce ground speed on

slopes and rough terrain. When encountering rough

terrain during transport, reduce the power unit

speed to minimize the horizontal movement of the

implement.

Stabilizer bars should be used during transport to

reduce lateral movement of the implement.

Ensure the towing vehicle and trailer are safely

capable of transporting the implement and that

everything is properly secured.

IMPORTANT: DO NOT operate PTO until

driveline length is correct.

NOTE: The addition of an over-running

PTO clutch may change the length of

the PTO driveline required. Be sure to

refer to the instructions on the PTO

driveline installation. Be sure that the

driveline system guarding is adequate.

11

OPERATION

Never operate the power unit or the implement

while under the influence of alcohol or drugs.

Operate only in daylight or satisfactory artificial

light.

Do not allow bystanders in the area when

operating, attaching, removing, assembling or

servicing the power unit or implement.

Never discharge directly toward people, animals or

property.

Ensure the rear-guard assembly is in place to

reduce the possibility of objects being thrown.

This implement is intended for agricultural

applications only. Do not operate within 300 feet of

bystanders or public roads or highways.

Keep hands, feet, hair and clothing away from the

power unit and implement while the power unit

engine is running. Stay clear of all moving parts.

Always sit in the power unit seat when operating

controls or starting engine. Securely fasten seat

belt, place transmission in neutral, engage brake

and ensure all other controls are disengaged before

starting the power unit engine.

DO NOT EXCEED the power unit PTO at 540 RPM.

Look down and to the rear and make sure area

is clear before operating in reverse. REVERSE

OPERATION IS NOT RECOMMENDED.

Be aware that turning the power unit tightly may

cause the implement to come in contact with the

rear wheels of the power unit and cause damage or

injury.

Watch for hidden hazards on the terrain during

operation.

Do not operate on steep slopes.

Do not stop, start or change directions suddenly on

slopes.

Use extreme care and reduce ground speed on

slopes and rough terrain. When encountering rough

terrain, reduce the power unit speed to minimize

the horizontal movement of the implement.

Stop the power unit and equipment immediately

upon striking an obstruction. Turn o engine,

remove key, inspect, and repair any damage before

resuming operation.

MAINTENANCE

Make certain all movement of the power unit

and implement components has stopped before

approaching for service.

Before detaching the power unit from the

implement or performing any service or

maintenance, follow these steps: disengage power

to the power unit, lower the 3-point hitch and all

raised components to the ground, set parking

brake, stop engine, remove key and unfasten

seat belt. Before performing any service or

maintenance, disconnect driveline from tractor

PTO.

Before working underneath the power unit or an

implement, carefully read this manual’s instructions,

disconnect driveline, raise implement, securely

block up all corners with jack stands, and check

stability. Secure blocking prevents an implement

from dropping due to hydraulic leak down,

hydraulic system failures or mechanical component

failures.

Never go underneath an implement (lowered to

the ground or raised) unless it is properly blocked

and secured. Never place any part of the body

underneath the power unit or an implement or

between moveable parts even when the engine

has been turned o. Hydraulic system leak down,

hydraulic system failures, mechanical failures,

or movement of control levers can cause an

implement to drop or rotate unexpectedly and

cause severe injury or death. Follow the power unit

and implement manual for working underneath and

blocking procedures.

Always wear relatively tight and belted clothing to

avoid getting caught in moving parts. Wear sturdy,

rough-soled work shoes and protective equipment

for eyes, hair, hands, ears, and head. When

appropriate wear a respirator or filter mask.

Keep all persons away from you while performing

adjustments, service or maintenance.

SAFETY

12

Frequently check blades/tines/shanks. They should

be sharp, free of nicks and cracks and securely

fastened. Do not handle blades/tines/shanks with

bare hands. Careless or improper handling may

result in serious injury.

Do not modify, alter or permit anyone else to

modify or alter the power unit, the implement or

any of their components in any way, except as

outlined in this manual.

STORAGE

Always use a power unit to position an implement

for storage.

Block the implement securely for storage.

Keep children and bystanders away from storage

area.

OPERATING INSTRUCTIONS

1. Before each use, perform all necessary

maintenance described in the maintenance

section.

2. Read, understand, and follow the safety

information pertaining to training, preparation,

starting and stopping, operation, transportation,

maintenance, and storage at the beginning of

this manual.

SAFETY

WARNING: Never attempt to move

implement by hand.

13

ASSEMBLY

TOOLS REQUIRED

• TIN SNIPS

• SCREWDRIVER

• VICE GRIPS

• RATCHET

• PLIERS

• SOCKETS AND WRENCHES: 9/16”, 3/4”, 15/16”,

7/8”AND 1-5/16”. (Impact wrench is preferred)

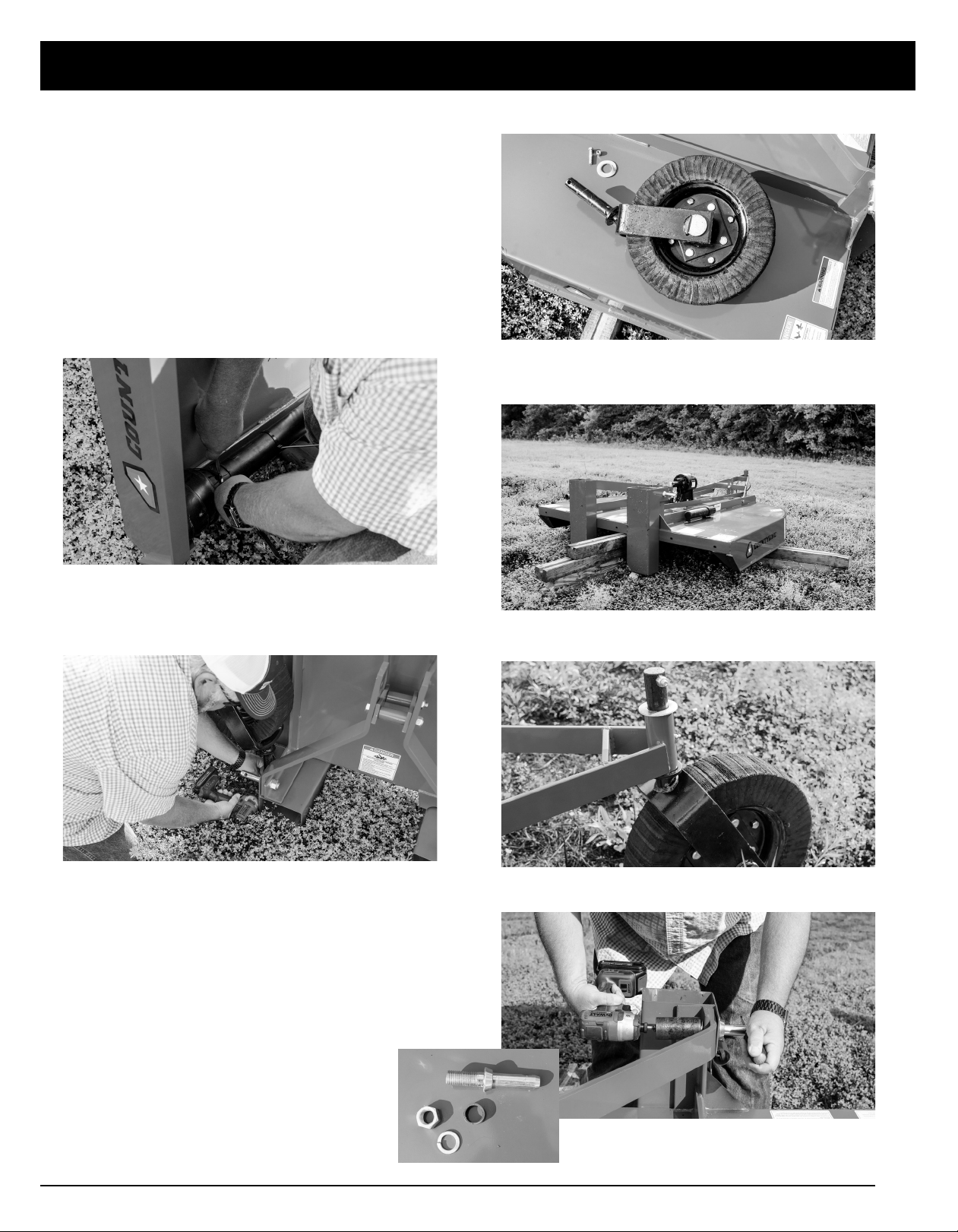

1. Cut the zip ties and remove the PTO Shaft from

the backside of the Rotary Cutter.

2. Remove 3/8” – 16 x 2” bolt and nut from the

tailwheel holder on the shipping boot, using a

9/16” wrench.

DO NOT DISCARD HARDWARE!

3. Remove the tailwheel and 3” washer.

4. Place the Rotary Cutter on a level spot. Block

up the front and back of the Rotary Cutter.

5. Install the tailwheel with 3” washer on top.

Secure with 3/8” – 16 x 2” bolt and nut. Tighten.

6. Using 1-5/16” wrench/socket, remove the CAT I

pins from the shipping boots.

14

ASSEMBLY

7. Once the CAT I pins are removed, lift up on the

cutter to remove from the shipping boots.

8. Line up the holes on the A-frame and re-insert

CAT I pins, bushing, washer and nut. Hand

tighten only.

9. Remove the two zip ties from the tailwheel

assembly and back braces.

10. Raise the lift arms in the upright position, using

the bottom pivot point.

11. Remove nut on one side of the A-frame using

15/16” wrench.

12. Place the backstrap brace on the bolt, as

pictured, using the locknut. Hand tighten.

Repeat for other side.

13. Pull Lift Arms until they are into place.

NOTE: Set aside the CAT 1 pins, bolts,

washers and bushings.

CAUTION: Shipping boots may fall off.

CAUTION: Possible pinch point.

15

ASSEMBLY

14. Go back and tighten the CAT I pins, on both

sides, using a 1-5/16” wrench/socket.

15. Tighten the nuts on the backstraps.

16. Remove the warning label on the gearbox.

17. Remove the shaft boot on the gearbox.

18. Remove the snap ring.

19. Slide the PTO shield back by using a screwdriver

to apply pressure and release the locking collar.

(There will be 3 tabs on the locking collar) Once

the locking collar is released, slide the PTO

shield back.

16

ASSEMBLY

20.Remove the PTO shear bolt.

21. Slide the PTO shaft onto the gearbox shaft.

22. Replace the snap ring.

23. Align the shear bolt holes, install, and tighten

PTO shaft shear bolt.

24. Assembly of your Rotary Cutter is now

complete. Please read the next section of

this manual for filling the gearbox with oil,

lubricating instructions, and sizing your PTO (if

applicable).

17

ASSEMBLY

BEFORE PUTTING YOUR

ROTARY CUTTER INTO

SERVICE

NOTE: Fill the gearbox using EP 85-90W gear

oil. For all grease fittings use TYPE/Grade II tube

grease.

1. Grease the two fittings on the PTO shaft. There

is one on each end of the shaft in the universal

joint.

2. Grease the two fittings on each end of the PTO

Shield.

3. Re-install the PTO shield by sliding the shield

over the universal joint making sure the shield

locks in place.

4. Grease the two fittings in the rear tailwheel

assembly.

5. Using a 7/8” wrench, remove the fill plug

and using a 7mm wrench, remove the drain

plug. Both are located on the backside of the

gearbox.

6. Fill the gearbox with 80W/90 or 85W/140 gear

oil until level with the drain plug. (Holds approx.

1 quart)

7. Replace and tighten both plugs on the gearbox.

IMPORTANT: This Rotary Cutter was shipped

without oil in the gearbox and without

grease in the grease fittings. UNIT MUST BE

SERVICED BEFORE USE.

18

11. Pull back on shield to make sure driveline is

locked.

12. Do not pull back on pin this will release latch.

13. Lower tractor PTO shield, if equipped.

Checking Driveline/Cutter

Clearance

1. Raise cutter slowly and check for clearance be-

tween driveline shield and cutter deck.

2. Check clearance between tractor tires and foot

guards or chain deector.

3. Check to see if hitch height position will provide

clearance desired.

4. Shorten center link or lengthen lift links to

provide clearance. (See your tractor Operator’s

manual.)

5. Raise and lower cutter slowly to check for

binding or interference. Check cutter-to-tractor

driveline telescoping length to ensure that it does

not bottom out. Modify driveline if necessary.

(See MODIFYING PTO DRIVELINE in Assembly

section.)

ATTACHING TO A TRACTOR

1. Back up tractor to cutter with hitch points

approximately in alignment.

2. Engage tractor parking brake and/or place

transmission in Park.

3. Shut o tractor engine and remove key.

4. Remove center link mounting hardware and

hitch pin assemblies at both hitch masts.

5. Install tractor draft links on hitch pins. Secure

with quick lock pins (stored on tractor draft

links.)

6. Align center link with upper hole in cutter mast

straps and install center link mounting hardware.

7. Shut o tractor engine.

8. Raise tractor PTO shield, if equipped.

9. Support driveline, cradling it in your hand.

10. Pull pin back toward cutter. Align splines by

rotating cutter driveline. Push driveline onto

tractor PTO shaft until pin snaps into place.

ATTACHING

DANGER: To avoid bodily injury or machine

damage whenever Rotary Cutter is attached,

put transmission in PARK position and check

the full range of hitch for interference, binding,

or PTO separation. Do not stand between

tractor and Rotary Cutter.

IMPORTANT: Prevent driveline damage from

contact with frame or machine damage from

contact with tractor tires. Raise cutter slowly

and check for interference. If necessary,

shorten center link or lengthen lift links to

provide clearance to full lift height.

NOTE: Final adjustments should be made

before operating cutter. See ADJUSTING

CUTTING HEIGHT AND ANGLE in Operating

the Cutter section. Center link should be

installed in lowest hole at tractor end if there

are multiple holes. Lift height may also be

limited by installing stops on rockshaft control

lever bracket.

NOTE: If the tractor draft links will not open

wide enough to fit over hitch pin assemblies in

their normal configuration the hitch pins can

be inverted so that the draft links can hook up

to the inside.

DANGER: Shut off tractor engine before

attaching PTO driveline. Entanglement in

rotating driveline can cause serious injury or

death.

IMPORTANT: Keep driveline and powershaft

splines clean of paint, dirt and chaff. Apply

grease to tractor PTO shaft before attaching

PTO driveline.

IMPORTANT: PTO driveline may be too long

for some tractor models, causing tractor

transaxle damage. Hold driveline sections

parallel to each other and check for a

minimum of 6 inches overlap.

IMPORTANT: Do not use shielding bell on

driveline to lift driveline into position. Damage

to shielding can occur.

19

Final Inspection and Adjustments

IMPORTANT: PTO driveline may be too long for some tractor models, causing tractor transaxle

damage. Modify driveline if necessary.

Attach Rotary Cutter to tractor and check cutter-to-tractor driveline telescoping length

clearance.

(See MAINTENANCE BEFORE EACH USE in Lubrication and Maintenance section.)

• Modify PTO Driveline (If Necessary)

1. To adjust the length, hold the half-shafts

next to each other in the shortest working

position and mark them.

2. Shorten inner and outer guard tubes

equally.

3. Shorten inner and outer sliding profiles by

the same length as the guard tubes.

4. Round o all sharp edges and remove burrs.

Grease sliding profiles. No other changes

may be made to PTO drive shaft and guard.

5. Chains must be fitted so as to allow

sucient articulation of the shaft in all working

positions.

6. The PTO drive shaft must not be suspended

from the chains!

MODIFY PTO DRIVELINE

MODIFYING PTO

20

SIZING THE PTO SHAFT

Refer to Figure 1

1. Detach the driveline from tractor PTO shaft and

pull outer and inner drivelines apart.

2. Reattach outer driveline to tractor PTO shaft.

Pull on inner and outer drivelines to ensure

universal joints are properly secured.

3. Hold inner and outer drivelines parallel to each

other:

a. Measure 1” (“B” dimension) back from

outer driveline universal joint shield and

make a mark at this location on the inner

driveline shield.

b. Measure 1” (“B” dimension) back from

inner driveline universal joint shield and

make a mark at this location on the outer

driveline shield.

4. Remove driveline from tractor and gearbox

shafts.

5. Measure from end of inner shield to scribed

mark (“X” dimension). Cut o inner shield at the

mark. Cut same amount o the inner shaft (“X1”

dimension).

6. Measure from end of outer shield to scribed

mark (“Y” dimension). Cut o outer shield at

the mark. Cut same amount o the outer shaft

(“Y1” dimension).

7. Remove all burrs.

8. Continue with “Check Driveline Maximum

Length”.

INNER SHAFT

INNER DRIVELINE

OUTER DRIVELINE

INNER SHIELD

OUTER SHAFT

OUTER SHIELD

UNIVERSAL

JOINT SHIELD

TRACTOR END

IMPLEMENT END

Figure 1 - Driveline Shortening

A

B

B

X

Y

X1

Y1

FREE LENGTH IMPLEMENT END

INNER PROFILEOUTER PROFILE

1/3 1/3 1/3 1/3 1/3

OVERLAP

MAXIMUM ALLOWABLE LENGTH

Outer Shielding has been removed for clarity.

FREE LENGTHTRACTOR END

Figure 2 - Driveline Maximum Extended Length

CHECK DRIVELINE MAXIMUM

LENGTH

Refer to Figure 2

Make sure driveline’s collapsible length is

acceptable.

The driveline maximum allowable length must,

when fully extended, have a minimum overlap

of the profile tubes by not less than 1/3 the free

length with both inner and outer profile tubes

being of equal length.

1. Apply multi-purpose grease to the inside of the

outer shaft and reassemble the driveline.

2. Assemble the two driveline profiles together

with 1/3 of the profile tubes overlapping as

shown below. Once assembled, measure and

record the maximum allowable length for future

reference.

3. Attach inner driveline yoke to the cutter’s

gearbox shaft. Attach outer driveline yoke to

the tractor’s PTO shaft.

4. Move yoke ends of driveline back and forth to

insure they are secured to the tractor and cutter

shafts. Reattach any end that is loose.

5. Hook driveline safety chain on the tractor end

of driveline to cutter frame. Re-latch safety

chain to the driveline shield.

MODIFYING PTO

IMPORTANT: Small chains are supplied with

the driveline. They must be attached to the

inner and outer driveline shields and to the

tiller and tractor to restrict shield rotation.

This manual suits for next models

2

Table of contents

Popular Cutter manuals by other brands

TYROLIT Hydrostress

TYROLIT Hydrostress PPH25RR Series Operating instructions and spare parts list

METRO PROFESSIONAL

METRO PROFESSIONAL GVC1002 instruction manual

MSW Motor Technics

MSW Motor Technics MSW-PN-100 user manual

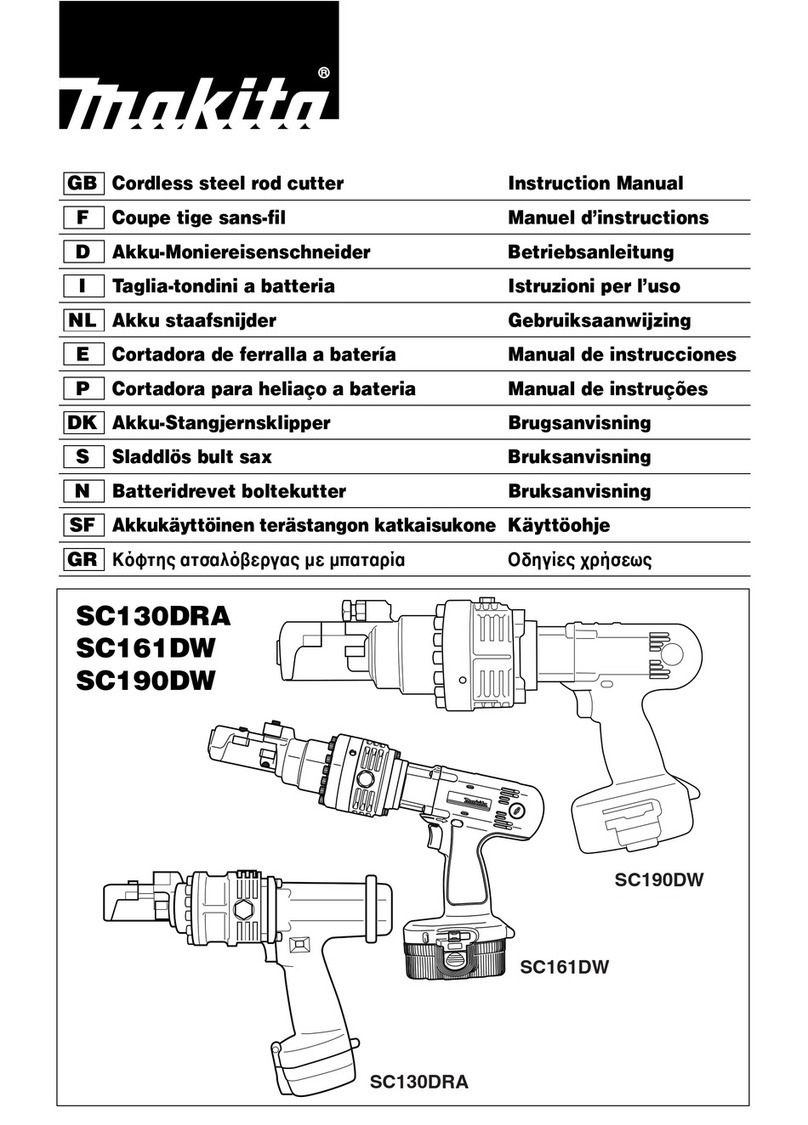

Makita

Makita SC130DRA instruction manual

Kubota

Kubota AP-SC4060 Operator's manual

Roberts

Roberts 10-63 owner's manual