4

PHW SERIES PRESSURE WASHER

OPERATOR’S MANUAL

LANDA PHW • 9/02

IMPORTANT SAFETY

INFORMATION

CAUTION: To reduce the risk of

injury, read operating instruc-

tions carefully before using.

1. Read owner's manual thor-

oughly. Failure to follow instruc-

tions could cause malfunction

of the machine and result in

death, serious bodily injury and/

or property damage.

2. Know how to stop the product and bleed pressures

quickly. Be thoroughly familiar with the controls.

3. Stay alert - watch what you are doing.

4. All installations must comply with local codes. Con-

tact your electrician, plumber, utility company or the

selling distributor for specific details. To comply with

the National Electrical Code (NFPA 70) and provide

additional protection from risk of shock, this product

is provided with a ground fault circuit interrupter

(GFCI) built into the power cord plug (250V 30 amp

or less, 1 PH). If replacement of the plug or cord is

needed, use only identical replacement parts.

DANGER: Improper connection of the equipment-

grounding conductor can result in a risk of electro-

cution. Check with a qualified electrician or service

personnel if you are in doubt as to whether the outlet

is properly grounded. Do not modify the plug provided

with the product. If it will not fit the outlet, have a

proper outlet installed by a qualified electrician.

WARNING: Do not use gasoline,

crankcase drainings or oil con-

taining gasoline, solvents or alco-

hol. Doing so will result in fire and/

or explosion.

WARNING: Risk of explosion-do

not spray flammable liquids.

5. In oil burning models, use only

kerosene, No. 1 home heating

fuel, or diesel. If diesel is used, add a soot remover

to every tankful.

WARNING: Risk of asphyxiation.

Use this product only in a well

ventilated area.

6. Avoid installing machines in

small areas or near exhaust

fans. Adequate oxygen is

needed for combustion or dan-

gerous carbon monoxide will re-

sult.

INTRODUCTION

Thank you for purchasing a Landa Pressure Washer.

This manual covers the operation and main-

tenance of the PHW3-11021D, PHW4-20021A,

PHW4-20021B, PHW4-20021C, PHW4-20021G,

PHW4-20021H, PHW4-20025K, PHW4-20025N,

PHW4-20025P, PHW4-30021A, PHW4-30021B,

PHW4-30021C, PHW4-30021F, PHW4-30021H,

PHW4-30021M, PHW4-30021G, PHW4-30021P,

PHW4-30025N, PHW5-30021B, PHW5-30021C,

PHW5-30021F, PHW5-30021H, PHW5-30021N and

PHW5-30025N washers. All information in this manual

is based on the latest product information available at

the time of printing.

Landa, Inc. reserves the right to make changes at any

time without incurring any obligation.

The PHWS Series was designed for maximum use

of 8 hours per day, 5 days per week.

Owner/User Responsibility:

The owner and/or user must have an understanding of

the manufacturer’s operating instructions and warnings

before using this Landa pressure washer.Warning infor-

mation should be emphasized and understood. If the op-

erator is not fluent in English, the manufacturer’s instruc-

tions and warnings shall be read to and discussed with

the operator in the operator’s native language by the pur-

chaser/owner, making sure that the operator compre-

hends its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’ instructions.

This manual should be considered a permanent

part of the machine and should remain with it if

machine is resold.

When ordering parts, please specify model and

serial number.

UNPACKING

Carefully unpack your new

LANDA

washer and check

contents against packing slip. Basic equipment with each

machine includes:

1. Pressure washer assembly

2. High pressure discharge hose

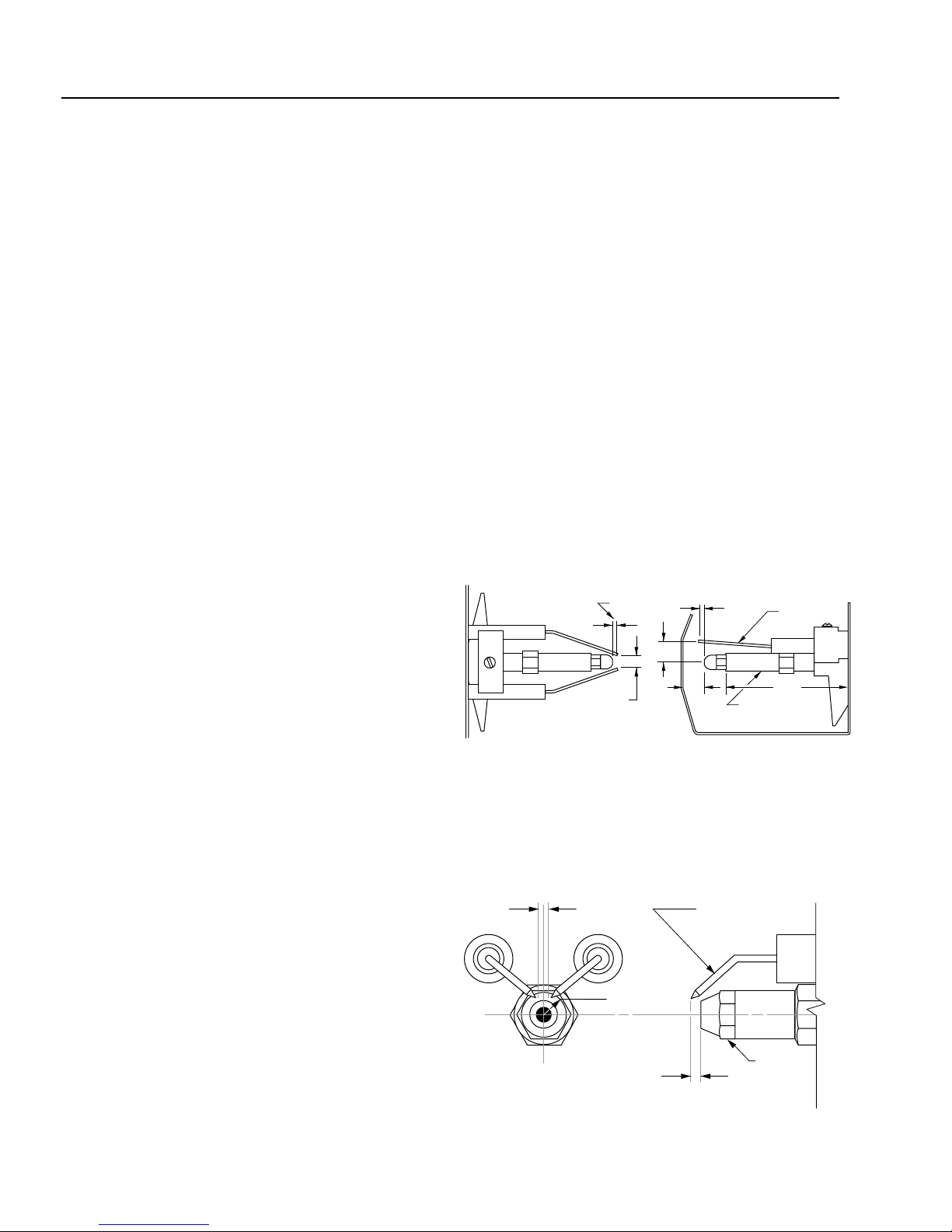

3. Wand assembly

4. Spray gun on machines where applicable

5. Operator’s manual

WARNING

RISK OF EXPLOSION:

DO NOT USEWITH

FLAMMABLE

LIQUIDS.

WARNING

RISK OF

ASPHYXIATION.

USE THIS PRODUCT

ONLY IN A WELL

VENTILATED AREA.

WARNING

READ OPERATOR’S

MANUALTHOROUGHLY

PRIOR TO USE.

CAUTION