Crommelins CPT24S Administrator Guide

1

CROMMELINS™ POWER TROWELS

Thank you for your selection of a CROMMELINS™ Power Trowel.

This Operation Manual explains its use, installation, checking and maintenance.

We highly recommend that you retain this manual for ready reference regarding

proper handling of the CROMMELINS™ Power Trowel.

Spare Parts & Service

Phone: 1300 554 524

Freecall Fax: 1800 636 281

spareparts@crommelins.com.au

www.crommelins.com.au

WA Metro 9350 5588

WA Regional 1800 655 588

East Coast 1300 650 659

OPERATION & INSTRUCTION MANUAL

2

Thank you very much for purchasing a CROMMELINS™ POWER TROWEL.

This manual covers operation and maintenance of the CROMMELINS™ POWER TROWEL.

This CROMMELINS™ POWER TROWEL can be used in the mining, construction, hire

industries and general use.

Please take a moment to familiarise yourself with the proper operation and maintenance

procedures in order to maximise the safe and efficient use of this product.

Keep this owner’s manual at hand, so that you can refer to it at anytime.

Due to constant efforts to improve our products, certain procedures and specifications

are subject to change without notice.

When ordering spare parts please have handy your products model number and serial

number. Record these numbers in the boxes below for future reference.

Please fill in the following blanks after checking the production number and serial

number on your product. (The location of these numbers, vary depending on product).

CONTENTS

Introduction & Contents ...................................................................................... 2

Safety Precautions & Belt Setting ....................................................................... 3

Pre Start-up Checking .......................................................................................... 4

Operation ........................................................................................................... 5

Shutdown & Maintenance .................................................................................. 6

Storage ................................................................................................................. 7

Specifications Charts .......................................................................................... 8-9

Trouble Shooting ................................................................................................. 10

Power Trowel Diagram ........................................................................................ 11

Power Trowel Parts List ........................................................................................ 12

Power Trowel Reducer Diagram .......................................................................... 13

Power Trowel Reducer Parts List .......................................................................... 14

Power Trowel Spider Diagram ............................................................................ 15

Power Trowel Spider Parts List ............................................................................ 16

SERIAL NO.

MODEL NO.

3

This manual contains important information on how to use the following power trowels

models CPT24S, CPT34R, CPT34RD, CPT40R, CPT40RD and CPT46S properly and safely.

Please read through this manual before you attempt to operate this product.

SAFETY PRECAUTIONS

Before operating this piece of equipment, the operator should read this manual.

Whenever possible, he/she should be shown how to operate the unit by an experienced

operator. It is dangerous for an inexperienced person to operate any machine. Trial and

error is not the safe way to become familiar with a piece of equipment.

To prevent injury wear the following protective clothing: Gloves, hard hat, work boots, ear

plugs, safety goggles and any other protective devices required by job conditions.

•Stay AWAY from blades during operation.

•Be cautious with the ventilation of work place. Avoid operating machine in closed

area, since engine exhaust contains poisonous gases.

•Be careful with hot components. Mufflers and other parts of the engine are hot during

operation and right after shutdown.

•Fasten fuel cap tightly and close fuel strainer cock during transportation.

BELT SETTING

STEP 1 –Loosen engine base bolt (underneath engine) to allow engine-base movement.

STEP 2 –Insert V-belt into clutch pulley and reducer pulley one at a time.

STEP 3 –Adjust the engine position by moving engine-base to ensure v-belts are tight

enough.

IMPORTANT: Normal slack should be approximately 10-15mm (1/2”) when the belts are

forcibly depressed in the middle position between rotor pulley and clutch pulley.

Tighten all engine bolts and cover V-belt and pulley with belt cover, tighten cover bolts.

4

PRE START-UP CHECKING

•Consult engine manual for detailed starting information.

•Check all bolts and screws for tightness. Loose bolts and screws may cause damage to

the unit.

•Make sure that all dirt, mud, etc., are thoroughly removed from areas such as cooling air

inlet of engine, carburettor, and air cleaner.

•Check V-belt tightness. The normal slack should be approximately 10-15mm (1/2”) when

the belts are forcibly depressed in the middle position between two pulleys. To set belt

tightness; refer to Belt Setting at page 3.

•Check fuel level and refill as required.

•Check engine oil level. If engine oil level is low, refill it with the correct engine oil as

stated in the engine manual.

CAUTION! –Make sure nobody is in the vicinity of the trowel when starting the engine; it

might move suddenly with force.

STARTING (PETROL UNITS)

STEP 1 –Open engine fuel cock.

STEP 2 –Set throttle lever to starting position.

STEP 3 –For cold engine starting, close carburettor choke lever.

STEP 4 –Set engine switch to “ON”.

STEP 5 –Pull recoil starter.

IMPORTANT: Do not pull recoil starter rope to the end as it may cause damage. When the

rope is pulled out, release the rope slowly. Do not let the rope snap back.

STEP 6 –After engine starts, open the choke halfway and warm up the engine for 2-3

minutes with low speed position. The warm up procedure should particularly be

followed during cold weather.

STARTING (DIESEL UNITS)

STEP 1 –Set speed control to low speed.

STEP 2 –Pull recoil starter rope until resistance is felt.

STEP 3 –Bracing foot against engine, pull recoil starter rope with both hands.

IMPORTANT: Do not pull recoil starter rope to the end as it may cause damage. When the

rope is pulled out, release the rope slowly. Do not let the rope snap back.

5

OPERATION

CAUTION! –Poisonous fumes. Start and operate only in a well-ventilated area. Be careful

with hot components, mufflers and other engine parts are hot during operation. Do not

touch them.

STEP 1 –Adjust throttle lever to the desired speed.

STEP 2 –Follow the pattern illustrated below during operation.

-Smooth partially set floor surface; operate the machine with blades

fattened. For a luster finish, operate with the blades slightly tiled. Over tilted

blades on unset floor with create a wavy surface.

-Floor that has completely set is difficult to smooth. If this is the case, tilt

blades as high as possible. Sprinkle water on the floor beforehand.

6

SHUTDOWN –PETROL UNIT

STEP 1 –Move throttle lever to low speed position quickly and run engine for 2-3 minutes

at low speed.

STEP 2 –Turn of the stop switch, the engine stops completely.

STEP 3 –Close engine fuel cock.

STEP 4 –Cover the machine after the muffler has cooled off and keep the trowel in a dry

place.

EMERGENCY SHUTDOWN: Move throttle lever to OFF and press engine stop button.

SHUTDOWN –DIESEL UNIT

STEP 1 –Move throttle lever to low speed position quickly and run engine for 2-3 minutes

at low speed.

STEP 2 –Move the throttle lever to the stop position.

STEP 3 –Cover the machine after the muffler has cooled off and keep the trowel in a dry

place.

7

MAINTENANCE

CAUTION!

FLAMMABLE LIQUID. When performing maintenance, stop engine and do not smoke in

adjacent area.

HIGH TEMPERATURE. Allow machine and engine to cool down before performing

maintenance. Contact with hot components can cause serious injury.

MOVING PARTS. Make sure engine is shutdown before maintenance. Contact with moving

parts can cause serious injury.

Daily Service

•Wash blades and rotary parts with water before any adhered concrete hardens. Then

dry thoroughly and apply grease or oil on them.

•Constantly check for any lose screws, nuts and bolts; retighten any loose parts.

•Grease spider blade assembly (4 x nipples) with Castrol EPL2 or equivalent.

Weekly Service (every 50 hours of operation)

•Refer to engine service manual.

Reduction Gear Maintenance

•Lubricating oil in reduction gear should be changed after the first 50 hours and 250

hours of operation; and at every 1000 hours of operation thereafter.

•Following oil is recommended for reduction gear –USE SAE 140 GEAR OIL.

•Spray lubricant onto cable pulley and adjuster slide.

STORAGE

Storing for a long period

•Thoroughly drain the fuel from the fuel tank, fuel pipe and carburettor.

•Pour a few drops of motor oil into the cylinder by removing the spark plug. Rotate the

engine several times by hand so that the cylinder interior is covered with oil.

•Clean the outer surface of the machine with an oil-moistened cloth. Cover the unit and

store in a humidity-free, dust-free area.

8

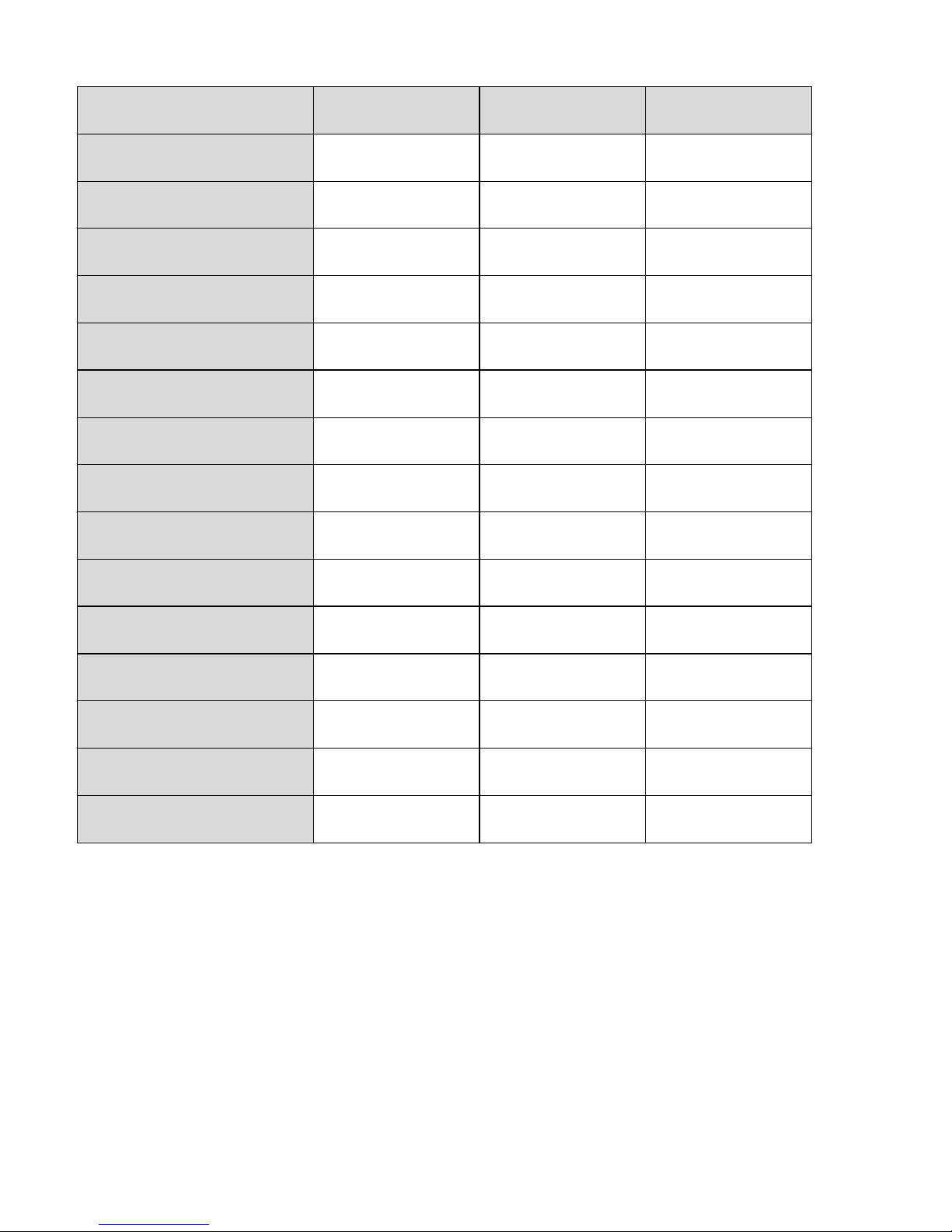

POWER TROWEL SPECIFICATION CHART

MODEL

CPT24S

CPT34R

CPT34RD

Weight (kg)

50kg

75kg

75kg

Engine Make

Subaru

Subaru

Subaru

Engine

4.5hp EX13

6.0hp EX17

4.8hp DY23

Engine Features

OHC

OHC

OHV

Fuel Type

Petrol

Petrol

Diesel

Fuel Tank

2.7L

3.6L

3.2L

Noise Level db@7m

64.0

66.0

74.0

Manufacturers Warranty

2 yrs

2 yrs

2 yrs

Engine Warranty

3 yrs

3 yrs

3 yrs

Trowel Size

24” (610mm)

34” (860mm)

34” (860mm)

Overall WxLxH (mm)

660x1460x980

932x1700x1000

1080x1700x1000

Blade Diameter

610mm

860mm

1016mm

Blade Dimensions

225x120

195x325

200x376

Quantity of Blades

4

4

4

Blade Revolution (RPM)

50 - 100

50 - 100

50 - 100

9

POWER TROWEL SPECIFICATION CHART

MODEL

CPT40R

CPT40RD

CPT46S

Weight (kg)

78kg

93kg

102kg

Engine Make

Subaru

Subaru

Subaru

Engine

6.0hp EX17

4.8hp DY23

9.0hp EX27

Engine Features

OHC

OHV

OHC

Fuel Type

Petrol

Diesel

Petrol

Fuel Tank

3.6L

3.2L

6.1L

Noise Level db@7m

66.0

74.0

70.0

Manufacturers Warranty

2 yrs

2 yrs

2 yrs

Engine Warranty

3 yrs

3 yrs

3 yrs

Trowel Size

40” (1016mm)

40” (1016mm)

46” (1170mm)

Overall WxLxH (mm)

1080x1700x1000

1080x1700x1000

1155x1775x1000

Blade Diameter (mm)

1016

1016

1170

Blade Dimensions (mm)

200x376

200x376

195x480

Quantity of Blades

4

4

4

Blade Revolution (RPM)

50 - 100

50 - 100

50 - 100

10

TROUBLE SHOOTING GUIDE

If the power trowel malfunctions immediately shut the machine down. Following are

some simple trouble shooting tips:

PROBLEM

CAUSE

SOLUTION

Engine stops suddenly

or does not run

1. No fuel in the engine

2. Spark plug carbonised

3. Containment is being

snagged up to fuel

strainer

1. Refill Fuel

2. Clean spark plug

3. Clean fuel strainer

Machine is slow or

erratic

1. Loose V-belt

1. Adjust V-Belt (refer to belt

installation and setting)

Engine runs but the

machine does not

1. Clutch slip

1. Disassemble clutch and clean

it, then reassemble

IF THE FAULT PERSISTS, CONTACT YOUR LOCAL DEALER.

11

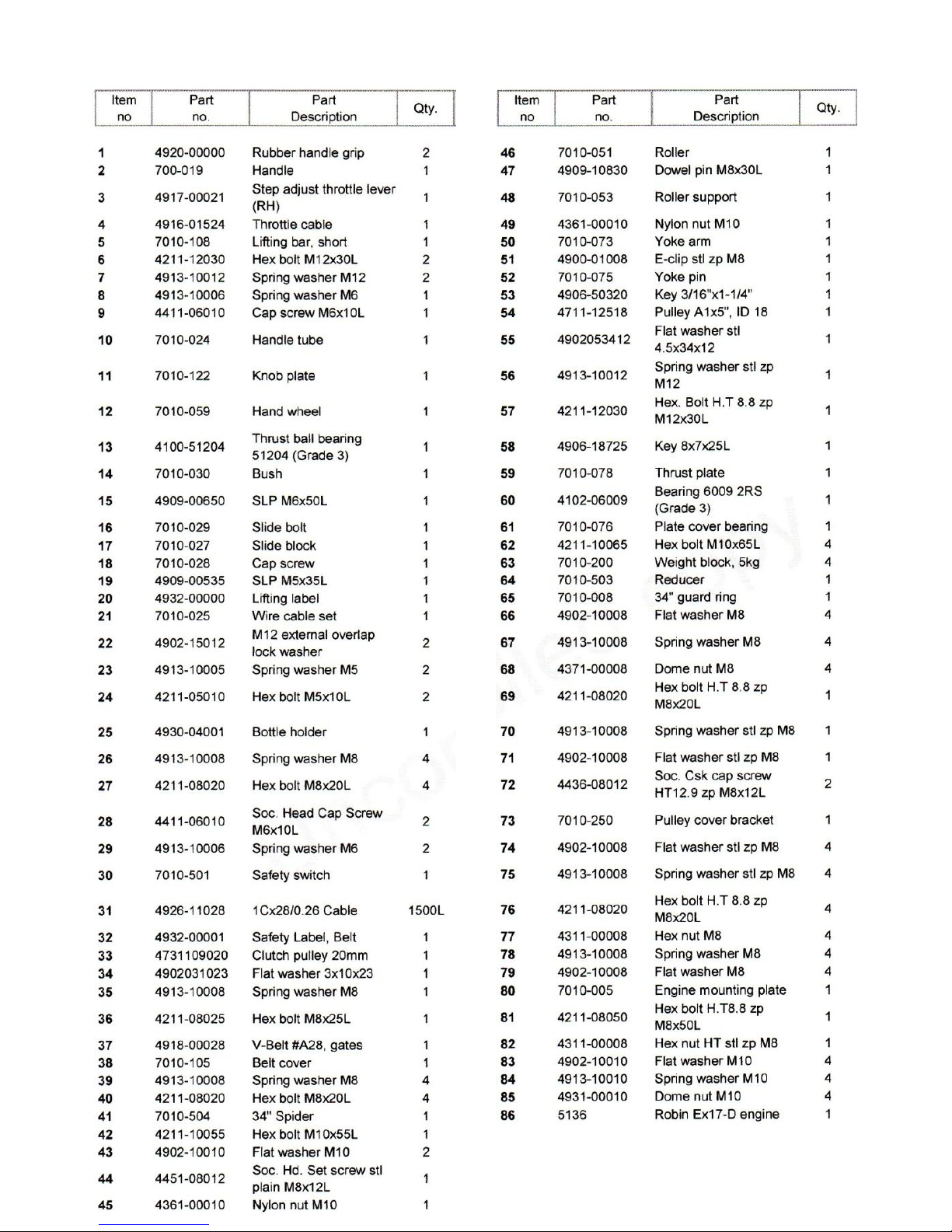

POWER TROWEL PARTS DIAGRAM

12

POWER TROWEL PARTS LIST

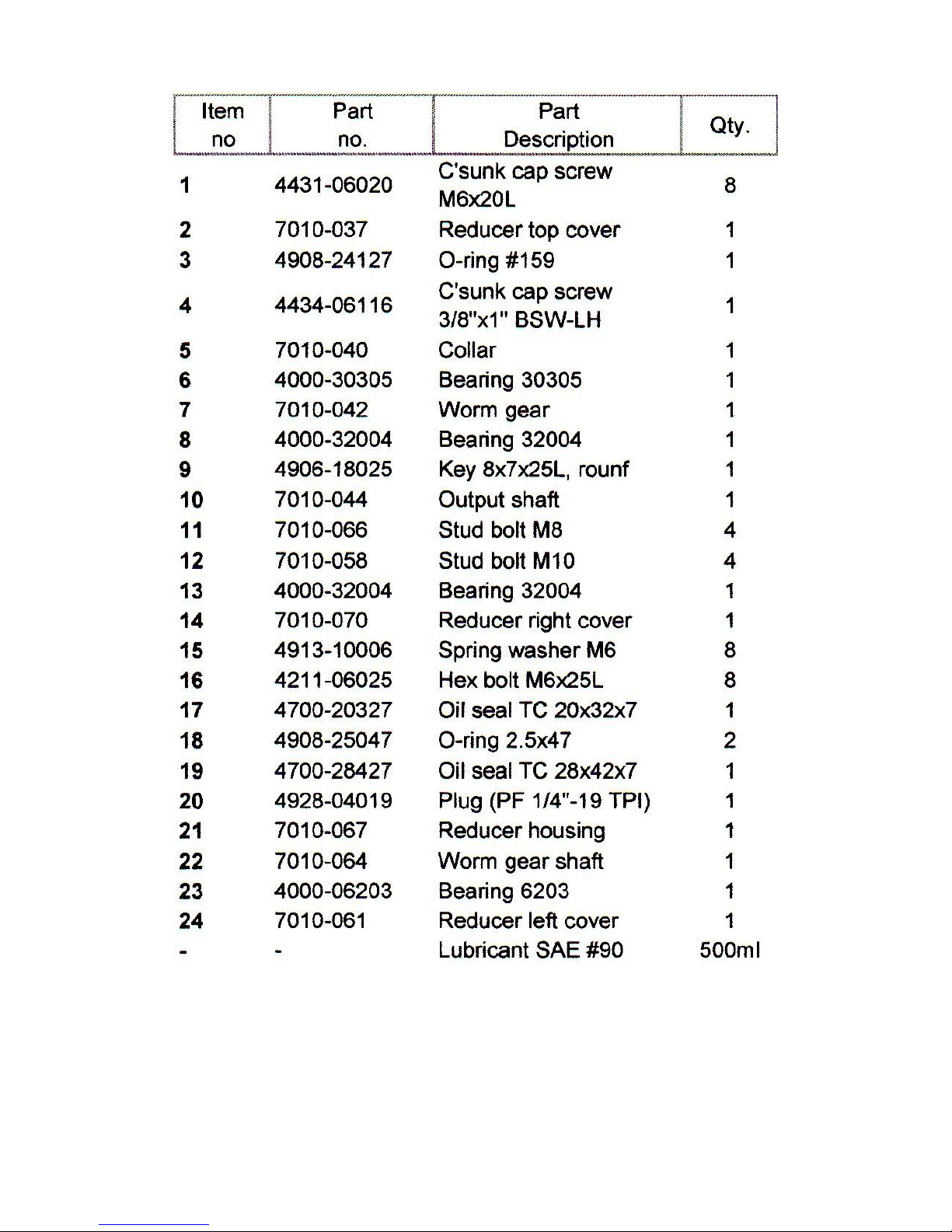

13

POWER TROWEL REDUCER DIAGRAM

14

POWER TROWEL REDUCER PARTS LIST

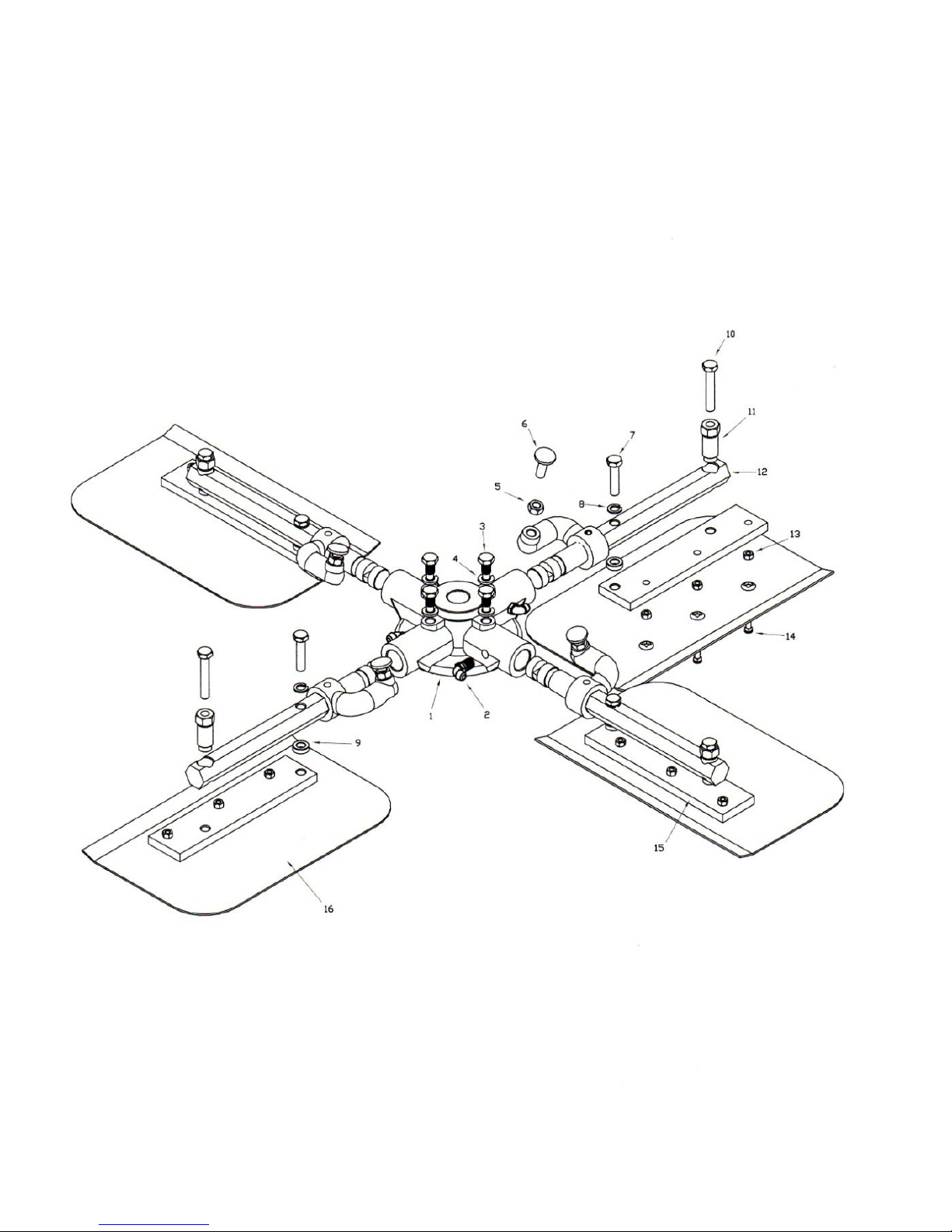

15

POWER TROWEL SPIDER DIAGRAM

16

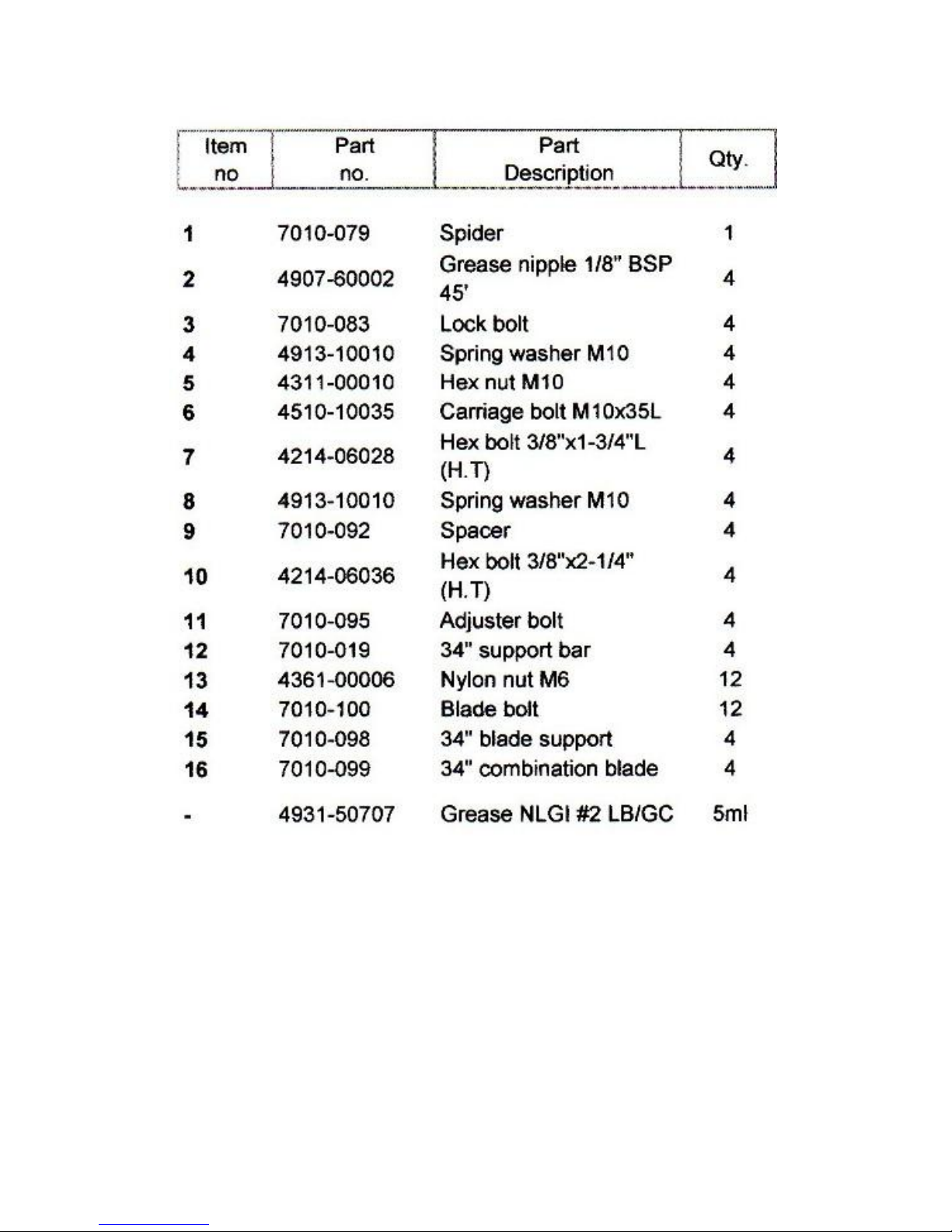

POWER TROWEL SPIDER PARTS LIST

16 CPT70140SET 40” Blade Set (Qty 4) 1

16 CPT70146SET 46” Blade Set (Qty 4) 1

This manual suits for next models

5

Table of contents