CRANE PUMPS & SYSTEMS BAF-1212 User manual

A Crane Co. Company

INSTALLATION and OPERATION MANUAL

Break Away Fitting For Submersible Pumps

IMPORTANT! Read all instructions in this manual before operating pump.

As a result of Crane Pumps & Systems, Inc., constant product improvement program,

product changes may occur. As such Crane Pumps & Systems reserves the right to

changeproductwithoutpriorwrittennotication.

420 Third Street 83 West Drive, Bramton

Piqua, Ohio 45356 Ontario, Canada L6T 2J6

Phone: (937) 778-8947 Phone: (905) 457-6223

Fax: (937) 773-7157 Fax: (905) 457-2650

www.cranepumps.com Form No. 780988-Rev. H

Models: Without Check Valve

Standard P/N “NS” P/N

127300 BAF-1212 127303

127301 BAF-1220 127311

127302 BAF-2020 127312

127306 BAF-2030 127305

127304 BAF-3030 127314

Models: With Check Valve

Standard P/N “NS” P/N

127307 BAF-1212CV 127310

127308 BAF-1220CV 127313

127309 BAF-2020CV 127315

2

Other brand and product names are trademarks or registered trademarks of their respective holders.

® Barnes is a registered trademark of Crane Pumps & Systems, Inc.

1997, 1998, 2002, 2/06, 9/06 Alteration Rights Reserved

TABLE OF CONTENTS

SAFETY FIRST............................................................................................... 3

A. SPECIFICATION..............................................................................................4

B. GENERAL INFORMATION ..............................................................................5

C. Installation/Dimensions .................................................................................... 5

BAF-1212, 1220, 2020.....................................................................................6

BAF-1212CV, BAF-1220CV, BAF-2020CV ......................................................7

BAF-2030 ...................................................................................................8

BAF-3030 ...................................................................................................9

D. Sectional & Parts List BAF 1212, 1220, 2020..................................................10 - 11

Sectional & Parts List BAF-CV 2030, BAF-CV 3030........................................12 - 13

RETURNED GOODS POLICY.........................................................................14

WARRANTY

REGISTRATION

3

Please Read This Before Installing Or Operating Pump.

This information is provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help recognize this information,

observe the following symbols:

IMPORTANT! Warns about hazards that can result

in personal injury orIndicates factors concerned with

assembly, installation, operation, or maintenance which

could result in damage to the machine or equipment if

ignored.

CAUTION! Warns about hazards that can or will cause minor

personal injury or property damage if ignored. Used with symbols

below.

WARNING! Warns about hazards that can or will cause serious

personal injury, death, or major property damage if ignored. Used

with symbols below.

Only qualied personnel should install, operate and repair

pump. Any wiring of pumps should be performed by a qualied

electrician.

WARNING ! To reduce risk of electrical shock, pumps and

control panels must be properly grounded in accordance

with the National Electric Code (NEC) or the Canadian

Electrical Code (CEC) and all applicable state, province,

local codes and ordinances. Improper grounding voids

warranty.

WARNING! To reduce risk of electrical shock, always

disconnect the pump from the power source before

handling or servicing. Lock out power and tag.

WARNING! Operation against a closed

discharge valve will cause premature bearing

and seal failure on any pump, and on end

suction and self priming pump the heat build

may cause the generation of steam with resulting dangerous

pressures. It is recommended that a high case temperature

switch or pressure relief valve be installed on the pump body.

CAUTION ! Never operate a pump with a plug-in type

power cord without a ground fault circuit interrupter.

CAUTION ! Pumps build up heat and pressure

during operation-allow time for pumps to cool

before handling or servicing.

WARNING ! Do not pump hazardous materials

(ammable, caustic, etc.) unless the pump is specically

designed and designated to handle them.

CAUTION ! Do not block or restrict discharge hose, as

discharge hose may whip under pressure.

WARNING ! Do not wear loose clothing that may

become entangled in moving parts.

WARNING ! Keep clear of suction and discharge

openings. DO NOT insert ngers in pump with power

connected.

Always wear eye protection when working on pumps.

Make sure lifting handles are securely fastened each

time before lifting. DO NOT operate pump without safety

devices in place. Always replace safety devices that

have been removed during service or repair. Secure the

pump in its operating position so it can not tip over, fall

or slide.

DO NOT exceed manufacturers recommendation for

maximum performance, as this could cause the motor

to overheat.

DO NOT remove cord and strain relief. DO NOT connect

conduit to pump.

WARNING ! Cable should be protected at all times to

avoid punctures, cut, bruises and abrasions. Inspect

frequently. Never handle connected power cords with

wet hands.

WARNING ! To reduce risk of electrical shock, all wiring

and junction connections should be made per the NEC

or CEC and applicable state or province and local

codes. Requirements may vary depending on usage

and location.

WARNING! Submersible Pumps are not approved for

use in swimming pools, recreational water installations

decorative fountains or any installation where human

contact with the pumped uid is common.

WARNING! Products returned must be cleaned,

sanitized, or decontaminated as necessary prior

to shipment, to insure that employees will not be

exposed to health hazards in handling said material. All

Applicable Laws And Regulations Shall Apply.

Bronze/brass and bronze/brass tted pumps may

contain lead levels higher than considered safe for

potable water systems. Lead is known to cause cancer

and birth defects or other reproductive harm. Various

government agencies have determined that leaded

copper alloys should not be used in potable water

applications. For non-leaded copper alloy materials of

construction, please contact factory.

Crane Pumps & Systems, Inc. is not responsible

for losses, injury, or death resulting from a failure to

observe these safety precautions, misuse or abuse of

pumps or equipment.

SAFETY FIRST!

Hazardous uids can

cause re or explo-

sions, burnes or death

could result.

Extremely hot - Severe

burnes can occur on contact.

Biohazard can cause

serious personal injury.

Hazardous uids can Hazard-

ous pressure, eruptions or ex-

plosions could cause personal

injury or property damage.

Rotating machinery

Amputation or severe

laceration can result.

Hazardous voltage can

shock, burn or cause death.

4

Each BAF break away tting consists of a cast iron base

elbow which is bolted to the oor of the wet well, lower

guide rail supports, cast iron movable elbow (BAF-CV’s

include ap check valve and clean-out cap), which is free

to ride up and down the guide rails. A sealing plate with

o-ring seat is used to connect moveable elbow to the base

elbow.

The guide rail and lifting chain (supplied separately)

are attached to the base elbow at one end and to a

stainless steel Upper Rail support, which is attached to

the underside of the wet well cover at the other end or the

wall. The guide rails serve only to guide, they carry none

of the pump weight. 1” (25mm) schedule 40 Galvanized

or Stainless Steel should be used for guide rails.

An optional intermediate guide pipe bracket should be

used for depths of 13 feet (4M) or more.

The BAF’s can basically be used on any pump with the

appropiate discharge size that does not exceed 200

lbs (91kg) in weight, or operate above 150 ft. TDH (45

Meters).

Quantity of One BAF (1) each for Simplex and Two (2) for

Duplex.

Assemblies DO NOT include Pump, Discharge piping,

Guide Rails, Lifting Chain, nor Gate Valve with Handle.

Available: Stainless Steel Lifting Chain, Intermediate Pipe

Support Bracket.

SECTION: A - SPECIFICATIONS:

Stainless Steel Intermediate Rail Support

Must be Ordered Separately

BAF

Model #

Intermediate

Rail Support

P/N

Dim

“A”

Dim

“B”

Dim

“C”

BAF-1212 750940 5.25” 2.75” 1.25”

BAF-1220 750941 5.25” 2.75” 1.25”

BAF-2020 750941 5.25” 2.75” 1.25”

BAF-2030 750944 6.25” 2.75” 1.25”

BAF-3030 750944 6.25” 2.75” 1.25”

BAF-1212CV 750940 5.25” 2.75” 1.25”

BAF-1220CV 750941 5.25” 2.75” 1.25”

BAF-2020CV 750941 5.25” 2.75” 1.25”

5

SECTION: B - GENERAL INFORMATION

B-1) Introduction:

Crane Pumps & Systems Break Away Fittings (BAF) are

precision engineered and manufactured of the highest

quality castings. Each one is individually inspected by a

Quality Assurance Program to allow years of continuous

service.

Through proper installation this unit will provide superior

service. This manual will provide basic information for

installation, maintenance, and repair.

B-2) Receiving:

Upon receiving this unit, inspect it for damage or

shortages. If damage has occurred, le a claim

immediately with the delivery company that delivered your

equipment. If the manual is removed from the crating, do

not lose or misplace it.

B-3) Storage:

This unit has been packaged and protected for shipping

and indoor storage. If it is to be stored outside for an

extended period, additional protection must be added.

Short Term - For best results, retain BAF factory

assembled, in a dry atmosphere with constant temperature

for up to six (6) months.

Long Term - Any length of time exceeding six (6) months,

but not more than twenty four (24) months. The units

should be stored in a temperature controlled area, a roofed

over walled enclosure that provides protection from the

elements (rain, snow, wind blown dust, etc..), and whose

temperature can be maintained between +40 deg. F and

+120 deg. F. If extended high humidity is expected to be

a problem, all exposed parts should be inspected before

storage and all surfaces that have the paint scratched,

damaged, or worn should be recoated. All surfaces should

then be sprayed with a rust-inhibiting oil.

B-4) Service Centers:

For the location of the nearest Barnes Service Center, check

your Barnes representative or Crane Pumps & Systems, Inc.,

Service Department in Piqua, Ohio, telephone (937) 778-8947

or in Brampton, Ontario, Canada (905) 457-6223.

SECTION: C INSTALLATION

C-1) Location:

The Break Away Fitting, when used in conjunction with

Barnes Submersible Sewage Pumps is recommended for

operation in a non-hazardous wet well, tank, or lift station.

WARNING ! - UNIT NOT RECOMMENDED FOR

OPERATION IN CLASS 1, GROUP D, DIVISION

1 HAZARDOUS LOCATION WET WELL, BASIN,

OR LIFT STATION.

C-2) Design Layout:

See the dimensional drawings on the following pages for

the required anchor bolt locations for the stationary elbow

to be installed with four anchor bolts set in a metal sleeve

and accurately set into concrete. Hook bolts can be used,

however, they are more difcult to locate in concrete. Use

required shims under the stationary elbow base to level

the horizontal ange and then grout under the base as

required. A 30 day concrete cure is required before a full

load can be applied to the anchor bolts.

The 1” schedule 40 guide rail pipes must be plumbed

after mounting on stationary base elbow. Pipe material

may be galvanized steel or stainless steel (optional from

manufacturer or supplied by customer).

C-3) Intermediate Support Assembly:

Whenever the guide pipe lengths exceed 13 feet, an

intermediate guide rail support bracket should be used.

The intermediate guide rail support brackets may be

supported from the vertical discharge pipe. (Intermediate

supplied separately as optional item).

C-4) Installing Pump To Break Away Fitting:

See the following diagrams for installation guidelines that

apply to vertical discharge pumps ONLY.

C-5) Thread Locking Compound:

Thread locking compound can be purchased locally

in small quantities. When used, they provide an extra

assurance the bolted joint will remain together. These

Anaerobic Adhesive/Sealant Thread Locking compounds

are available in several grades from several suppliers and

recommendations are as follows:

DESCRIPTION LOCTITE® PERMA-LOC® STALOC®

Thread Locking

Compound #242

(General Purpose)

242 MM5 T42

Thread Locking

Compound

#RC609

(High Strength)

RC609 HM128 T70

6

Model: BAF-1212, 1220, 2020

7

Model: BAF-1212CV, 1220CV, 2020CV

8

Model: BAF-2030

9

Model: BAF-3030

10

Series: BAF & BAF-CV, 1¼& 2” Discharge

11

Part No. Model No. Inlet Discharge Item #10 Item #18 Item #18

Material

127300 BAF-1212 1¼” 1¼” 300211 780695DI Ductile Iron

127301 BAF-1220 1¼” 2” 300212 780695DI Ductile Iron

127302 BAF-2020 2” 2” 300212 780695DI Ductile Iron

127303 BAF-1212NS 1¼” 1¼” 300211 780695AB Bronze

127307 BAF-1212CV 1¼” 1¼” 300211 780695DI Ductile Iron

127308 BAF-1220CV 1¼” 2” 300212 780695DI Ductile Iron

127309 BAF-2020CV 2” 2” 300212 780695DI Ductile Iron

127310 BAF-1212CVNS 1¼” 1¼” 300211 780695AB Bronze

127311 BAF-1220NS 1¼” 2” 300212 780695AB Bronze

127312 BAF-2020NS 2” 2” 300212 780695AB Bronze

127313 BAF-1220CVNS 1¼” 2” 300212 780695AB Bronze

127315 BAF-2020CVNS 2” 2” 300212 780695AB Bronze

Parts List: BAF

Parts List

Item

No. Qty. Part No. Description Material

1 1 127085 Nameplate S.S.

2 2 001628 Drive Screw, #4, .187” S.S.

3 2 127292 O-Ring, -211 Buna

4 1 780682 Base Elbow, 2” Cast Iron

5 4 1-73-1 Hexhead Screw, ½-13 x 2.25” LG. 18-8 S.S.

6 4 20-12-1 Split Lock Washer, ½” 18-8 S.S.

7 4 15-6-1 Hex Nut, ½-13 18-8 S.S.

9 1 0007272 Flange Gasket, 2” Rubber

10 1 See Chart Companion Flange Cast Iron

11 1 780685 Pipe Guide Upper Bracket D.I.

12 2 780686 Guide Plug S.S.

13 2 11-63-1 Socket Head Screw, ⅜-16 x 1.25” LG 18-8 S.S.

14 5 20-14-1 Split Lock Washer, ⅜” 18-8 S.S.

15 1 085666 Eye Bolt, ⅜-16 x 1.00” S.S.

16 1 M-5329 O-Ring, -334 Buna

18 1 See Chart Sliding Elbow, 2”

19 1 625-01555 O-Ring, -229 18-8 S.S.

20 1 780740 Clamp, 1¼ - 2” S.S.

21 3 20607-A Socket Head Screw, ⅜-16 x 1.50” S.S.

22 1 780743 Flanged Nipple, 1¼” x 8” LG S.S.

23 1 740269 Lifting Chain S.S.

24 1 780747 Flanged Nipple, 1¼” x 2.50” LG S.S.

25 1 101337 Check Valve, 1¼” BRZ.

26 1 137956 Nipple, 1¼” X 4½” S.S.

27 1 780744 Flanged Nipple, 2” x 8.00” LG S.S.

28 1 780748 Flanged Nipple, 2” x 2.50” LG S.S.

29 1 101337A Flap Check Valve, 2” S.S.

30 1 075478 Close Nipple, 2” S.S.

31 3 740220 Shackle, 5/16”S.S.

12

Series: BAF, 3” Discharge

13

Part No. Model No. Inlet Discharge Item #18 Item #18

Material

127304 BAF-3030 3” 3” 780696DI Ductile Iron

127305 BAF-2030NS 2” 3” 780696AB Bronze

127306 BAF-2030 2” 3” 780696DI Ductile Iron

127314 BAF-3030NS 3” 3” 780696AB Bronze

Parts List: BAF

Parts List

Item

No. Qty. Part No. Description Material

1 1 127085 Nameplate S.S.

2 2 001628 Drive Screw, #4, .187” S.S.

3 2 127292 O-Ring, -211 Buna

4 1 780684 Base Elbow, 3” Cast Iron

5 4 1-96-1 Hexhead Screw, ⅝-11 x 2.50” LG. 18-8 S.S.

6 4 20-24-1 Split Lock Washer, ⅝” 18-8 S.S.

7 4 15-21-1 Hex Nut, ⅝-11 18-8 S.S.

9 1 0007200 Flange Gasket, 3” Rubber

10 1 780671 Companion Flange, 3” Cast Iron

11 1 780685 Pipe Guide Upper Bracket D.I.

12 2 780686 Guide Plug S.S.

13 2 11-63-1 Socket Head Screw, ⅜-16 x 1.25” LG 18-8 S.S.

14 6 20-14-1 Split Lock Washer, ⅜” 18-8 S.S.

15 1 085666 Eye Bolt, ⅜-16 x 1.00” S.S.

16 1 2-31003-342 O-Ring, -342 Buna

18 1 See Chart Sliding Elbow, 3”

19 1 625-01552 O-Ring, -238 Buna

20 1 780741 Clamp, 3” S.S.

21 4 20607-A Socket Head Screw, ⅜-16 x 1.50” 18-8 S.S.

22 1 780746 Flanged Nipple, 3” x 2.87” LG S.S.

23 1 740269 Lifting Chain S.S.

24 1 780745 Flanged Nipple, 2” x 3.50” LG S.S.

25 1 780742 Clamp, 2” S.S.

26 3 740220 Shackle, 5/16”S.S.

IMPORTANT!

WARRANTY REGISTRATION

Your product is covered by a warranty:

www.cranepumps.com/downloadables/CATALOGS_OIPMs/Warranty/24MonthWarranty.pdf

If you have a claim under the provisions of the warranty, contact your local

Crane Pumps & Systems, Inc. Distributor.

RETURNED GOODS

RETURN OF MERCHANDISE REQUIRES A “RETURNED GOODS AUTHORIZATION”.

CONTACT YOUR LOCAL CRANE PUMPS & SYSTEMS, INC. DISTRIBUTOR.

Products Returned Must Be Cleaned, Sanitized,

Or Decontaminated As Necessary Prior To Shipment,

To Insure That Employees Will Not Be Exposed To Health

Hazards In Handling Said Material. All Applicable Laws

And Regulations Shall Apply.

IMPORTANT!

WARRANTY REGISTRATION

Your product is covered by the enclosed Warranty.

If you have a claim under the provision of the warranty, contact your local

Crane Pumps & Systems, Inc. Distributor.

Notes

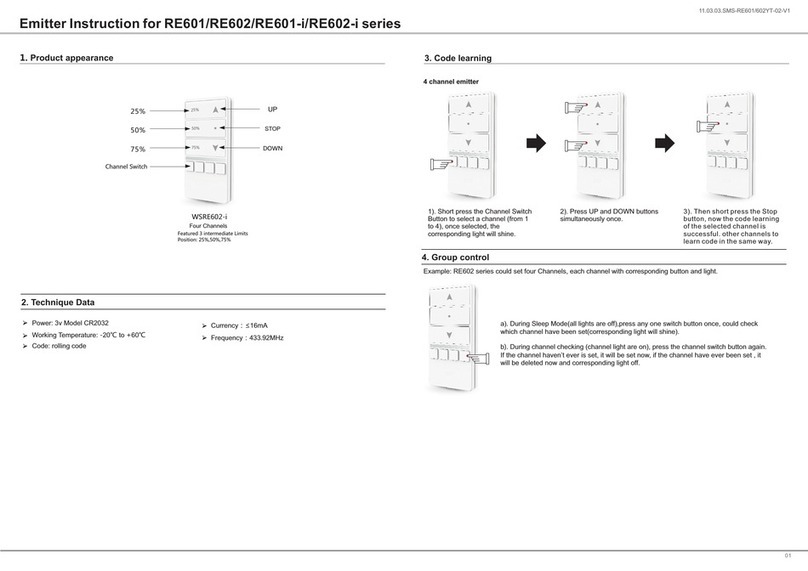

This manual suits for next models

22

Table of contents

Popular Control Unit manuals by other brands

Wistar

Wistar WSRE602-i instructions

Samson

Samson 36-8 Mounting and operating instructions

THE BOLD LOOK OF KOHLER

THE BOLD LOOK OF KOHLER K-10970 installation guide

Crystal Vision

Crystal Vision Indigo AVDELAY 3G user manual

M-system

M-system R3-NF1 instruction manual

Allmatic

Allmatic CT3IND Manual for installation

Yamaha

Yamaha Disklavier DKC55RCD XG Mark III Service manual

Atheros

Atheros AR5BXB61 manual

Telit Wireless Solutions

Telit Wireless Solutions SE867-AGPS user guide

VAT

VAT 162 Series Installation, operating, & maintenance instructions

Centrometal

Centrometal Cm-SOL Technical instructions

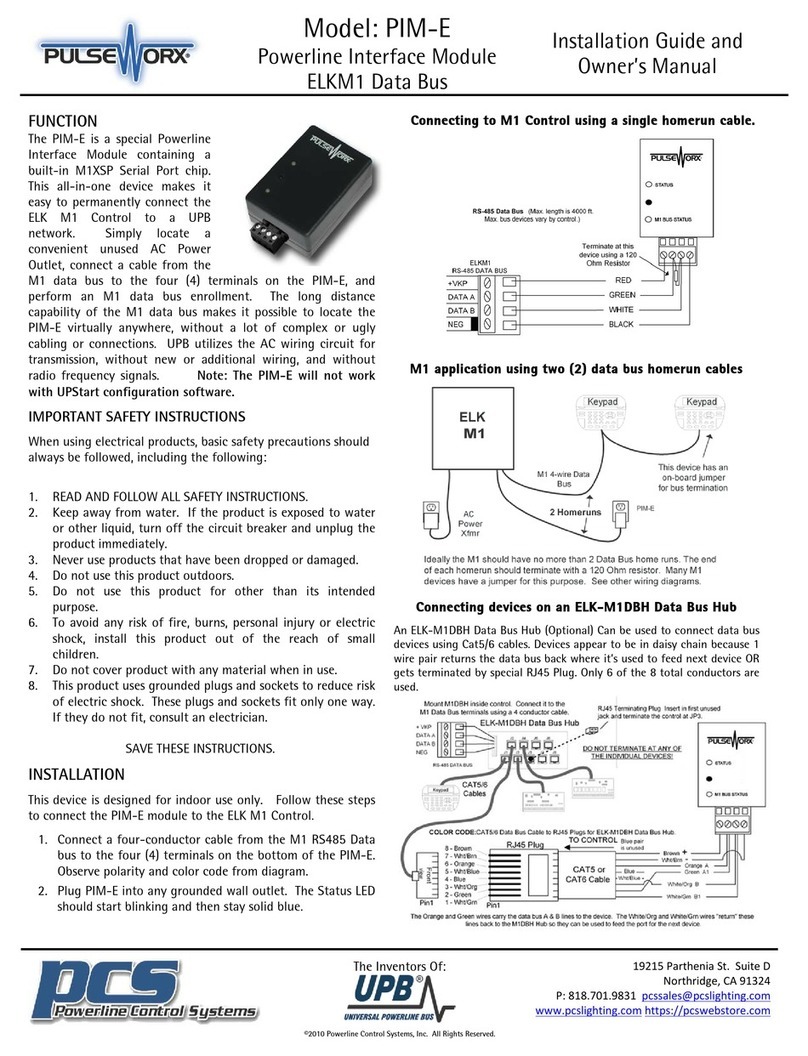

PulseWorx

PulseWorx PIM-E Installation guide and owner's manual