Covidien Kendall SCD 700 Series Operation manual

Kendall SCD™

700 Sequential Compression System

Operation and Service Manual

700 Système de compression séquentielle

- Manuel d’utilisation et d’entretien

700 Sequenzielles Kompressionssystem

- Bedienungs- und Servicehandbuch

Sistema di compressione sequenziale 700

- Manuale d’uso e di manutenzione

Sistema de compresión secuencial 700

- Manual de funcionamiento y mantenimiento

700 Sekventiellt kompressionssystem

- Användar- och servicehandbok

700 sequentieel compressiesysteem

- Bedienings- en onderhoudshandleiding

Sistema de Compressão Sequencial 700

- Manual de Funcionamento e Assistência

700 jaksoittainen kompressiojärjestelmä

- Käyttö- ja huolto-ohjekirja

700 Sekventielt kompressionssystem

- Bruger- og servicevejledning

Σύστημα διαδοχικής συμπίεσης 700

- Εγχειρίδιο λειτουργίας και σέρβις

Sekvenční kompresní systém 700

- Uživatelská a servisní příručka

700 Szekvenciális kompressziós rendszer

- Kezelési és szervizelési kézikönyv

700 Система терапевтическая для

последовательной компрессии

- Руководство по эксплуатации и

обслуживанию

System stopniowanego ucisku 700

- Podręcznik obsługi i serwisu

700 Sıralı Kompresyon Sistemi

- Çalıştırma ve Servis El Kitabı

700 Sekvensielt kompresjonssystem

- Bruker- og servicehåndbok

Sekvenčný kompresný systém 700

- Príručka na obsluhu a servis

Sistem de compresie secvenţială 700

- Manual de operare şi întreţinere

Система за последователна компресия 700

- Ръководство за работа и сервиз

Kendall SCD 700 Series

TABLE OF CONTENTS

Indications ..................................................................................................................... EN-1

Leg Compression .................................................................................................................................................... EN-1

Foot Compression ................................................................................................................................................... EN-1

Contraindications ........................................................................................................... EN-1

Leg Compression ................................................................................................................................................... EN-1

Foot Compression ................................................................................................................................................... EN-1

Cautions ......................................................................................................................... EN-2

Kendall SCD 700 Series Explanation of Symbols Used ......................................................... EN-2

Front Panel Display ......................................................................................................... EN-3

Section I - General Operating Instructions ........................................................................ EN-3

Set up ...................................................................................................................................................................... EN-3

Start-up .................................................................................................................................................................. EN-4

Garment Selection and Verification ....................................................................................................................... EN-4

Normal Operation and Pressure Adjustment ........................................................................................................ EN-5

Vascular Refill Detection ........................................................................................................................................ EN-5

Garment Compatibility ..........................................................................................................................................EN-6

Tubing Set Compatibility ....................................................................................................................................... EN-6

Section II - Battery Operation .......................................................................................... EN-7

Unit plugged in and Powered On (Charging) ........................................................................................................ EN-7

Unit not plugged in and Powered On (Operating on Battery) ............................................................................. EN-7

Unit Powered Off (charging when plugged in) ................................................................................................... EN-8

Charging the Battery .............................................................................................................................................EN-8

Battery Warnings ...................................................................................................................................................EN-8

Section III - Fault Conditions and Troubleshooting ............................................................ EN-9

Section IV - Service and Maintenance .............................................................................EN-13

Introduction .........................................................................................................................................................EN-13

Warranty and Factory Service .............................................................................................................................EN-13

Service Precautions: .............................................................................................................................................EN-13

Fan Filter and Ventilation ......................................................................................................................................EN-14

Fuses .....................................................................................................................................................................EN-14

Suggested Preventative Maintenance Schedule ................................................................................................EN-14

Alarm History .......................................................................................................................................................EN-14

Cleaning ............................................................................................................................................................... EN-14

Electrical/Electronics Description ........................................................................................................................EN-15

Pneumatic Operation Description ....................................................................................................................... EN-15

Section V - Test Methods and Calibration .........................................................................EN-15

Test Mode Look up Chart...................................................................................................................................... EN-16

Test Mode T1 - Burn-In ........................................................................................................................................EN-16

Test Mode T2 - General Function Test ................................................................................................................. EN-16

Test Mode T3 - Pressure Transducer Calibration ...................................................................................................EN-16

Test Mode T4 - Pressure Transducer Calibration Verification ................................................................................EN-17

Test Mode T5 - Self Test .......................................................................................................................................EN-17

Test Mode T6 - Performance Test ........................................................................................................................ EN-18

Test Mode T7 - Manufacturing Test ......................................................................................................................EN-18

Test Mode – Alarm History ..................................................................................................................................EN-18

Kendall SCD 700 Series

TABLE OF CONTENTS

Section VI - General Disassembly / Reassembly ................................................................EN-19

Battery Pack (Removal / Installation - see Figure 6) ..........................................................................................EN-19

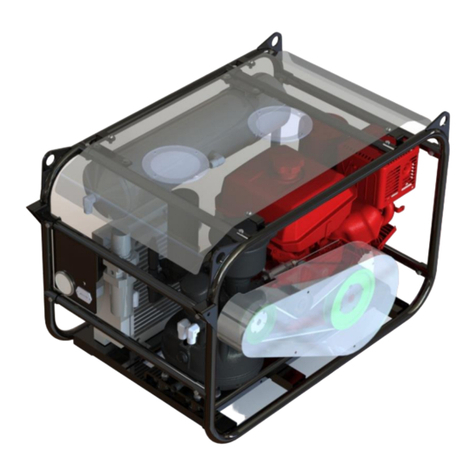

Compressor (Removal / Installation - see Figure 8) ...........................................................................................EN-19

Muffler (Removal / Installation) ......................................................................................................................... EN-19

Valve Manifold (Removal / Installation) .............................................................................................................EN-19

Power Supply Board (Removal / Installation) .................................................................................................... EN-20

Fan and Fan Filter (Removal / Installation - see Figure 6) .................................................................................EN-20

Main CPU Board and Graphical Display (Removal/Installation - see Figure 6) ................................................. EN-20

Adjustable Bed Hook (Removal/Installation) .....................................................................................................EN-20

Section VII - Parts Listing ................................................................................................EN-21

Section VIII - Specifications.............................................................................................EN-22

Section IX - Schematics ..................................................................................................EN-25

Figure 6 - Parts Assembly Diagram – Exploded view (Page 1 of 2) .................................................................EN-25

Figure 6 - Parts Assembly Diagram (front enclosure)– Exploded view (Page 2 of 2) .......................................EN-26

Figure 7 - Pneumatic & Electrical Schematic.......................................................................................................EN-27

Figure 8 - Rear Enclosure View ............................................................................................................................. EN-28

Figure 9 - Front Enclosure View............................................................................................................................EN-29

EN-1 Kendall SCD 700 Series

Indications

The Kendall SCD 700 Sequential Compression System (hereby referenced as “Kendall SCD 700 Series”) is designed to

apply intermittent pneumatic compression to increase venous blood flow in at-risk patients in order to help prevent

deep vein thrombosis and pulmonary embolism. The System consists of the controller, the tubing sets (provided

with the controller) and single-patient use garments (purchased separately from this controller). The garments, both

leg sleeves and foot cuffs, compress the limbs to enhance venous blood movement. After the compression cycle has

reached set pressure, the Controller measures the time it takes for the limbs to refill with blood and waits that period

of time before the next compression is initiated.

Leg Compression

The use of the Kendall SCD 700 Series Compression System with Leg Sleeves is indicated for:

1. Deep vein thrombosis and pulmonary embolism prophylaxis.

Foot Compression

The use of the Kendall SCD 700 Series Compression System with Foot Cuffs is indicated for:

1. Circulation enhancement.

2. Deep vein thrombosis prophylaxis.

3. Edema - Acute.

4. Edema - Chronic.

5. Extremity pain incident to trauma or surgery.

6. Leg Ulcers.

7. Venous stasis / venous insufficiency.

If you need further information regarding the Kendall SCD 700 Series Compression System or its clinical benefits,

please contact your Covidien Sales Representative.

Contraindications

Leg Compression

The Kendall SCD 700 Series Compression System may not be recommended for use with Leg Sleeve on patients with

the following:

1. Any local leg condition in which the sleeves may interfere, such as: (a) dermatitis, (b) vein ligation [immediate

postoperative], (c) gangrene, or (d) recent skin graft.

2. Severe arteriosclerosis or other ischemic vascular disease.

3. Massive edema of the legs or pulmonary edema from congestive heart failure.

4. Extreme deformity of the leg.

5. Suspected pre-existing deep venous thrombosis.

Foot Compression

The Kendall SCD 700 Series Compression System may not be recommended for use with Foot Cuffs on patients with

the following:

1. Conditions where an increase of fluid to the heart may be detrimental.

2. Congestive heart failure.

3. Pre-existing deep vein thrombosis, thrombophlebitis or pulmonary embolism.

Use with caution on the infected or insensitive extremity.

EN-2

Kendall SCD 700 Series

Cautions

1. Federal (U.S.A.) law restricts this device to sale by or on the order of a physician.

2. Patients with diabetes or vascular disease require frequent skin assessment.

3. Explosion hazard. Not suitable for use in the presence of a flammable anesthetic mixture with air or with oxygen

or nitrous oxide.

4. Do not operate the controller if the power cord is damaged.

WARNING: Do not attempt to repair or replace broken tubing connectors as hazardous inflation of the sleeves may occur.

Kendall SCD 700 Series Explanation of Symbols Used

Caution, consult

accompanying

documents

Controller

Serial Number

Type BF

Protection Against

Electronic Shock

Reorder number for

the device located

on the carton label

Manufacturing

Date Code Equipotential

ground point

Federal (USA)

law restricts this

device to sale by

or on the order of

a physician. 0123

CE Mark

Underwriters

Laboratories (UL)

Classification mark

for Canada and the

United States

EN-3 Kendall SCD 700 Series

Front Panel Display

1

2

3

6

7

4

5

Item Explanation Item Explanation

1 Power On Indicator 5 Battery Status Indicators 1-3

2 Power On/Standby Button 6 Right Arrow Button

3 A - Button 7 B - Button

4 AC Power/Battery

Charging Indicator

Section I - General Operating Instructions

Set up

Bed

Foot

Board

• Place the Controller on the footboard. This is done by grasping the device

handle and the top portion of the pivoting bed hook and squeezing to open

the gap. Place it on the foot board so it straddles the foot board and release

the bed clamp. See the figure at right. Ensure its security. If required, alter-

natively, the device can be placed on a horizontal surface appropriate for the

environment, such as on a table, within reasonable proximity to the point of

use. Be sure to allow adequate air flow to the vents located at the power cord

cover and below the tube set connection points.

• The controller can operate with one or two garments attached to the patient.

• Plug the tubing set(s) into the back of the controller. Route the tubing toward

the patient’s limbs, being careful to leave access ways clear and eliminate

tripping hazards.

• Plug the tubes into garment(s) wrapped onto the patient’s limbs.

• Match the left and right ports, marked B and A respectively, with the left and right limbs of the patient. Although

the operation of the controller is not affected, troubleshooting can be easier. Check tubing set(s) for kinking and

secure attachment at the controller and the garment(s).

• Plug the controller power cord into a properly grounded hospital grade receptacle. The blue AC Power Indicator

will illuminate. If no AC Power is accessible, the controller can be run using its own internal battery power.

EN-4

Kendall SCD 700 Series

Start-up

• Press the Power On/Standby button to begin normal operation. If using leg sleeves, no further user intervention

is required unless there is a fault condition detected or if therapy must be discontinued.

• The Controller will beep, flash all the LED’s and illuminate the display screen. Quick internal device checks are

performed, which may be audible to the user.

• The pump will begin to operate as part of the Garment Selection and Verification procedure.

• Detection of inoperative LED’s, display screen and the audible alarm function at start-up is the user’s responsibility.

Garment Selection and Verification

After startup, the Garment Configuration procedure allows the user to select when foot compression is required at

either of the two Controller ports:

• On the display, the Port A Leg and Port B Leg images blink to indicate the default garment configuration (leg

compression).

• Pressing either the A or B Button will cause the corresponding port’s leg image to shift to a foot image to signify

foot compression. The buttons must be pressed for each port that is connected to a foot cuff to turn on the cor-

responding foot image(s).

Note: Leg sleeve compression is the default configuration when the Controller is first powered on. Therefore, the A

and B Button(s) do not have to be pressed to begin compression therapy when leg sleeves are being used.

The A and B buttons need to be pressed only when foot compression is to be used.

NOTE: If a garment is attached anytime after the Garment Detection procedure has started, the system must be

restarted to ensure that the proper therapy will be applied to the limb(s).

Also after startup, the Controller immediately begins conducting the Garment Selection and Verification procedure at

each port to determine if the garments have been properly attached to the controller:

• If necessary, prior to the completion of Garment Selection and Verification, the A and B Button(s) may be pressed

again to shift the garment image from the foot to the leg.

• During this phase, the compressor and valves are operating and air is delivered out the Controller ports to detect

the number and type(s) of garment(s) connected [Leg Sleeve(s) and/or Foot Cuff(s)].

• If the Controller senses a properly attached garment and the type of garment detected matches the User-selected

garment (or the default) configuration, then the corresponding image of a Leg Sleeve or Foot Cuff for both the A

or B side will be displayed on the screen.

• If the Controller senses a properly attached garment but the type of garment detected does not match the User-

selected garment (or the default) configuration, then a Garment Mismatch alarm is triggered. Garment Mismatch

errors can be corrected by pushing the corresponding A and B buttons to change the User-selected garment type

(Leg or Foot). In the example below, the screen shows Foot Cuffs and indicates the user must press both A and B

buttons (FIGURE 1).

A B

FIGURE 1

EN-5 Kendall SCD 700 Series

• Once the Garment Detection procedure is completed and any garment mismatch errors are addressed, the A and B

button(s) will be disabled and normal operation begins by starting the compression therapy.

• If only one Controller port is connected to a garment for single-limb compression, then the User-selected garment

(or the default) configuration setting (Leg or Foot) for the open port will be ignored and both the leg and foot will

be grayed out such as the example shown below (FIGURE 2).

A B

FIGURE 2

• If any garments are not properly detected or if no garments are attached to the Controller, the system will trigger

an E13 alarm. See section IV (Fault Conditions and Troubleshooting) in this manual. Check the garment applica-

tion and tubing connections. In this case, either the system can be turned off and restarted or the corresponding

A and B Button(s) can be pressed to confirm problem resolution and operation will continue without having to

power the controller down and restarting.

Normal Operation and Pressure Adjustment

• Verify that the corresponding garment images match the disposable garment(s) applied to the patient.

• The Controller automatically begins the process of applying intermittent compression alternating between limbs

or to one if only one garment is applied

• On successive cycles, the controller automatically adjusts its operating parameters to maintain set pressure.

• The pressure setting depends on the type of garment: 45 mmHg for Leg Sleeves; 130 mmHg for Foot Cuffs.

Vascular Refill Detection

• The Kendall SCD 700 Series Compression System incorporates Covidien’s patented “Vascular Refill Detection”

method to customize the therapy for each patient’s physiology. This system measures the time it takes for the

veins in the limb to refill after having been compressed by the system. The time is then used in subsequent cycles

as the time between compressions.

• The Vascular Refill Detection method is used when first powering on the System after it reaches set pressure and

every thirty minutes thereafter.

• The method works best when the patient is still, however it will accommodate movement.

• If an error is detected during any measurement or if the compression is not within the System pressure specifica-

tions, the refill time measurement will be repeated after the next compression cycle.

• The time between compressions on the same limb will never be shorter than twenty seconds or longer than sixty

seconds.

• If both Controller ports are being used, then the longer of the two measurements will be used to adjust the time

between cycles.

EN-6

Kendall SCD 700 Series

Garment Compatibility

The Kendall SCD 700 Series Compression System is designed for use with Kendall SCD garment Reorder Codes:

Kendall SCD Sequential Compression

Comfort Sleeves

74010 Thigh Length X-Small

74011 Thigh Length Small

74012 Thigh Length Medium

74013 Thigh Length Large

74021 Knee Length Small

74022 Knee Length Medium

74023 Knee Length Large

Express Sleeves

9529 Knee Length Medium

9530 Thigh Length Medium

9545 Thigh Length Small

9736 Thigh Length Medium (sterile)

9780 Thigh Length Large

9789 Knee Length Large

9790 Knee Length X-Large

73011 Thigh Length Small

73012 Thigh Length Medium

73013 Thigh Length Large

73022 Knee Length Medium

73023 Knee Length Large

Kendall SCD Sequential Compression

Comfort Tear-Away Sleeves

74041 Thigh Length Small

74042 Thigh Length Medium

74043 Thigh Length Large

Express Tear-Away Sleeves

9530T Thigh Length Medium

9545T Thigh Length Small

9780T Thigh Length Large

73041 Thigh Length Small

73043 Thigh Length Large

73042 Thigh Length Medium

Express Foot Cuff

5897 Regular

5898 Large

Further instructions for garment application and use are included with the Leg Sleeve and Foot Cuff packaging.

Tubing Set Compatibility

The garments connect to the Controller via the Tubing Sets provided with the Controller. Additional or replacement

Tubing Sets are available as Reorder Code 9528. The Extension Tubing Sets are also available as Reorder Code 9595.

EN-7 Kendall SCD 700 Series

Section II - Battery Operation

The Kendall SCD 700 Series Compression System is designed to operate normally on AC line power or DC battery

power without interruption. There are three Battery Status Indicator LED’s used to represent the charge level of the

battery. Once the Controller is powered on, it may take the system a few seconds to establish communication with

the battery and display the charge level. The battery Indicator shown below is located in the upper right hand corner

of the user interface. See FIGURE 3.

Warning: If the ground integrity of the mains power cable is in question, the device should be operated

on battery power until the ground integrity can be insured.

FIGURE 3

1 32

Battery Status Indicators

Unit plugged in and Powered On (Charging)

Battery State Battery Status 1 Battery Status 2 Battery Status 3

100% charge Green Green Green

67-99% charge Green Green Green (Pulsing)

34-66% charge Green Green (Pulsing) Off

0-33% charge Green (Pulsing) Off Off

Unit not plugged in and Powered On (Operating on Battery)

Battery State Battery Status 1 Battery Status 2 Battery Status 3

67-100% charge Green Green Green

34-66% charge Green Green Off

< 34% charge Green Off Off

15-40 minutes left* Amber (Flashing) Off Off

< 15 minutes left* Red (Flashing) Off Off

EN-8

Kendall SCD 700 Series

Unit Powered Off (charging when plugged in)

Battery State Battery Status 1 Battery Status 2 Battery Status 3

0 -100% charge Off Off Off

With 15-40 minutes of battery charge left, an alarm will sound in a sequence of three beeps once every two minutes.

Once there is less than 15 minutes of battery charge left, the alarm will sound continuously and the dead battery icon

will display as shown in FIGURE 4.

FIGURE 4

Charging the Battery

The battery will begin charging as soon as the unit is plugged into an AC power source. The amount of time required

to charge the battery will vary depending on the battery’s overall condition, age, and the controller’s state during

charging. For example, charging a new, fully drained battery will take approximately 4 hours with the controller

on standby and 8 hours with the controller powered on. The Battery Status indicators should always be used to

determine the state of charge for the battery. A fully charged battery will typically provide 6-8 hours of operation

time depending on the sleeve configuration, sleeve application, and the battery condition.

Note: If the operation time on battery power is extremely short the battery should be returned for service or

replacement.

Note: The battery performance may be reduced if it is left unused for extended periods of time. It is recommended

that the battery pack be stored with a minimum charge of 50% and kept near 25°C (77°F) if prolonged storage is

necessary.

Battery Warnings

The Kendall SCD 700 Series Compression System battery pack contains Lithium Ion (Li-Ion) battery cells and must be

used properly for safety and to maintain optimal performance.

• Store spare battery packs between –20°C (-4°F) and 60°C (140°F).

• Do not drop, impact, or immerse in water.

• Do not touch or ingest any leaking electrolyte. If contact occurs, rinse skin and/or eyes immediately and seek

medical attention if irritation develops. If ingested, contact local poison control center.

• Do not open battery, dispose of in fire, or short circuit. Doing so may cause the battery to ignite, explode, leak, or

become hot and cause personal injury.

• Dispose of improperly working or damaged battery packs according to local regulations.

• Charge only with specified chargers according to Covidien’s instructions.

EN-9 Kendall SCD 700 Series

Section III - Fault Conditions and Troubleshooting

When the microprocessor detects a fault condition, it interrupts the normal operation of the Controller, deactivates

all valves to vent the air from the garment(s), displays a fault code, and sounds an audible alarm. If a Garment

Mismatch alarm is triggered the user may remedy the problem by pressing the corresponding A and B Button(s).

Some alarms will remain active until the Controller is turned off, or the battery runs out of charge (if operating on

battery power). Others can be reset once the user confirms the cause of the alarm and remedies the problem.

Alarm Types: Description Example

Service Required Alarm code is present because of a

failed internal component. It can not be

addressed by the user.

E5

Manual Reset Required Alarm that can be troubleshot and

corrected by the user but requires the

device to be powered off and on. If

the alarm persists, then the controller

requires service.

A B

E1

User Resettable This type of alarm allows the user to

remedy the issue and resume operation

by pressing the A and B button(s)

corresponding with the port affected

without powering the unit down. For

this type of alarm, a check mark will be

shown indicating what port is the area

of concern. A yellow triangle indicates a

low concern alarm. If the triangle is red

it is indicative of an alarm related to a

pressure that is high in an abnormal way.

If the alarm persists, then the controller

requires service.

A B

E3

EN-10

Kendall SCD 700 Series

Alarm Codes

Alarm Code Alarm Type Description Troubleshooting

Garment Mismatch Error User Resettable The Garment Detection

procedure has detected

a garment configuration

(Leg or Foot flashing green)

that does not match the

User-selected configuration

(Leg or Foot red).

Press the port

configuration button(s)

to turn the foot selection

on/off depending on

what type of garment(s)

is connected to the

Controller. If the proper

garment is selected and

the problem persists have

the Controller serviced by a

professional.

A B

System High Pressure Alarm Manual Reset required System pressure has

exceeded 90 mmHg (Leg

sleeve) or 180 mmHg (Foot

Cuff).

Check for kinked tubes or

patient interference with

the garments, like pressing

foot against foot board

A B

E1

High Pressure (Leg Sleeves) User Resettable Leg Sleeve pressure is

greater than 47 mmHg

for 10 consecutive cycles;

or pressure is above 65

mmHg for 5 consecutive

cycles.

Check for a tight leg

sleeve and adjust fit

appropriately. Also check

for a partially occluded

tube.

A B

E2

High Pressure (Foot Cuffs) User Resettable Foot Cuff pressure is

greater than 135 mmHg

for 10 consecutive cycles

or pressure is above 160

mmHg for 5 consecutive

cycles.

Check for a tight foot

cuff and adjust fit

appropriately. Also check

for a partially occluded

tube.

A B

E2

Low Pressure (Leg Sleeves) User Resettable Leg Sleeve pressure is

less than 43 mmHg for 10

consecutive cycles.

Check for a loose leg

sleeve and adjust fit

appropriately. Also check

for leaks in the sleeve or

the tube connections

A B

E3

Low Pressure (Foot Cuffs) User Resettable Foot Cuff pressure is less

than 125 mmHg after 5

consecutive cycles.

Check for a loose foot

cuff and adjust fit

appropriately. Also check

for leaks in the cuff or the

tube connections

A B

E3

EN-11 Kendall SCD 700 Series

Alarm Code Alarm Type Description Troubleshooting

Low Pressure (Leg Sleeves) User Resettable Leg Sleeve pressure is not

between 35 and 55 mmHg

for 12 consecutive cycles.

Check garment application

for proper fit. Check for

patient interference with

the garments, like pressing

the foot against the foot

board.

A B

E4

Low Pressure (Foot Cuffs) User Resettable Foot Cuff pressure is not

between 110 and 150

mmHg for 12 consecutive

cycles.

Check garment application

for proper fit. Check for

patient interference with

the garments, like pressing

the foot against the foot

board.

A B

E4

Valve Feedback Alarm Service Required If a valve electrically

malfunctions, this error

will be displayed.

Service Technician only:

Verify that the valve

assembly wires are

properly connected

and confirm solenoid

actuation.

E5

Software Error Service Required Upon startup, and

periodically during

operation the

microprocessor performs

diagnostic tests. If a

software error is detected,

this alarm will be triggered.

Return to Covidien for

service

E6

Compressor Alarm Service Required If the compressor

electrically malfunctions

this error will be displayed.

Service Technician only:

Verify that the compressor

wires are properly

connected.

E7

Vent Alarm User Resettable The pressure in a garment

is greater than 20 mmHg

at the end of any vent

period.

Check tubing for kink or

occlusion. Check garment

application (too loose or

tight).

Service Technician only:

Check for kinked internal

tubing.

A B

E8

EN-12

Kendall SCD 700 Series

Alarm Code Alarm Type Description Troubleshooting

Temperature Alarm Manual reset required If the internal case

temperature of the

Controller drops below

5°C (41°F) or exceeds 55°C

(131°F).

High temperature: Make

sure the controller is not

covered by bedding and

that the fan port, located

near the power cord is not

obstructed.

Low Temperature: Allow

the system to warm to

room temperature

E9 E9

Battery Alarm Service Required Safe battery operation of

the controller can not be

ensured.

Service Technician

Only: Ensure that an

unauthorized battery

pack replacement has not

been made. Replace pack

or return to Covidien for

service.

E10

Tubing Disconnect Alarm User Resettable Pressure measured in

the inflatable garment is

below 10 mmHg for 10

consecutive cycles or no

garments are detected

during startup.

Check for disconnected

tube sets or garments and

reconnect.

A B

E12

Pressure Transducer Alarm Service Required The system could not sense

a pressure rise of more

than 5 mmHg during an

inflation cycle or during

start up.

Service Technician Only:

Check the transducer tube

inside the controller and

ensure it is neither kinked

or disconnected.

E13

Low Battery Alarm Recharge Battery There is less than 15

minutes of battery charge

remaining. The pump and

valves will continue to

operate for as long as there

is enough power.

Plug the Controller into an

AC power outlet.

EN-13 Kendall SCD 700 Series

Section IV - Service and Maintenance

This service manual is intended for use as a guide to technically qualified personnel when evaluating System

malfunctions. It is not to be construed as authorization to perform warranty repairs. Unauthorized service will void

the warranty.

Introduction

The Kendall SCD 700 Series Controller contains no user serviceable parts. User maintenance is covered in the sections

that follow. All other maintenance must be performed by technically qualified service personnel.

Service technicians should be familiar with the operator’s portion of this manual and the operating principles of the

Kendall SCD 700 Series Compression System. If a Controller is to be returned to Covidien for service, a description of

the operating conditions and the fault code displayed should accompany the unit. The fault codes displayed by the

Controller are useful in diagnosing service problems.

This manual describes service procedures to the circuit board level, with an exploded view of the Controller shown

in Figure7. If a component failure on a circuit board is suspected, the unit should be returned for service. It is

recommended that the system be returned with the circuit board in place, as removal of the board(s) involves

additional risk of mechanical damage and damage from electrostatic discharge (ESD).

Warranty and Factory Service

Covidien warrants that your Kendall SCD 700 Series Compression System is free from defective material and

workmanship. Our obligation under this warranty is limited to the repair of Controllers returned to a service center,

transportation charges prepaid, within one year of delivery to the original purchaser. Specifically, we agree to

service and/or adjust any Controller as required if returned for that purpose, and to replace and repair any part

which, upon our examination, is proven to have been defective. This warranty does not apply to the Tubing Set or

the disposable garments, or to equipment damaged through shipping, tampering, negligence, or misuse, including

liquid immersion, autoclaving, ETO sterilization, or the use of unapproved cleaning solutions. To the extent permitted

by applicable law, this limited warranty does not cover, and is intended to exclude, any and all liability on the part of

the Company, whether under this limited warranty or any warranty implied by law, for any indirect or consequential

damages for breach hereof or thereof. Except as expressly provided above in the limited warranty, to the extent

permitted by applicable law, the Company hereby negates and disclaims all express and to the extent permitted by

applicable law, implied warranties, including the warranties or merchantability and fitness for a particular purpose.

Controllers requiring repairs should be sent to a service center. Call one of the service centers listed. Obtain a return

material authorization number and ship the controller, prepaid and insured in the original carton.

CANADA

Covidien Canada

7500 Trans Canada Highway

Pointe-Claire, Qc H9R 5H8

877-664-TYCO (8926)

UNITED STATES

Covidien

5920 Longbow Drive

Boulder CO 80301

1- (800) 255-8522

OUTSIDE U.S. AND CANADA

Covidien

Service Centre

Unit 2 Talisman Business Centre

London Road

Bicester, England OX26 6HR

(+44)1869328065

Service Precautions:

• Always unplug the controller from Mains voltage before servicing the controller.

• Use proper techniques such as grounding straps and pads to protect printed circuit board assemblies from ESD

(Electrostatic Discharge)

EN-14

Kendall SCD 700 Series

Fan Filter and Ventilation

CAUTION: Unplug the Controller before accessing the fan filter.

The fan filter must be kept clean to ensure continued trouble-free operation. The Controller should never be run

without the fan filter in place. Clean or replace the filter when required . See instructions in the General Disassembly/

Reassembly Section.

During system use, obstruction of the fan cover and vents should be avoided. Free flow of air is necessary to prevent

overheating and premature component failure.

Fuses

CAUTION: Unplug the Controller before replacing the fuse(s).

Blown fuses should only be replaced by those indicated on the power supply board near the location of the fuses

at the AC inlet. Use only 1.6 A, 250 VAC, 5x20mm Slo Blo fuses. The use of fuses that have the Semko and/or VDE

marking is preferred. If a fuse blows a second time, it should be presumed that the Controller is defective and

requires further service. Please contact your service center. Fuses are not accessible from the outside of the controller.

Refer to the Disassembly/Reassembly procedures later in the manual. The fuses are located on the power supply

board as part of the power inlet module under the fuse cover.

Electrical Safety CAUTION: Be sure the Controller is disconnected from the AC power source before any

disassembly. A potential SHOCK HAZARD exists when the front cover is removed even with the unit turned off.

Note: The power supply cord/plug serves as the electrical supply mains disconnect device.

To facilitate electrical safety testing, the controller has an equipotential lug, located on the back of the device

opposite the power cord. There are no other grounded exposed metal parts. Power cord resistance should not

exceed 0.1 ohm. If ground resistance exceeds this value or the insulation integrity of the unit has been compromised

through mechanical damage, the Controller should be returned to a service center for testing and repair.

Suggested Preventative Maintenance Schedule

Proposed Maintenance After Any Repair Once Per Year

Inspect and Clean Fan Filter X As Required

Verify Transducer Calibration (Test Modes T3 and T4) X X

Electrical Safety Tests X X

General Function Test (Test Mode T2) X

Alarm History

The Kendall SCD 700 Series Compression System stores the ten most recent alarm codes for use in troubleshooting

devices returned from use. There is a test access mode, discussed later in this manual that describes exactly how to

use the feature.

700 SERIES CONTROLLER CLEANERS

Chemical component (with approximate

concentrations)

Commercial

Example

0.5% bleach solution Dispatch™*

70% Isopropanol alcohol Generic

0.37% o-Phenylophenol Precise™*

0.15% dimethyl benzyl Ammonium Chloride, 0.15%

dimethyl ethylbenzyl Ammonium Chloride

Spray Nine™*

7.35% Hydrogen Peroxide, .023% Peracetic Acid Sporgon™*

3.4% Glutaraldehyde Cidex™*

Dodecylbenzene Sulfonate, Coconut Diethanolamide

diluted per instructions

Manu-klenz™*

Cleaning

CONTROLLER CLEANING

The Controller enclosure can be cleaned with a soft cloth

dampened with water or a mild detergent. To sanitize the

device, apply cleaning agents with a cloth or wipe. Avoid

excessive spraying, especially in the areas of the connection

ports on the back of the device. If any liquid enters the

ports, then internal component damage will likely result.

The table at right provides optional cleaners and their

chemical components.

EN-15 Kendall SCD 700 Series

The SCD 700 Series Compression System cannot be effectively sterilized by liquid immersion, autoclaving, or ETO

sterilization, as irreparable damage to the System will occur.

TUBE SET CLEANERS

Chemical component (with approximate

concentrations)

Commercial

Example

0.5% bleach solution Dispatch™*

70% Isopropanol alcohol Generic

7.35% Hydrogen Peroxide, .023% Peracetic Acid Sporgon™*

Dodecylbenzene Sulfonate, Coconut Diethanolamide

diluted per instructions

Manu-klenz™*

TUBE SET CLEANING

The tube sets can be cleaned with a soft cloth dampened

with water or a mild detergent. Do not immerse. The table

at right provides optional cleaners and their chemical

components.

Electrical/Electronics Description

Line voltage is fed into the controller through the power

cord to the power supply mounted in the rear case of the

controller. It is important to disconnect the power cord at

the outlet before opening the controller case. Exposure to high voltage on the Power Supply PC Board is likely to occur

if it is electrically live.

The power supply converts AC line voltage, 100 to 240 VAC, to DC voltage to power the controller components,

including the main Controller PC Board that is mounted onto the front case. Alternately, the main Controller PC Board

may be directly powered by the battery pack. The Controller PC Board controls all functionality of the system and

includes the transducer and buzzer. It does not contain any high voltage. The buttons and indicator LED’s on the front

display of the controller are integrated into the membrane panel which connects to the Controller PC Board.

Covidien does not recommend any attempt to repair printed circuit boards. In manufacturing, extensive testing is

performed that cannot be duplicated in the field without specialized equipment. Improper repair could result in

patient or user hazards.

Pneumatic Operation Description

When the controller is turned on, the compressor operates and the valves are cycled to verify the garment type

selected by the user. After garment selection and verification has completed, an inflation cycle is initiated, releasing

air through the set of valves, mounted to a manifold. A transducer monitors the pressure in the garments. The

reading from the transducer assists the controller in adjusting the pump’s motor speed to deliver the proper pressure

to the garments in the appropriate amount of time.

T5

T2 T3 T4 T5 T6 T7

FIGURE 5

Section V - Test Methods and Calibration

The Kendall SCD 700 Series Compression System

has various test modes that can be accessed by

the service technician. They are intended for use

by qualified personnel. To activate the test modes

follow these steps for entering “Test Access Mode”.

FIGURE 5 shows the user interface features used in

Test Access Mode.

• Plug the controller into an outlet supplying the

appropriate line voltage. Do not activate the

test modes while operating on battery power.

• Press the B Button at the same time while

turning the controller on. Hold thet B button

for a moment until test mode access can be confirmed visually

• The buzzer will beep and T1 will be underscored and will illuminate signifying “Test Mode T1”.

• The user can cycle through the test modes by pressing the Right Arrow button. Each test mode is indicated by

the slider under the corresponding test modeand the selected test mode is shown at the bottom of the screen for

clarity. Pressing the Right Arrow Button with the last test mode number illuminated alarm history will cycle the

test mode back to Test Mode T1.

EN-16

Kendall SCD 700 Series

• After selecting the desired test mode, the B Button can be pressed to initiate the test.

• If test access is entered but no test mode is selected within 2 minutes, it is assumed that the test access mode was

entered inadvertently and a Low Pressure alarm will be triggered.

• If a test mode is entered and left idle for 5 minutes the unit will revert back to test access mode selection.

• To exit Test Access Mode, turn the controller off.

Test Mode Look up Chart

T1 – Burn-In Feature

T2 – General Function Test

T3 – Pressure Transducer

Calibration

T4 – Pressure Transducer

Calibration Verification

T5 – Self Test

T6 – Performance Test

T7 – Manufacturing Test

Alarm History Mode

Test Mode T1 - Burn-In

Note: Burn-In mode is used in manufacturing to ensure proper

assembly, to identify premature failures. This mode is not generally

used outside of the manufacturing environment.

• Verify nothing is plugged into the ports on the back of the controller

and enter test access mode. Select Test Access Mode 01.

• Press the B Button to begin Burn-In. The compressor will operate

and the valves will actuate, releasing air out of the ports. The

process repeats continuously until the Burn-In period is complete

(approximately 16 hours).

• The battery will be discharged then charged to approximately 70%

charge level.

• When 16 hours of Burn-In is completed the controller will go into

alarm mode, blinking Test Access Mode T1. The buzzer will not pip

during this alarm.

Test Mode T2 - General Function Test

• With nothing plugged into the ports on the back of the controller,

enter test access mode. Select Test Access Mode T2.

• Press the B Button to begin the test.

• Pressing the A Button during this test will cause each one of the

LED’s to illuminate one at a time in succession and the alarm to pip.

• Pressing and holding the B Button will increase the pump speed to

its maximum in 4-5 seconds.

• Releasing the B Button will allow the pump to decrease its speed.

• The valves will actuate in succession (valve #1 through valve #6) for

two seconds each.

Test Mode T3 - Pressure Transducer Calibration

Note: The transducer used in the Kendall SCD 700 Series Compression System is a state-of -the-art, highly precise and

virtually drift free device.

Factory calibration certification is void if the case is opened. Recalibration is rarely required and should be done only

when necessary.

Always perform test T4 before test T3 to verify the pressure transducer calibration.

Required Equipment: A regulated, precision air source accurate to ±0.1mmHg over a range of 0 to 130 mmHg.

• With nothing plugged into the ports on the back of the controller, enter test access mode. Select Test Access Mode 03.

• Press the B Button to begin the test.

• The T3 will blink on the display screen until the calibration procedure is completed or an error condition occurs.

• Valve #1 will be energized throughout the procedure, so that the user can verify the calibration of the pressure

transducer with the controller case open or closed. The pressure standard can either be directly connected to the

EN-17 Kendall SCD 700 Series

transducer with the case open, or it can be attached to the Bladder #1 location at Port A with the case closed. The

Bladder #1 location is the left-most fitting within Port A (as viewed from the back of the Controller).

• The controller will prompt the user to apply the pressure to the controller by displaying the required pressure on

the screen. Once the applied pressure is confirmed and stable, the B Button is pressed to proceed to the next pres-

sure. The controller requires a multipoint calibration at 0, 18, 45 and 130 mmHg.

• It is required that the pressure source be accurate to +/- 0.1 mmHg and that it is stable.

• The controller will start calibration by displaying “0 mmHg”. Each time the B Button is pressed the display will ad-

vance to the next pressure in succession. After the last calibration step, press B again to reenter Test Access Mode.

• Upon completion, the new calibration values are recorded into memory and the unit beeps and reverts back to Test

Access Mode.

• If the calibration test mode is exited before the process is completed, the previous calibration values remain

unchanged.

• If a pressure outside of an expected range is sensed during any of the calibration steps an alarm will be activated.

Test Mode T4 - Pressure Transducer Calibration Verification

Note: The transducer used in the Kendall SCD 700 Series Compression System is a state-of-the-art, highly precise and

virtually drift free device.

Factory calibration certification is void if the case is opened. Recalibration is rarely required and should be done only

when necessary.

Always perform test T4 before test T3 to verify the pressure transducer calibration.

Required Equipment: A regulated, precision air source accurate to ±0.1mmHg over a range of 0 to 130 mmHg.

• With nothing plugged into the ports on the back of the controller, enter test access mode. Select Test Access Mode T4.

• Press the B Button to begin the test.

• The T4 will blink on the display screen until the calibration verification procedure is completed or an error condi-

tion occurs.

• Valve #1 will be energized throughout the procedure, so that the user can verify the calibration of the pressure

transducer with the controller case closed. The pressure standard can be directly connected to the Bladder #1 loca-

tion at Port A with the case closed. The Bladder #1 location is the left most fitting within Port A (as viewed from

the back of the Controller).

• The controller will prompt the user to apply the pressure to the controller by displaying the required pressure on

the screen. Once the applied pressure is confirmed and stable, the B Button is pressed to proceed to the next pres-

sure. The controller requires a multipoint calibration at 0, 18, 45 and 130 mmHg.

• It is required that the pressure source be accurate to +/- 0.1 mmHg and that it is stable.

• The controller will start calibration verification by displaying “0 mmHg”. Each time the B Button is pressed the

display will advance to the next pressure in succession. After the last step, press B again to reenter Test Access

Mode.

• For each of the calibration verification steps, the target pressure will be shown on the screen. If the system reads

pressure applied to the controller outside the correct range, then the pressure value will be shown in red with

either a less than symbol “<” or greater than “>” symbol to indicate the direction of the error. If the pressure read

is within the calibration range, then the target value will be shown in green

• Calibration Verification mode does not change calibration values.

Test Mode T5 - Self Test

• Enter Test Access Mode and select Test Access Mode 05.

• Press the B Button to begin the self test.

• The T5 will blink on the display screen until the test is completed.

• The alarm will pip and the unit will perform the full array of tests performed during Start-up.

Other manuals for Kendall SCD 700 Series

6

This manual suits for next models

1

Popular Air Compressor manuals by other brands

Chicago Pneumatic

Chicago Pneumatic RCP Series user manual

Vmac

Vmac UNDERHOOD 40 Series installation manual

IronAir

IronAir TTD1146OF operating instructions

GreenWorks Tools

GreenWorks Tools 4101302 user manual

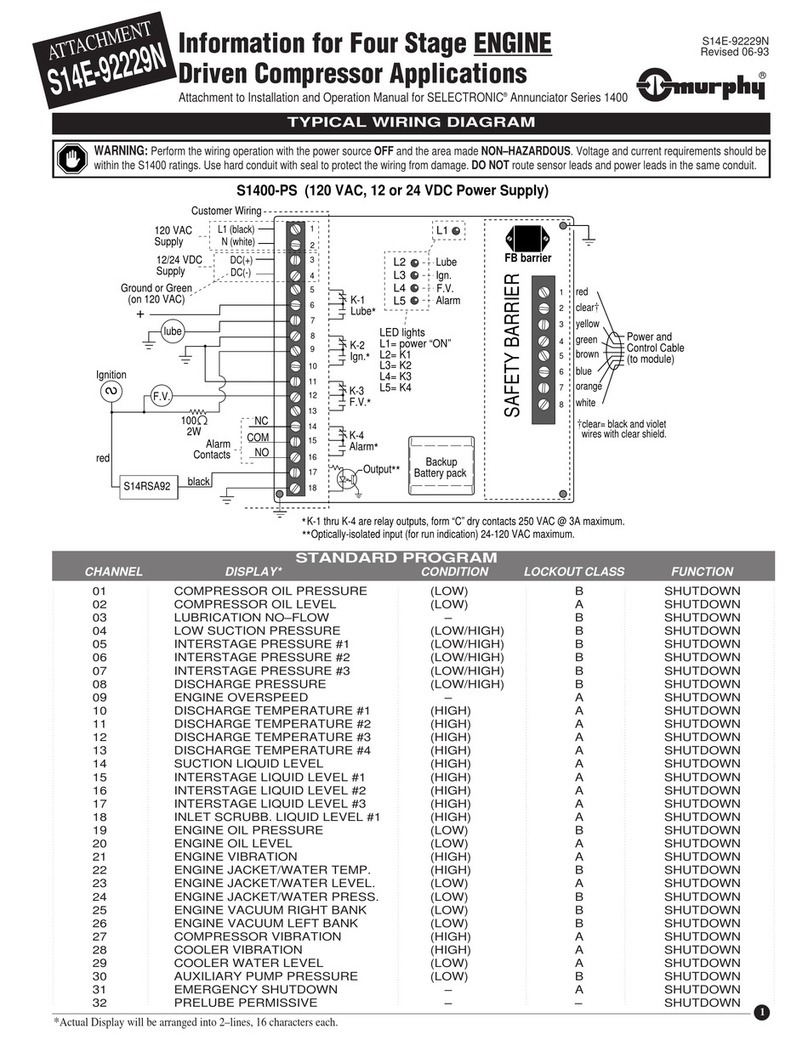

Murphy

Murphy S14E-92229N manual

Black & Decker

Black & Decker Start-It 90550871 instruction manual

Quincy Compressor

Quincy Compressor QGS 90 Instruction book

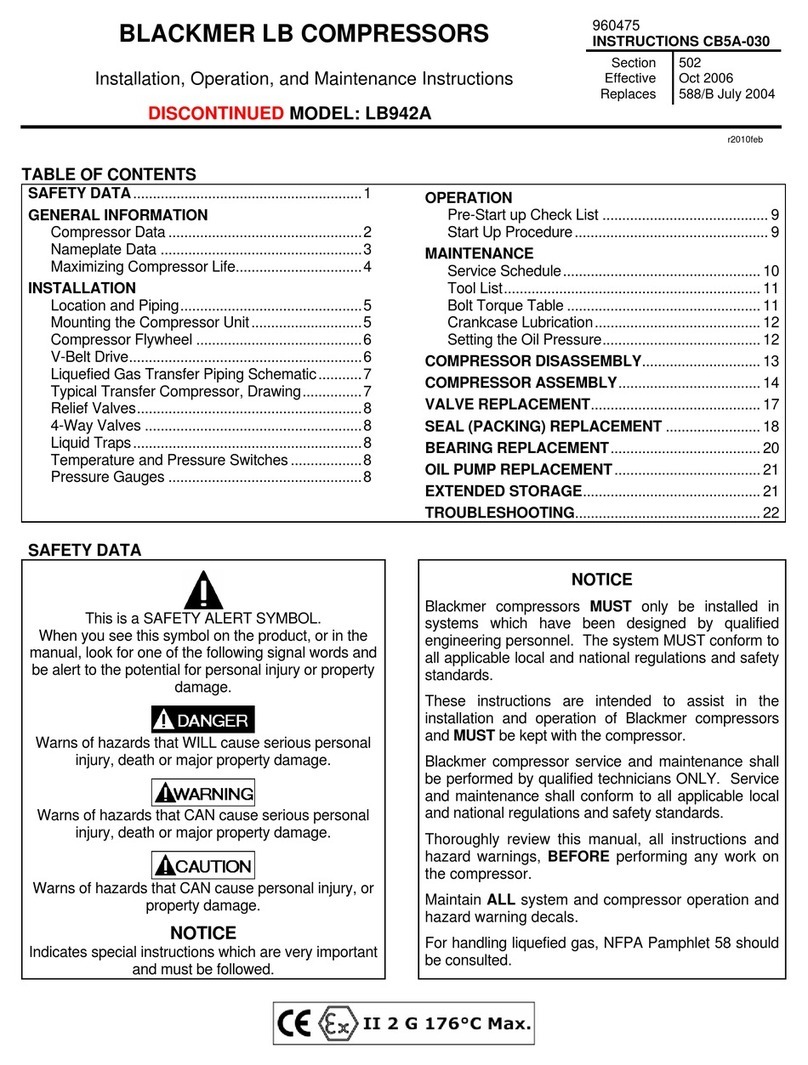

BLACKMER

BLACKMER LB942A Installation, operation and maintenance instructions

Mea

Mea SMARTPACK 35 Owner's/operator's manual

Hino

Hino J08EVB manual

Certa

Certa CT180ARCMPA quick start guide

Campbell Hausfeld

Campbell Hausfeld HU500000 operating instructions