Cri-Man TBMex 2,2/4 Installation and user guide

“TBM” SERIES

SUBMERSIBLE HORIZONTAL

MIXERS

USE AND MAINTENANCE MANUAL

TYPE

SERIAL NUMBER

POWER

DATE

CRI-MAN S.R.L.

Via Costituzione, 50/F – 42015 Correggio (RE) – ITALY

Tel. 0522/732204 - 0522/732465 - Fax 0522/746363

DIRECT:

TBM 1,5 / 6N

TBM 2,2 / 6N

WITH GEAR BOX:

ATEX STANDARD

TBMex 2,2/4 TBM 2,2/4

TBMex 3/4 TBM 3/4

TBMex 4/4 TBM 4/4

TBMex 5,5/4 TBM 5,5/4

TBMex 7,5/4 TBM 7,5/4

TBMex 9/4 TBM 9/4

TBMex 11/4 TBM 11/4

TBMex 15/4 TBM 15/4

TBMex 18,5/4 TBM 18,5/4

Use and Maintenance instructions

Submersible horizontal mixers

“ TBM “ series

Release 03 / 2014

2

I N D E X

Page

1. General information

.................................................................................................................................4

2. Precautions

......................................................................................................................................................4

3. Prescriptions and general recommendations

................................................................5

4. Safety precautions

....................................................................................................................................5

4.1 Safety regulations for Atex version

.........................................................................................................6

5. Product description and use

...........................................................................................................8

5.1. Sectors for use

...............................................................................................................................................8

5.2. Reception and nameplate exemplification

.........................................................................................8

5.3. Technical description

................................................................................................................................10

6. Transport and storage

.........................................................................................................................14

7. Installation

.......................................................................................................................................................14

8. Electrical connections

.........................................................................................................................15

8.1. Connection of electrical motor to control panel

.............................................................................15

8.2. Earth conductors connection

...............................................................................................................19

8.3. Engine protection connections

............................................................................................................19

9. Commissioning and operation

....................................................................................................19

9.1. Atex version

.................................................................................................................................................158

Use and Maintenance instructions

Submersible horizontal mixers

“ TBM “ series

Release 03 / 2014

3

10. Prevention maintenance checks

............................................................................................20

11. Decommissioning and disposal

.............................................................................................21

12. Guarantee

.....................................................................................................................................................22

13. Troubleshooting

.....................................................................................................................................22

13.1. Indications of problems

..........................................................................................................................22

13.2. Possible reasons for the problems

....................................................................................................22

14. Annexes

..........................................................................................................................................................23

Use and Maintenance instructions

Submersible horizontal mixers

“ TBM “ series

Release 03 / 2014

4

1. GENERAL INFORMATION

The instructions provided in this manual and regarding safety are marked with this symbol.

Non complying with these warnings may expose the personnel to risks for their health.

The instructions marked with this symbol must be complied with as they mainly concern

electricity-related hazards.

WARNING Instructions accompanied by this word concern the correct operation, storage or

conditions of the equipment. This word indicates only the main precautions to be considered for safe,

correct and reliable operation together with all the indication provided by the manual.

The descriptions and drawings contained in this publication are to be intended as non-binding.

Subject to the essential features of the machine described, CRI-MAN reserves the right to make any

change to components, machine parts, details and accessories, as it will deem it appropriate for product

improvement purposes or for construction or commercial requirements, at any time and without any

obligation to update this publication.

2. PRECAUTIONS

Keep this manual with care for future reference. Copies of the mixer nameplates showing specifications

and technical operation details of the machine purchased are an integral part of this manual.

The mixers described in this manual are for farming or industrial use; therefore, the equipment shall only

be installed, operated, serviced and repaired by specifically trained and qualified personnel.

Reading this operation and maintenance manual is absolutely necessary before transporting, installing,

commissioning, operating, adjusting, assembling, disassembling and servicing the mixer.

This manual is an integral part of the product supplied. It is the Purchaser’s responsibility to instruct all

the operating personnel who will use, handle or service the equipment to carefully read and study this

manual.

The mixers described in this manual are not intended for domestic use, or the like, and must never be

left within children’s reach or, in general, within reach of any person who has not been trained to their

use, installation or maintenance.

The content of this manual applies to the serial version of the equipment; similar mixers supplied as "job

orders” may not fully correspond to the aspects described in this manual.

The supplier of this product shall not be held liable for any damage caused to persons, animals or

objects if the instructions contained in this manual have not been fully complied with.

Supplementary nameplates supplied with the mixer shall be kept together with this operation and

maintenance manual and the electric control equipment for easy and prompt consultation.

For safety reasons and to ensure that guarantee conditions are fulfilled, do not use the equipment in

case of failure or a sudden change in the product.

It is the Purchaser’s liability to provide the mixer with appropriate alarm and protection systems, as well

as to carry out the necessary checks and maintenance to prevent any accident or damage due to

malfunction.

To request further information, please contact CRI-MAN directly or call its authorized Support Centers.

Use and Maintenance instructions

Submersible horizontal mixers

“ TBM “ series

Release 03 / 2014

5

3. PRESCRIPTIONS AND GENERAL RECOMMENDATIONS

-The equipment or any of its parts must not be used or operated by personnel who has not been

expressly authorised to do so.

-It is forbidden to carry out any maintenance, repair, modification operation that is not strictly

necessary for the working cycle when the machine is on. First of all, disconnect all the power inputs

of the machine.

-Do not remove any protection guards installed on the machine.

-Do not use the equipment for any purpose other than those for which it has been intended.

-When work is over, always disconnect the equipment from electrical power.

-Any maintenance operation regarding electric or non-electric parts shall be carried out in

compliance with CEI 64-8 462.2 463.1 573.3 standards.

4. SAFETY PRECAUTIONS

Any operation shall be carried out on the mixer by specifically trained and qualified personnel with the

appropriate tools and equipment in full compliance with the instructions given in this manual.

Both in the event of a new installation or for maintenance purposes, comply with all hygiene, accident

prevention and safety standards and regulations, as well as with applicable local hazard prevention

legislation. The Purchaser is liable for complying with these regulations and safety instructions.

In particular, strictly comply with the following recommendations:

System inspections

1) Considering the nature of the fluids to be processed, wear appropriate personal protection clothes

and outwear to avoid any contact of the skin with equipment or contaminated fluids.

2) The operating personnel must receive all the vaccines against any possible disease which may be

transmitted through wounds, contact or inhalation.

3) Before performing any action on the mixer, ensure that all the power cords that feed the equipment

are disconnected from the main power supply.

4) Before displacing the equipment from its location, first disconnect the power cords from the contact

boxes of the electric drive units and disconnect feed; displace the mixer with the appropriate

equipment for the purpose.

Mixer inspections

1) The mixer or any accessory must be accurately and completely cleaned with water o specific

products before any operation;

2) If the equipment is disassembled, handle the pieces with special protection gloves;

3) Check the degree of insulation of the electric motor and the efficiency of the earth connection

before conducting any electrical power test.

4) The external surface of the motor can exceed 80°C. Use any necessary device to prevent

burnings.

The mixer cannot be used:

−Before carefully reading Use and Maintenance instructions

−During mixer maintenance and repairing operations

−During tank maintenance and repairing

−During mixer placement operations

−When mixer is damaged or there is the suspicion of possible damage

−When liquid level is less than 0.5m above propeller diameter

The design of the mixer may not be altered without the permission of the manufacturer. If there is any

change in the use to which the mixer is put or in the properties of the liquid to be agitated, please

contact the manufacturer of the mixer.

Use and Maintenance instructions

Submersible horizontal mixers

“ TBM “ series

Release 03 / 2014

6

4.1 Safety regulations for Atex version

TBMex mixers are designed for places in which it is possible to have specific potential explosive

athmosphere: Cri-Man assumes no liability for installations or repairs performed by non-

qualified personnel and without respecting standards regarding potentially explosive

atmosphere.

Follow this indications when installing flame-proof explosion mixers:

−TBMex mixers are built in accordance with standards EN1127-1, EN13463-1, EN 13463-5, EN

13463-8, EN13980, EN60079-0, EN60079-1, in the way to be installed in presence of specific

potential explosive atmosphere.

−The classification of potentially explosive atmosphere zone gives the indication of characteristic

the equipment has to respect: verify, referring to the marking on mixer plate, directive and

harmonized standards, that the characteristics of explosion-proof mixer meet the requirement of

the classification. If not, do not install the machine.

−Install accessories in accordance with applicable standards (EN 60079-14).

−During installation and maintenance, check that the power supply is turned off and that it is not

possible to reinsert it before starting to use the mixer.

−Do not perform any maintenance before shutting down power supply or in presence of

potentially explosive atmosphere.

−Do not replace any component in the electric motor: this type of maintenance can be carried out

by Cri-Man or authorized personnel.

−The user must be aware of the chemical and physical properties of gases and/or vapors present

in explosion-protected zones, as well as the risks posed by the presence of electrical

components.

−Maintenance work on electrical equipment must be carried out in accordance with applicable

standards (EN 60079-17).

−Do not start a mixer if not totally immersed in liquid to be processed. Starting without load for

maintenance or inspection have to be carried out in a zone not classified as potentially

explosive.

Cri-Man mixers TBMex are marked as follows:

II 2 G Ex d IIB T5 (reference EN 60079-0, EN 60079-1)

II 2 G c k T5 (reference EN 13463-1, EN 13463-5, EN 13463-8)

Legenda:

Symbol Description Note

II Group II equipment Except from mines

2 Category 2 High level of protection

G Presence of gas vapors or fogs

Ex Protection in accordance with harmonized

standards

d Flame-proof explosion protection Referred to electrical motor

IIB For gas type B All gas except from H

2

, C

2

H

2

, CS

2

T5 Temperature class Maximum surface temperature 100°C

c Protection by constructional safety Non electrical components

k Protection by liquid immersion Non electrical components

Use and Maintenance instructions

Submersible horizontal mixers

“ TBM “ series

Release 03 / 2014

7

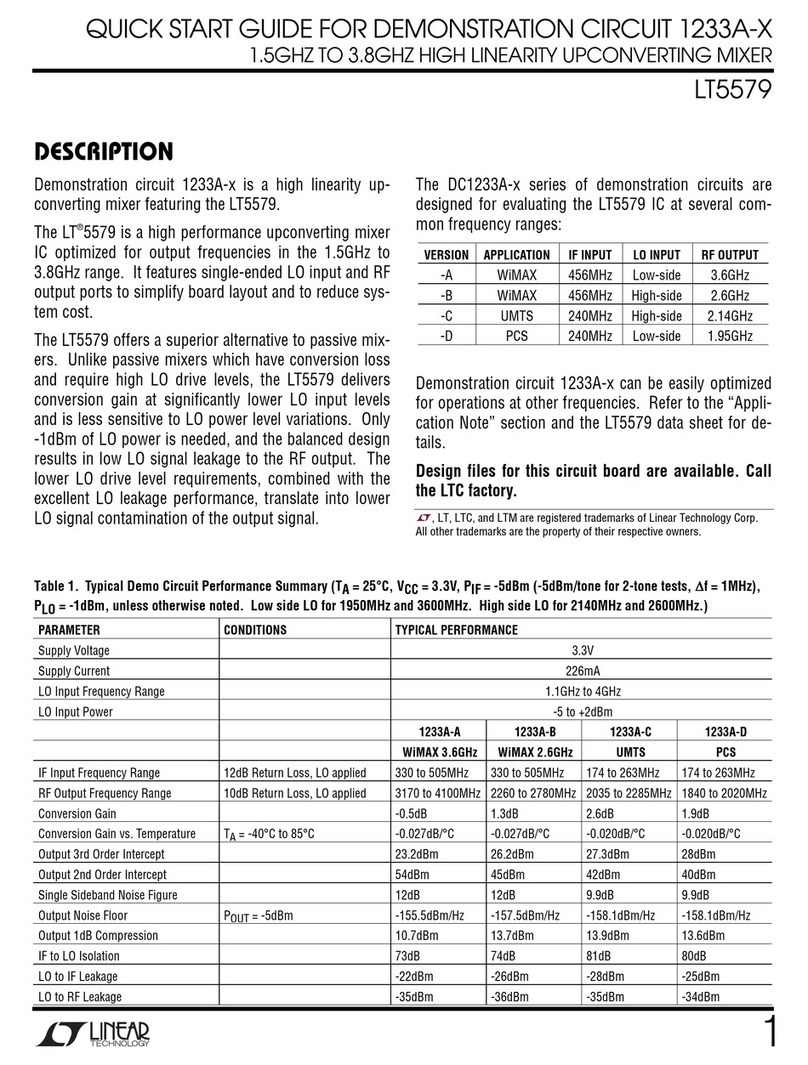

Here below a table of correspondence between the dangerous areas for potentially explosive

atmospheres (94/9/CE), the categories (94/9/CE) and the protection level of equipment EPL (EN 60079-

0).

Before the installation of an Atex mixer, ensure that it is suitable for that zone.

Dangerous Zone Atmosphere

Cathegory

(G= gas, D= dust)

Zone 0 Continuous presence or

for long periods

1G

Zone 1 Probable arising

1G or 2G

Zone 2

Presence of gas,

vapors potentially

explosive

Non probable arising

1G, 2G or 3G

Zone 20 Continuous presence or

for long periods

1D

Zone 21 Probable arising

1D or 2D

Zone 22

Presence of clouds of

combustible dust in the

air

Non probable arising

1D, 2D or 3D

In all areas in which potential explosive atmosphere can arise, must be installed equipment in

compliance with categories identified from directive 94/9/CE (Atex).

Use and Maintenance instructions

Submersible horizontal mixers

“ TBM “ series

Release 03 / 2014

8

5. PRODUCT DESCRIPTION AND USE

5.1. Sectors for use

Mixers manufactured by Cri-Man S.r.l. are ideally suited to applications involving the mixing, i.e. the

homogenizing and suspending of liquids of low to medium viscosity.

Please contact Cri-Man S.r.l. for further information on other applications, such as the mixing of viscous

media or explosive materials.

5.2. Reception and nameplate exemplification

In the event of damage, please contact the nearest service center or the manufacturer.

Check that the received material correspond to what indicated in transport document and that it is not

damaged.

WARNING This machine may not be operated under conditions which exceed either the threshold

values stated on the factory specification plate, or any other instructionscontained in the operating

regulations or the contractual documentation. All prescribed electrical connection figures, as well as all

installation and servicing instructions, must be adhered to without exception. Any use of the machine

which exceeds the conditions contained in the operating manual can result in the failure of the machine.

Non-compliance with this warning can result in personal injury and material damage.

Note :

All descriptions and instructions in this guide are based on standard models. These operating

regulations do not take into account all details and variations in design and construction nor any

possible eventualities or events that may occur during erection, operation or servicing.

These operating regulations do not take any local safety regulations into account. The operator of this

installation is responsible for ensuring that such regulations are adhered to and that they are followed by

the installation personnel who install the mixer.

The type plate on the casing identifies the type of mixer, the most important operating data and the

machine number or serial number respectively. These details must always be given when information is

required, when reordering machines or spare parts.

In the event of damage, please contact the nearest service center or the manufacturer.

The factory plate on the casing identifies the type of mixer, the most important operating data and the

machine number or serial number respectively. These details must always be given when information is

required, when ordering machines or spare parts.

Use and Maintenance instructions

Submersible horizontal mixers

“ TBM “ series

Release 03 / 2014

9

Mixer plate

TBM standard

Via Costituzione, 50F

42015 Correggio (RE) Italy

Tel. 0522/ 3.22.04

x

II 2 G Ex d IIB T5 Gb

II 2 G c k T5

0948

Matricola / N°

non aprire se in tensione / do not open when energized

ISSeP 13 ATEX034

TBMex

Tipo : Complete electric mixer code

Atex : Complete Atex code

Matricola : Serial Number: first numbers indicate year of production

P

N

[kW]

: Electrical motor Power

: Alternate current

Hz : Frequency

Cos Ø : Power factor

avv. : Type of starting allowed

S1 : Continuous service

V : Electrical motor voltage

IP68 : Motor protection level

I

N

[A] : Rated absorption

cl. F : Insulation class

Q [l/se] : Capacity

N°

poli

: Numbers of poles

g/min : RPM propeller

For safe and proper operation, must not be exceeded maximum performance

characteristics described on mixer’s plate.

[A]

I

N

P

N

[kW]

Tipo

avv.

V

Matricola

Hz cosØ n

°

poli

g/min

Q [l/sec]

H [m]

Via Costituzione, 50F

42015 Correggio (RE) Italy

Tel. 0522/ 3.22.04

RoHS

2002/95/EG

Use and Maintenance instructions

Submersible horizontal mixers

“ TBM “ series

Release 03 / 2014

10

5.3. Technical description

General information

Manifacturer: Cri-Man S.r.l.

Type of mixer: Submersible horizontal mixer direct and with gear box, standard and

Atex version

Type designation: (TBM .../6) (TBM .../4) (TBMex …/4)

Power cable: 10.0 meters (standard length, suitable for basins up to

7 meters depth)

Corrosion protection mixer: Painted with two component epoxy resin with substrate with zinc

phosphate

Motor

Manifacturer: Cri-Man S.r.l.

Protective system: IP 68 a 20 m

Insulation class: F

Sealing: Radial mechanical seal

Motor casing material: Cast iron, EN GJL 250

Gearbox

Manifacturer: Cri-Man S.r.l.

Type: Planetary gearbox

Gears: Hardened and ground

External sealing: 2 radial shaft sealig rings

Internal sealing: Mechanical seal

Shaft bearings: 2 taper roller bearings

Gearbox casing: Cast iron, EN GJL 250

Propeller

Number of blades: 2 - 3

Propeller diameter 290 - 780 mm

Material: Stainless steel

Use and Maintenance instructions

Submersible horizontal mixers

“ TBM “ series

Release 03 / 2014

11

Mixers type TBM .../6N

Type TBM…/6 mixers are available in following configurations:

Mixer type: TBM 1.5/6N TBM 2.2/6N

Motor:

Motor size 100 100

Mech. nom. rating 1.5 [kW] 2.2 [kW]

Electr. actual power [kW] 1.97 2.90

Nominal speed [rpm] 925 940

Rated current

1)

[A] 4.2 5.9

Power Factor [cos Ø] 0.75 0.73

Operating mode S1, Y S1, Y

Mains voltage [V] 3 x 400 3 x 400

Permissible motor voltage [V] 230/400 230/400

Mains frequency required [Hz] 50 50

Starting type Y Y

Propeller:

Number of blades 3 3

Diameter [mm] 297 347

Capacity

1)

[m

3

/h] 643 876

Propeller speed [rpm] 925 940

General data:

Axial thrust force 1) [N] 230 313

Output torque 1) [Nm] 15.2 22.4

Weight with console [in kg] 54 57

1)

in clean water. Values obtained in accordance with ISO 21630.

Use and Maintenance instructions

Submersible horizontal mixers

“ TBM “ series

Release 03 / 2014

12

Mixers type TBM .../4, TBMex…/4

Type TBM .../4, TBMex…/4 mixers are available in the following configurations:

Mixer type: TBM 2.2/4 TBM 3/4 TBM 4/4 TBM 5.5/4N TBM 7.5/4N

TBMex 2.2/4 TBMex 3/4 TBMex 4/4 TBMex 5.5/4 TBMex 7.5/4

Motor:

Motor size 100 100 100 132 132

Mech. nom. rating 2.2 [kW] 3.0 [kW] 4.0 [kW] 5.5 [kW] 7.5 [kW]

Electr. actual power [kW] 2.80 3.60 4.85 6.50 8.80

Nominal speed [rpm] 1420 1420 1405 1430 1440

Rated current

1)

[A] 5.3 6.8 9.1 12.5 15.8

Power Factor [cos Ø] 0.78 0.78 0.78 0.85 0.85

Operating mode S1, Y S1, Y S1, ∆S1, ∆S1, ∆

Mains voltage [V] 3 x 400 3 x 400 3 x 400 3 x 400 3 x 400

Permissible motor voltage [V] 230/400 230/400 400/690 400/690 400/690

Mains frequency required [Hz] 50 50 50 50 50

Starting type Y Y Y∆Y∆Y∆

Gearbox :

Reduction 4.39 4.39 4.39 4.39 4.39

Output speed [g/min] 323 323 320 326 328

Propeller:

Number of blades 2 2 2 2 2

Diameter [mm] 445 460 515 535 585

Capacity

1)

[m

3

/h] 1333 1581 2146 2391 3254

General data:

Axial thrust force 1) [N] 441 580 853 981 1520

Output torque 1) [Nm] 65 87 119 161 218

TBM weight [kg] 75 78 81 109 115

TBMex weight [kg] 77 80 83 112 118

1)

in clean water. Values obtained in accordance with ISO 21630.

Mixers in Atex version (TBMex…) are manifactured in accordante with standards:

EN60079-0 and EN 60079-1. Type: II 2G Ex d IIB T5 Gb

EN13463-1, EN13463-5, EN13463-8. Type II 2G c k T5

Use and Maintenance instructions

Submersible horizontal mixers

“ TBM “ series

Release 03 / 2014

13

Mixer type: TBM 9/4N TBM 11/4 TBM15/4N TBM 18.5/4N

TBMex 9/4 TBMex 11/4 TBMex 15/4 TBMex 18.5/4

Motor:

Motor size 132 160 160 160

Mech. nom. rating 9 [kW] 11 [kW] 15 [kW] 18.5 [kW]

Electr. actual power [kW] 10.8 12.5 16.8 20.0

Nominal speed [rpm] 1440 1450 1450 1450

Rated current

1)

[A] 19.0 23.5 30.0 36.0

Power Factor [cos

ϕ

] 0.83 0.81 0.83 0.83

Operating mode S1, ∆S1, ∆S1, ∆S1, ∆

Mains voltage [V] 3 x 400 3 x 400 3 x 400 3 x 400

Permissible motor voltage [V] 400/690 400/690 400/690 400/690

Mains frequency required [Hz] 50 50 50 50

Starting type Y∆Y∆Y∆Y∆

Gearbox :

Reduction [-] 4.39 4.13 4.13 4.13

Output speed [g/min] 328 351 351 351

Propeller:

Number of blades [-] 2 2 2 2

Diameter [mm] 595 600 720 780

Capacity

1)

[m

3

/h] 3628 3977 5335 6884

General data:

Axial thrust force 1) [N] 1826 2158 2697 3826

Output torque 1) [Nm] 261 299 408 503

TBM weight [kg] 123 183 193 203

TBMex weight [kg] 126 187 197 207

1)

in clean water. Values obtained in accordance with ISO 21630.

Mixers in Atex version (TBMex…) are manifactured in accordante with standards:

EN60079-0 and EN 60079-1. Type: II 2G Ex d IIB T5 Gb

EN13463-1, EN13463-5, EN13463-8. Type II 2G c k T5

Use and Maintenance instructions

Submersible horizontal mixers

“ TBM “ series

Release 03 / 2014

14

6. TRANSPORT AND STORAGE

The mixer may only be lifted using the suspension points provided.

The winch or lifting tackle supplied incl. the chain or cable to raise and lower the mixer in the basin may not

be used as a universal form of lifting equipment.

Never hang the motor cable to handle the mixer!

ATTENTION During transport and storage, keep the machine fixed on its base support; be sure that it is

well fixed in order to avoid falls that could cause damage to things, people or to the machine.

Receipt of goods

The shipment must be inspected for damage immediately on arrival. If necessary, a damage claim form must

be completed in the presence of the haulage operator/driver since remedying any damage free of charge is

otherwise impossible.

Storage

If the mixer has to be stored, it is essential to select a storage area that is free from oscillations and vibration

in order to prevent the roller bearings from being damaged. The machine must also be stored on dry

premises in which the ambient temperature is not subject to major fluctuations.

If the mixer has had to be stored for more than one year, the gearbox oil must be replaced. This must also

be done even if the machine has never been in use previously. (Natural aging of mineral oil lubricants).

7. INSTALLATION

All stainless steel threads must be greased in advance with a suitable paste.

Always ensure that installation and fitting tools (cutoff disks, open-ended wrenches, screwdrivers,

files, etc.) are strictly separated for use with stainless steel parts and normal steel parts. If this is

not done, microscopic rust particles on these tools can be pressed into the stainless steel parts where they

will trigger off a corrosive reaction that can lead to their destruction in time.

Installation must be in accordance with all local safety regulations. CRI-MAN cannot accept any

liability due to improper mounting of the machine.

The fully assembled machine must be positioned and rigidly fixed using its fixing holes. In case

(recommended) use of Cri-Man equipment, refer to installation instructions.

Use and Maintenance instructions

Submersible horizontal mixers

“ TBM “ series

Release 03 / 2014

15

8. ELECTRICAL CONNECTIONS

8.1. Connection of electrical motor to control panel

DANGER!

The voltage-carrying and rotating parts of electric machines can cause severe or fatal injuries.

Installation, connection, commissioning as well as servicing and repair work may only be carried out by

qualified technicians with due regard for:

−these instructions

−all other project documentation relating to the drive, commissioning instructions and electrical

−all currently valid national and local regulations relating to safety and accident prevention

As a principle all electrical connections must be carried out by a qualified electrician.

All electrical connection necessary to operate the mixer are responsibility of the installer, who also has the

responsibility to ensure that the control panel is in accordance with National rules, and that it has an

adequate degree of protection with respect to installation area. Install electrical equipment in dry area.

Otherwise make use of special equipment.

Electrical motor characteristics are indicated on data plate.

The mixer is supplied complete of connection to mains. The core code numbers are indicated along the

corresponding cores (s. connection diagram in 8.3.4).

Before connecting the motor, the actual operating voltage must be compared with the voltage data on the

motor specification plate and with the motor windings. Please refer to Fig. 8.3.

WARNING After ensuring the electric connection, ensure that the direction of rotation is correct: watching

the mixer from the back side of the motor, the propeller must rotate clockwise. In order to reverse the

direction of rotation, exchange two phases.

Three phases conductor (L1, L2, L3) must not be confused with neutral conductor (N) or earth conductor

(yellow-green).

Do not change the position of cables coming from the electrical motor to the terminal board (U1, V1, W1, or

U2, V2, W2) to avoid errors in Y-∆starting system.

WARNING Undersized or poor-quality electrical equipment may undergo rapid contact deterioration and

consequently power the motor incorrectly, which may damage the equipment. In order to ensure safe

operation, install good-quality electrical equipment.

WARNING The use of inverters or soft-starters, if not correctly planned and implemented, could damage

the mixer, not only in its electrical components but also the mechanical elements.

If the associated problems are not fully understood, request assistance from the Cri-

Man

Technical Offices.

Operation with Inverters or Soft-starters:

The structure and motor insulation used are suitable for use with Inverters and Soft-starters but some

essential operating conditions must be satisfied:

-Comply with the electromagnetic compatibility directives.

-The lower threshold frequency must be regulated so that the machine does not operate below 30 Hz.

-The upper frequency threshold must be regulated so that the nominal motor power is not exceeded

(max frequency 50 Hz).

The most recent inverters operate at high repetition frequencies and with sharp increases in voltage ramp.

This reduces power losses and motor noise but generates sharp voltage peaks in the motor coil. These

voltage peaks negatively influence the duration of transmission, relative to the operating voltage and the

cable length between the motor and inverter. The voltage ramp dU / dt, typical of a PWM inverters, must be

lower than 1 kV / µs. In general this value does not affect traditional asynchronous motors, like those used in

the TBM series mixers, if the cable has a length less than 40 to 50m. In any case it is good practice to fit at

least three sinusoidal filters between the motor and inverter and if the cable is longer than stipulated above

other types of filters are required.

Use and Maintenance instructions

Submersible horizontal mixers

“ TBM “ series

Release 03 / 2014

16

Any starting equipment shall be provided with:

1) general disconnecting switch with minimum 3 mm contact opening and suitable block in the open

position;

2) a suitable magnetic protection device to protect cables against short circuits;

3) a suitable device against earth-connected failures of the mixer;

4) a suitable protection device against phase failure;

5) a voltmeter and an amperometer;

6) a minimum current relay, if necessary.

Engineers must ensure that the power system is protected against inadvertent start-up due to any failure and

subsequent resetting of power supply.

Electrical connections shall be established by specifically qualified personnel in strict compliance

with all applicable accident prevention regulations (CEI 64-8) and with the wiring diagrams

attached to the switchboards. Ensure that the frequency and voltage values shown on the motor

nameplates do correspond to those of the power supply line.

WARNING If the cables have been disconnected and reconnected, check the direction of rotation again:

the phases may have been inverted. Check absorption on each phase; any unbalance must not exceed 5%.

In the event that greater values are reached, which may be caused by the motor but also by the supply line,

check absorption values in the other two motor-mains combinations, operating with double inversions to

maintain the same direction of rotation. The best connection will be obtained when the absorption difference

per phase is lower. Note that if the higher absorption is always found on the same phase of the line, the main

cause for the unbalance is due to the mains power.

Use and Maintenance instructions

Submersible horizontal mixers

“ TBM “ series

Release 03 / 2014

17

Connection diagram:

For Y – D

DD

Dstarting, use electrical motor cables following the instructions of control panel electrical scheme.

TRIPHASE MOTOR

MAIN VOLTAGE MOTOR

WINDINGS •

••

•CONNECTIONS AND STARTINGS AVAILABLE

VOLTS VOLTS STAR CONNECTION

Y DELTA

CONNECTION ∆Y ∆STARTING

230/400 •

••

••

••

•

230 400/690

230/400 •

••

•

400 400/690 •

••

••

••

•

U1

4

THERMAL

PROBES THERMAL

PROBES

CABLE CABLE

TT

V2

W1

U2

V1W2

8736251 3 1

V2

7

T

W2

4 5 6 2

V1U1 W1 U2

8

T

TERMINALS

Y/G Y/G

TERMINALS

COIL

REMOTE CONTROL

ELECTRIC MIXER

COIL

REMOTE CONTROL

ELECTRIC MIXER

ISOLATOR

SAFETY

wvu

POWER SUPPLY LINE

L1 L2 L3

w

L3

u

L1

v

L2

SAFETY

ISOLATOR

POWER SUPPLY LINE

DELTA CONNECTION STAR CONNECTION

DIRECT STARTS FOR 230/400 V 50 Hz

Use and Maintenance instructions

Submersible horizontal mixers

“ TBM “ series

Release 03 / 2014

18

STATO FORNIT.

Descrizione della modifica

SOTTOGRUPPO

COMPLESSO MATERIALE

RIF. UNI

OGGETTO

N°Mod.

PTS TBM 5.5-7.5-9 kW 9 MOTORS LEADS

DIMENSIONI

00

TRATT. TERMICI

Firma

Quantità

Peso

0.06567

DISEGNO

N ° Fogli

Scala 1:1

DIS.

Data

Data Controllo

EL.CONNECT.IN THE FRAMEWORK OF POWER

A termine di legge è rigorosamente vietato riprodurre e

comunicare a terzi il contenuto del presente disegno.

L.S.

30.04.14

0

0

0

0000

00 00

00

TOLL. GENERALI

UNI-ISO 8015

UNI EN 22768/2-mk

UNI-ISO 8062-CT10

34 1

U11 U12

5 2

V11 V12

6

W11 W12

7 98

U22 V22 W22

L3L2L1

POWER SUPPLY LINE 230V 60Hz

u v w

SAFETY

ISOLATOR

ELECTRIC PUMP

REMOTE CONTROL

COIL

10 11

T T

CABLE

YELLOW-GREEN

POWER CABLE

NUMERATION

SHOWN ON CABLE

CORRESPONDENCE

WITH TERMINAL

51 2

U11

3 4

V11 U12

7

W11 V12

8 96

V22 W12 W22

L3L2L1

u v w

10 11

T T

CABLE

YELLOW-GREEN

NUMERATION

SHOWN ON CABLE

U22

POSSIBLE DIRECT STARTS IN ELECTRIC THREE-PHASE MOTORS DUAL VOLTAGE WINDING WIRES TO 9

STAR CONNECTION

ELECTRIC STATOR WINDING DUAL VOLTAGE: 230/460V 60Hz

DOUBLE STAR CONNECTION

POWER SUPPLY LINE 460V 60Hz

CORRESPONDENCE

WITH TERMINAL

TERMINAL

THERMAL

PROBES

TERMINAL

THERMAL

PROBES

POWER CABLE

THREE-PHASE MOTORS WITH 9 LEADS- CONNECTIONS AND POSSIBLE STARTING

230/460

460

230

VOLTS VOLTS AND STARTINGS

POSSIBLE CONNECTIONS

SUPPLY

POWER

DOUBLE STAR CONN. STAR CONNECT. START. DOUBLE ST.- ST.

MOTOR WINDING

VOLTAGE ELECTRIC

DIRECT STARTING

ELECTRIC PUMP

REMOTE CONTROL

COIL

SAFETY

ISOLATOR

Use and Maintenance instructions

Submersible horizontal mixers

“ TBM “ series

Release 03 / 2014

19

8.2. Earth conductors connection

Yellow/Green earth terminals found in all power supply cables shall be connected to the earth

circuit of the system before connecting the other terminals; for disconnection, they must be the

last clamps to be disconnected.

8.3. Engine protection connections

Description

Electrical motors are equipped with thermal probes to avoid overheating. Thermal probes are normally

closed bimetallic switches installed in the motor windings. It is obligatory to connect them to a suitable power

source cut-out device

Once a temperature of 150°C (302°F) has been exceeded, the switches open and interrupt the power supply

to the remote control coil, thus stopping the electric motor. When windings are cooled, the contacts of

bimetallic switches reclose, allowing the motor to be started again. It is necessary that it should be given a

new start command in case of operation of the probes: provide adequate predisposition in control panel.

The probes can be connected at a max. voltage value of 250V and have a max. capacity of 1.6A a cosφ=

0.6.

Overload protection

The motor is to be protected against overload through a thermal delay relay according to NIN.

This is to be adjusted to the rated current indicated on the machine plate.

In case of star-delta starting the adjustable value is to be I

N

x 0.58. In both motor cables (U1, V1, W1 and U2,

V2, W2) electro-thermal all-pole triggers are to be incorporated.

9. COMMISSIONING AND OPERATION

When all the checks described in paragraph 8 have been scrupulously carried out, go on to the setting up

and then the running stage of the mixer. Before starting the machine, ensure that no solid parts are in the

tank. Mixer cannot be started if the propeller is not immersed at least whit 0.5m liquid over the higher part of

the propeller. Additional requirements for mixer Atex are given in §4.

During the use of the mixer it is important to observe a series of checks and/or warnings in order to preserve

mixer integrity.

These checks are detailed in §10 .

WARNING The machine is not equipped with a lighting device: it has to be installed in well-lit area.

9.1. Atex version

Once started the mixer ensure, during first hours of work, that the surface temperature of electrical motor and

gear box doesn’t exceed 93°C. Perform this control stopping electrical feeding of the motor and, with mixer

stopped, keep it away from the liquid and put it in an area far away from the dangerous zone. In case of

rising up of the temperature over the 93°C, stop immediately the machine and contact CRI-MAN.

Additional requirements for mixer Atex are given in §4.

Use and Maintenance instructions

Submersible horizontal mixers

“ TBM “ series

Release 03 / 2014

20

10. PREVENTION MAINTENENCE CHECKS

To ensure a regular work of the mixer for a log while, the operator must perform regular checks and

periodical maintenance and, eventually replace worn parts. The mixer comes ready for the use, complete

with greese and oil like in table of §14.

Service operation Lubrification Inspection

Electric motor

Keep the motor casing

clean (otherwise cooling is

affected). Motor casing

only to be opened by the

manufacturer

.

Check the wearing of

electrical motor body: it must

not be damaged, to ensure

correct mechanical resistance

The roller bearings are

sealed for life.

(To be replaced only if

they develop noise.)

Neither servicing is

required

.

Power cable

-

-

The power cable must be

checked twice a year for

surface damage, strain

and kinks, etc. Immediate

replacement by the

manufacturer in case of

damage.

Planetary gears

The gearbox must be

checked for leaks twice a

year.

First oil change after 500

operating hours.

Then every 5,000

operating hours, or

after a maximum of

one year.

Oil level inspection:

The oil level must be checked

twice a year

. (see page 19)

If necessary top up with ISO

VG 150.

Propeller

-

-

Check the mixer blades

periodically. Remove any

materials wound round the

blades, such as ropes,

threads, etc. They may

cause uneven running and

oscillation of the

installation.

This manual suits for next models

17

Table of contents