I IIIIIIllllII I •i iiiiiiiiiiiiiiiiii Illt l ,HlUIlUUlII,U

B. PRE_PERATION CHECKS

_WARNING

Review all Warnings and Safety Instructions in this

manual.

.

,

Before operating your tool, always:

I. Inspect the entire tool before each use. Replace 7.

damaged parts. Check for fuel leaks and make sure all

fasteners are in place and securely fastened.

2. Replace trimmer head parts that are cracked,

chipped or damaged before using this tool. 8.

3. Use only Sears flexible, non-metallk, monof'flament 9.

trimming line of the Correct diameter. Never use

wire, rope, string, etc. 10.

4. Use only with the shield properly attached.

II I _ _ £ Illl Illllllllllll I Illlllll I Illlllllllllllllllll

€. STARTING INSTRUCTIONS (For location of controls,

Use only the specified trimmer head. See "Specifica-

tions?' Make sure the trimmer head is properly

installed and securely fastened, Refer to "Assembly"

Be sure the Wimmer head stops turning when engine

idles. See "Carburetor AdjustmentsY

Make carburetor adjustments with tbe drive shaft

housing supported to prevent the trimmer fine

from contacting any object. Hold the tool by hand.

Do not use the shoulder strap for support.

Keep others away when making carburetor

adjustments.

Use only accessories or attachments as recom-

mended by Sears for this tool.

Clean the air filter if dirty before operating the tool.

Refer to._'Specificafions,' for air filter location.

IIII I II ]111111111111111111111II I IIIIII IIIIIII[--

refer to "Specifs_tions.")

1. Before starting the engine:

a. Fuel engine. Move 10feet away from fueling site.

b. Extend line4 inches from the Trimmer Head k)pro-

vide and adequate load on the engine.

AWAmCm

The trimmer head will turn as soon as the engine starts.

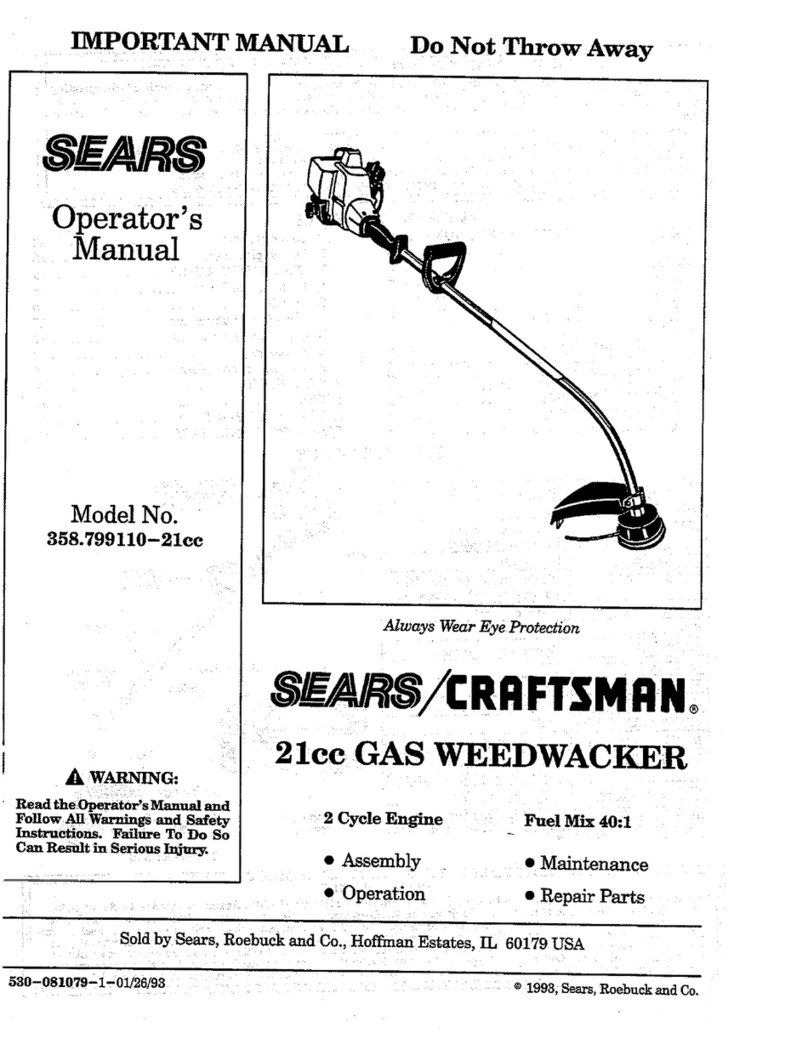

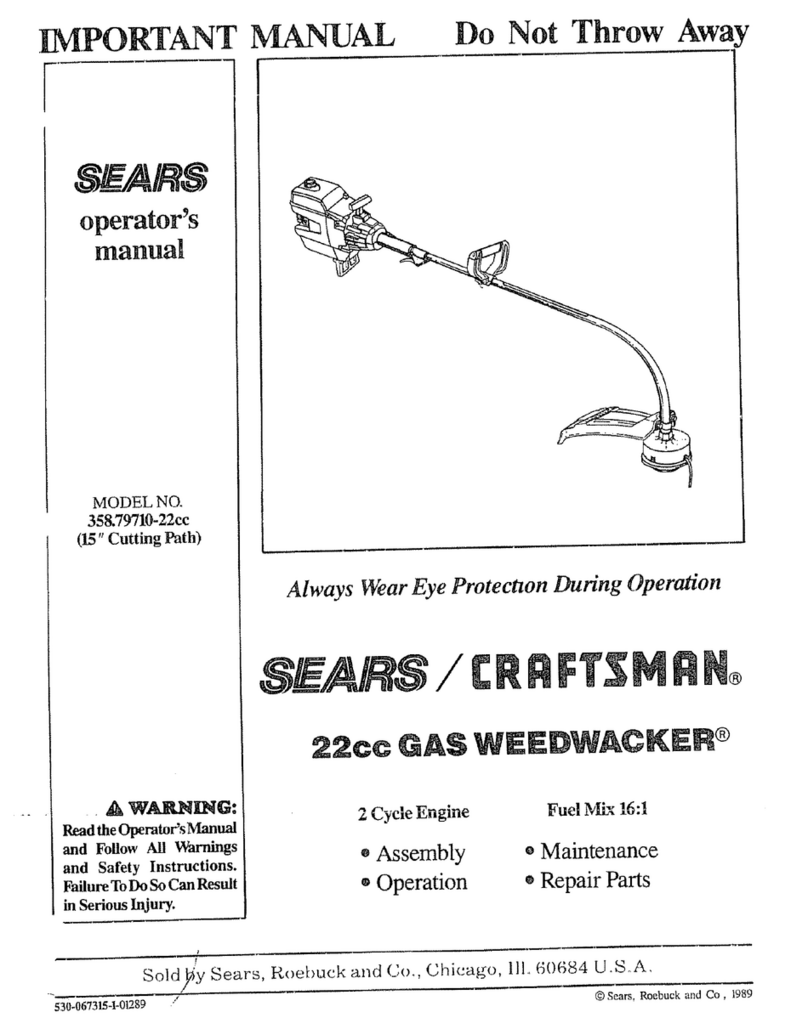

c. Stand Lu the operating position. Rest Shield on

ground, supporting Trimmer Head up off ground

away from tr_s, bushes, onlookers, etc. Figure 7.

d. With optional Shoulder Strap, place Shoulder Strap

on your shoulder. Start engine before clipping

Shoulder Strap to the tool.

2. For a Cold Engine:

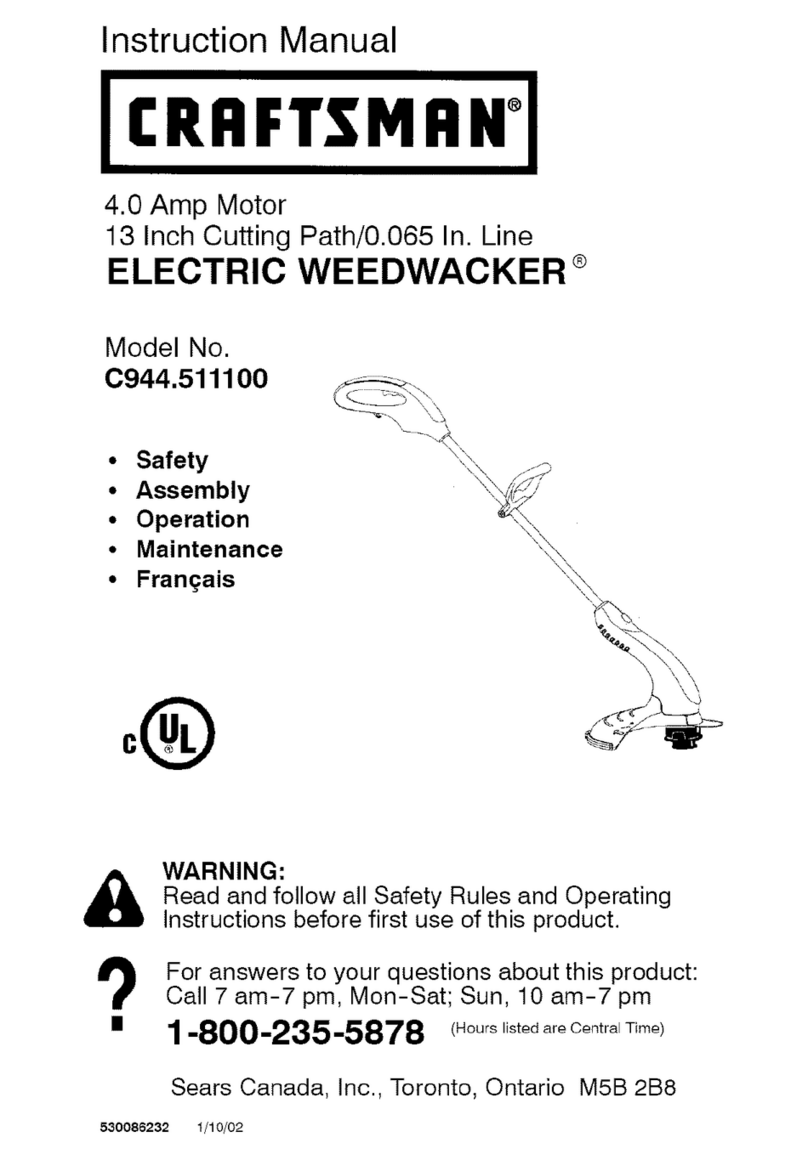

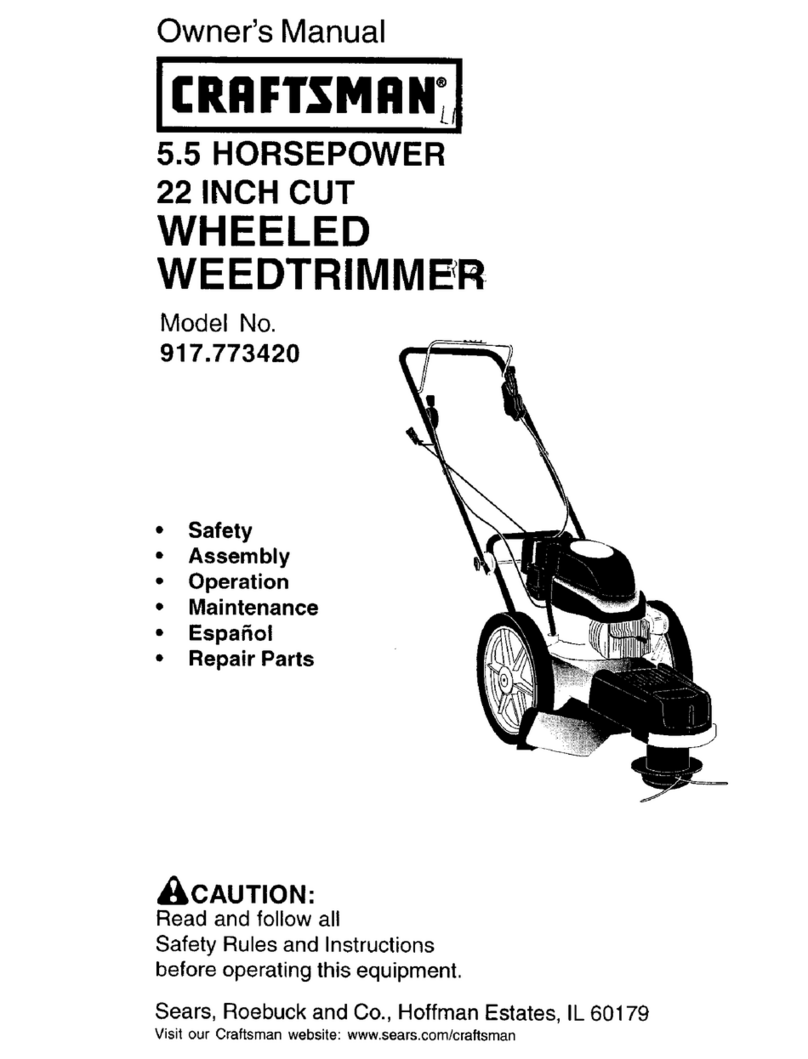

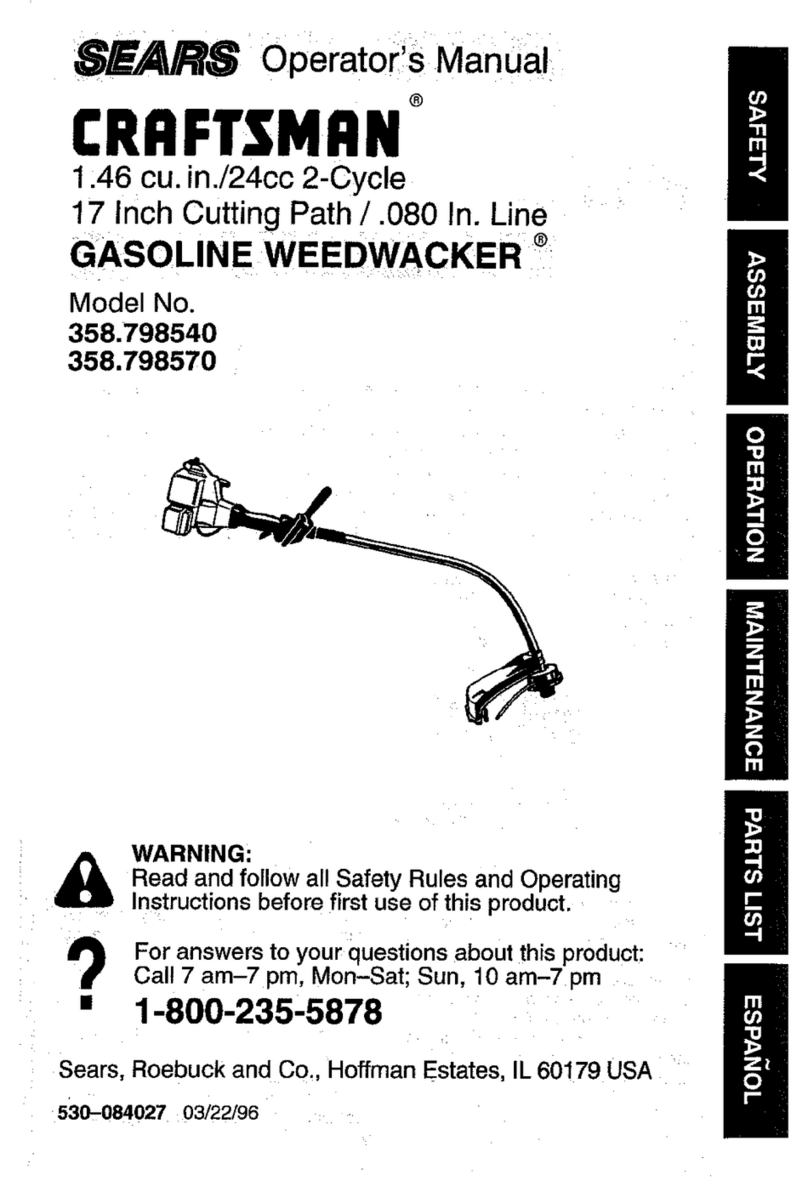

a. Pull Choketo full-chokeposition. Figure 8.

b. Grip rear handle and _ Throttle Trigger fully

squeezed through step "f."

•c. Pull Starter Rope sharply until engine pops or

attempts torun, but no more than8 pulls at fi_ choke

to avoid flooding the engine. The engine "pop" or

'hltempts to run" may be hard to hear. _w operator

mustU_n carefully. After 8pulis, proceed to step

"d." even if enginehas not attempted to run.

•d. Push Choke.to half-choke position. Figure 9.

e, Pull Starter Rope sharply until engine runs, but no

more than 5 pulis,

NOFE: Ifengine has not starteAafter5pulls, repeat

steps "a" through "e."

f. Allow engine to nm 5seconds, then push Choke to

no-choke position. Figure 10. Keep Trigger fully

squeezed until engine runs smoothly.

NOTE: If engine dies with Choice at no-choke

position, repeat steps "d" through "f"

AW_G

Avoid any bodily contact with the muffler on a warm

engine. A hot muffler can cause seriousburns.

3. For a Warm Engine:

a. Pull Choke to half-choke position. Figure 9.

b. Grip rear handle and keep Throttle Trigger fully

squeezed until engine runs.

e. Pull Starter Rope sharply until engine runs, but no

more than 5 pulls.

d. Push Choke to no-choke position. Figure 10.Keep

Trigger fully squeezed until engine runs smoothly.

N(II'E: If engine does not run after 5 pulls, it is

probablyflooded. Wait a few minutes and repeatpro-

cedure using no-chokeposition. Figure 10.

4. For a Warm Engine (After Running out

of IAter):

a. Refuelengine. Move 10feetaway from fueling site.

b. Pull Choke to full-choke position. Figure 8.

c. Grip rear handle and keep Throttle Trigger fully

squeezxxl until engine runs.

d. Pull Starter Rope sharply until engine pops or

attempts to run, but no more than 5 pulis.

e. Push Choke to no-choke position. Figure 10.

f. Pull StarterRope until engine rum, but no moi_than

5 pulls. Keep Trigger fully squeezed untilengine

runs smoothly.

NOTE: If engine has not started, pu!l Starter Rope

5 more pulls. If engine still does not rtm, it is pro-

bably flooded. Wait a few minutes and repeat pro-

cedure using no-choke position. Figure I0.

(

[ _G POSITION

Lo 7

1 ! FULL CHOKg. tHALFCHOKE

Figures 'igure 9

tNOCHOKE

_1 ........ _HHH,

Figure 1o