4

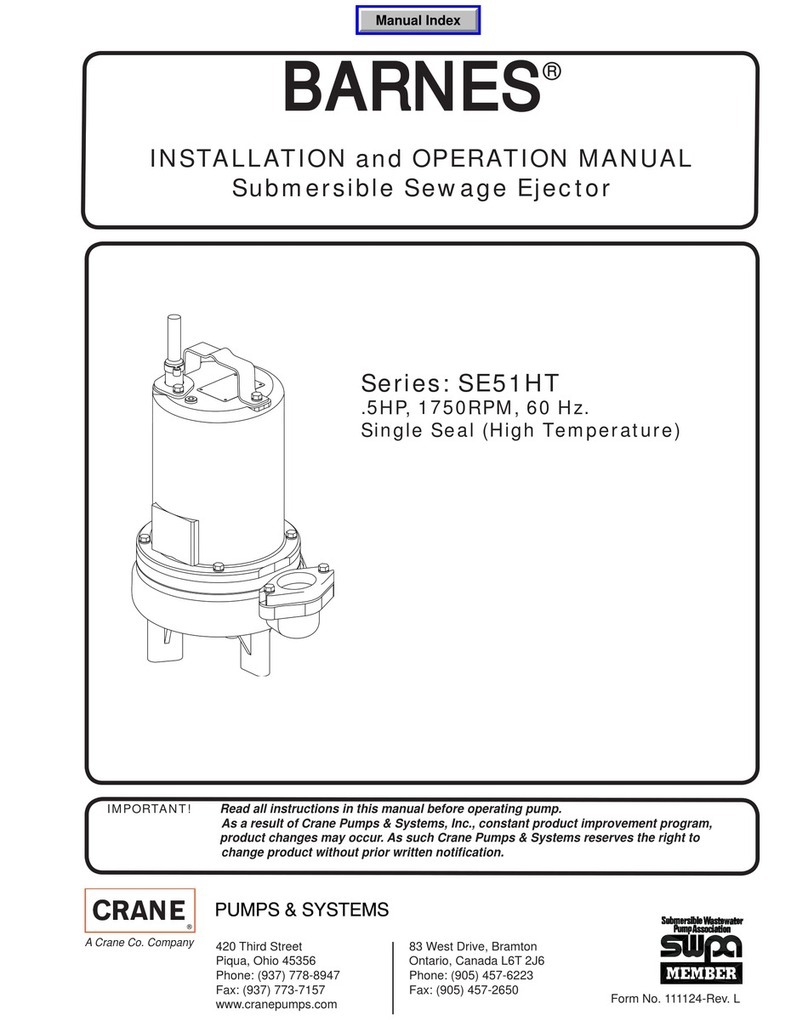

DISCHARGE.............2” NPT, Female, Vertical, Bolt-on Flange

LIQUID TEMPERATURE:

Standard............104°F (40°C) Continuous

High Temp .........200°F (93°C) Continuous

VOLUTE....................Cast Iron ASTM A-48, Class 30

MOTOR HOUSING ...Cast Iron ASTM A-48, Class 30

SEAL PLATE ...........Cast Iron ASTM A-48, Class 30

IMPELLER:

Design ...............2 Vane, open, with pump out vanes on

back side. Dynamically balanced, ISO G6.3

Material .............Cast Iron ASTM A-48, Class 30

SHAFT.......................416 Stainless Steel

SQUARE RINGS.......Buna-N

HARDWARE .............300 Series Stainless Steel

PAINT ........................Air Dry Enamel

SEAL:

Design ..............Single Mechanical

Material..............Carbon/Ceramic/Buna-N

Hardware -300 Series Stainless

CORD ENTRY...........15 ft. (5 m), 20ft. (6.1 m) Cord with plug

on 120 volt & .5HP, 240 volt, 1 phase.

Quick connect custom molded for sealing

and strain relief

SPEED ......................1750 RPM (Nominal)

UPPER BEARING.....Single Row, Ball, Oil lubricated

Load...................Radial

LOWER BEARING....Single Row, Ball, Oil lubricated

Load...................Radial & Thrust

MOTOR:

Design ..............NEMA L -Single Phase, NEMA B -Three

phase Torque Curve, Oil Filled, Squirrel

Cage Induction

Insulation ...........Class B, Class F for High Temp.

Class F on selected models

SINGLE PHASE........Permanent Split Capacitor (PSC)

Includes Overload Protection in Motor

THREE PHASE.........200-240/480 is Tri-Voltage notor 600V.

Requires overload Protection to be

included in control panel

LEVEL CONTROL ...."A" - Wide Angle, PVC, Mechanical,

20 ft (6.1m) cord with Piggy-Back Plug, N/O

"AU"- Wide Angle, Polypropylene,

Mechanical, N/O Integral to pump.

ON and OFF Points are adjustable

OPTIONAL EQUIPMENT Seal Material, Impeller Trims,

Additional cord, Normally Closed Temperature Sensors with

cord for 3 phase pumps (Requires relay in control panel),

*Inlet Strainer for High Temperature Models.

(*) 3/4” Spherical solids handling with optional inlet stainer.

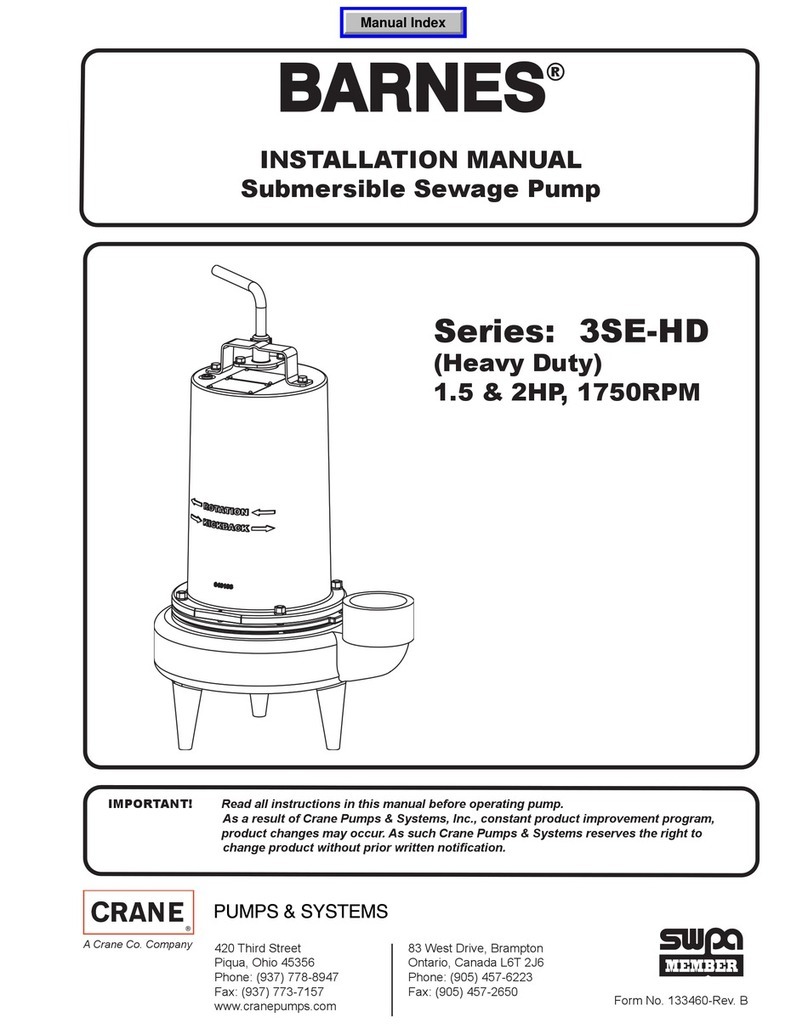

DISCHARGE ............3” NPT, Female, Vertical, Bolt-on Flange

LIQUID TEMP ...........104°F (40°C) Continuous

VOLUTE....................Cast Iron ASTM A-48, Class 30

MOTOR HOUSING ...Cast Iron ASTM A-48, Class 30

SEAL PLATE ...........Cast Iron ASTM A-48, Class 30

IMPELLER:

Design ...............2 Vane, open, with pump out vanes on

back side. Dynamically balanced, ISO G6.3

Material .............Cast Iron ASTM A-48, Class 30

SHAFT .....................416 Stainless Steel

SQUARE RINGS.......Buna-N

HARDWARE .............300 Series Stainless Steel

PAINT ........................Air Dry Enamel

SEAL:

Design ..............Single Mechanical or Tandem Mechanical

with Oil Filled Reservoir

Material..............Carbon/Ceramic/Buna-N

Hardware -300 Series Stainless

CORD ENTRY............. 15 ft. (5 m), 20 ft. (6.1 m) Cord. Plug on

120 Volt & .5HP. 240 Volt 1 Phase Quick

connect custom molded for sealing

and strain relief

SPEED ......................1750 RPM (Nominal)

UPPER BEARING.....Single Row, Ball, Oil lubricated

Load...................Radial

LOWER BEARING....Single Row, Ball, Oil lubricated

Load...................Radial & Thrust

MOTOR:

Design ..............NEMA L -Single Phase, NEMA B -Three

phase Torque Curve, Oil Filled, Squirrel

Cage Induction

Insulation ...........Class B

Class F on selected models

SINGLE PHASE........Permanent Split Capacitor (PSC)

Includes Overload Protection in Motor

THREE PHASE ............200-240/480 is Tri-Voltage. 600V. Requires

Overload Protection to be included in

control panel

OPTIONAL EQUIPMENT..... Seal Material, Impeller Trims,

Additional cord, Normally Closed Temperature Sensors with

cord for 3 phase pumps (Requires relay in control panel),

Normally Open Moisture Sensor with cord for DS pumps.

SECTION: A - PUMP SPECIFICATIONS:

2” Pumps (Standard & High Temperature) 3” Pumps

IMPORTANT ! - Standard Temperature

1.) PUMP MAY BE OPERATED “DRY” FOR EXTENDED PERIODS WITHOUT

DAMAGE TO MOTOR AND/OR SEALS.

2.) THIS PUMP IS NOT APPROPRIATE FOR THOSE APPLICATIONS

SPECIFIED AS CLASS I DIVISION I HAZARDOUS LOCATIONS.

3.) INSTALLATIONS SUCH AS DECORATIVE FOUNTAINS OR WATER

FEATURES PROVIDED FOR VISUAL ENJOYMENT MUST BE INSTALLED

IN ACCORDANCE WITH THE NATIONAL ELECTRIC CODE ANSI/NFPA 70

AND/OR THE AUTHORITY HAVING JURISDICTION. THIS PUMP IS NOT

INTENDED FOR USE IN SWIMMING POOLS, RECREATIONAL WATER

PARKS, OR INSTALLATIONS IN WHICH HUMAN CONTACT WITH

PUMPED MEDIA IS A COMMON OCCURRENCE.

IMPORTANT ! - High Temperature

1.) PUMP MAY BE OPERATED “DRY” FOR EXTENDED PERIODS WITHOUT

DAMAGE TO MOTOR AND/OR SEALS.

2.) INSTALLATIONS SUCH AS DECORATIVE FOUNTAINS OR WATER

FEATURES PROVIDED FOR VISUAL ENJOYMENT MUST BE INSTALLED

IN ACCORDANCE WITH THE NATIONAL ELECTRIC CODE ANSI/NFPA

70 AND/OR THE AUTHORITY HAVING JURISDICTION. THIS PUMP IS

NOT INTENDED FOR USE IN SWIMMING POOLS, RECREATIONAL

WATER PARKS, OR INSTALLATIONS IN WHICH HUMAN CONTACT WITH

PUMPED MEDIA IS A COMMON OCCURRENCE.

3.) MUST USE A HIGH TEMPERATURE WIDE ANGLE LEVEL CONTROL IN

HIGH TEMPERATURE APPLICATIONS.