Cramer TOURINO PICK-UP User manual

Tourno pick-up

Original Operation Manual English

02-2014

Operation Manual

Models

TOURNO pick-up

Machine no.

Tourno pick-up

Original Operation Manual English

- 2 -

List of contents

1 Important general information.................................................................................................................. 3

1.1 General.......................................................................................................................................... 3

1.2 Symbols......................................................................................................................................... 3

1.3 Limitation of liability ....................................................................................................................... 3

1.4 Copyright ....................................................................................................................................... 3

1.5 Warranty........................................................................................................................................ 3

2 Safety....................................................................................................................................................... 4

2.1 Use in compliance with intended purpose..................................................................................... 4

2.2 Possible misuse............................................................................................................................. 4

2.3 General sources of risks................................................................................................................ 4

2.3.1 Use and operation.................................................................................................................... 4

2.3.2 Product-specific risks ............................................................................................................... 4

2.3.3 Risks by motor operation.......................................................................................................... 4

2.3.4 Operating risks ......................................................................................................................... 4

2.3.5 Risks for children, elderly persons and pets ............................................................................ 4

2.4 Maintenance.................................................................................................................................. 4

2.5 Staff and operator qualification...................................................................................................... 4

2.6 Safety instructions......................................................................................................................... 5

2.7 Required protection equipment for operation................................................................................ 5

2.8 Safety devices ............................................................................................................................... 5

2.9 Behaviour in case of fire................................................................................................................ 5

2.10 Environmental protection............................................................................................................... 5

3 Design and function................................................................................................................................. 6

3.1 Brief description............................................................................................................................. 6

3.2 Overview........................................................................................................................................ 6

3.3 Displays and operating elements.................................................................................................. 7

3.4 Working position and areas of risk..............................................................................................10

3.5 Accessories and spare parts.......................................................................................................10

3.6 Transport ..................................................................................................................................... 10

3.7 Storage (short-term) .................................................................................................................... 10

3.8 Storage (long-term) ..................................................................................................................... 10

4 First commissioning (first inspection of the machine) after installation .................................................10

4.1 Safety........................................................................................................................................... 10

4.2 Assembly..................................................................................................................................... 10

4.3 First commissioning and functional test ...................................................................................... 10

5 Operation ............................................................................................................................................... 11

5.1 Start and stop .............................................................................................................................. 11

5.2 Normal operation......................................................................................................................... 11

5.3 Activities after use ....................................................................................................................... 11

6 Maintenance .......................................................................................................................................... 12

6.1 Safety........................................................................................................................................... 12

6.2 Maintenance work ....................................................................................................................... 12

6.2.1 Machine cleaning ................................................................................................................... 12

6.2.2 Check safety precautions....................................................................................................... 12

6.3 Maintenance plan ........................................................................................................................ 13

7 Troubleshooting..................................................................................................................................... 13

7.1 Safety........................................................................................................................................... 13

7.2 Service address........................................................................................................................... 13

7.3 First action for troubleshooting.................................................................................................... 13

8 Technical data ....................................................................................................................................... 14

9 Declaration of conformity....................................................................................................................... 15

Tourno pick-up

Original Operation Manual English

- 3 -

1 Important general information

We are pleased that you have selected a machine from

Cramer GmbH in Germany.

Please read this Operation Manual before you use the

machine for the first time and observe the notes and

safety instructions.

Imprint

Cramer GmbH

Reimersstr. 36

D-26789 Leer

Phone: +49491/60950

Fax: +49491/6095200

Info@cramer.eu

District court of Aurich HRB 110877

VAT ID: DE 814 305 398

1.1 General

Information on this Manual

•Observing the instructions in this manual allows for the

safe and efficient handling of the machine.

•The operator must have read this manual carefully and

understood it before starting working with the machine.

•Compliance with the safety instructions contained is a

prerequisite for using the machine without any risk.

Keeping the Operation Manual

•The Operation Manual is an integral part of the machine

and shall be kept in its immediate vicinity.

•The operator must have access to this Manual at any

time.

Traffic regulations

•Any applicable traffic regulations have to be complied

with in regard to manoeuvring and transporting the

machine on public roads.

Accident prevention regulations

•General safety and local accident prevention regulations

must also be observed.

•National occupational safety regulation shall be complied

with.

Other applicable documents

Installation instructions, declaration of conformity

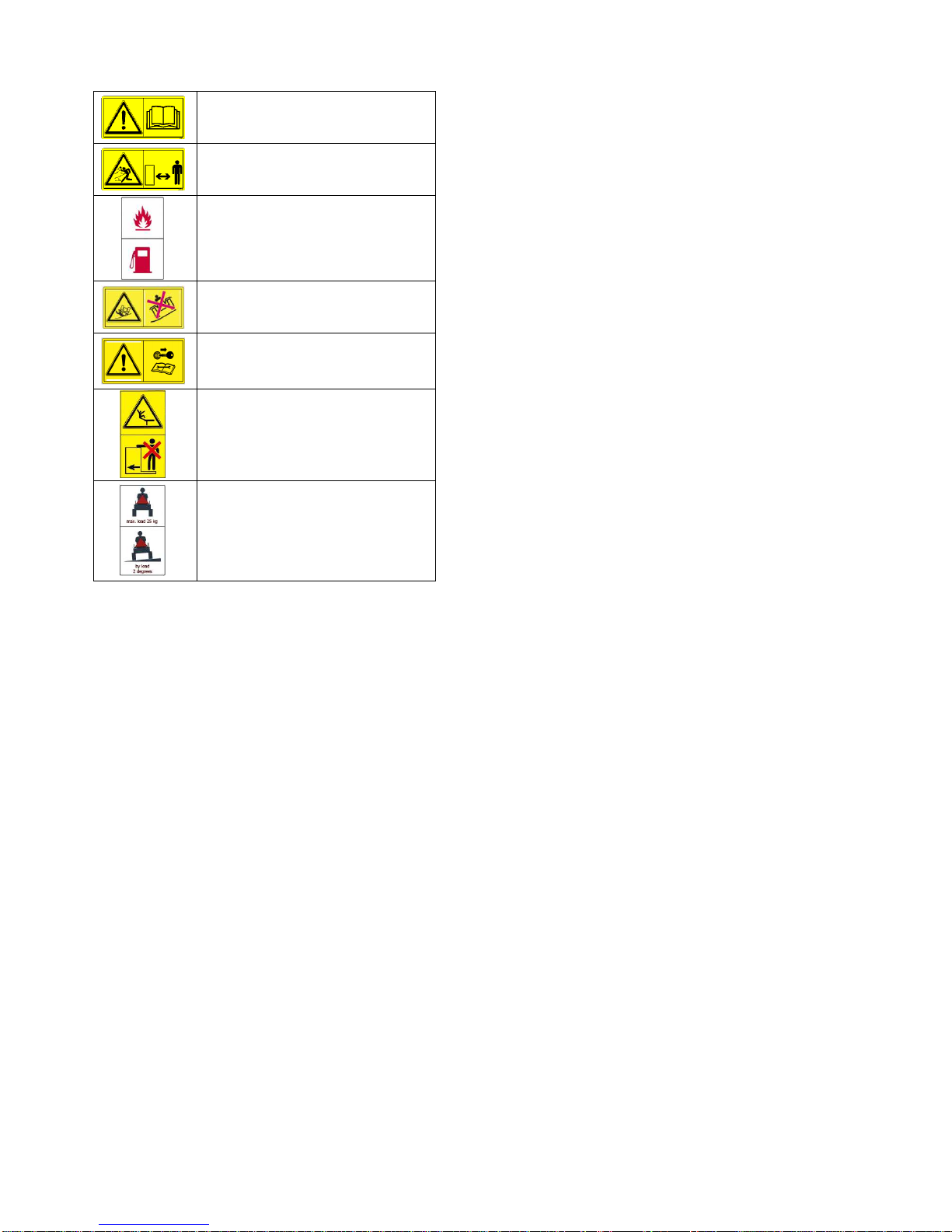

1.2 Symbols

DANGER !

This symbol cautions against an immediate

threat resulting in serious injuries or death if

not avoided.

WARNING !

This symbol cautions against a potentially

dangerous source of risk which may result in

death or serious injury if not avoided.

ATTENTION !

Indication of a potential risk which may result

in minor injuries if not avoided.

NOTE !

This symbol indicates a potential risk source which may

result in damage to property or minor personal injuries.

1.3 Limitation of liability

Liability on part of the manufacturer is excluded in the

following cases:

•Non-compliance with the Operation Manual

•Use not in compliance with intended purpose.

•Assignment of untrained staff

•Use of unauthorized spare parts Only original

components may be used.

•Unauthorized modifications of the machine.

1.4 Copyright

© Cramer GmbH

Copying of the Operation Manual is only permissible for

internal training purposes.

1.5 Warranty

The General Terms and Conditions of Business as issued by

us in every country shall be applicable. Failures within the

statutory warranty period will be remedied by us free of

charge if they are caused by a material or manufacturing

defect in our responsibility. Please contact your dealer in

case of a failure and submit the proof of purchase.

Tourno pick-up

Original Operation Manual English

- 4 -

2 Safety

2.1 Use in compliance with intended purpose

The machine has been approved as carrier for various

Cramer mounting tools.

Any use exceeding this is considered not in

compliance with the intended purpose. The

manufacturer shall not be liable for damage resulting

from use not in compliance with the intended

purpose; the risk for this shall be in the sole

responsibility of the user.

Use in compliance with the intended purpose shall also

include compliance with the operation and maintenance

provisions specified by the manufacturer.

2.2 Possible misuse

•Do not access any slopes transversely (danger of tilting).

•Avoid jerky steering movements when using the machine

on a slope (danger of tilting).

•Avoid high speeds in bends or when driving round

obstacles (damage to property).

2.3 General sources of risks

2.3.1 Use and operation

•Prior to starting the machine, the machine shall be

checked for its proper condition and operational safety.

•The operation shall use the machine in compliance with

its intended purpose.

•Indoor machine operation is prohibited.

•The machine is only approved for floorings as indicated in

the Operation Manual.

•The machine may only be operated by staff who was

instructed in its use or who provided evidence of their

operating capability, and who have explicitly been

instructed to operate the machine.

•When starting the motor, no other persons should be in

the vicinity of the machine.

•Any protection equipment must be properly attached and

in functional order.

•Never leave the machine unattended.

•When leaving the machine, stop the motor and secure the

machine against unintended movement.

•The operator shall be responsible for accidents involving

other persons or their property.

•Riding on treads or platforms is not permissible.

2.3.2 Product-specific risks

•Do not run over any highly flammable materials or hot

objects (e.g. barbecue coal) - danger to life by burns!

2.3.3 Risks by motor operation

•Do not touch any parts of the motor during or after

operation. Significant risk of burning by hot surfaces.

•Stop the motor and let it cool down before working on the

machine as well as before performing maintenance,

cleaning and repair work.

•Do not refill the tank when the motor is running - danger of

life by burning and explosion.

•Immediately remove spilled fuel with a cloth - danger of

life by burning and explosion.

•Keep fuel in designated containers.

•Exhaust gases are toxic and dangerous to health; they

must not be inhaled.

2.3.4 Operating risks

•Do not access any slopes with an inclination exceeding

10°.

•When using the machine transverse to the direction of

travel, this is only possible on slopes up to 10°.

•When the tipping trough is full, only slopes up to 2° may

be accessed.

2.3.5 Risks for children, elderly persons and

pets

•The operator shall take account of surrounding conditions,

e.g. the effects of noise on persons and animals.

•The machine must never be left on a slope.

•Children, elderly persons and pets/livestock must not stay

near the machine.

•Children must not play with/on the machine.

2.4 Maintenance

•Servicing, maintenance and repair work as well as

troubleshooting shall only be carried out when the

machine is switched off and the motor is at a standstill. As

required, the spark plug connectors shall be

disconnected.

•The machine must not be cleaned with spray water (risk

of short circuits or other damage).

•Safety checks pursuant to local regulations for non-

stationary commercially used machines shall be complied

with.

•Wear suitable gloves and use appropriate tools for

working on the machine.

•Only use the manufacturer's original spare parts.

2.5 Staff and operator qualification

•Persons with physical, sensory or mental handicaps or

persons with insufficient experience or knowledge must

not operate the machine unless a person in charge for

their safety acts as operation or instruction supervisor.

•People under the age of 16 must not operate the

machine.

•The operator's responsiveness must not be affected, e.g.

by drugs, alcohol or medications.

•The operator shall have been instructed in the operation

of the machine.

•The operator shall be familiar with the Operation Manual.

Tourno pick-up

Original Operation Manual English

- 5 -

2.6 Safety instructions

The operation manual and safety

instructions must be read and observed

prior to starting the machine.

Risk by flinging parts with running motor.

Keep a safety distance of 3m.

Fuel is extremely flammable and

explosive. Stop the motor and let it cool

down prior to fuelling.

Avoid slopes where the carrier might slip

or tilt. Slope line: 10° max.

Lateral inclination: 10° max.

Stop the motor and remove the key prior

to maintenance and repair work.

Riding on treads or platforms is not

permissible.

The max. load capacity of the tipping

trough of 25 kg must not be exceeded.

Do not access any slopes with an

inclination exceeding 2° when loaded.

2.7 Required protection equipment for operation

•Rugged footwear

•Close-fitting clothing

•Ear protection

•Safety gloves

2.8 Safety devices

•Do not remove any covers during operation.

•Immediately remedy any damage to safety devices.

2.9 Behaviour in case of fire

1. Stop immediately.

2. Stop the motor.

3. Leave the machine.

4. Remedy the risk situation.

2.10 Environmental protection

•Oils, fuels, greases and filters shall be disposed of

properly and separately in accordance with legal

regulations. Please do not dispose of any wastes in the

environment.

•Packaging materials are recyclable. Please make sure

that they are collected for reuse.

•Legacy devices contain valuable recyclable materials

which should be collected for reuse. These devices may

be disposed of through appropriate collection systems.

Tourno pick-up

Original Operation Manual English

- 6 -

3 Design and function

3.1 Brief description

The TOURNO pick-up is a machine used as carrier for Cramer mounting tools. For better road adhesion and traction, the machine

has a front-wheel drive and a double-axle drive for the four wheel drive version, respectively. The machine has an articulated

steering with a steering stool. The speed is controlled progressively by a hydrostatic drive. Various Cramer mounting tools may be

connected to the front and back of the TOURNO pick-up for different applications.

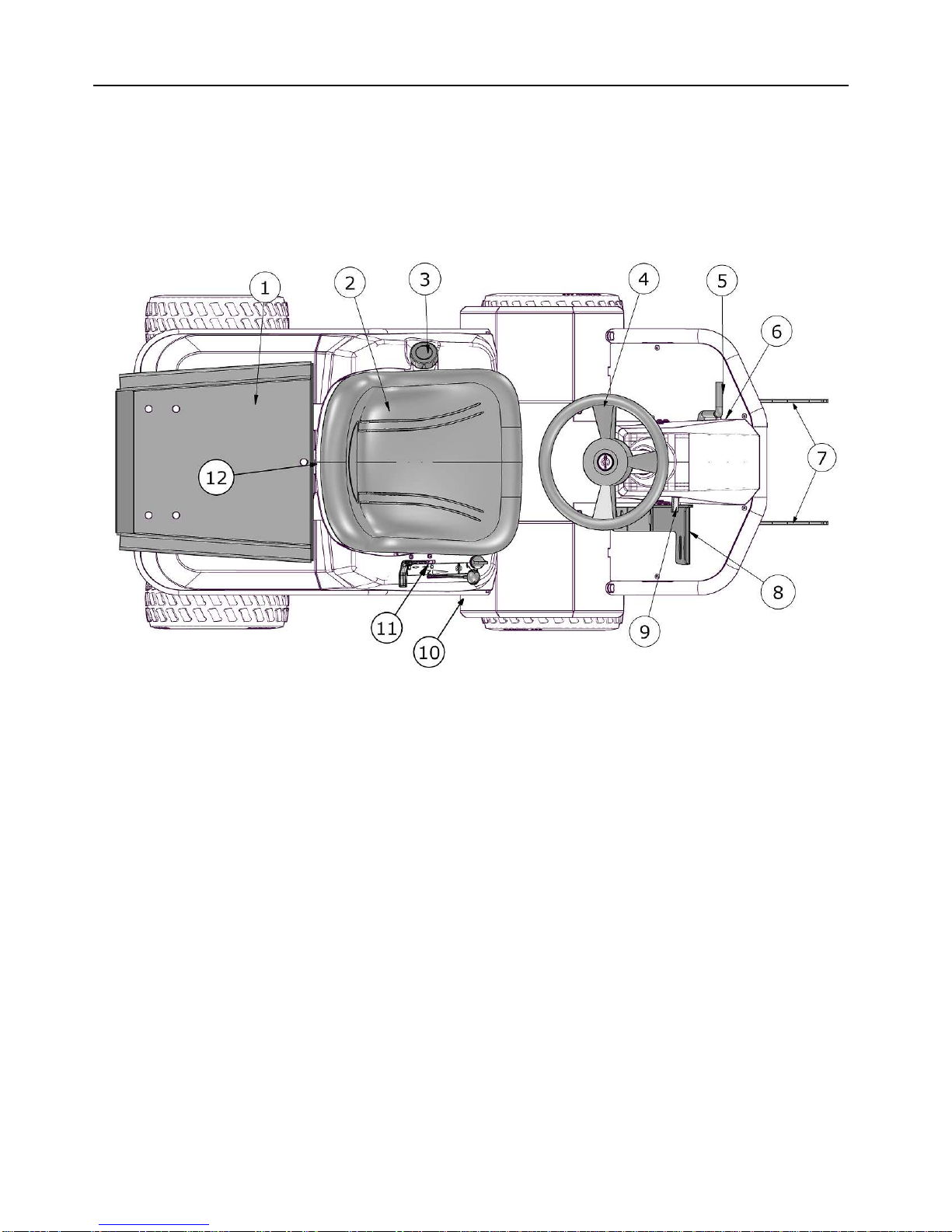

3.2 Overview

1

Tipping trough

2

Driver's seat

3

Tank/Tank lid

4

Steering wheel

5

Pedal for lifting and lowering the front device

6

Pedal locking

7

Receipt carrier for front devices

8

Accelerator pedal

9

Pedal unlocking

10

Motor-gear connection

11

Operating panel

12

Tipping trough twist lock

Tourno pick-up

Original Operation Manual English

- 7 -

3.3 Displays and operating elements

Operating panel

!

"#

#$##

%

&

#!'

(

(''

Note!

"#

Motor-gear connection

The lever is located behind the right front wheel.

)""!""#!'"*

#'#+

,-!!"

,#."####

Note!

-#""#*"

Accelerator pedal

###!!#

%+# upper

'

(+# lower

'

Tourno pick-up

Original Operation Manual English

- 8 -

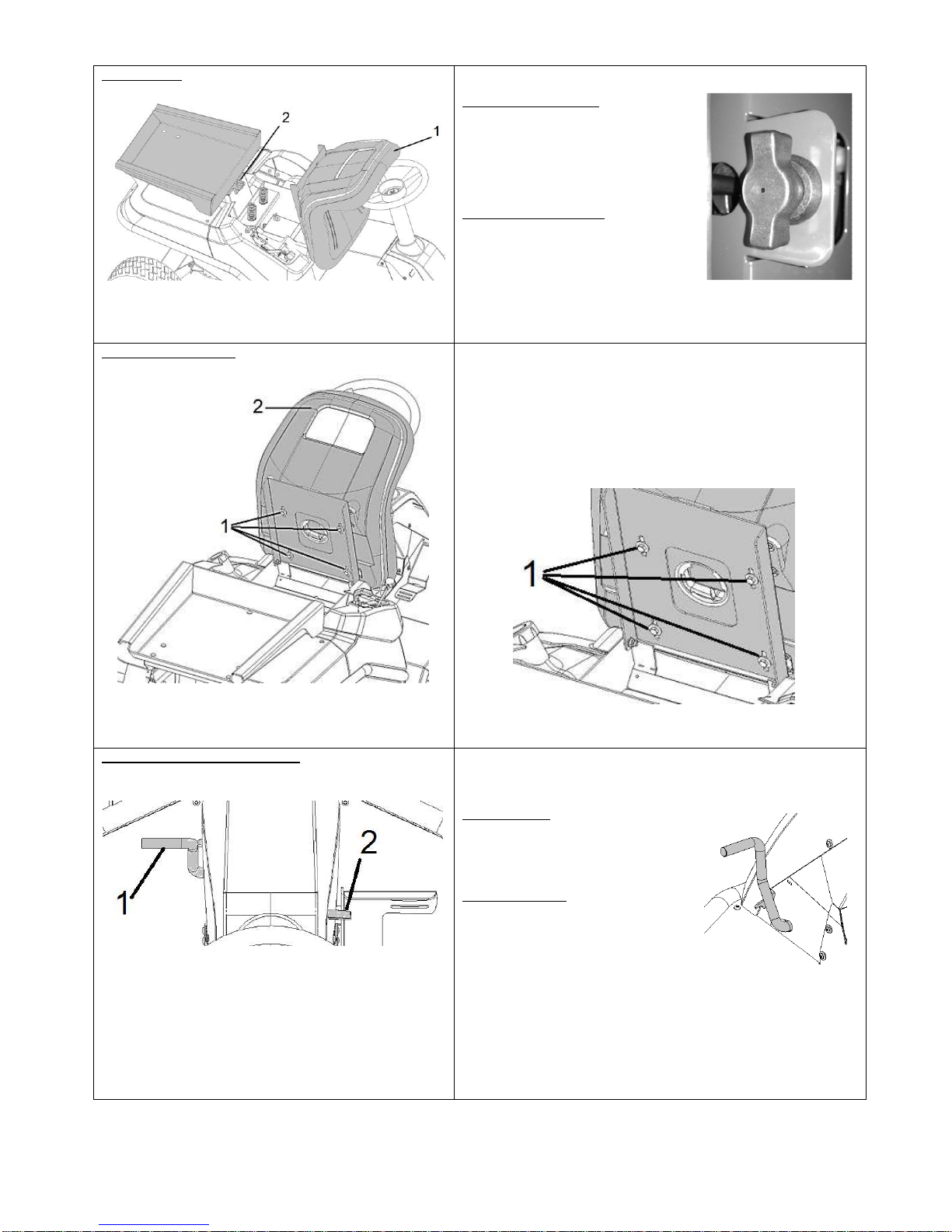

Tipping trough

Driver's seat

2Tipping trough twist lock

Lifting the tipping trough:

1. Tilt the driver's seat to the top

2. Turn the twist lock until the tipping

trough can be lifted.

3. You may now lift the tipping trough on

the driver's seat side.

Closing the tipping trough:

1. Completely lower the tipping trough

2. Turn the lock until the tipping trough is

fixed

3. Tilt the driver's seat back.

Driver's seat adjustment

1Hexagon bolt with washer

2Driver's seat

In order to adjust the driver's seat forward or backward, four bolts on the

bottom of the seat have to be loosened.

1. Tilt the driver's seat to the top

2. Slightly loosen all four bolts

3. Adjust the driver's seat and fix it in this position

4. Tighten the bolts again

5. Tilt the driver's seat back.

Lifting and lowering the front device

1Pedal for lifting and lowering the front device and locking the

lifted front device

2Pedal unlocking.

In order to lift or lower the front device, the following steps are to be

observed:

Lift front device:

1. Push the pedal downward with your

foot until it engages behind the

locking.

Lower front device:

1. Slightly push the pedal downward and

hold it.

2. Press the lever for unlocking until the

securing device disengages.

3. You may now slowly lift your foot until the mounting tools is

completely lowered.

Note!

Do not transfer the machine with lowered front device.

Tourno pick-up

Original Operation Manual English

- 9 -

eceiver points

789:7*up has two receiver points to mount Cramer accessory devices.

1Receiver point for trailer devices

2Receiver point for front devices

Tourno pick-up

Original Operation Manual English

- 10 -

3.4 Working position and areas of risk

Working position:

On the driver's seat

Areas of risk:

•Area of action in front of the machine

•Area of action behind the machine

3.5 Accessories and spare parts

Original parts

Only original spare parts and original accessories may be

used.

3.6 Transport

Transport without packaging

•Lift the front device first as appropriate

•Stop the machine.

•Subsequently activate the parking brake

•Finally fix the machine by using lashing straps.

3.7 Storage (short-term)

The machine:

•must not be stored in the open air.

•must not be exposed to aggressive materials.

•must be cleaned with a soft brush before being stored.

3.8 Storage (long-term)

The following recommendations will help to ensure the long-

standing functionality of your Cramer machines:

1. Ensure that fuels are prepared for long-term storage

(longer than 30 days), e.g. add fuel stabilizer.

2. Clean the machine - Important! Also clean the underfloor.

3. Renew motor oil

4. Treat spark plugs

5. Check machine for wear, repair paint damage

6. Store the TOURNO pick-up in a dry place.

Please refer to the attached motor operation manual for

instructions on how to care for the motor!

4 First commissioning (first inspection of the machine) after installation

Installation and first commissioning shall be performed by your authorized Cramer dealer.

4.1 Safety

Unauthorized restart

•It is prohibited to start the machine while another person

is working on it.

Risks of non-applied protection devices

WARNING !

Danger of injuries due to missing protective

covers!

Lack of covers may cause injuries by flinging materials.

Do not open or remove any covers during operation.

Requirements at location of use

•Only leave the machine on plane surfaces and solid

ground.

4.2 Assembly

Please refer to installation instructions in Annex before first

commissioning.

4.3 First commissioning and functional test

Prior to first commissioning, alls missing machine parts have

to be composed as indicated in the installation instruction.

Only then the following functional test shall be performed:

Machine start

1. Fill the fuel tank

2. Release parking brake

3. Check motor and oil level (see Motor Operation

Manual)

4. Set throttle to choke

5. Start machine / turn ignition key

6. After a short time, move throttle to FULL THROTTLE

position

7. If no functional failures occur until then, the machine is

ready for use.

Tourno pick-up

Original Operation Manual English

- 11 -

5 Operation

5.1 Start and stop

Start

1. Release parking brake

2. Set throttle to Choke

3. Put ignition key into ignition lock

4. Turn ignition key to Start

5. The machine is now running

6. After a short time, move throttle to Full throttle position

Stop

1. Set throttle to Idle

2. Turn ignition key to Stop

3. The machine is out of operation now

Emergency stop

•Turn ignition key to Stop

5.2 Normal operation

WARNING !

Risk of injuries by highly flammable

materials and heat!

Materials hitting a hot surface may result in serious burns

on the body when they inflame; e.g. hot or burning materials

such as coal.

Keep away highly flammable materials from the

machine.

Do not move the machine over any spilled fuel or similar

substances.

1. Basic setting:

•Park machine on an even surface

•Refill consumables

•Set throttle to Stop

•Fix mounting devices as required

2. Start the machine.

•Release parking brake

•Set throttle to Choke on operating panel

•Put ignition key into ignition lock and turn to Start to start

the machine

•Let the motor run for a short time

•Only then move throttle to Full throttle

•In the Full throttle position, accessories may be used.

Forward drive

Press the right upper part of the foot pedal downward

Backward drive

Press the right lower part of the foot pedal downward

3. Stop machine.

•Bring machine to a stop

•Set throttle to Idle

•Turn ignition key to Stop to put the machine out of

operation

•Remove ignition key

5.3 Activities after use

1. Stop the motor.

2. Roughly remove dirt and sand by using a soft hand

brush.

3. Check machine condition; remedy damage to paint

coating, if any

4. The machine must be left in a clean and dry condition.

Tourno pick-up

Original Operation Manual English

- 12 -

6 Maintenance

6.1 Safety

DANGER !

Risk of injury by inappropriately

performed maintenance work!

Defective work may result in serious bodily injuries and

damage to property.

Make sure that you have sufficient working space.

Disconnect spark plug connectors when working on

the machine

Place components separately.

Remount all components.

Remount all safety covers.

Keep the risk area clear of persons.

6.2 Maintenance work

6.2.1 Machine cleaning

The machine should be cleaned regularly so that damage to

the paint coating or plastic components can be detected.

Please observe the notes listed for cleaning in order to avoid

damage to the electronics.

1. Park machine on an even surface before cleaning it and

activate the parking brake.

2. Clean the machine with a soft brush.

3. Subsequently clean the machine with a damp cloth.

NOTE !

Machine damage!

Do not clean the machine with spray water.

6.2.2 Check safety precautions

Safety precautions comprise:

- Cover of blades and V-belts

- Covers of drive wheels

- Motor cover

The machine must not be operated if the covers show any

signs of damage or are removed. They are to be replaced in

case of damage or loss. The machine must not be started

without safety precautions.

ATTENTION!

Risk of injuries by combustion motors

Cleaning and repair work must never be carried out

during operation or when the machine runs idle, since this

may result in burns and cuts.

Stop machine and motor and let them cool down

Tourno pick-up

Original Operation Manual English

- 13 -

6.3 Maintenance plan

Maintenance Prior to each use Annually Intervals in hours

25 50 100 200

Cleaning X (Item 6.2.1)

Check safety precautions X (Item 6.2.2)

Check all screws for tight seat O

Check motor oil level B

Check air filter B

Clean or replace air filter (normal use) B

Clean or replace air filter (dusty conditions) B

Adjust tire pressure O

Check machine for damage or corrosion on paint

coating and remedy as appropriate O

Grease rotating points and joints O

Check machine for fuel or oil leaks O

Replace fuel filter B

Replace spark plugs B

X = Described in this Operation Manual in the indicated section.

O = Not described in the present Operation Manual

B = Description is enclosed in attached motor operation instructions.

7 Troubleshooting

7.1 Safety

Procedure for failures and accidents

1. Initiate emergency stop (leave working position).

2. Stop the machine.

3. Determine the failure cause.

4. Remedy failure or contact specialist dealer.

7.2 Service address

Please contact your sales consultant in case of failures,

problems or otherwise. Please always indicate the machine

serial no. in inquiries. (Please refer to nameplate on the

machine or on the Operation Manual cover).

.

7.3 First action for troubleshooting

Failure Cause / Remedy Notes

Motor will not start

Check tank filling level and refill as appropriate

Observe motor

manufacturer

Operation

Manual!

Check and adjust choke setting

Ignition plug failure →Clean ignition plug contacts or replace ignition plug

Fuel pump clogged →Check pump and clean fuel filter

Starter does not

move Check battery and load or refill as appropriate

Contact to battery poles insufficient →clean and grease poles

Motor is running

rough

Ignition plug failure →Clean ignition plug contacts or replace ignition plug

Notify authorized dealer if

failure persists.

Only use original spare

parts!

Clean air filter - See Maintenance

Clean fuel filter - See Maintenance

Battery cannot be

loaded sufficiently

Battery cells are damaged →Replace battery

Battery acid level too low →Refill distilled water

Contact problems, clean and grease poles

Drive performance

null or weak

Air in gear unit →Set both gear units to manual operation, start motor and push

accelerator pedal several times, both forward and backward (bleeding). In case of

insufficient remedy, please contact your authorized dealer.

Tourno pick-up

Original Operation Manual English

- 14 -

8 Technical data

Tourno pick-up

Machine data

Length x Width x Height, cm 185 x 97 x 110

Deadweight transport weight), kg 200

Drive speed

forward km/h

Backward km/h

6

4.5

Climbing power, max. ° 10

Climbing power with load, max. ° 2

Working width, cm 90

Power transmission Hydrostatic front drive

Motor

Model Briggs & Stratton

Intek

Engine size, cm³ 344 cm³

Max. motor speed, rpm 3200

Min. motor speed, rpm 3100

Net capacity KW/HP at 3600 rpm 13.5

Fuel type Petrol

Tank contents, litres Approx. 8.5

Motor oil type 10W-30

Motor oil filling quantity, litres 1.4

Tires

Drive wheel 15x6,00-6

Air pressure, bar 2.0

Wheel drive Front drive

Ambient conditions

Temperature, °C See Briggs & Stratton motor data

Working ground Green areas, asphalt, concrete, paving, industrial floors

Application area Normal use in facilities and landscaping maintenance

Noise emission

Guaranteed acoustic power level, dB 99

Sound pressure level at operator ear, dB 85

Hand-arm vibration, m/s² <2.5

Whole-body vibrations m/s² <0.5

Responsibility limits for components:

Motor Briggs & Stratton

Year of construction 2014

Tourno pick-up

Original Operation Manual English

- 15 -

9 Declaration of conformity

EU Declaration of conformity pursuant to machine directive 2006/42/EC Annex II 1-A

The authorized party with residence in the EU,

Cramer GmbH

Reimersstr. 36

26789 Leer

herewith declares, that the following product

Manufacturer:

Cramer GmbH

Reimersstr. 36

26789 Leer

Product designation:

Carrier vehicle

Make:

Cramer GmbH

Serial number:

see cover nameplate

Type(s):

TOURNO pick-up

complies with all relevant regulations of the above-stated Directive as well as all other applicable Directives - including their

amendments applicable at the date of this declaration.

The following other EU Directives were applied:

EMC Directive 2004/108/EC

EU Directive 2000/14/EC

The following harmonized standards were applied:

EN 836:1997+A4:2011

EN ISO 12100:2010

EN ISO 3744:2010

DIN EN ISO 5349-2:2001-12

ISO 2631-1:1997-05

Name and address of person authorized to compile the technical documentation:

Andre Schwarzkopf

Cramer GmbH

Reimersstraße 36

26789 Leer

Site:

Leer

Date:

04/03/2014

A. Bruns

A. Schwarzkopf

Managing Director

CE Officer

Tourno pick-up

Original Operation Manual English

- 16 -

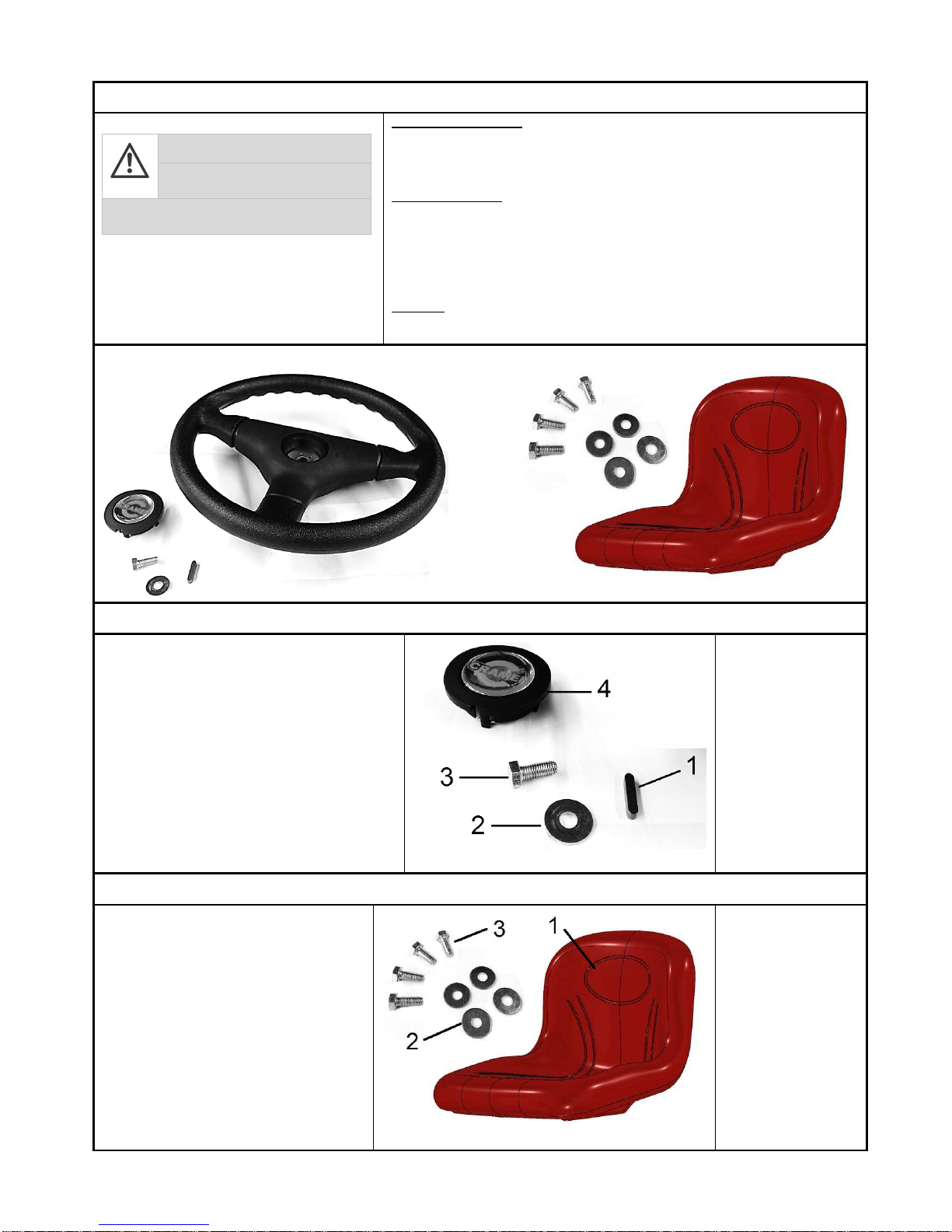

Installation prior to first commissioning (for authorized Cramer dealer)

Installation of driver's seat and steering wheel

Delivery, packaging, assembly

ATTENTION!

Squeezing hazard during

installation!

Parts of the body may be squeezed when

components are mounted.

Risk of high dead weight

•

The machine must not be lifted manually.

•

Pull machine from pallet.

•

Remove machine parts separately from packaging.

Transport inspection

•

Check the machine for completeness and potential damage upon delivery.

•

The machine shall be supplied to the specialist dealer in a partially assembled

condition.

•

Assembly and start-up have to be performed by a specialist dealer and/or an expert

in this field.

Packaging

•

Please dispose of packaging materials separately.

Overview

Fix steering wheel

1. Place the feather key into the groove on the

steering axle and hold it. Place the steering

wheel on the steering axle.

2. Place the washer on the opening in the centre

of the steering wheel.

3. Fix it by the hexagon bolt through the steering

wheel opening.

4. Position cap and press it on.

1. Feather key

2. Washer

3. Hexagon bolt

4. Cap

Fix driver's seat

1. Place driver's seat on seat base. The

openings under the seat and the base

must be flush. (Please also refer to no.

3.3, Driver's seat adjustment)

2. Place the washers on the hexagon bolts

and screw them into the openings under

the seat; tighten them.

1. Driver's seat

2. Washer

3. Hexagon bolt

This manual suits for next models

3

Table of contents