19Crafted with CRAFTSMAN MARINE

7Maintenance schedule

Recording of data for verification

After every 10 hours of operation or each time before starting

After the first 50 hours of operation

After every 100 hours of operation (or at least once a year)

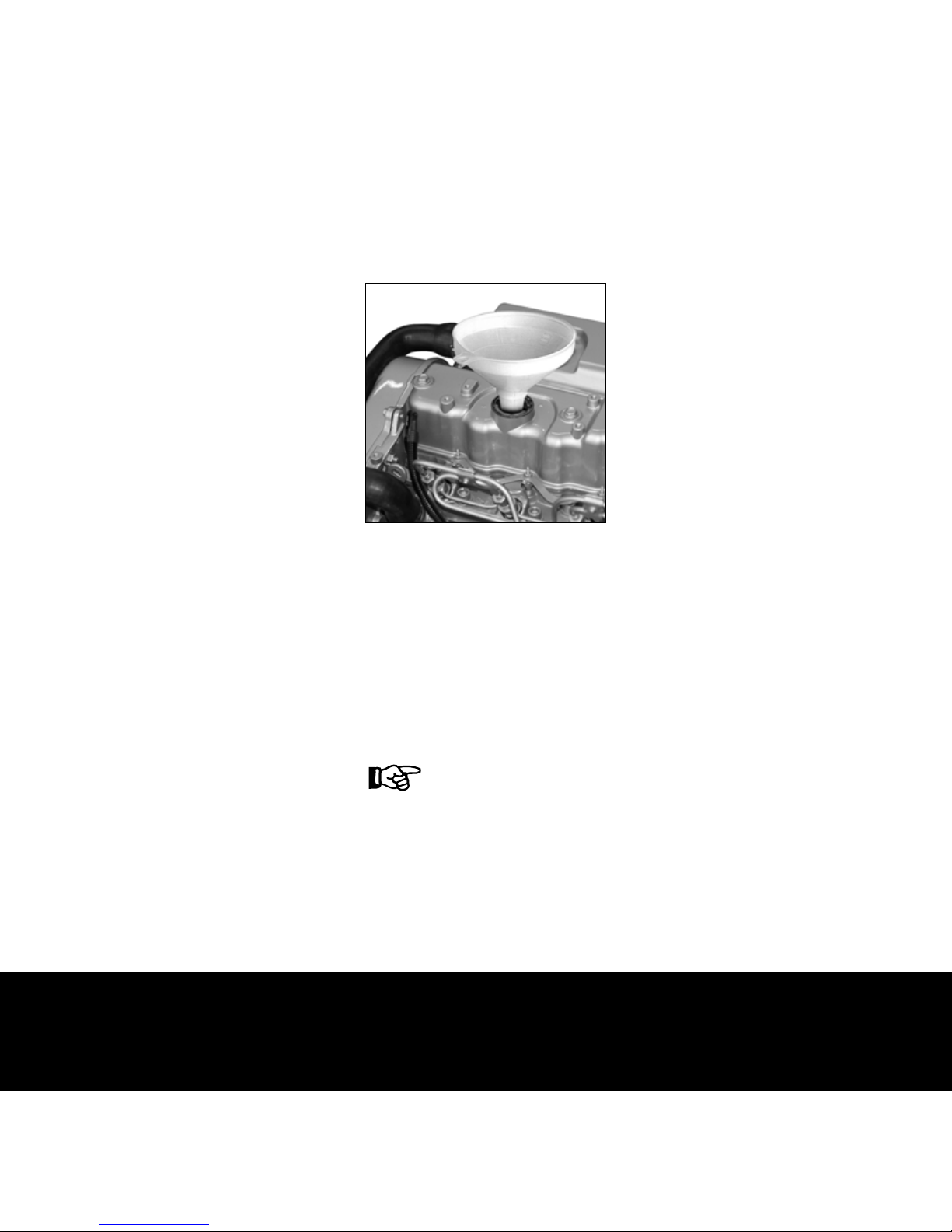

• Check level of engine lubricating oil (page 20)

• Check level of cooling liquid (page 23)

• Check cooling water strainer for blockage of the water flow (page 25)

Ask your dealer to execute this maintenance job:

Ask your dealer to execute this service job:

• Drain water from the fuel filter/water separator (page 27)

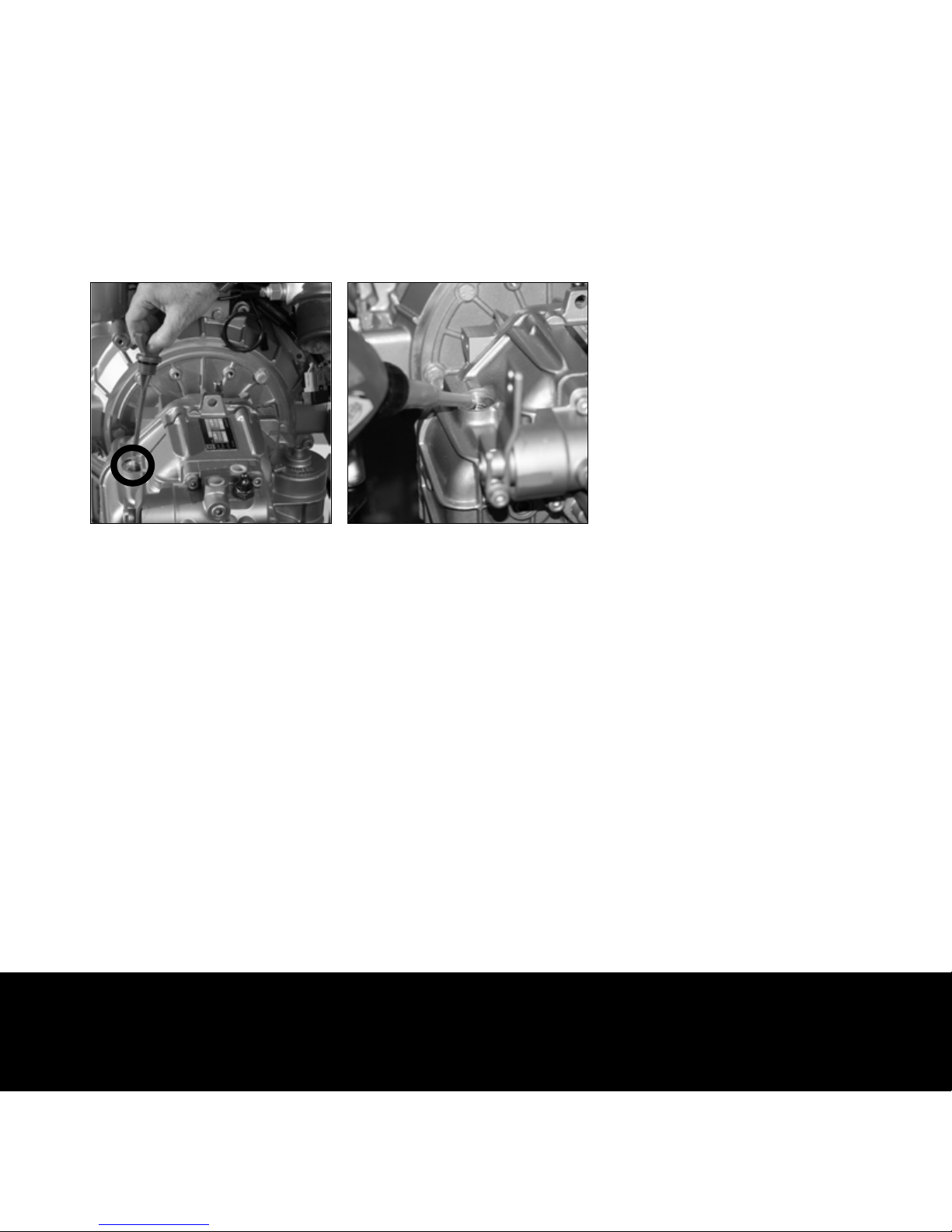

• Change engine lubrication oil (page 20)

• Replace oil filter (page 21)

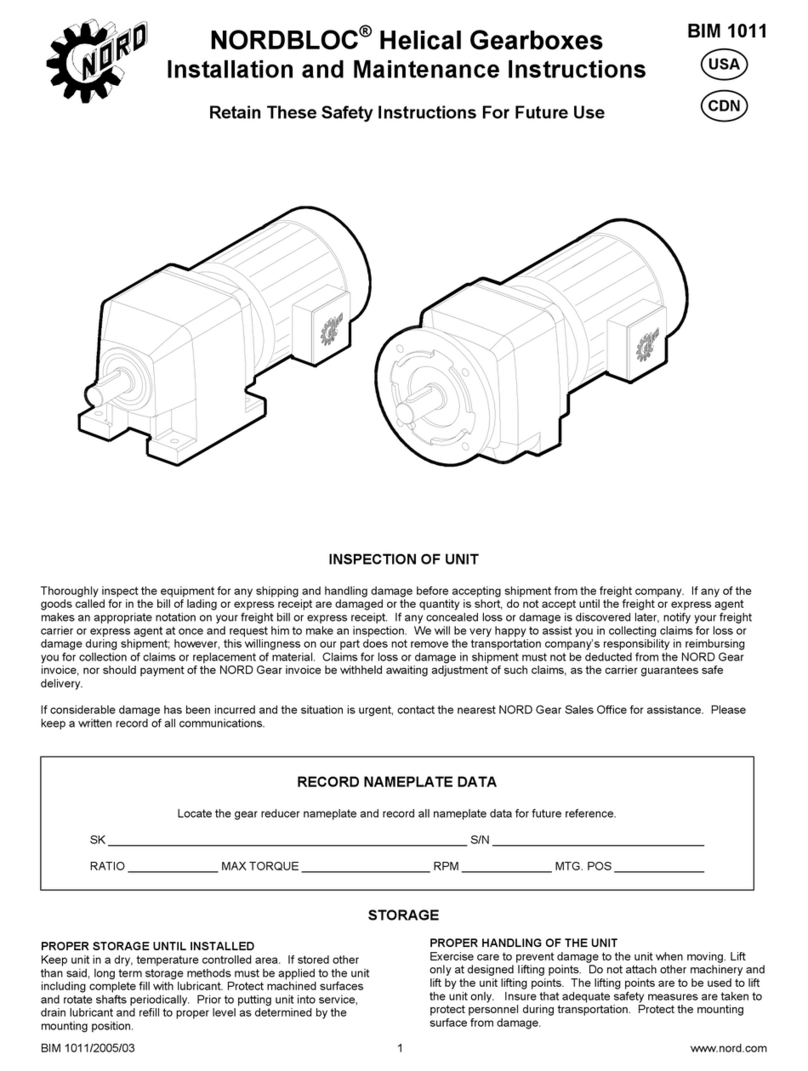

• Change lubricating fluid in gearbox (page 22)

• Replace fuel filter (page 26)

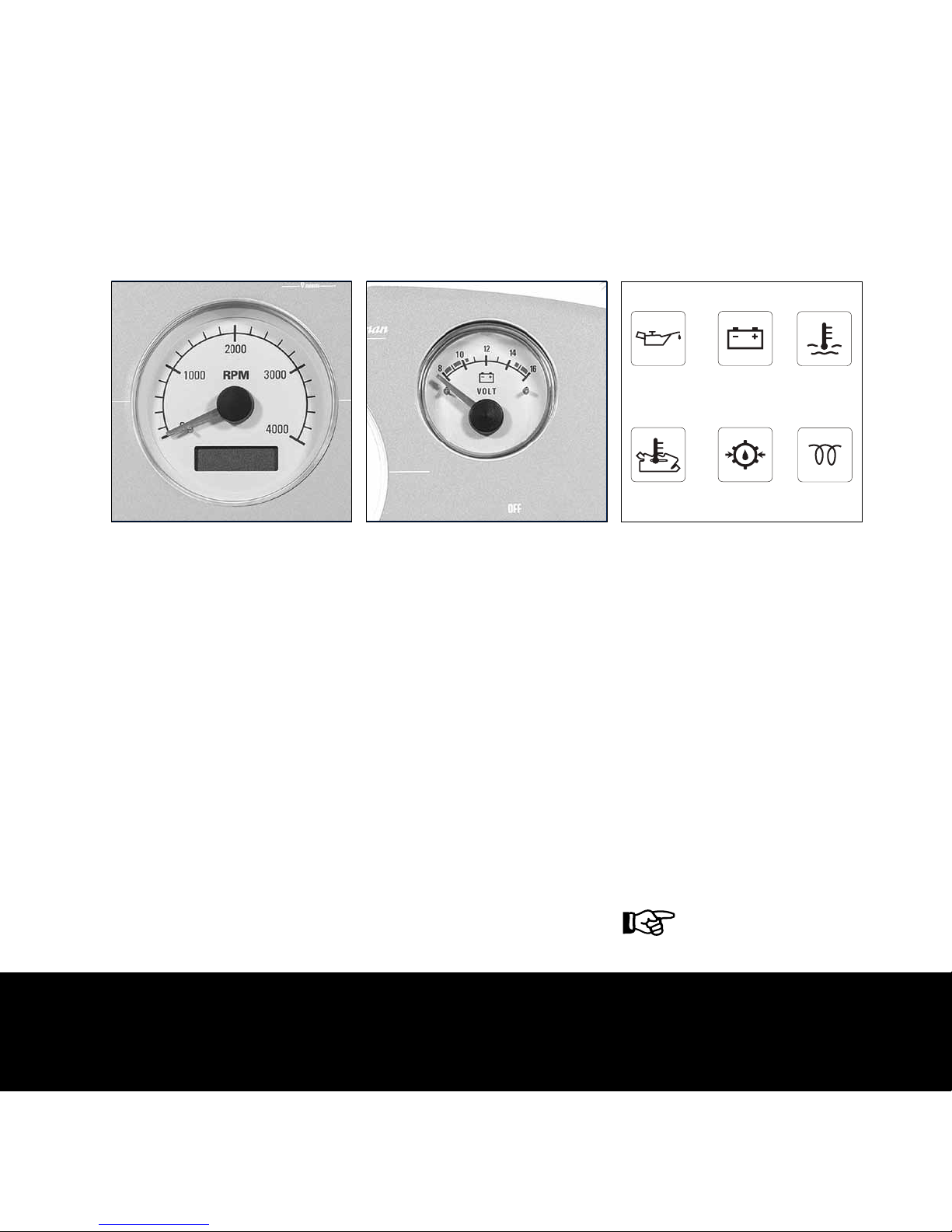

• Verify idling revolutions and adjust if necessary (page 15)

• Drain water from the fuel filter/water separator

• Change engine lubrication oil

• Replace oil filter

• Verify level of lubricating fluid in gearbox

• Replace fuel filter

• Check batteries, electrical cables and connections

• Check impeller raw water pump

In order to ensure a long life span of your engine, it is imperative to adhere to the following directives pertaining to the periodical maintenance of the engine and its compo-

nents. In the case of inadequate maintenance, serious damage can be caused to the engine and no warranty claim can be accepted by the manufacturer. These are the jobs to

be performed:

After every 500 hours of operation (at least once a year)

Have your dealer check and execute the following:

• Verify the tolerance of the valves

• Replace the fuel filter

• Change the oil in the gearbox

• Clean the filter, which is located just before the fuel lift pump

• Verify the flexible engine mountings for the rubbers to have the correct

compression and adjust if necessary

• Check all hoses and hose connections for leaks

• Verify the tension of the V-belt

After every 1000 hours of operation (or at least once every two years)

After every 1600 hours of operation (or at least once every 10 years)

Have your dealer check and execute the following:

Ask your dealer to execute this maintenance job:

If necessary

• Verify the proper functioning of the raw water pump

• Replace the cooling liquid in the inner cooling circuit

• Check valve clearance and adjust if required

• Replace timing belt

-Bleed the fuel system (page 27)

-Verify the number of revolutions when idling (page 15)

Only service the engine when it is stopped!