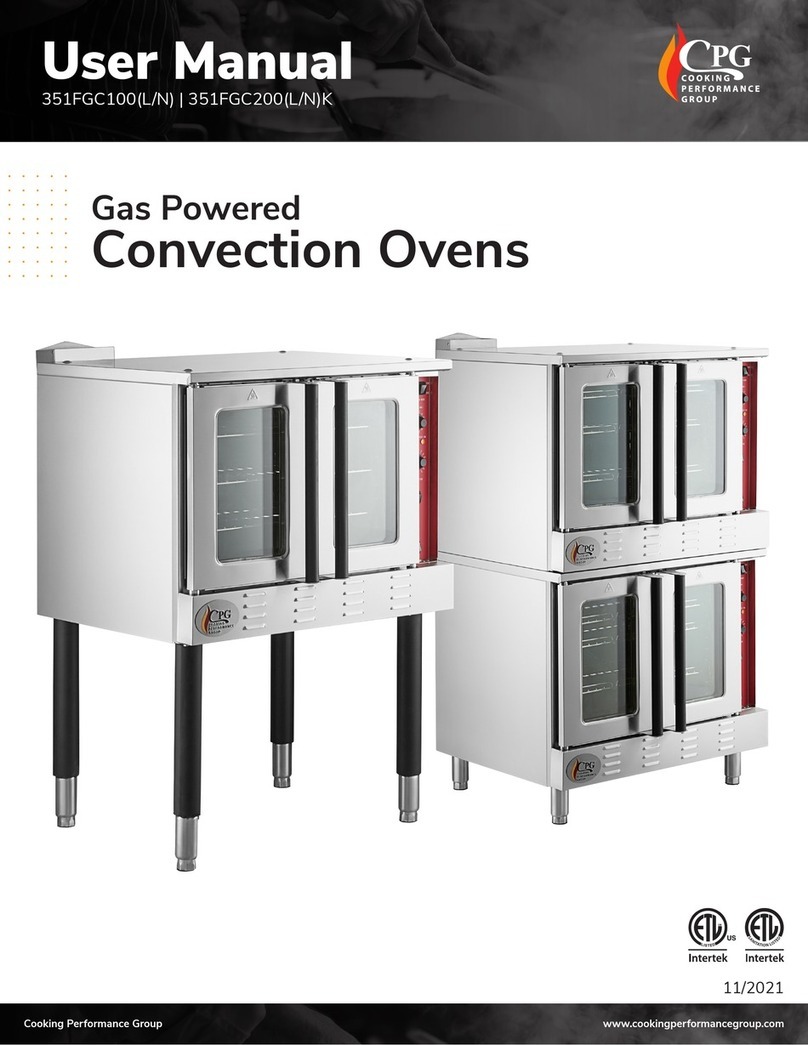

CPG 351FGC100 User manual

NOTICE

This manual is for a certied service technician and should not be used by those who are not

properly trained. This manual cannot cover all possible conditions that may occur and is not

intended to be all encompassing. You should read this manual in its entirety and the specic

repair you wish to do prior to starting the repair. This will allow you to determine if you have

the correct tools, instruments, and skills to perform the procedure.

¾"

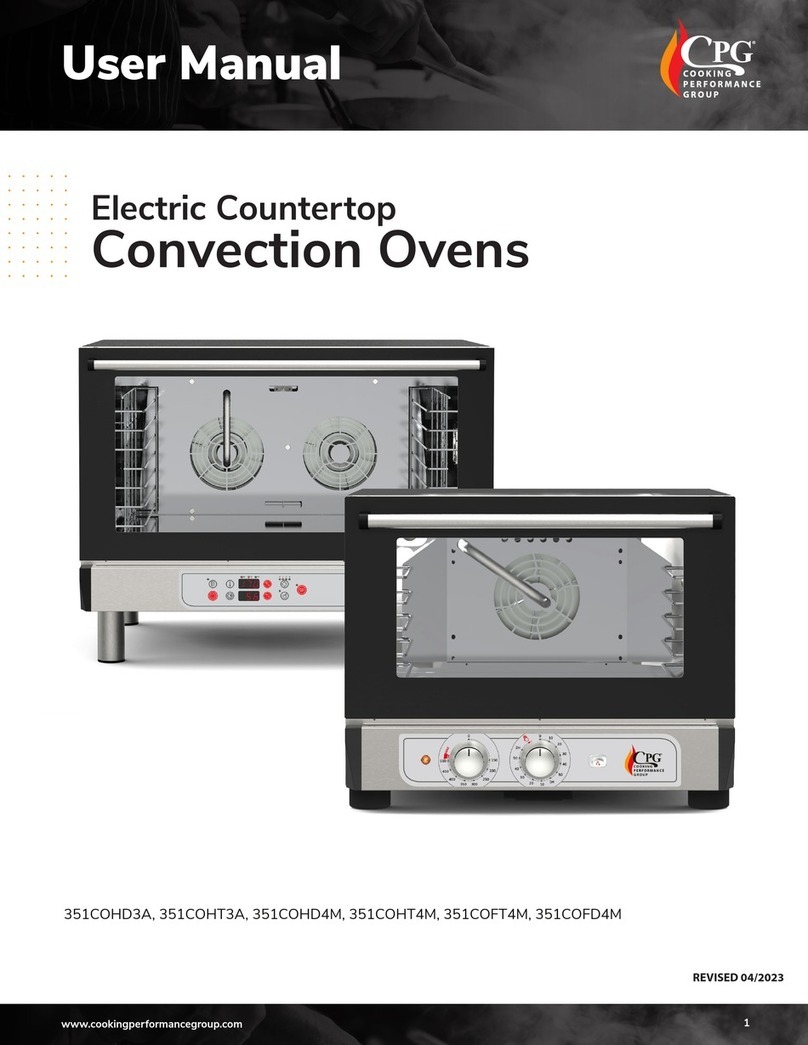

Gas Powered

Convection Ovens

03/2022

Service Manual

351FGC100(L/N) | 351FGC200(L/N)K

351FGC100DD(L/N) | 351FGC200DD(L/N)K

Cooking Performance Group . www.cookingperformancegroup.com

. www.cookingperformancegroup.com2

Service Manual

351FGC100(L/N) | 351FGC200(L/N)K

351FGC100DD(L/N) | 351FGC200DD(L/N)K

Contents

Troubleshooting ..........................................3

Part Testing

Main Power Switch ..................................4

Cook/Cool Switch (Fan Mode).........................4

Fan Speed Switch ...................................5

Light Switch ........................................5

Timer ..............................................6

Buzzer .............................................6

Thermostat .........................................6

Transformer.........................................7

Ignition Module......................................7

Door Switch ........................................8

Heat on Indicator Light ...............................8

Surface Ignitor ......................................9

Flame Sensor .......................................9

Gas Solenoid Valve ................................ 10

Temperature Sensor ............................... 10

Panel Safety Switch ............................... 10

Part Replacement

Fan Motor ........................................ 11

Gas Burner Components ........................... 11

Internal Gas Regulator ............................. 12

Gas Conversion ................................... 12

Regulator Press Adjustment ........................ 12

Door Latch Removal ............................... 13

Door Latch Adjustment ............................ 13

Wiring Diagram ........................................ 14

Parts Diagram .......................................15-18

www.cookingperformancegroup.com 3

Service Manual

351FGC100(L/N) | 351FGC200(L/N)K

351FGC100DD(L/N) | 351FGC200DD(L/N)K

Troubleshooting

Problem Possible Solution

Burner will not turn on

Ensure gas supply is turn on.

Ensure gas supply is at the correct pressure.

Ensure unit is plugged in and has correct voltage.

Ensure unit power switch is on.

Ensure doors are closed and cook switch is engaged.

Check thermostat is set above current inside oven temperature.

Check ignition module is not locked out with RED LED light blinking.

Check surface igniter.

Check internal gas valve.

Burner will not turn off

Check thermostat is turned "OFF".

Check temperature sensor/probe.

Check internal gas valve.

Burner ames are

small or weak

Check gas supply pressure is correct.

Check manifold pressure with manometer.

Check burner air openings, adjust if needed.

Check orice opening for each burner.

Check ventilation is setup correctly.

Burner ame will not

light or maintain ame

Check gas pressure at manifold.

Check burner air openings, adjust if needed.

Check surface igniter.

Check orice openings.

Check ame sensor.

Check ignition module.

Burners are producing

a black soot

Ensure correct gas is supplied, reference nameplate.

Ensure correct ventilation is set up.

Check burner air openings.

Check orice openings.

Blower fan will not turn on

Ensure unit is plugged in and power switch is 'ON'.

If in 'cook' mode, ensure doors are closed.

Check correct voltage is going through power switch.

Check voltage is getting to fan.

Check fan speed switch.

Check both door switches.

Oven is not reaching

temperature

Ensure thermostat is set to correct temperature.

Ensure fan is running.

Ensure burners are staying on.

Check thermostat probe.

. www.cookingperformancegroup.com4

Service Manual

351FGC100(L/N) | 351FGC200(L/N)K

351FGC100DD(L/N) | 351FGC200DD(L/N)K

Part Testing

Main Power Switch

Cook/Cool Switch (Fan Mode)

1. Check for continuity, disconnect wires from rear terminals on switch, check between middle

and lower terminals when 'ON'. If none found, replace switch. If found move to next check

below.

2. With unit plugged in, check for 0.5 amps at 120 volts from #3 wire to #5 wire at back of

power switch (middle to lower terminal). (Fig. 1)

3. Check for any discoloration or deformations of electrical connections. If any are found,

replace connections.

1. Check for continuity. Disconnect wires from rear terminals on switch, check between middle

and top terminal when switch is on 'COOK' and then between middle and lower terminal

when switch is on 'COOL'. If continuity is not found in both switch positions, replace switch.

If found in both positions, see below for more testing.

2. With unit turned 'ON', check for 0.5 amps at 120 volts from

middle to top terminal when switch is on 'COOK'. (Fig. 3)

3. With unit turned 'ON'; check for 0.5 amps at 120 volts from

middle to lower terminal when switch is on 'COOL' (Fig. 3)

4. Check for any discoloration or deformations of electrical

connections. If any are found,

replace connections.

CAUTION: Components can be HOT

!

Fig. 1

Fig. 3

Fig. 2

www.cookingperformancegroup.com 5

Service Manual

351FGC100(L/N) | 351FGC200(L/N)K

351FGC100DD(L/N) | 351FGC200DD(L/N)K

Fan Speed Switch

Light Switch

1. Disconnect wires from rear of switch. Check continuity between middle and top terminals

and switch in 'HI' position. Then check continuity between middle and lower terminals and

switch is in 'LOW' position. If continuity is not found in both switch positions, replace switch.

If found in both positions, see below for more testing.

Fan running check:

- Fan speed = HI, check for voltage at the neutral (rear of the unit) and at the rear of switch,

bottom terminal. Voltage = 120 volts at 0.5 amps (Fig. 4)

- Fan Speed = Low, check for voltage at the neutral (rear of the unit) and at the rear of the

switch, top terminal. Voltage = 120 volts at 0.5 amps (Fig. 4)

2. Middle terminal on switch should always have power when unit is on.

3. Check for any discoloration or deformations of electrical connections. If any are found,

replace connections.

1. Disconnect wires from rear of switch. Check continuity between middle and lower terminal

when switch is 'ON', position. If continuity is not found in 'ON' position, replace switch. If

found, see below for more testing.

2. Reconnect wires and with light switch turned 'ON' and unit plugged in and 'ON'. Check for

voltage between neutral and lower terminal.

3. Check for any discoloration or deformations of electrical connections. If any are found,

replace connections.

Fig. 4

Fig. 6

Fig. 5

Fig. 7

. www.cookingperformancegroup.com6

Service Manual

351FGC100(L/N) | 351FGC200(L/N)K

351FGC100DD(L/N) | 351FGC200DD(L/N)K

Timer

Buzzer

Thermostat

1. Disconnect wires from rear of timer.

Turn timer knob to 0 minutes, check for

continuity across terminals on rear of

switch. If none is found, replace timer.

(Fig. 9)

2. Turn knob to between 1 and 60 minutes,

check that no continuity is found. Turn

knob to 'OFF', check that no continuity

is found. If continuity is found, replace

timer. (Fig. 9)

3. Check for any discoloration or

deformations of electrical connections.

If any are found, replace connections.

1. Disconnect wires from buzzer. Check

across terminals for approx. 2.4

kilo-ohms +/-10%. If outside of range,

replace buzzer. (Fig. 10)

2. Check for any discoloration or

deformations of electrical connections.

If any are found, replace connections.

1. Visually check board for any burners

or discoloration or corrosion. If found,

replace thermostat.

2. Check for 120 volts from COM terminal

(Fig. 12A) to input terminal (Fig. 12B).

3. Check for 24 volts from COM terminal

(Fig. 12A) to output terminal (Fig. 12C).

4. Check for any discoloration or

deformations of electrical connections. If

any are found, replace connections

Fig. 8

Fig. 10

Fig. 9

Fig. 11

Fig. 12

C

BA

www.cookingperformancegroup.com 7

Service Manual

351FGC100(L/N) | 351FGC200(L/N)K

351FGC100DD(L/N) | 351FGC200DD(L/N)K

Transformer

Ignition Module

1. Check for 120 volts at terminals (Fig. 13A).

2. Check for 24 volts at terminals (Fig. 13B). If voltage is

not correct, replace.

3. 24 volts goes to thermostat, 'HEAT ON' lamp and gas

solenoid valve.

4. Check for any discoloration or deformations of electrical

connections. If any are found, replace connections.

Check that module has power, check for 120 volts from L1 connection to GND connection and

also from L1 connection to a Neutral wire on the back of unit (Fig. 15 & 16).

Red Light Denitions:

- Solid red, no blinks: control fail, replace ignition module

- 2 blinks: ame on, but no call for heat, check thermostat

- 3 blinks: no ame, ignition locked out, check ignition sequence parts (surface igniter, gas

solenoid valve, ame detector)

S1 connection - 120 VAC surface igniter

L1 connection - 120 VAC input power (live)

W connection - Fan motor then thermostat

V1 connection - Gas solenoid valve

GND connection - Ground

S2 connection - Flame sensor

Fig. 14 Fig. 15 Fig. 16

Fig. 13

B

A

. www.cookingperformancegroup.com8

Service Manual

351FGC100(L/N) | 351FGC200(L/N)K

351FGC100DD(L/N) | 351FGC200DD(L/N)K

Door Switch

Heat on Indicator Light

1. Disconnect wires from rear of switch. Check continuity between terminals when switch lever

is in 'CLOSED', position. If continuity is not found in 'CLOSED' position, replace switch. If

found, see below for more testing.

2. With wires disconnected, check for no continuity between terminals when switch lever is

'OPEN'. If continuity is found, replace switch. If not found, see below.

3. With unit 'ON' and unit plugged in, check for 120 volts from each terminal to neutral when

switch is 'CLOSED', (Fig. 18) image shows terminal closest should only have 120 volts when

door is closed.

4. Check for any discoloration or deformations of electrical connections. If any are found,

replace connections.

1. With unit 'ON', plugged in and unit calling for heat, check for 24 volts between terminals.

Replace if no voltage is found or light does not light (Fig. 19).

2. Check for any discoloration or deformations of electrical connections. If any are found,

replace connections.

Fig. 17

Fig. 19

Fig. 18

www.cookingperformancegroup.com 9

Service Manual

351FGC100(L/N) | 351FGC200(L/N)K

351FGC100DD(L/N) | 351FGC200DD(L/N)K

Surface Igniter

Flame Sensor

1. Visually check that surface igniter 'glows' when thermostat rst calls for heat. Check with

unit 'ON' and thermostat calling for heat (Fig. 20 & 21).

2. Check for 120 volts from S2 connection on ignition module to Neutral wire on back of unit

(Fig. 22).

3. Check for 0.8 - 1.5 amps from S2 connection on ignition module to Neutral wire on back on

unit (Fig. 22).

4. Disconnect wire terminals, check resistance through igniter, approx. 23 Ohms at 70°F.

1. Visually check that ame sensor 'glows' when burner ames are 'ON'. Check with unit 'ON',

thermostat calling for heat and burner ames 'ON' (Fig. 25).

2. Check for 5 VDC on ignition module 'FC' terminals. If less than 2 VDC, replace ame sensor

(Fig. 24).

Fig. 20

Fig. 23

Fig. 21

Fig. 25

Fig. 22

Fig. 24

. www.cookingperformancegroup.com10

Service Manual

351FGC100(L/N) | 351FGC200(L/N)K

351FGC100DD(L/N) | 351FGC200DD(L/N)K

Gas Solenoid Valve

Temperature Sensor

Panel Safety Switch

1. Ensure gas is being supplied to unit. Check

incoming pressure using manometer on inlet

side of valve.

2. Check if solenoid valve is getting 24 VAC. If

no voltage, check ignition module. If voltage

is found, and still no gas is coming through,

replace gas valve (Fig. 26).

3. Check for any discoloration or deformations of

electrical connections. If any are found,

replace connections.

1. Disconnect wiring from thermostat. Check

resistance of sensor across wire terminals,

1.1 kilo-ohms +/- 10 % at 70° F. Replace

if outside of range (valve will change with

temperature) (Fig. 27).

2. Check for any discoloration or deformations of

electrical connections. If any are found,

replace connections.

1. Disconnect wires from rear of switch. Check

continuity between terminals when switch is in

'CLOSED' position. If continuity is not found in

'CLOSED' position, replace switch. If found, see

below for more testing (Fig. 28).

2. With wires disconnected, check for no continuity

between terminals when switch is in 'OPEN'. If

continuity is found, replace switch. If not found

see below.

3. With unit 'ON' and unit plugged in, check for 120 volts from each terminal to neutral when

switch is 'CLOSED'. Replace if not found on both terminals.

4. Check for any discoloration or deformations of electrical connections. If any are found,

replace connections.

Fig. 26

Fig. 27

Fig. 28

www.cookingperformancegroup.com 11

Service Manual

351FGC100(L/N) | 351FGC200(L/N)K

351FGC100DD(L/N) | 351FGC200DD(L/N)K

Fan Motor

Gas Burner Components

1. Turn unit off, disconnect gas and electrical

connections.

2. Remove right side panel to disconnect motor

wires from inside plug (Fig. 29).

3. Remove wiring from rear of unit (Fig. 30 & 31).

4. Open front doors. Remove racking and top rear

rack brackets from inside of oven.

5. Remove inside rear cover with a 10mm socket

or wrench, 2 bolts (Fig. 32 & 33).

6. Remove mounting bolts for fan motor with a

10mm socket or wrench (Fig. 34).

7. Pull fan assembly into inside of oven (Fig. 35).

8. Reassembly is reverse of removal.

1. Turn unit off. Disconnect gas and electrical

connections.

2. Remove front lower cover panel with a Phillips

screw driver.

3. Loosen and remove compression nut from gas

supply line to burner manifold (Fig. 36).

4. Remove 4 hex head bolts with an 8mm socket

from the burner manifold (Fig. 37).

5. Replace orices as needed or for gas

conversion, use a 14mm wrench.

6. Remove 4 hex bolts with an 8mm socket from

burner assembly to access the burners, surface

igniter and ame sensor (Fig. 38 & 39).

7. Remove surface igniter and/or ame sensor

with a Phillips screw driver as required for

replacement (Fig. 40).

8. Disconnect wiring from ignition module if

replacing surface igniter or ame sensor.

Fig. 29

Fig. 32

Fig. 34

Fig. 39

Fig. 36

Fig. 37

Fig. 38

Fig. 33

Fig. 35

Fig. 40

Fig. 30 Fig. 31

Part Replacement

. www.cookingperformancegroup.com12

Service Manual

351FGC100(L/N) | 351FGC200(L/N)K

351FGC100DD(L/N) | 351FGC200DD(L/N)K

ALL GAS CONNECTIONS MUST BE CHECKED FOR LEAKS

!

ALL GAS CONNECTIONS MUST BE CHECKED FOR LEAKS

!

Internal Gas Regulator

Gas Conversion

Regulator Pressure Adjustment

1. Turn unit off. Disconnect gas and electrical connections.

2. Remove hex bolts holding right side on with an 8mm

socket.

3. Loosen and remove compression nut and union joint from

either side of regulator to remove from unit (Fig. 41).

4. Remove ttings from both sides of old valve and install

on new valve with an appropriate thread sealant.

5. Install is reverse of removal. Ensure there are no gas

leaks.

1. Convert from one gas type to another by changing the burner orices. Reference 'Gas Burner

Components' on Page 11.

2. Replace regulator adjustment spring assembly. Reference 'Regulator Pressure Adjustment'

below.

3. Add new gas decals to Serial plate and internal regulator to reect change in gas supply type.

1. Manifold pressure can be adjusted. If needed and if

incoming pressure allows.

2. Remove right side panel hex bolts with an 8mm socket

and remove panel, then remove front lower cover.

3. Install manometer onto burner manifold behind lower

front panel to check pressure (reference serial plate for

required pressure), monitor if changes are needed

(Fig. 42).

4. Remove adjustment cover cap on inlet side of

regulator with a at screw driver (Fig. 43).

5. Turn adjustment screw under cap as follows:

Counter-Clockwise: Decrease pressure

Clockwise: Increase pressure

Fig. 41

Fig. 42

Fig. 43

www.cookingperformancegroup.com 13

Service Manual

351FGC100(L/N) | 351FGC200(L/N)K

351FGC100DD(L/N) | 351FGC200DD(L/N)K

Door Latch Removal

Door Latch Adjustment

1. Turn off power switch and gas supply to unit.

2. Disconnect unit from power supply.

3. Open front door(s) on unit to access latch.

4. Remove 2 Phillips head screws and pull latch from

top of door (Fig. 44).

5. Installation is reverse of removal.

1. Turn off power switch and gas supply to unit.

2. Disconnect unit from power supply.

3. Open front door(s) on unit to access latch.

4. Remove 2 Phillips head screws and pull latch from

top of door.

5. Push in on top portion of latch to remove tension

from lower locking nuts.

6. With an 8mm socket and/or wrench, turn the 2 nuts

to adjust the latch as needed.

7. Clockwise will lower the latch roller into the door.

Counterclockwise will raise the latch roller out of

the door.

8. Installation is reverse of removal.

Fig. 44

Fig. 45

. www.cookingperformancegroup.com14

Service Manual

351FGC100(L/N) | 351FGC200(L/N)K

351FGC100DD(L/N) | 351FGC200DD(L/N)K

Wiring Diagram

www.cookingperformancegroup.com 15

Service Manual

351FGC100(L/N) | 351FGC200(L/N)K

351FGC100DD(L/N) | 351FGC200DD(L/N)K

Parts Diagram

Item # Description Part #

2Blower Motor - 2 Speed 351010239

2A Blower Wheel 351010212

3Temperature Probe 351170022

4Oven Light 351130151

8Gas Safety Valve - NG 351220079

8A Gas Safety Valve - LP 351220098

9Panel Safety Switch 351080026

Item # Description Part #

15 Burner Assembly See Burner Assembly

16 Burner Orifice - LP 351302150211

16A Burner Orifice - NG 351302150212

17 Control Panel Assembly See Control Panel Assembly

19 Door Assembly - Right See Door Assembly

20 Door Assembly - Left See Door Assembly

22 Door Switch 351080079

. www.cookingperformancegroup.com16

Service Manual

351FGC100(L/N) | 351FGC200(L/N)K

351FGC100DD(L/N) | 351FGC200DD(L/N)K

Burner Assembly

Item # Description Part #

1Flame Sensor 351220004

2 Burner 35165002071

5Flame Spreading Plate 35165002068

7Surface Igniter 3511170039

www.cookingperformancegroup.com 17

Service Manual

351FGC100(L/N) | 351FGC200(L/N)K

351FGC100DD(L/N) | 351FGC200DD(L/N)K

Control Panel Assembly

Item # Description Part #

1 Buzzer 351100086

3Power Switch 351080141

4Ignition Module 351150304

5 Timer 351120028

7 Transformer 351100149

Item # Description Part #

8 Thermostat 351030169

9Heat Light 351130140

Fan Speed Switch 351080141

Light Switch 351080141

Cool/Cook Switch 351080141

. www.cookingperformancegroup.com18

Service Manual

351FGC100(L/N) | 351FGC200(L/N)K

351FGC100DD(L/N) | 351FGC200DD(L/N)K

Door Assembly

Item # Description Part #

1 Door Latch 35165002016

Door Assembly - Left 35165002014

Door Assembly - Right 35165002011

Other manuals for 351FGC100

1

This manual suits for next models

11

Table of contents

Other CPG Convection Oven manuals