CQR SDTRAPPER User manual

CQR Security. 125, Pasture Road, Moreton,Wirral. CH46 4TH, United Kingdom

Tel: +44 (0) 151 606 1000 Support: +44 (0) 151 606 6311

email: info@cqr.co.uk Web: http://www.cqr.co.uk

Environmental Advice.

This product is covered by current WEEE regulations. Please consider the eect on the

environment when disposing of it. Do not put in a domestic waste bin. Only dispose of

at an appointed recycling centre.

RoHS compliant.

PD6662 and EN50131 GRADE 2 environmental CLASS II.

Please read these instructions fully before installation.

SDTRAPPER

Intelligent Shock Detector

Installation Instructions

Specication

1

Supply Voltage 9 - 30 volts DC

Quiescent Current 17mA at 12 volts DC

Alarm Current 11mA at 12 volts DC

Operating Temp -20 to +50 degrees centigrade

Indication Tri-Colour LED

Red = Alarm

Amber = Engineer

Green = Day

Alarm Relay Normally closed, open in alarm (3 seconds)

Alarm Relay 150mA at 24V

Rating 10 ohm 0.25W resistor in series

Tamper Switch Normally , open on lid removal

Tamper Rating 50mA at 12V

Alarm Memory Up to 10 Trappers with individual

annunciation.

Slave Sensors Up to 2 CQR shock sensors and/or

magnetic contacts.

Dimensions 21mm x 25mm x 92mm

Explanation of Features

Time Integrated Pulse Count Analysing System.

The alarm threshold may be reached by either a single shock signal

of the required magnitude or by an accumulation of multiple shocks

of varying sizes within the time window.

The length of the time will be automatically set by the magnitude of

the rst shock. If the initial shock is small, so too will the time

window. If the initial shock is large, the time window will also be

large (up to 60 seconds).

This ensures that small signals which are likely to be caused by

birds, trees etc are quickly ignored and do not accumulate to an

alarm level, whilst larger or more frequent shocks which are more

likely to be intrusion attempts, are validated and stored in the pulse

count memory.

Engineer Selectable Features

1. Shock strength analysis and indication, (via amber LED)

2. Quiet and condence modes, (ashing green LED)

3. Alarm memory latch with sequential recall (up to 10 units)

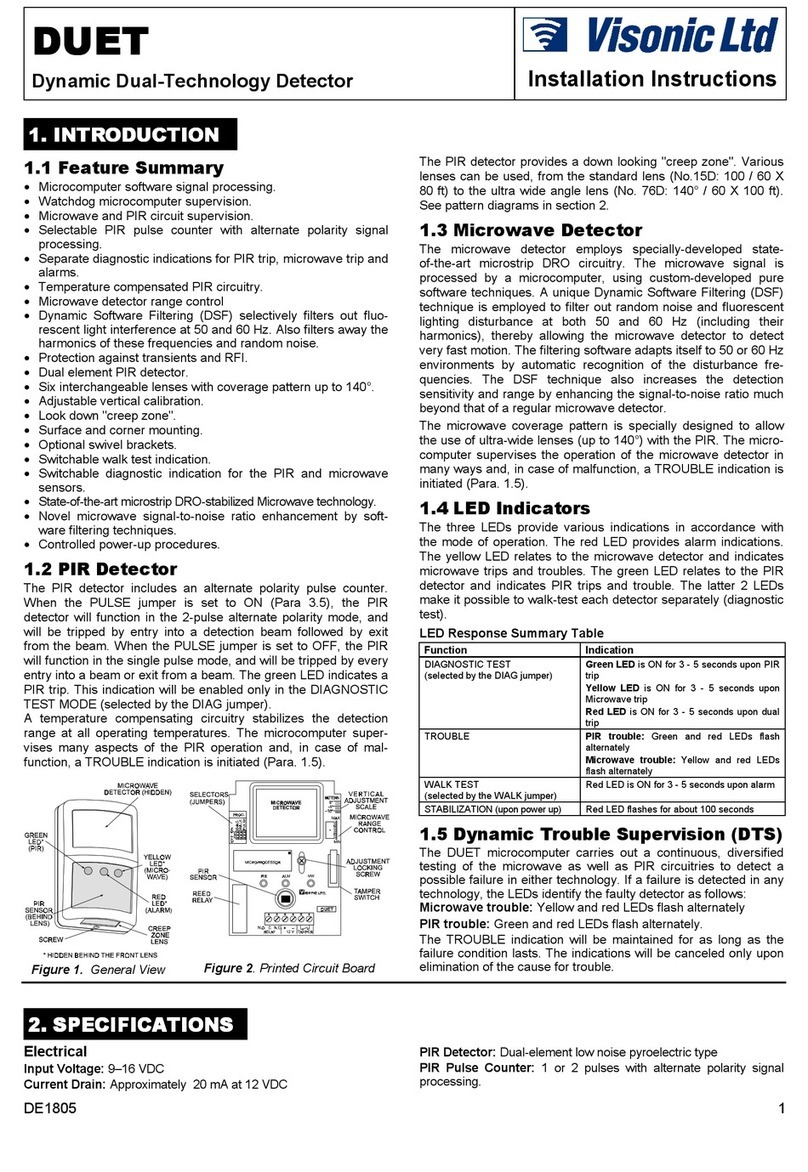

Locate the Trapper base referring to Fig 1. and Fig 2. overleaf.

PSTESV21v0ALARMA/TNC LOOP

Fitting and Assembly

Fig. 1 Fixing point (remove shock

sensor to access)

Relay 124QE

Shock level setting

Function selection

Fixing point

Grommet

knock out

Cable

Entry

0V

12V DC

Set input

(Optional)

Spare

Alarm output

(N/C)

Tamper Output (N/C)

Slave sensor loop (N/C)

Tri-Colour LED

Tamper switch

Cover screw

Location point

2. Firmly strike the outer limits of the protected surface, using

a hard object, refer back to Fig. 6.

3. After 3 seconds the LED will ash amber to indicate level of

shock received.

1 ash= 20% of an alarm, 2 ashes = 40%,

3 ashes = 60% (as in Fig. 13), 4 ashes = 80%, red = alarm.

4. Ideally the LED should give 3 or 4 ashes, assuming a single

large shock almost sucient to cause a breakageto the protected

surface.

5. If LED shows red, reduce the sensitivity, if less than 3 amber

ashes, increase the sensitivity using the jumper plugs.

i.e 1+4=5 or 1+2=3. Remove link“E”.

An alarm detection is not normally required unless the protected

material is actually broken.

Alarm Memory Control

1. Connect in parallel, the “set” of each trapper (up to 10) and then

connect the set line, via a 1K resistor (provided) to the control

panel“set”/ “latch”output as in Fig. 14.

2. Ensure that the control panel set output goes high when the

system is set.

3.While the system is set, the trapper(s) will not give any LED

indication.

4. Activation will cause the alarm relay to operate.

5. Any alarm activations while the system is set, will be memorised

and reported by the amber ashing LED when the alarm is unset

6. 1 ash = 1st to alarm, 2 ashes = 2nd to alarm and so on up to

the 10th unit to alarm.

Any units that did not alarm will show a green ashing LED.

7.To reset the alarm memory, apply the “set”input signal for

3 seconds and then remove. Otherwise the trapper(s) will

reset the next time that the system is set.

Condence Mode

1. Remove the link“Q” and t to one pin only as in Fig.15.

2.The green LED will ash at 2Hz unitl either,

a. An alarm condition (red LED for 3 seconds) or,

b. Smaller shock(s) are stored in the pulse count memory

(every 5th green ash will miss, as in Fig. 16.

Quiet Modes

1. Fitting link“Q”will disable the green ashing LED as in Fig. 17

2. Linking the +12V input to the “set”input will disable all LED

functions as in Fig 18.

Fig. 13 = 60%

Fig. 14 X4321

1K +ve

Set

Fig. 15

124QE

Fig. 16

124QE

Fig. 17

Fig. 18 A A SP S 12V 0V

Only use in conjunction with Intruder Alarm Systems.

V3: 20191202

23

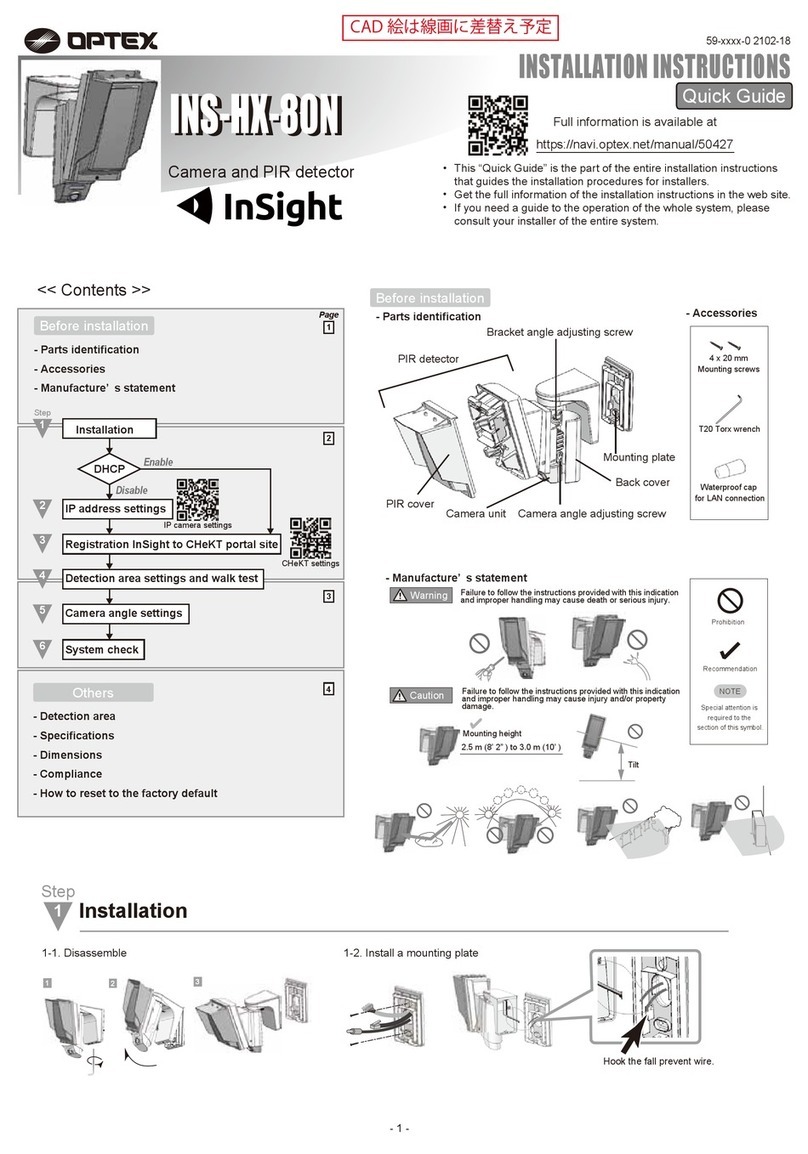

Factory Window Casement Window Residential Door

Wood Awning Window Sash Window Triple Sliding Glass door

T

S

S

T

T

T

TT

SS

If detection area is too large or interrupted, t slave detector(s)

X

The Shock Sensor module is to be placed into the base moulding

as seen in Fig. 3

Fig. 2

Fig. 3

Ensure arrow on the module points vertically upwards

This can be done by turning the cradle through 90°.

This adjustment allows horizontal or vertical mounting through 360°

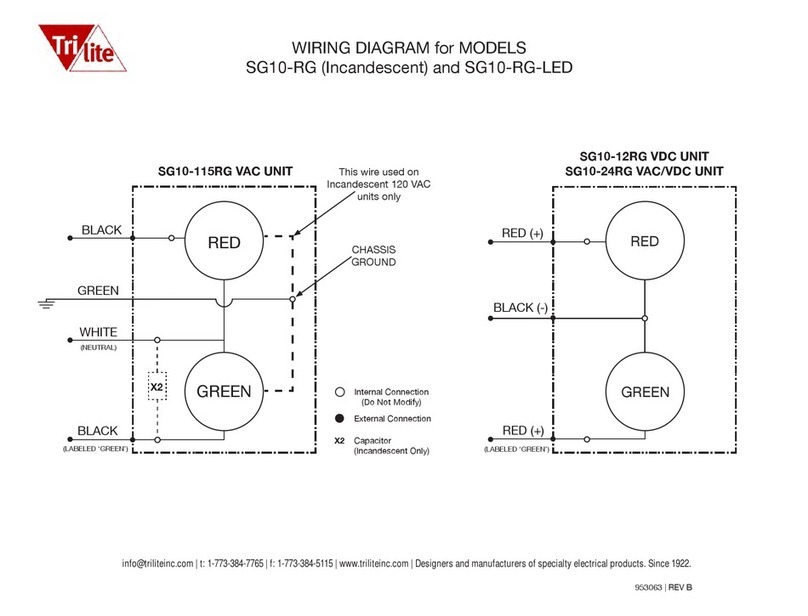

Wiring

Using a standard alarm cable of either 6 cores (std operation) or 8

cores (latch operation), make the connections to the host control

panel and slave sensor(s) and/or contacts if used.

SD

1/3/4

Slave Sensor

or

N/C Contact

(optional)

L

L

A/T

A/T

A

A

SP

SET

+ 12V

0V

Fig. 4

Remove link if slave

sensors are tted

N/C Anti-Tamper

N/C Alarm Relay

Spare

Set input

(optional)

1K

12V DC Supply

Setting the Sensitivity

The detection sensitivity may be set either automatically, whereby

the Trapper will indicate the required setting once a test shock is

applied to the protected surface, or manually referring to the amber

shock strength LED as an indicator.

Automatic Sensitivity Control

1. Apply power and remove links (LK1, 2, 4 and Q) as in Fig. 5

2. Remove and the ret link“E” to reset memory.

3. Firmaly strike the ptotected area at a point furthest from the

detector, using a hard object or suitable calibration tool, as in Fig.6.

Fig. 5

124QE

Strike

Here

Trapper

Fig. 6

4.The shock signals received by the Trapper will be remembered as

80% of an alarm signal.

5.The LED will ash red a number of times .

Count the ashes and select the shock level by tting the links,

as in Fig. 7

6. Repeat steps 1 to 5

7. Remove Link “E”, 2 the detection level is now set.

The green LED will ash at 2 Hz

If the LED does not ash, the trapper has not received a shock

signal.This may be because:

a.The test shock was too small, or

b.The detection area is too large.

To correct either:

a. Increase the test shock or

b. Fit additional slave sensor(s) to increase detection area.

If the detection area is too large or interrupted, t slave detector(s)

as shown in Fig. 9

Testing the level of Detection

1. Set the required detection level, by tting the sensitivity links.

2. Fit the link“E”as in Fig. 10.

3. Strike the protected surface.

4. After 3 seconds the LED will ash amber to indicate level of

shock received.

1 ash = 20% of an alarm, 2 ashes = 40%,

3 ashes = 60% as in Fig. 10a, 4 ashes = 80%, red = alarm.

5.The amber LED will continue to ash (with short pauses) to

show the memory status.

6. As more small shocks are applied, the LED will show the

accumulated level of shock held in the pulse count memory.

7. Repeat steps 2 to 4 throughout the protected area, to assess the

level of detection achieved.

Remove link “E” when detection testes are complete.

Note: The pulse count memory may be cleared by causing the

Trapper to go into alarm (Red LED).

Manual Sensitivity Control

1. Fit Link“E”and the three sensitivity links as required as in Fig. 11.

Fig. 7

124

Three Flashes 1+2 =3

Flashes LK1 LK2 LK4

1 On O O

2 O On O

3 On On O

4 O O On

5 On O On

6 O On On

7 On On On

Fig. 8

Maximum

Minimum

*

*

Fig. 9

Slave Trapper

Fig. 10

124QE

Fig. 10a = 60%

Fig. 11

124QE

The table in Fig. 8 below shows link positions