CREATIVE CONCEPTS Pucker Powder Quick start guide

3x3

3x2

3x1

Creative Concepts, Inc.

1500 Georgia Road

Irondale, Alabama 35210

Phone: 205-838-0570

Fax: 205-838-0999

3x Instructions V1 August 1, 2012

3x Unit

Assembly and Mounting

Instructions

Page 1 of 12

Pucker Powder ®

From the Staff of Creative Concepts:

Thank you for your recent purchase of our 3x Dispensing Unit. Our company

is constantly evolving and working to make our products simpler and more

marketable for you our customer. It is your suggestions and recommendations

that have molded our business to where it is today. Customer care is critical to

our operation and we therefore hope that you will contact us with any

comments or concerns. All of us at Creative Concepts look forward to a long

and prosperous business relationship with you. Please call our toll free line at

866-838-0570 with any questions or comments.

1. Storage: Pucker Powder, powdered candies should be stored at 80

degrees Fahrenheit maximum and 70% maximum humidity.

2. Do not get candy wet.

3. Allergen Statement: All of Pucker Powder’s powdered candies

current recipes and the processes are free of Major Food Allergens and their

derivatives. The Major Food Allergens are diary, egg, fish, shellfish, tree nuts,

peanuts, wheat, and soybeans.

Covered by Patents: US D476,855 S , 8,042,581 Additional Patents

Pending.

Page 2 of 12

Index

Part Identification 4

Assembly Instructions 5

Mounting Instructions 6 - 9

Candy Loading Instructions 10

Cleaning Machine & Mechanism 11

Troubleshooting 12

Page 3 of 12

Part Identification

A

Main Sign

Side Panels

Catch Bin & Perf Fun Mechanism

Leveling Brace

Lower Frame

Upper Frame

Wall Bracket

Front Sign

Page 4 of 12

Page 5 of 12

BA C

STEP 1, Join the 3x Units. NOTE: If using a single 3x unit, go to STEP 2.

A. Wing Nut and Screw.

B. Align the units and connect them together using Wing Nuts and Screws as shown.

C. View of correctly positioned Wing Nut and Screw.

STEP 2, Installing the sign panels.

A. Align the holes in the graphic panels with the holes in the metal frame. Insert the screws as shown

and tighten the wing nuts. NOTE: There are two extra holes that will not be used at this time..

B. Align the holes in the back graphic panel and attach the sign using three screws and wing nuts.

A

8-32 x ½ screw

and wing nut

B

The unit may be secured and used in almost any situation. The images below

represent some of the more common scenarios. A package containing

several items is included and may be used to mount the unit.

“Multi-Purpose Wall Bracket” may be used to mount the unit to

either slat wall, peg board or smooth surfaces.

“Wood Screws” may be used on areas such as wood and other

porous surfaces. NOTE: Permanent holes will be created in the

surface when using this method.

OR

“Tie Straps” may be used on wire racks and shelving.

Do not use for installing the unit to a wall or vertical

surface.

OR

“Double Sided Tape” may be used on any smooth surface.

NOTE: If unit is removed, some tape and adhesive residue may

be left on the surface. Do not use for installing the unit to a

wall or vertical surface.

OR

Shelf Mount Peg Board or

Smooth Wall Mount

Slat Wall Mount Counter Top Mount

Page 6 of 12

Use these “Screws and Wing Nuts” to attach to surfaces with

holes already in them such as some shelving.

OR

Page 7 of 12

CAUTION, Do not use “Tie

Straps” for installing the unit

to a wall or vertical surface.

METAL SHELVING OR WIRE RACKS

Remove the metal catch tray to

access the mounting holes in the

unit. It may be necessary to pre-

drill 1/8” diameter holes for the

screws. NOTE: Permanent holes

will be created in the surface

when using this method.

WOOD OR PORUS SURFACES

Remove the protective covering

from the “Double Sided Tape”

strips and apply the to the bottom

of the unit as shown. Carefully

set the unit in place and press

down on the areas of the tape.

Do not use “Double Sided

Tape” for installing the unit to

a wall or vertical surface.

SMOOTH SURFACES

Slat Wall

Position the top edge of

the adapter bracket into

one the grooves in the

slat wall and tilt it

downward to lock it into

place as shown. Loosen

the thumbscrews 6

complete turns.

Peg Board

Position the top edge

of the adapter bracket

into the holes in the

peg board and tilt it

downward to lock it into

place as shown.

Loosen the

thumbscrews 6

complete turns.

Page 8 of 12

Flat Wall

A. Remove the thumbscrews from the bracket.

B. Turn the bracket over and twist the thumbscrews approximately 3 complete turns into the

threaded holes as shown (do not tighten).

C. Mount the bracket to the wall as shown by using anchors suitable for your wall material.

NOTE: USE A MININUM OF 3 ANCHORS WITH TWO OF THEM IN THE HOLES

INDICATED ABOVE. EACH ANCHOR MUST BE RATED WITH AN ULTIMATE PULL-OUT

STRENGTH OF 30 POUNDS OR MORE.

A B C

USING THE MULTI-PURPOSE WALL BRACKET

MOUNTING THE UNIT TO THE WALL

Mounting the 3x Unit

Align the two large holes in the 3x Unit with

the two thumbscrews. Slide the 3x Unit

over and down the shafts of thumbscrews.

Tighten the thumbscrews against the 3x

unit until it is secure (Do not over tighten

the thumbscrews).

Remove the rear bracket

Remove the two screws and wing nuts

holding the bracket in place. Remove the

rear bracket.

Page 9 of 12

Adding Candy

Loosen the thumbscrew Remove the Fun Mech.

Remove the cap and foil seal from the bottle of candy. Insert the

bottle into the Fun Mech and rotate them as shown.

Align the bottle and

thumbscrew, and position

them into the unit.

Secure the Fun Mech by

tightening the thumbscrew .

Page 10 of 12

!!! DO NOT OVERTIGHTEN THUMBSCREW!!! (Over tightening may result in breaking mechanism

shaft and/or stripping threads of thumbscrew)

Option 1. Place the mechanism in any home or commercial dish washing unit.

Allow to completely dry before re-assembly. The drying process may take

several hours. Shake the Funnel Mechanism briskly to check for any signs of

remaining moisture. If moisture is found, allow more time to dry.

Option 2. Wash the mechanism in hot soapy water and rinse thoroughly. The

Funnel Mechanism should be shaken briskly in the water to loosen any

accumulated candy. Allow to completely dry before re-assembly. The drying

process may take several hours. Shake the Funnel Mechanism briskly to check

for any signs of remaining moisture. If moisture is found, allow more time to dry.

Cleaning Machine – To keep your 3x Unit looking its best , clean the outside of

the machine with a cloth dampened with warm water and mild soap once every

two weeks recommended.

Cleaning Fun Mechanism

Cleaning Machine & Mechanism

Page 11 of 12

Troubleshooting

Page 12 of 12

PROBLEM CAUSE REMEDY

CANDY WILL NOT FLOW A.) CANDY CLOGGING

MECHANISM

A.) CANDY CLUMPING

B.) MECHANISM IN NEED

CLEANING

A.) REMOVE MECHANISM

AND SHAKE CANDY/BOTTLE

TO LOOSEN

CLUMPING/CLOGGING

B.) REFER TO CLEANING

INSTRUCTIONS PAGE 11.

CANDY WILL NOT STOP

FLOWING

MECHANISM

STICKING/STUCK OPEN

MECHANISM IN NEED OF

CLEANING

REFER TO CLEANING

INSTRUCTIONS PAGE 11.

Table of contents

Popular Toy manuals by other brands

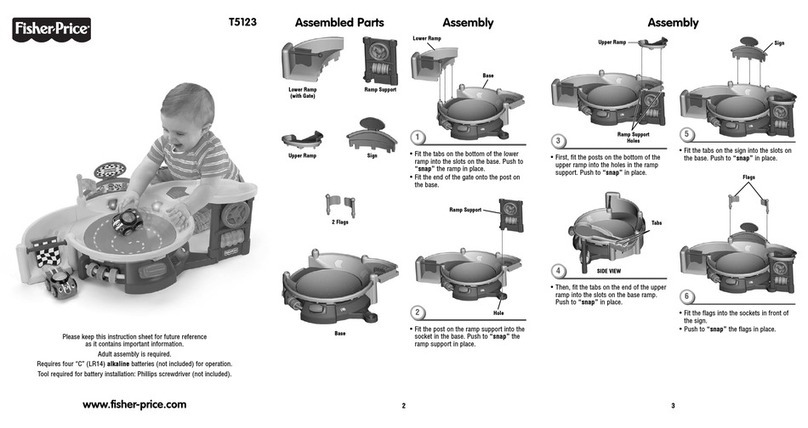

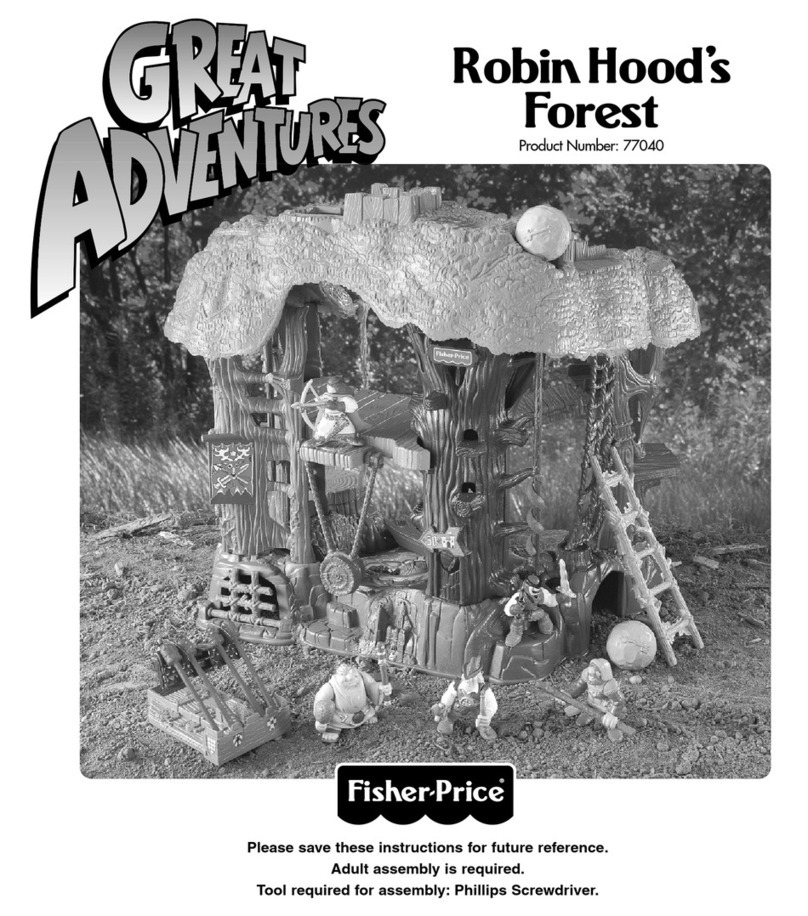

Fisher-Price

Fisher-Price GREAT ADVENTUTES Robin Hood's Forest quick start guide

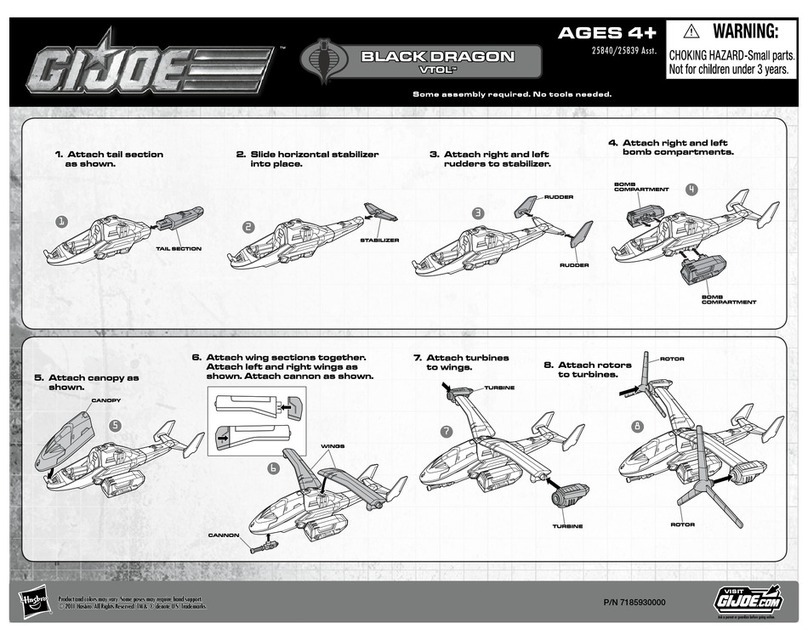

Hasbro

Hasbro G.I. Joe Black Dragon VTOL instructions

Eduard

Eduard Schürzen Pz.IV Ausf.J Zimmerit manual

Eduard

Eduard Super Étendard exterior quick start guide

Joustra

Joustra Atelier Сreatif Tricotin & Pompons manual

LEGO

LEGO education 9688 Assembly