Crommelins CPV Series Administrator Guide

1

CROMMELINS™ PRESSURE CLEANERS

Thank you for your selection of a CROMMELINS™ Pressure Cleaner.

This Operation Manual explains its use, installation, checking and maintenance.

We highly recommend that you retain this manual for ready reference regarding

proper handling of the CROMMELINS™ Pressure Cleaner.

WA Metro 9350 5588

WA Regional 1800 655 588

East Coast 1300 650 659

sales@crommelins.com.au

OPERATION & INSTRUCTION MANUAL

2

Thank you very much for purchasing a CROMMELINS™ PRESSURE CLEANER.

This manual covers the operation and maintenance of the CROMMELINS™ PRESSURE

CLEANER.

Please take a moment to familiarise yourself with the proper operation and maintenance

procedures to maximise the safe and efficient use of this product.

Keep this owner’s manual at hand, so that you can refer to it at any time.

Due to constant efforts to improve our products, certain procedures and specifications

are subject to change without notice.

When ordering spare parts please have handy your products model number and serial

number. Record these numbers in the boxes below for future reference.

CONTENTS

Introduction & Contents ...................................................................................... 2

Safety Instructions ............................................................................................... 3-4

Engine & Pressure Pump Precaution .................................................................. 5

Pre-Operation Check List .................................................................................... 6

Operation Instructions ........................................................................................ 7-8

Shutdown Instructions / Checks & Maintenance................................................... 8-9

Specifications Charts .......................................................................................... 10-14

Trouble Shooting ................................................................................................. 15-17

Warranty (FAQ) ................................................................................................... 18

SERIAL NO.

MODEL NO.

3

SAFETY

This manual contains important information on how to use the CPV and CPC Series

Pressure Cleaners properly and safely. Please read through this manual before you

attempt to operate this product.

Ensure safe operation, this pressure cleaner is designed to give safe and dependable

service if operated according to the instructions.

WARNING! Fluids under high pressure from spray or leaks can penetrate the skin and

cause extremely serious injury, including death or the need for amputation. This product

must be used ONLY by personnel that have been instructed in the safe use of this

machine. Observe all warnings when you operate, maintain and repair the pressure

cleaner.

•Children and pets must keep away from the area of operation at all times.

•Always make a pre-operation inspection before starting the engine. (For more

information read engine operational manual)

•Must know how to stop the engine quickly and understand the operation of all

controls.

•Stop engine without fail before replenishing fuel tank. Never replenish fuel while the

engine is running or remains hot otherwise spilled or evaporated fuel is liable to catch

fire from the engine spark or muffler heat. Wipe off spilled fuel before starting engine.

•Mufflers and other hot parts are dangerous. Do not touch them with hands or any

other body parts.

•Do not place flammable objects near the unit.

•Be careful with the operating place and ventilation, avoid operating the machine in a

closed room, tunnel or other badly ventilated places, as its exhaust fumes contain

deadly poisonous carbon monoxide. If the machine is unavoidably operated in such a

place, discharge the exhaust fumes outside the room by a suitable means.

•Observe the following cautions when transporting. Close fuel tank cap securely and

close fuel tap tightly during transportation. Drain petrol or diesel from fuel tank before

transporting over a long distance or on rough roads.

To prevent injury wear the following protective items: Gloves, work boots, ear plugs,

safety glasses and any other protective items (hard hat, mask) required by job conditions.

4

SAFETY PRECAUTIONS

•NEVER point the spray gun at people, animals or plants.

•NEVER put your hand or fingers over the spray tip.

•NEVER try to stop or deflect leaks with your hand or body.

•NEVER purchase and use chemicals or detergents that are toxic,

flammable or high acidic/alkaline base, and always request a material safety data sheet

(MSDS) for the product you are purchasing.

•NEVER use a powder type detergent or chemical that is not manufactured for pressure

washer use, i.e. dish detergent, laundry soap.

•NEVER attempt any repairs or maintenance with the engine running or the pump and

gun primed.

•NEVER spray flammable liquids, toxic chemicals (such as insecticide or weed killer) as

personal injury or death could result from fire, explosion, or poisoning while damaging

the environment.

•NEVER leave the pressure cleaner unattended once you have started it. If you must

leave, follow complete shutdown instructions to prevent unauthorized and untrained

personnel from operating the machine.

•NEVER move the machine by pulling the hose.

•NEVER put any type of trigger lock onto the gun.

•ALWAYS face nozzle and wand to the ground when testing.

•NEVER exceed the pressure rating of the unit's recommended pressure.

•NEVER change quick couplers with the nozzle under pressure and without the gun safety

in the “ON” or “LOCK” position.

•NEVER run the machine without water, this will damage the pump and void warranty.

•The machine should be located as close as possible to the water supply.

•Locate the machine on a solid and level surface so that engine and pump crankcase oil

lubricate components properly. Avoid areas where water can build up in the working

area as possible injury can occur caused by the surface becoming slippery from water

build up.

•Locate the machine so the operator has easy access to the pressure cleaner and its

controls.

•To prevent excessive hose damage, locate the pressure cleaner so that the hose does

not cross traffic areas.

•Be sure that all system components and accessory items are original equipment, using

other accessories voids any warranty offered by the manufacturer.

•NEVER alter or modify the pressure cleaner as personal injury or death could result.

5

ENGINE PRECAUTIONS

WARNING! Read engine owners/operators manual before using or attempting to service

this machine.

•DO NOT fill fuel tank while engine is running. Allow engine to cool before refuelling.

•DO NOT operate the engine when an odour of fuel is present, or other explosive

conditions exist.

•IF FUEL IS SPILT, move the machine away from the area of the spill and avoid creating

any source of ignition until the fuel has been removed.

•DO NOT store, spill, or use fuel near an open flame or devices such as a stove, furnace,

water heater which utilize a pilot light, or devices which can create a spark.

•RE-FUEL OUTDOORS or in well ventilated area.

•DO NOT operate engine if the air cleaner or cover directly over the carburettor air

intake is removed.

•DO NOT choke the carburettor to stop the engine.

•DO NOT tamper with the governor springs, governor links or other parts which may

increase the governed engine speed.

•DO NOT tamper with the engine speed selected by the original equipment

manufacturer.

•CAUTION! DO NOT run at excessive speeds. Operating the engine at excessive speeds

increases the danger of personal injury.

•DO NOT touch hot mufflers, cylinders or fins, as contact may cause burns.

PRESSURE PUMP PRECAUTIONS

•NEVER allow the pump to run for more than a 3 minute period without opening the

gun. (This will cause pump damage due to excessive water temperature and void the

warranty)

•NEVER let the pump run when the machine is not connected to the water supply.

•NEVER run acid or hard caustics through the pump.

•ALWAYS use citrus based detergents.

•NEVER use hot water through the pump.

•Machine must be turned off and pressure released from pump and gun, before

checking for leaks, tighten connections if necessary.

6

PRE-OPERATION CHECK LIST

•Be sure you understand all the safety precautions and have been instructed in the

safe use of the machine.

•Wear face, feet and eye protection to prevent injury from spray and flying debris.

•Wear protective gloves, rubber boots, and other protective clothing as required.

•Understand all safety precautions and first aid for any detergent or chemical being

used.

•Check that all lines and hoses are not kinked, twisted or damaged. Replace any

damaged hose.

•Check that the machine is connected to a water supply and that the water supply is

on.

•Tighten all fluid connections securely.

•Replace red transit bungs with dipsticks supplied on pump head.

•Check that oil and fuel levels are at the correct levels before operating.

•Before starting machine, be sure pump is primed and air is purged from the system by

allowing water to flow through the pump.

SET-UP & USE

Follow these instructions for set-up and use of your high pressure cleaner.

1. Position the machine on a solid level surface with slopes for drainage to prevent

water build-up on the floor or surface. Position the machine so that the operator has

easy access to the pressure cleaner and its controls. Be sure ventilation WARNINGS

are observed.

2. Check and determine that the water supply source is capable of exceeding the output

in litres per minute of the pump. If you are drawing water from a clean static source,

rather than a pressure main, the pressure cleaner must be primed and placed as close

as possible to the water source. The intake hose used must be as large as possible.

When drawing water from a pressure source, you need a hose with 16mm or 5/8”

outside diameter.

3. Connect the high pressure hose to the pressure washer and tighten securely.

OPERATION INSTRUCTIONS

WARNING! High pressure spray, improperly used could damage the equipment you wish

to clean or the surrounding environment. Practice on scrap materials, gradually

increasing pressure applied to the object by adjusting the nozzle or moving the nozzle

closer to the object until it is cleaned without being damaged.

The manufacturer does not accept responsibility for damage caused by the consumer's

failure to adjust or operate the machine in accordance with the instruction provided in

the owner manual supplied with the machine.

7

OPERATION INSTRUCTIONS

Follow these instructions to operate the machine:

1. Use the pre-operation checklist to help avoid personal injury.

2. Set gun assembly to low pressure

a. CPV Series – Do not fit nozzle to lance

b. CPC Series – Twist gun assembly side handle anti-clockwise to low

pressure)

c. CPH Series – Allow water to flow through lance

3. Prime the pump and purge air from the system by squeezing the gun trigger before

starting the machine, with the unit attached to a pressure main. Let the water flow

from the wand until air is purged from system.

4. STARTING (PETROL UNITS)

STEP 1 – Open engine fuel cock.

STEP 2 – Set throttle lever to starting position.

STEP 3 – For cold engine starting, close carburettor choke lever.

STEP 4 – Set engine switch to “ON”.

STEP 5 – Pull recoil starter. (IMPORTANT: Do not pull recoil starter rope to the end as

it may cause damage. When the rope is pulled out, release the rope slowly. Do not let

the rope snap back)

STEP 6 – After engine starts, open the choke halfway and warm up the engine for 2-3

minutes with low speed position. The warm up procedure should particularly be

followed during cold weather.

STARTING (DIESEL UNITS)

STEP 1 – Set speed control to low speed. Larger engines press speed lever down till it

locks into place.

STEP 2– Pull recoil starter rope until resistance is felt.

STEP 3 – Bracing foot against frame, pull recoil starter rope with both hands.

STEP 4- If electric start, turn the key until engine starts. (IMPORTANT: Do not pull

recoil starter rope to the end as it may cause damage. When the rope is pulled out,

release the rope slowly. Do not let the rope snap back)

5. For high pressure spraying

a. CPV Series – Select desired spray pattern (0°,15°, 40° or BLACK detergent

nozzle). DO THIS ONLY WHEN THE TRIGGER IS NOT SQUEEZED AND THE

GUN SAFETY LOCK IS ON.

b. CPC Series – Twist gun assembly side handle clockwise to increase

pressure

6. The manufacturer has adjusted the pump pressure to its maximum operating

pressure. Simply adjust the pressure required for cleaning with a selected nozzle

from the quick connection nozzle set.

8

OPERATION INSTRUCTIONS cont...

7. You are now ready to start cleaning with your pressure cleaner. Hold the spray gun

firmly and squeeze the trigger. Always begin high pressure cleaning with the nozzle

at least 1 metre from the object being cleaned and gradually move the nozzle closer

to the object until it is cleaned.

8. To draw chemical/detergent, be sure the pick-up tube is installed into the

chemical/detergent container with the tube sub merged in the solution. Change

quick connection nozzle to the detergent nozzle and squeeze the gun trigger. The

detergent will be drawn up and out of the lance. When the object is covered replace

the detergent nozzle with a high pressure one.

9. Never allow the pump to run for more than a 3 minute period without opening the

gun. This will cause the pump damage due to excessive water temperature and void

the warranty. (A thermal relief valve has been added to the pump to reduce the

possibility of overheating. However, malfunction of this device does not constitute

pump warranty for damage caused by overheating.)

10. As you operate the machine, be sure the water inlet supply hose does not become

kinked.

11. The maximum engine RPM has been set by the manufacturer. Tampering with the

engine governor will void pump warranty.

12. Do not exceed the manufacturer's maximum pressure by increasing the unloader

adjustment. (This will void pump warranty.)

SHUTDOWN INSTRUCTIONS

1. Make sure the gun is closed.

2. SHUTDOWN – PETROL UNIT

STEP 1 – Move throttle lever to low speed position.

STEP 2 – Turn of the red stop switch.

STEP 3 – Close engine fuel cock.

EMERGENCY SHUTDOWN: Move throttle lever to OFF and press engine stop button.

SHUTDOWN – DIESEL UNIT

STEP 1 – Electric start models. Turn key to the off position.

STEP 2 – Move throttle lever to low speed position, then push red lever till the engine

stops

STEP 3 – Move the throttle lever to the stop position.

9

SHUTDOWN INSTRUCTIONS cont....

3. Turn off the water supply and remove the water supply hose from the pump. Pull the

gun trigger to release any built up pressure (make sure you do not spray people or

objects.)

4. Disconnect the pressure hose from the pump and gun and store on the hooks provided

on the trolley.

5. For safety and your liability protection, remove high pressure hose and store gun/wand

in a secure place with this manual to eliminate possibility of unauthorized and

untrained personnel from operating the machine.

CHECKS & MAINTENANCE

Daily Checks

Regular inspection of your pressure cleaner is the key to prolonging its life. Follow these

simple daily checks. This must be done with the engine OFF.

1. Check air filter for dirt and clean or replace as required. Refer to engine owner manual.

2. Check engine oil level. (Dipstick is attached to inside of oil cap.) Refer engine owner

manual.

3. Check engine fuel level.

4. Check high pressure hose for kinks, twists or damage. Replace any damaged hose.

5. Check that the pump oil level is within operation range on the pump dipstick. Model

CPV2700X17 has a sealed oil filled gearbox and must be refilled by service dealer.

6. Check that the water supply is adequate for your machine.

7. Check water inlet filter (situated behind the water inlet connector) remove with long

nose pliers and clean as necessary.

Preventative Maintenance

Change pump oil after first 50 hours of use or first season, then every 300 hours or as

needed. Units that have a reduction gearbox fitted use SAE90 pump oil, all other units are

required to use SAE30 universal pump oil and follow the below steps:

1. Un-thread the oil cap on the top of the pump.

2. Put a container under the pump then unscrew the drain plug on the bottom of the

pump;

3. After oil drains away completely, screw the drain plug into the drain hole again, make

sure the o-ring is with the plug.

4. Refill pump oil via the top hole of the pump until the oil level is to the top of the oil

dipstick level indicator.

5. Screw on the oil cap.

N.B. Dispose of used oils as per your local environmental disposal by laws.

10

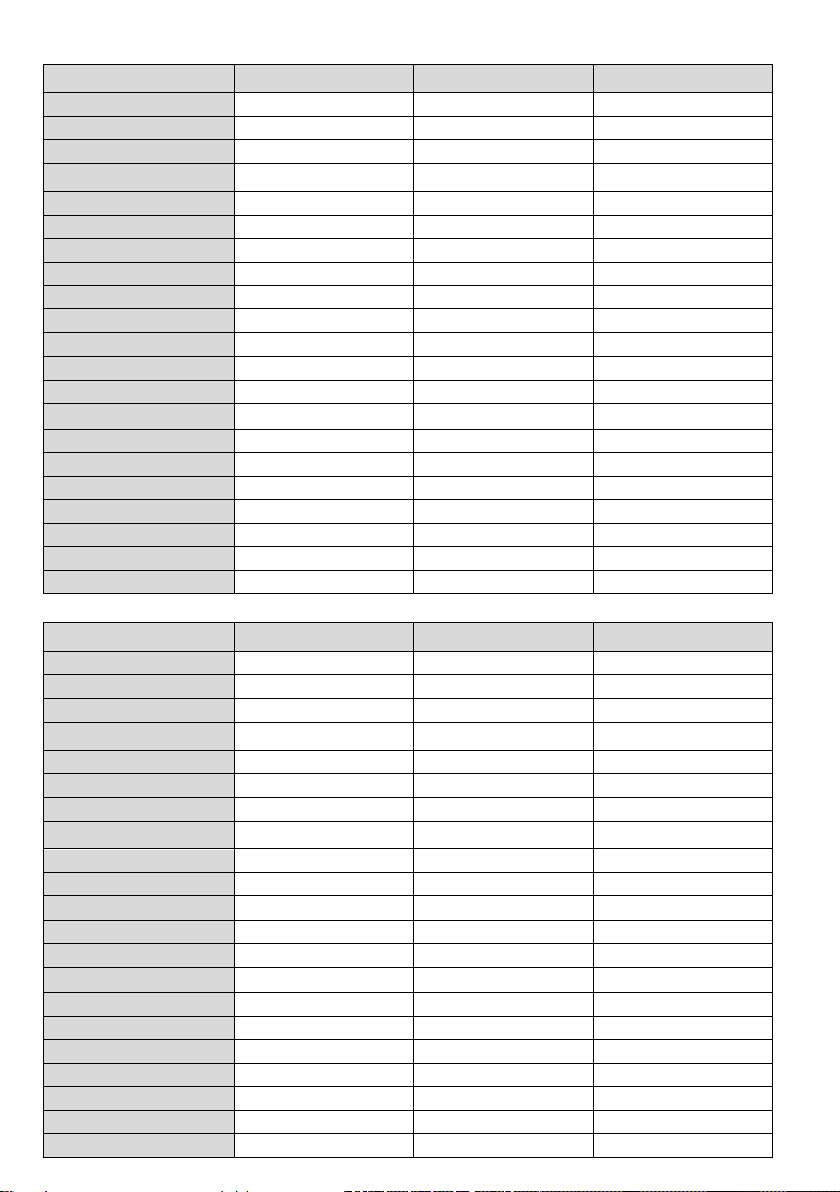

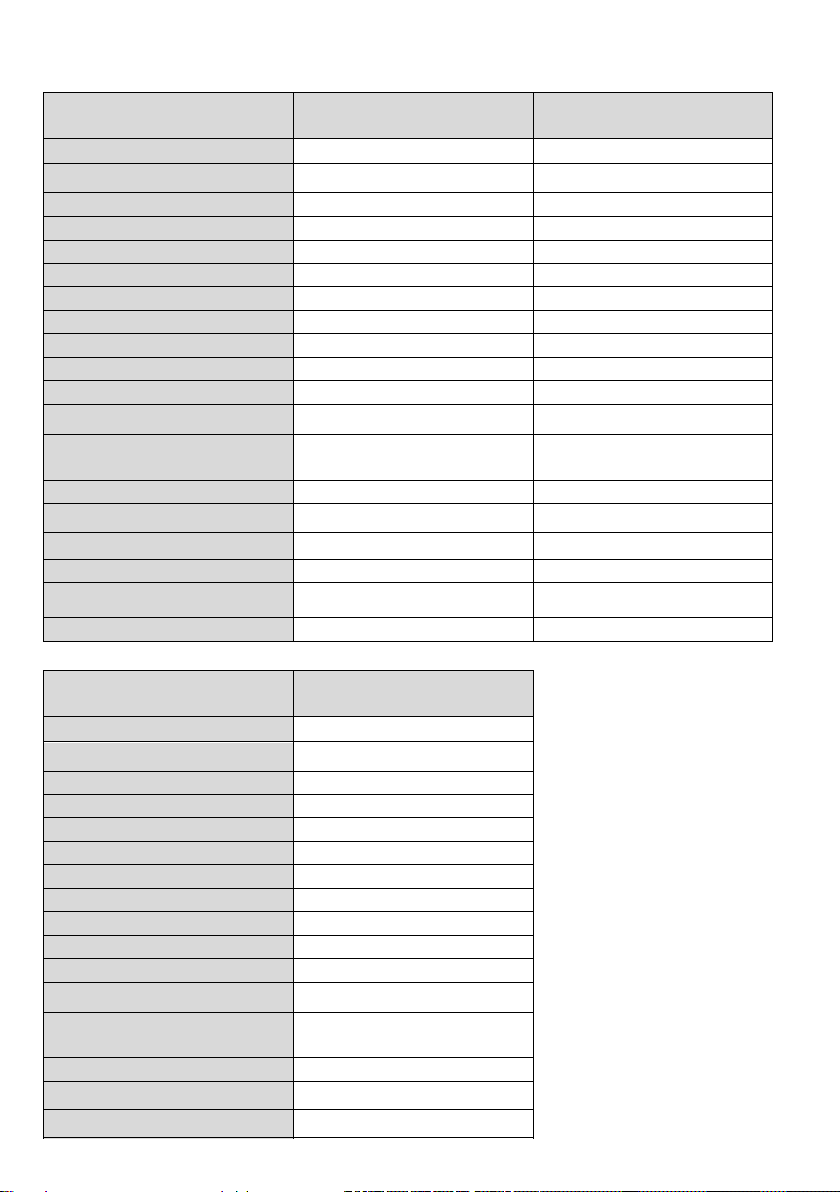

CPV SERIES PETROL SPECIFICATION CHART

MODEL

CPV2700X21

CPV3200X27

CPV4000X40

Pressure PSI max

2700

3200

4000

Bar (max)

180

220

275

Water Flow (L/min max)

11.4L

14.0L

15.0L

Water Flow (L/hr max) 684L 840L 840L

Water Pump

Triplex

Triplex

Triplex

Fuel Type

Petrol

Petrol

Petrol

Engine Make

Robin

Robin

Robin

Engine

7.0hp EX21

9.0hp EX27

14.0hp EX40

Starting System

Recoil Start

Recoil Start

Recoil Start

Fuel Tank (L)

3.6L

6.1L

7.0L

Noise Level db@7m

68db

70db

72db

Lance & Spray Gun

Single Lance HD Gun

Single Lance HD Gun

Single Lance HD Gun

Nozzles

0° /15° /40°/ detergent

0° /15° /40°/ detergent

0° /15° /40°/ detergent

Hose Type & Length

10m HD Braided Hose

10m HD Braided Hose

10m HD Braided Hose

Detergent Tank (L)

Detergent Suction Pickup

Detergent Suction Pickup

Detergent Suction Pickup

Weight (kg)

43.0kg

48.0kg

67.0kg

Dimensions (LxWxH) mm

670 x 520 x 960mm

720 x 520 x 960mm

920 x 600 x 960mm

Folded Dimensions

670 x 520 x 480mm

720 x 520 x 530mm

Manufacturer’s Warranty

2 years

2 years

2 years

Engine Warranty

3 years

3 years

3 years

Pressure Pump Warranty

1 year

1 year

1 year

CPC SERIES PETROL SPECIFICATION CHART

MODEL

CPC2000SP

CPC3000SP

CPC4000SP

Pressure PSI max

2700

3200

4000

Bar (max)

180

220

275

Water Flow (L/min max)

11.4L

14.0L

15.0L

Water Flow (L/hr max)

684L

840L

840L

Water Pump

Triplex

Triplex

Triplex

Fuel Type

Petrol

Petrol

Petrol

Engine Make

Robin

Robin

Robin

Engine 7.0hp EX21 9.0hp EX27 14.0hp EX40

Starting System

Recoil Start

Recoil Start

Recoil Start

Fuel Tank (L)

3.6L

6.1L

7.0L

Noise Level db@7m

68db

70db

72db

Lance & Spray Gun

Single Lance HD Gun

Single Lance HD Gun

Single Lance HD Gun

Nozzles

0° /15° /40°/ detergent

0° /15° /40°/ detergent

0° /15° /40°/ detergent

Hose Type & Length

10m HD Braided Hose

10m HD Braided Hose

10m HD Braided Hose

Detergent Tank (L)

Detergent Suction Pickup

Detergent Suction Pickup

Detergent Suction Pickup

Weight (kg)

43.0kg

48.0kg

67.0kg

Dimensions (LxWxH) mm

670 x 520 x 960mm

720 x 520 x 960mm

920 x 600 x 960mm

Folded Dimensions

670 x 520 x 480mm

720 x 520 x 530mm

Manufacturer’s Warranty

2 years

2 years

2 years

Engine Warranty

3 years

3 years

3 years

Pressure Pump Warranty

1 year

1 year

1 year

11

CPC SERIES DIESEL SPECIFICATION CHART

MODEL CPC2000YDE CPC3000YDE

Pressure PSI max

2000

3000

Bar (max) 138 206

Water Flow (L/min max)

12L

15L

Water Flow (L/hr max)

720L

900L

Water Pump

Triplex

Triplex

Fuel Type

Diesel

Diesel

Engine Make

Yanmar

Yanmar

Engine

4.7hp L48

10.0hp L100

Starting System

Electric Start

Electric Start

Fuel Tank (L)

2.4L

4.7L

Noise Level db@7m

94db at 1m

97db at 1m

Lance & Spray Gun Twin Lance HD Gun Twin Lance HD Gun

Nozzles

Detergent Nozzle, Turbo

Optional

Detergent Nozzle, Turbo

Optional

Hose Type & Length

10m Braided HP Hose

10m Braided HP Hose

Detergent Tank (L) Detergent Suction Pickup Detergent Suction Pickup

Weight (kg) 76.0kg 115.0kg

Dimensions (LxWxH)mm

900x650x860

900x650x860

Manufacturer’s Warranty 2yrs 2yrs

Pressure Pump Warranty

1yr

1yr

MODEL CPH3000RP

Pressure PSI max

3000

Bar (max) 206

Water Flow (L/min max)

13L

Water Flow (L/hr max)

780L

Water Pump

Triplex

Fuel Type

Petrol

Engine Make

Robin

Engine

9.0hp EX27

Starting System

Recoil Start

Fuel Tank (L)

6.1L

Noise Level db@7m

70db

Lance & Spray Gun Single Lance HD Gun

Nozzles Permanent attached

Hose Type & Length

10m Braided HP Hose

Detergent Tank (L) N/A

Weight (kg) 59kg

12

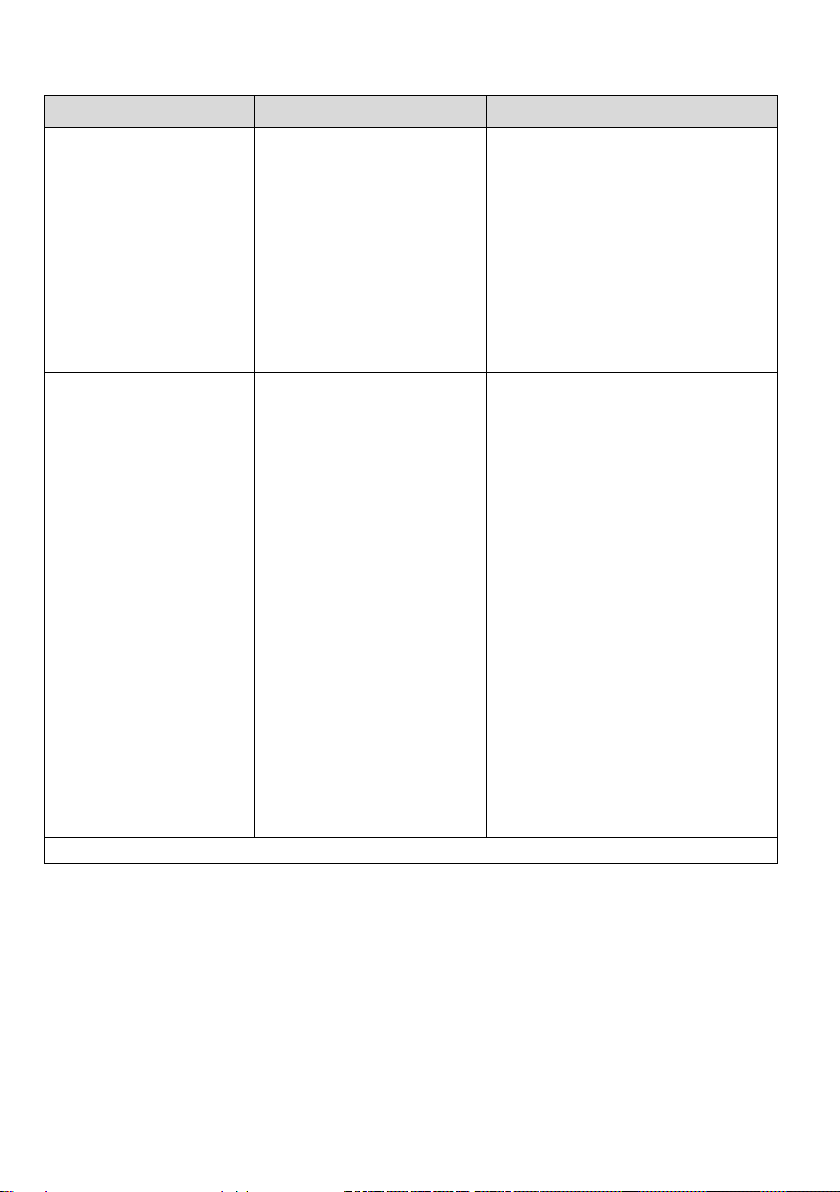

TROUBLE SHOOTING GUIDE

PROBLEM

CAUSE

SOLUTION

Engine won’t start

Units with Oil Alert

System

1. Engine switch in OFF

position

2. Throttle lever on/off

switch in OFF position

3. No fuel in engine

4. Worn, fouled or dirty

spark plug

5. Pressure build up in

pump

1. Engine not level or

engine oil level too

low

1. Turn engine switch to ON

position

2. Turn throttle lever to ON

position

3. Fill fuel tank or turn on fuel

supply

4. Replace with factory

recommended spark plug

5. Squeeze trigger on spray

wand to release pressure in

hose line

1. Place engine on level surface

or fill crankcase with oil

(refer to engine

manufacturers instruction

manual)

Engine with low power

1. Throttle control lever

not set to full throttle

position

2. Partially clogged gun

nozzle

1. Set throttle control lever to

full position

2. Clean nozzle of any blockage

Engine runs well at no

load but ‘bogs’ down

under full load

1. Engine speed too low

1. Contact your pressure

cleaner dealer

Engine will not start:

or starts and runs

rough

1. Low oil level

2. Dirty air filter

3. Out of petrol

4. Stale petrol

5. Spark plug wire not

connected to spark

plug

1. Fill crankcase to proper level

2. Clean or replace air cleaner

3. Fill fuel tank

4. Drain fuel tank, fill with fresh

fuel

5. Connect wire to spark plug

13

TROUBLE SHOOTING GUIDE

PROBLEM

CAUSE

SOLUTION

Engine shuts down

during operation

1. Low fuel level

2. Low oil level

1. Fill fuel tank

2. Fill crankcase with oil to

proper level or level machine

Engine lacks power

1. Dirty air filter

1. Clean or replace air filter

Engine ‘hunts’ or

falters

1. Choke is opened too

long

2. Blocked spray nozzle

1. Move choke to halfway

position until engine runs

smoothly

2. Remove and clean nozzle tip

CPV SERIES

No low pressure

detergent delivery

1. High pressure nozzle

on wand

2. Syphon hose or hose

filter blocked

1. Fit black detergent nozzle

2. Clean or unblock hose and

filter

Unit does not reach

required pressure

1. Restricted or

insufficient water

supply, or pump

sucking air

2. Detergent nozzle

fitted to lance

3. Water leak in high

pressure fittings, hose

or gun

4. Pump has operated

more than 3 minutes

without pulling trigger

5. Thermal relief valve

stuck open

1. Check water supply and

supply hose, and inlet water

filter

2. Replace with high pressure

nozzle

3. Use Teflon tape or pipe

sealant to tighten hose

fitting, replace hose or gun

4. Pull trigger at least 30

seconds every 3 minutes

5. Return unit to your pressure

washer dealer

14

TROUBLE SHOOTING GUIDE

PROBLEM

CAUSE

SOLUTION

CPC SERIES

No low pressure

detergent delivery

1. Twin lance not set to

low pressure

2. Syphon hose or hose

filter blocked

3. Detergent won’t flow

on low pressure

1. Loosen off black side handle

to low pressure flow

2. Clean or unblock hose and

filter

3. Detergent to thick, dilute as

required so as to pick-up on

low pressure

Unit does not reach

required pressure

1. Restricted or

insufficient water

supply, or pump

sucking air

2. Detergent nozzle

fitted to lance

3. Water leak in high

pressure fittings, hose

or gun

4. Pump has operated

more than 3 minutes

without pulling trigger

5. Thermal relief valve

stuck open

6. Pressure regulator (if

fitted) has been

wound down

1. Check water supply and

supply hose, and inlet water

filter

2. Replace with high pressure

nozzle

3. Use Teflon tape or pipe

sealant to tighten hose

fitting, replace hose or gun

4. Pull trigger at least 30

seconds every 3 minutes

5. Return unit to your pressure

washer dealer

6. Wind pressure regulator

clockwise to increase

pressure

If problem continues, take your pressure cleaner to a dealer for servicing.

15

NOTE

Most detergent delivery problems can be prevented by:

1. Using citrus based detergents

2. Flushing the chemical/detergent system before storing

3. NEVER use powdered detergents that are not manufactured specifically for use in

pressure cleaners (ie dish detergent)

WARRANTY (FAQ) Frequently Asked Questions

Q. My Pressure cleaner won't start…

A. Are all engine controls set properly?

A. Do you have fuel in your machine?

A. Check that the engine oil level correct?

Q. How do I get the soap suction to work?

A. Replace the high pressure nozzle with the BLACK detergent nozzle..

Q I don't have any water pressure…

A. Do you have any kinks, leakage or blockage in hoses, fittings and nozzles?

A. Is the Black detergent nozzle attached to the end of the lance?

A. Have you let the unit run in bypass for longer than 3 minutes (pump running, gun

trigger not depressed)

A. Have you checked the nozzle for excessive wear?

A. Check nozzle for blockages

WARRANTY

Consult the CROMMELINS Machinery warranty leaflet (supplied with your new product)

for full details and a list of service dealers for this product, also available online at

www.crommelins.com.au.

This manual suits for next models

10

Table of contents

Other Crommelins Pressure Washer manuals