RULES FOR SAFE OPERATION (Continued)

22. OUTDOOR USE EXTENSION CORDS. When tool

is used outdoors, use only extension cords suitable 32.

for use outdoors. Outdoor approved cords are

marked with the suffix W-A, for example -SJTW-A

or SJOW-A. 33.

23. KEEP cu'n'ERS CLEAN AND SHARP. Sharp

cutters minimize stalling and kickback.

24. KEEP HANDS AWAY FROM CUTTING AREA.

Keep hands away from cutters. Do not reach

underneath work while cutter is rotating. Do not

attempt to remove material while cutter is rotating.

25. NEVER USE IN AN EXPLOSIVE ATMOSPHERE.

Normal sparking of th_ motor could ignite fumes.

26. INSPECT TOOL CORDS PERIODICALLY and

if damaged, have repaired at your nearest Sears

Repair Center. Stay constantly aware of cord

location.

27. INSPECT EXTENSION CORDS PERIODI-

CALLY and replace if damaged.

28. KEEP HANDLES DRY, CLEAN, AND FREE

FROM OIL AND GREASE. Always use a clean

cloth when cleaning. Never use brake fluids,

gasoline, petroleum-based products or any strong

solvents to clean your tool.

29. STAY ALERT. Watch what you are doing and

use common sense. Do not operate tool when

you are tired. Do not rush.

30. CHECK DAMAGED PARTS. Before further use

of the tool, a guard or other part that is damaged

should be carefully checked to determine that it

will operate properly and perform its intended

function. Check for alignment of moving parts,

binding of moving parts, breakage of parts,

mounting, and any other conditions that may

affect its operation. A guard or other part that is

damaged should be properly repaired or replaced

by an authorized service center unless indicated

elsewhere in this instruction manual.

31. DO NOT USE TOOL IF SWITCH DOES NOT

TURN IT ON AND OFF. Have defective switches

34.

35.

36.

37.

replaced by an authorized service center.

INSPECT FOR and remove all nails from lumber

before trimming.

DRUGS, ALCOHOL, MEDICATION. Do not

operate tool while under the influence of drugs,

alcohol, or any medication.

WHEN SERVICING USE ONLY IDENTICAL

CRAFTSMAN REPLACEMENT PARTS.

POLARIZED PLUGS. To reduce the risk of

electric shock, this tool has apolarized plug (one

blade is wider than the other). This plug will fit in

a polarized outlet only one way. If the plug does

not fit fully in the outlet, reverse the plug. If it still

does not fit, contact aqualified electrician to

install the proper outlet. Do not change the plug

in any way.

DO NOT USE TOOL UNDER "BROWN-OUT"

OR OTHER LOW VOLTAGE CONDITIONS.

Also, do not use with any device that could cause

the power supply voltage to change.

SAVE THESE INSTRUCTIONS. Review them

frequently and use them to instruct others who

may use this tool. If you loan someone this tool,

loan them these instructions also.

WARNING:

Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains

chemicals known to cause cancer, birth defects or

other reproductive harm. Setne examples of these

chemicals are:

• lead from lead-based paints,

•crystalline silica from bricks and cement and other

masonry products, and

•arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your i

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such

as those dust masks that are specially designed to filter

[WARNING: Joutmicroscopic particles. ,

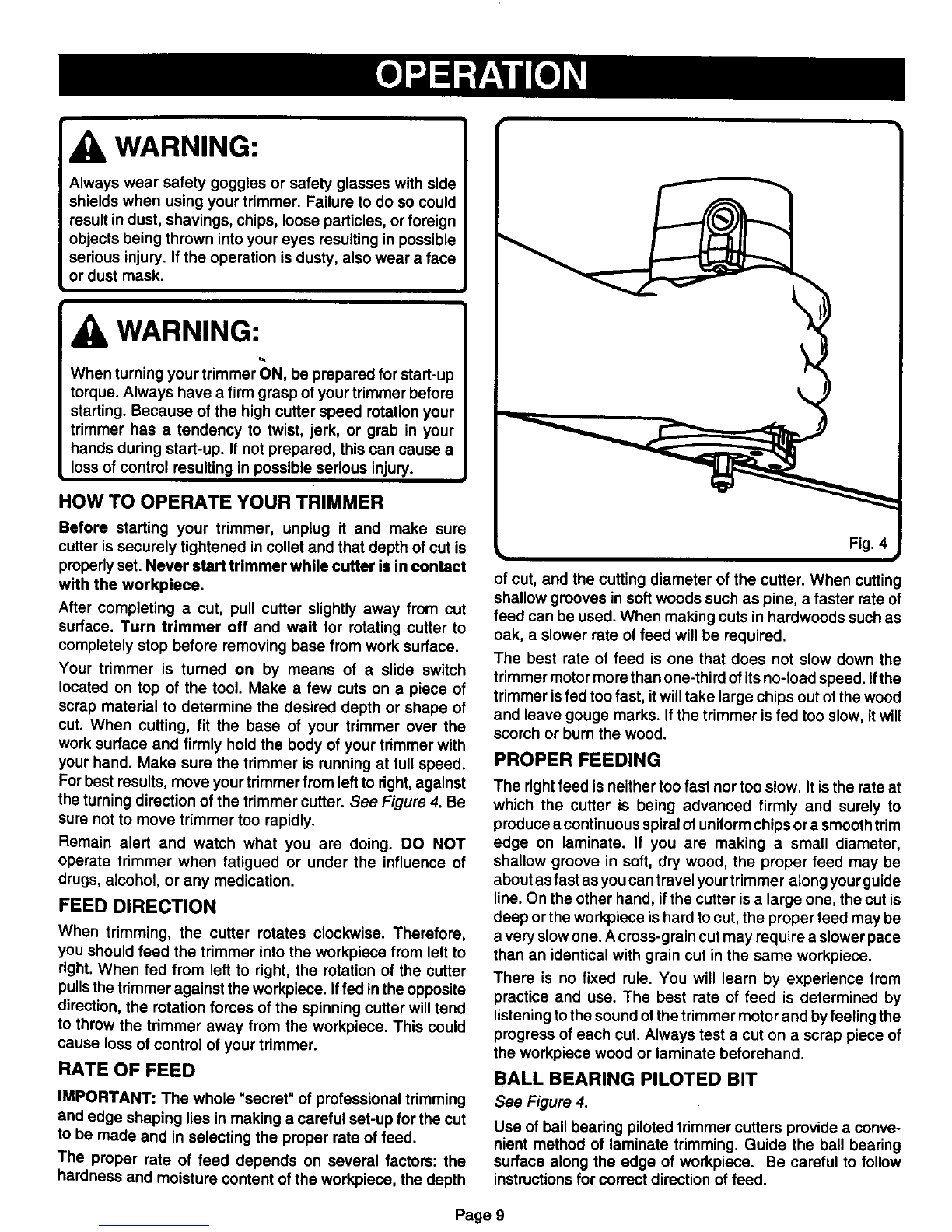

f_ The operation of any laminate trimmer can result in foreign objects being thrown Into your

|_/uu'_t ,,_UL_,._)] eyes, which can result In severe eye damage. Before beginning power tool operation,

|p_ always wear safety goggles or safety glasses with side shields and a full face shield when

i_needed. We recommend Wide Vision Safety Mask for use over eyeglasses or standard

L_safety glasses with side shields, available at Sears Retail Stores.

Page 4