5

SECTION B: GENERAL INFORMATION

B-1) To the Purchaser:

Congratulations! You are the owner of one of the finest pumps

on the market today. These products are engineered and

manufactured of high quality components. Over one hundred

years of pump building experience along with a continuing

quality assurance program combine to produce a pump which

will stand up to the toughest applications.

This manual will provide helpful information concerning

installation, maintenance, and proper service guidelines.

B-2) Receiving:

Upon receiving the pump, it should be inspected for damage

or shortages. If damage has occurred, file a claim immediately

with the company that delivered the pump. If the manual is

removed from the packaging, do not lose or misplace.

B-3) Storage:

Short Term- Pumps are manufactured for efficient

performance following short inoperative periods in storage.

For best results, pumps can be retained in storage, as factory

assembled, in a dry atmosphere with constant temperatures

for up to six (6) months.

Long Term - Any length of time exceeding six (6) months, but

not more than twenty-four (24) months. The units should be

stored in a temperature controlled area, a roofed over walled

enclosure that provides protection from the elements (rain,

snow, wind-blown dust, etc.), and whose temperature can be

maintained between +40 deg. F and +120 deg. F.

If extended high humidity is expected to be a problem, all

exposed parts should be inspected before storage and all

surfaces that have the paint scratched, damaged, or worn

should be recoated with a water base, air dry enamel paint. All

surfaces should then be sprayed with a rust-inhibiting oil.

Pump should be stored in its original shipping container. On

initial start up, rotate impeller by hand to assure seal and

impeller rotate freely.

B-4) Service Centers:

For the location of the nearest Prosser Service Center, check with

your Prosser representative or Crane Pumps & Systems, Inc.,

Service Department in Piqua, Ohio, telephone (937) 778-8947. or

Crane Pumps & Systems Canada, Inc., Bramton, Ontario,

(905) 457-6223

SECTION C: INSTALLATION

C-1) Location:

These pumping units are designed for use with hydraulic

systems in locations where electrical connections are

unavailable or hazardous. Before pumping fluids other than

water, consult the factory, giving fluid, fluid temperature,

specific gravity, viscosity, capacity in USGPM and total head

and/or pressure requirements, including friction loss through

discharge line, fittings, valves, etc. Maximum fluid temperature

for sustained operation is 140°F (60°C) at specific gravity 1.0.

Pump may operate up to 10 minutes running dry (not pumping

water) without damage. DO NOT allow pump to be buried in

mud or sand.

IMPORTANT ! - Pump should have strainer

affixed at all times. Inspect and clean the pump

strainer periodically for maximum efficiency and

performance.

C-2) Discharge:

Discharge hose is recommended. If rigid pipe is used, install

so that there is no weight or strain on the pump. Install a short

pipe nipple into the pump discharge to attach the discharge

hose above the hydraulic connections at the top of the pump.

Save and replace the plastic shipping plugs in the hydraulic

line connection at the top of the pump whenever the hydraulic

lines are disconnected. This is to protect against damage to

the connections and entrance of dirt.

C-3) Suction:

Completely submerge the suction strainer for maximum

pumping efficiency.Avoid entrance of air into the suction of the

pump. Strainer should always be installed on the pump while

operating.

C-4) Liquid Level Controls: (If Applicable)

Attach “ON” float to discharge hose or pump cable at desired

pump “ON” level. Attach “OFF” float to discharge hose or pump

cable at desired pump “OFF” level. The “OFF” float must be

below the “ON” float. To attach the floats, thread the cable

strap through the buckle with the ratchet pawl, cinch up tight,

thread excess strapping through outer buckle slot. Be certain

that the level controls cannot hang up or foul in its swing. It is

recommended that the pump is completely submerged when

the level control is in the “Off” mode.

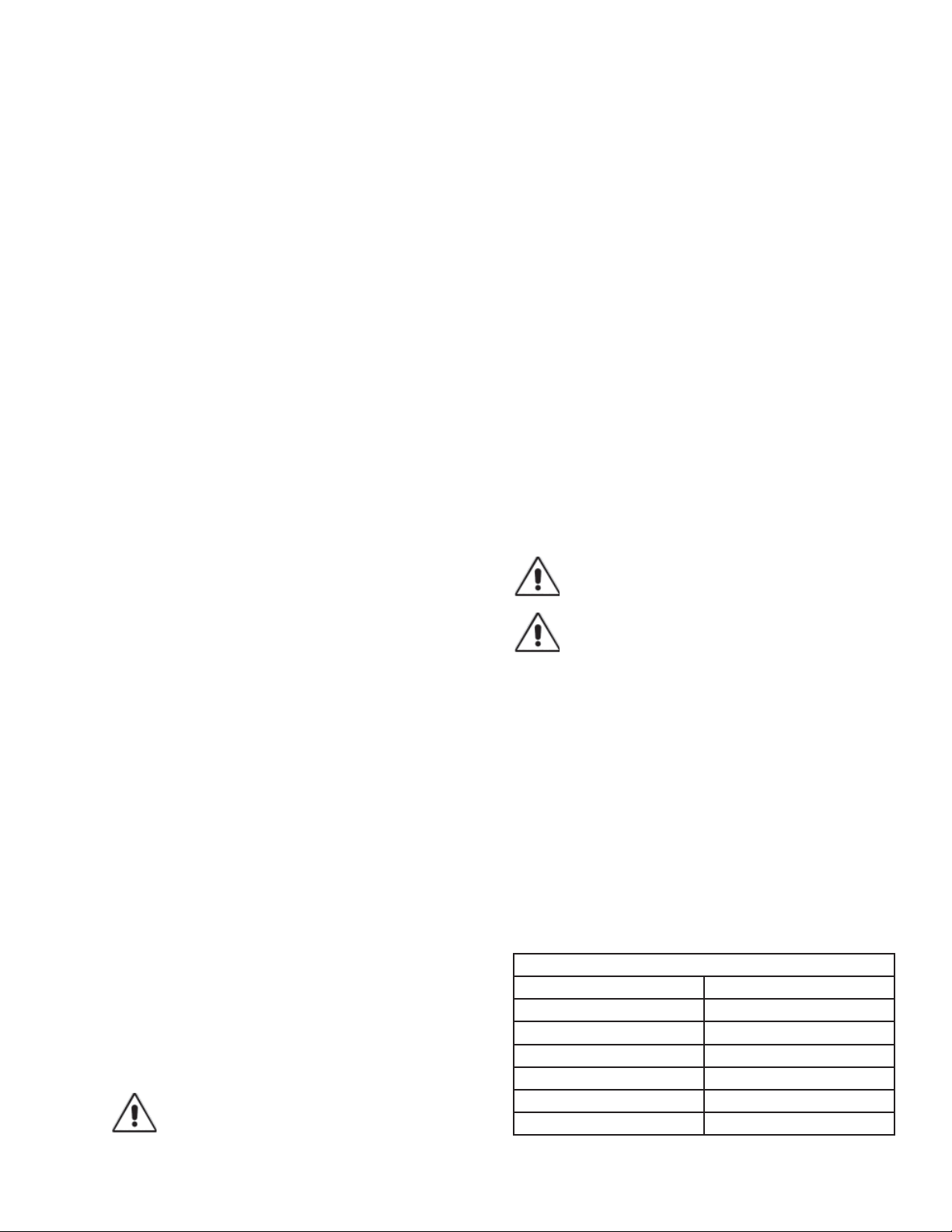

C-5) Hydraulic System:

Figures 1 and 2 shows a schematic drawing of a typical

hydraulic power system for driving a submersible pump.

WARNING!- Hydraulic system has high-pressure

capability. Exercise caution at all times.

CAUTION ! - Never block return (low pressure)

line. It’s best to use by-pass valve to control flow

of hydraulic fluid.

The 3HPV pump should be supplied with a maximum

hydraulic fluid flow of 7 GPM @ 2500 PSI. Maintain hydraulic

fluid temperature at 100°F (38°C) for optimum performance.

Maximum operating temperature is 180°F (82°C). Fluid

viscosity should be 214-320 SSU. An anti-wear hydraulic

fluid of approximately 200 SSU at 100°F is recommended.

Lower viscosity fluids can be used, but will increase the wear

rate within the hydraulic motor. A filter is required on the low

pressure return hydraulic fluid line. Use filter elements rated

at 10 micron absolute. Protect hydraulic hoses from cuts and

abrasion. Always use a back-up wrench when connecting and

disconnecting the hydraulic lines to the fittings on top of the

pump.

Use hydraulic oils with anti-wear additives as listed or their

equivalent.

TABLE 1 - SEAL CHAMBER OIL

SUPPLIER GRADE

Pennzoil AW46 Hydraulic Oil

Texaco Rando HDAZ

Shell Tellas Hydraulic Oil

Mobil D.T.E. 20 Series

Chevron EP Hydraulic Oils

Exxon J-58 Hydraulic Oil