Crompton Tyco Electronics SWITCHBOARD INTEGRA 1540 User manual

Installation and Operating Instructions

SWITCHBOARD INTEGRA 1540

http://energy.tycoelectronics.com

Energy Division

Tyco Electronics UK Limited

Crompton Instruments

Freebournes Road, Witham, Essex, CM8 3AH, UK

Tel: +44 1376 509 509

Fax: +44 1376 509 511

Crompton Switchboard

INTEGRA 1540

Power Measurements and Display Made Easy

Installation & Operating Instructions

Models INT - 1543 and INT - 1544

Crompton Instruments

Freebournes Road

Witham

Essex

CM8 3AH

England

Tel: +44 (0) 1376 509 509

Fax: +44 (0) 1376 509 511

E-Mail: [email protected]

Crompton Instruments 1540 MANUAL Issue 1 11/2002

Contents Page

Introduction 1

2 Installation 2

2.1 Display 2

2.2 EMC Installation Requirements 2

2.3 Case Dimension and Panel Cut-Out 3

2.3.1 Model INT-1540 3

2.4 Wiring 4

2.5 Auxiliary Supply 4

2.6 Fusing 4

2.7 Earth/Ground Connections 4

3 Connection Diagrams 5

3.1 View of Terminals 5

USA Style 5

3.3 European Style 6

4 Integra 1540 Display Screens 7

4.1 Screen 1 – System Screen INT-1540 7

4.2 Screen 2 – System %THD Screen 7

4.3 Screen 3 – Line to Neutral Voltages 7

4.4 Screen 4 – Line to Neutral Voltage %THD 8

4.5 Screen 5 – Line to Line Voltages 8

4.6 Screen 6 – Line to Line Voltages %THD 8

4.7 Screen 7 – Line Currents 9

4.8 Screen 8 – Line Currents %THD 9

4.9 Screen 9 – Neutral Current, Frequency and Power Factor 9

4.10 Screen 10 – Power 10

4.11 Screen 11– Active Energy (kW.h) 10

4.12 Screen 12 – Reactive Energy (kVAr.h) 10

4.13 Screen 13 – Active Power and Current Demands 11

4.14 Screen 14 – Active Power and Current Maximum Demands 11

4.15 Over Range 11

4.16 kW.h and kVAr.h Display Range 12

4.17 Error Messages 12

5 Programming 13

5.1 Password Protection 13

5.2 Set-Up Screens 16

5.2.1 Full Scale Current 16

5.2.2 Potential Transformer Ratio Primary Value 17

5.2.3 Demand Integration Time Edit 19

5.2.4 Resets 20

5.2.5 Pulsed Output, Pulse Duration 22

5.2.6 Pulse Rate 22

5.2.7 RS 485 Baud Rate 23

5.2.8 RS 485 Parity Selection 24

5.2.9 RS 485 Modbus Address 24

6 Outputs 26

6.1 Modbus‚ Implementation 26

6.2 RS485 Implementation for Johnson Controls Metasys 31

6.3 Pulsed Output 33

7 Maximum Demand Calculation 34

8 THD Calculation 35

9 Specification 36

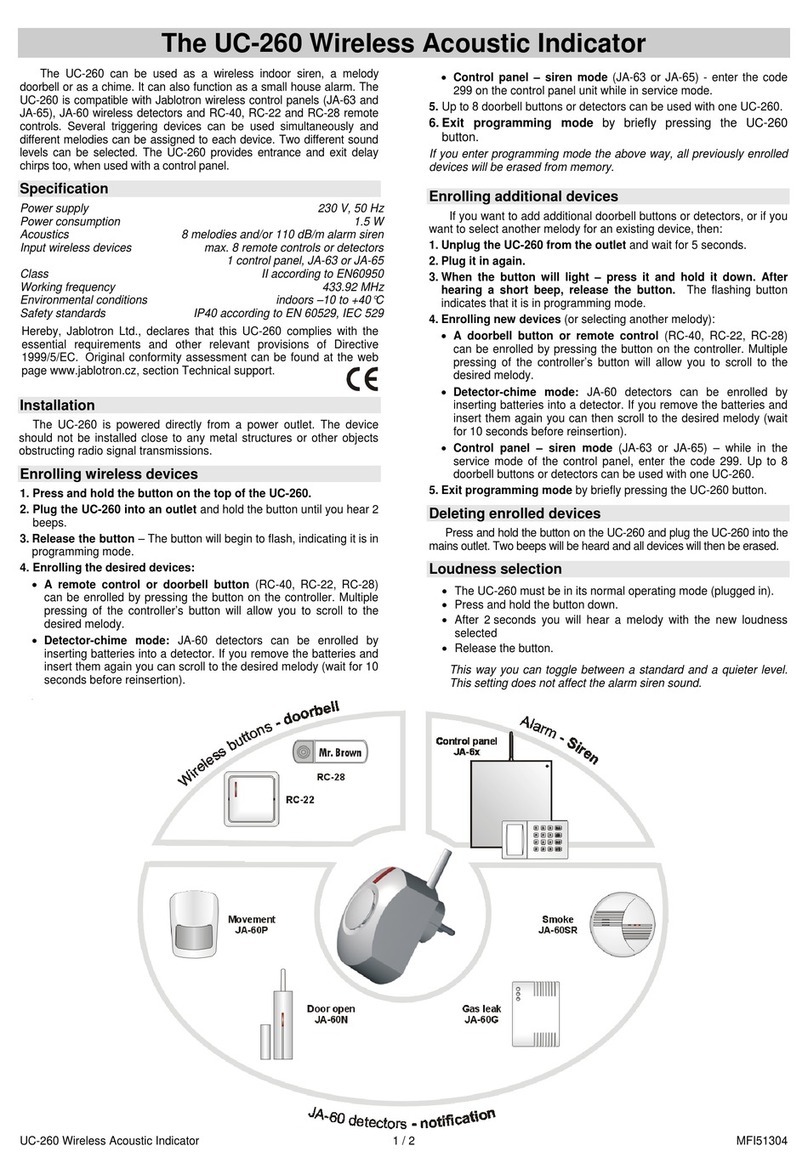

1 Introduction

The Crompton Switchboard 1540 is a panel mounted self contained measuring, display and

communication device.

This system will measure display and communicate up to 31 electrical parameters, integrating

high accuracy measurement technology with the simplicity and visibility of 7 segment LED

displays.

All voltage and current measurements are True RMS for accurate

measurement of distorted waveforms over a wide measuring

range. The Integra 1540 has excellent harmonic handling for true

power measurement.

Available in the following configurations:

3 Phase 3 Wire Unbalanced

3 Phase 4 Wire Unbalanced

The Integra 1540 front panel has two push buttons, referred to as

“keys”. The two keys take the user through the menu structure

with ease and simplicity, to display and configure to their

individual requirements.

The parameters available are shown in the table below.

1

Integra 1540 Measured Quantity Units of measurement

System Voltage Volts

System Current (Average) Amps

Average % Total Harmonic Distortion (THD) of System Voltage % of Total RMS

and Current

Voltage L-N (4 wire only) Volts

% Total Harmonic Distortion (THD) of voltage % of Total RMS

Voltage L-L (calculated in 4 wire) Volts

Current in 3 Phases Amps

% Total Harmonic Distortion (THD) of Current % of Total RMS

Neutral Current (4 wire only) Amps

Frequency Hz

Power Factor

Active Power kW, see note 1

Reactive Power kVAr, see note 1

Apparent Power kVA

Active Energy kW.h

Reactive Energy kVAr.h

Total System Current Demand Admd

Total System Active Power Demand kWdmd

Maximum Total System Current Demand Admd

Maximum Total System Active Power Demand kWdmd

Note 1. All power related measurements are importing only unless connected as exporting unit.

A pulsed relay output, representing kW.h, with selectable pulse width, and an RS485 ModbusTM

output (see Section 4 Integra 1540 Display Screens) are available as optional features.

Connections for both are via screw clamp terminals.

2 Installation

2.1 Display

The Switchboard Integra 1540 may be mounted in a panel of any thickness up to a maximum of

0.47”. Mounting is by four 1/4- 28 UNF corner studs and nuts. Consideration should be given to

the space required behind the instrument to allow for bends in the connection cables.

As the front of the enclosure conforms to IP54 it is protected from water spray from all

directions, additional protection to the panel may be obtained by the use of an optional panel

gasket. The terminals at the rear of the product should be protected from liquids.

Switchboard Integra 1540 should be mounted in a reasonably stable ambient temperature within

the range -20 to +70°C. Vibration should be kept to a minimum and the product should not be

mounted where it will be subjected to excessive direct sunlight.

WARNINGS:

●In the interest of safety and functionality these products must be installed by a qualified

engineer, abiding by any local regulations.

●Voltages dangerous to human life are present at some of the terminal connections of these

units. Ensure that all supplies are de-energised before attempting any connection or

disconnection. External installations must be sufficient to protect human life and

equipment under fault conditions.

●These products do not have internal fuses therefore external fuses must be used for

protection for safety under fault conditions.

2.2 EMC Installation Requirements

These products have been designed to meet the certification of the EU directives when installed

to a good code of practice for EMC in industrial environments, e.g.

●Screened output and low signal input leads. Other connecting leads must be screened or

have provision for fitting RF suppression components, such as ferrite absorbers, line filters

etc., if RF fields cause problems. N.B. It is good practice to install sensitive electronic

instruments, that are performing critical functions, in EMC enclosures that protect against

electrical interference causing a disturbance in function.

●Avoid routing leads alongside cables and products that are, or could be, a source of

interference.

●To protect the product against permanent damage, surge transients must be limited to 2kV

peak. It is good EMC practice to suppress differential surges to 2kV at the source. The unit

has been designed to automatically recover in the event of a high level of transients. In

extreme circumstances it may be necessary to temporarily disconnect the auxiliary supply

for a period of greater than 5 seconds to restore correct operation.

●The current inputs of these products are designed for connection into systems via current

transformers only; where one side is grounded.

2

2.3 Case Dimension and Panel Cut-Out

2.3.1 Model INT-1540

3

Model JIS ANSI

DIM A 3.54” (90.0mm) 3.37” (85.7mm)

DIM B 3.90” (99.0mm) 3.98” (101.2mm)

DIM X 3.54” (90.0mm) 3.37” (85.7mm)

DIM Y 3.98” (101.2mm) 4.06” (103.0mm)

DIM Z Ø0.22” (5.5mm) Ø0.31” (7.87mm)

2.4 Wiring

Input connections are made to screw clamp terminals. Choice of cable should meet local

regulations. Terminals for both current and voltage inputs will accept up to 3mm2x 2 diameter

cables or ring lugs suitable for 6-32 screws.

Output connections are made directly to the screw clamp style terminals. The choice of cable

should satisfy local regulations. See Section 6 Outputs for more detail.

2.5 Auxiliary Supply

Switchboard Integra 1540 should ideally be powered from a dedicated supply, however it may

be powered from the signal source, providing the source remains within the limits of the chosen

auxiliary voltage.

2.6 Fusing

It is recommended that all voltage lines are fitted with 1 amp HRC fuses.

2.7 Earth/Ground Connections

For safety reasons, CT secondary connections should be grounded in accordance with local

regulations.

4

3 Connection Diagrams

3.1 View of Terminals

3.2 USA Style

Importing Connections Exporting Connections

5

3.3 European Style

IMPORTING CONNECTIONS EXPORTING CONNECTIONS

6

4 Integra 1540 Display Screens

4.1 Screen 1 – System Screen INT-1540

The system screen is the default display. It appears when the unit is energised.

System Average Voltage (Volts) {Line to Line for 3 wire

systems, Line to Neutral for 4 wire systems}.

System Average Line Current (Amps).

System Total Active Power (kW).

Key >> brings up Screen 2, System %THD.

4.2 Screen 2 – System %THD Screen

Average % Total Harmonic Distortion for System Voltages.

Average % Total Harmonic Distortion for System Currents.

3 phase 3 wire supply: Key >> brings up Screen 5, L-L

Voltages.

3 phase 4 wire supply: Key >> brings up Screen 3, L-N

Voltages.

4.3 Screen 3 – Line to Neutral Voltages

Three phase, four wire systems only.

Voltage Line 1 to Neutral (Volts).

Voltage Line 2 to Neutral (Volts).

Voltage Line 3 to Neutral (Volts).

Key >> brings up Screen 4, Line to Neutral Voltage %THD.

7

4.4 Screen 4 – Line to Neutral Voltage %THD

Three phase, four wire systems only.

%THD of Line 1 Voltage to Neutral.

%THD of Line 2 Voltage to Neutral.

%THD of Line 3 Voltage to Neutral.

Key >> brings up Screen 7, Line Currents.

4.5 Screen 5 – Line to Line Voltages

Voltage Line 1 to Line 2 (Volts).

Voltage Line 2 to Line 3 (Volts).

Voltage Line 3 to Line 1 (Volts).

Three phase, three wire systems only:

Key >> brings up Screen 6, L-LV %THD.

4.6 Screen 6 – Line to Line Voltages %THD

Three phase, three wire systems only.

Line 1 to Line 2 Voltage %THD.

Line 2 to Line 3 Voltage %THD.

Line 3 to Line 1 Voltage %THD.

Key >> brings up screen 7, Line Currents.

8

4.7 Screen 7 – Line Currents

Line 1 Current (Amps).

Line 2 Current (Amps).

Line 3 Current (Amps).

Key >> brings up Screen 8, Line Currents %THD.

4.8 Screen 8 – Line Currents %THD

Line 1 Current %THD.

Line 2 Current %THD.

Line 3 Current %THD.

Key >> brings up Screen 9, Neutral Current, Frequency and

PF.

4.9 Screen 9 – Neutral Current, Frequency

and Power Factor

Neutral Current (Amps). (4-wire system only).

Frequency (Hz).

Power Factor (0 to 1).

Key >> brings up Screen 10, Power.

9

4.10 Screen 10 – Power

Reactive Power (kVAr).

Apparent Power (kVA).

Active Power (kW).

Key >> brings up Screen 11, Active Energy.

4.11 Screen 11– Active Energy (kW.h)

Active Energy (kW.h).

7 digit reading i.e. 0001243.

Key >> brings up Screen 12, Reactive Energy.

4.12 Screen 12 – Reactive Energy (kVAr.h)

Reactive Energy (kVAr.h).

7 digit reading i.e. 0000102.

Key >> brings up Screen 13 Active Power and Current

Demands.

10

4.13 Screen 13 – Active Power and Current Demands

System Total Active Power Demand (kWD).

System Total Current Demand (AD).

Key >> brings up Screen 14 Active Power and Current

Maximum Demands.

4.14 Screen 14 – Active Power and Current Maximum

Demands

Maximum System Total Active Power Demand (kWD).

Maximum System Total current Demand (AD).

Key >> takes you back to the start of the sequence with the

System Screen. See Section 4.1 Screen 1 – System Screen.

4.15 Over Range

The displayed values must be in the range –999 x 1000 to

9999 x 1000.

While operating within the specified range, the displayed

value will not over range for positive values.

Whilst displaying negative values the display will overflow for

values more negative than –999 x 1000, this situation will be

indicated by displaying four bars in the appropriate line:

Value on middle line has overflowed.

11

4.16 kW.h and kVAr.h Display Range

The kW.h and kVAr.h display range is limited to 9999999. If the unit is allowed to increment

beyond this value the internal count will continue to be updated, but the display will change to

seven bars. The counter will register from a count of 1 kW.h kVAr.h to a maximum of 9,999,999.

The value will continue to be available via the Modbus output.

4.17 Error Messages

The display screen repeatedly requests new values from the measurement processor, if there is

a problem obtaining these values the display will continue to retry but will alert the user by

displaying the message Err1. This message may be seen briefly during conditions of extreme

electromagnetic interference with the normal display returning once the interference has ceased.

If the Err1 message persists a short interuption to the auxiliary supply, up to 10 minutes, may

restore normal operation.

12

5 Programming

The following sections comprise step by step procedures for configuring the Switchboard 1540

for the individual user requirements.

To access the set-up screens press and hold the “ Adjust” and “>> Next” keys simultaneously

for 5 seconds. This will take the user into the password protection entry stage. (See Section 5.1

Password Protection). To return to the display screens at anytime during these procedures,

press the “ Adjust” and “>> Next” keys simultaneously for 5 seconds.

5.1 Password Protection

Password protection can be enabled to prevent unauthorised access to set-up screens, by

default password protection is not enabled.

Password protection is enabled by selecting a four digit number other than 0000, setting a

password of 0000 disables the password protection.

Enter Password, prompt for first digit.

(* Denotes that decimal point will be flashing).

Press the “ Adjust” key to scroll the value of the first digit

from 0 through to 9, the value will wrap from 9 round to 0.

Press the “>> Next” key to advance to the next digit.

In the special case where the Password is “0000” pressing the

“>> Next” key when prompted for the first digit will advance

to the “Password Confirmed” screen.

Enter Password, first digit entered, prompt for second digit.

(* Denotes that decimal point will be flashing).

Press the “ Adjust” key to scroll the value of the second

digit from 0 through to 9, the value will wrap from 9 round to

0.

Press the “>> Next” key to advance to the next digit.

13

Enter Password, second digit entered, prompt for third digit.

(* Denotes that decimal point will be flashing).

Use the “ Adjust” key to scroll the value of the third digit

from 0 through to 9, the value will wrap from 9 round to 0.

Press the “>> Next” key to advance to the next digit.

Enter Password, third digit entered, prompt for fourth digit.

(*decimal point indicates that this will be flashing).

Use the “ Adjust” key to scroll the value of the fourth digit

from 0 through to 9, the value will wrap from 9 round to 0.

Press the “>> Next” key to advance to verification of the

password.

Enter Password, fourth digit entered, awaiting verification of

the password.

Password Confirmed.

Pressing “ Adjust” key will advance to the “New/Change

Password” entry stage.

Pressing the “>> Next” key will advance to the Full Scale Set-

Up Screen. (See Section 5.2.1 Full Scale Current).

14

Password Incorrect.

The unit has not accepted the password entered.

Pressing the “ Adjust” key will return to the “Enter

Password“ stage.

Pressing the “>> Next” key exits the set-up menus and returns

operation to the normal display mode.

New/Change Password.

(* decimal point indicates that this will be flashing).

Pressing the “ Adjust” key will scroll the value of the first

digit from 0 through to 9, the value will wrap from 9 round to

0.

Pressing the “>> Next” key advances the operation to the next

digit and sets the first digit, in this case to “2”.

New/Change Password, first digit entered, prompting for

second digit. (*decimal point indicates that this will be

flashing).

Pressing the “ Adjust” key will scroll the value of the second

digit from 0 through to 9, the value will wrap from 9 round to

0.

Pressing the “>> Next” key advances the operation to the next

digit and sets the second digit, in this case to “1”.

New/Change Password, second digit entered, prompting for

third digit. (*decimal point indicates that this will be flashing).

Pressing the “ Adjust” key will scroll the value of the third

digit from 0 through to 9, the value will wrap from 9 round

to 0.

Pressing the “>> Next” key advances the operation to the next

digit and sets the third digit, in this case to “5”.

15

New/Change Password, third digit entered, prompting for

fourth digit. (* Denotes that decimal point will be flashing).

Pressing the “ Adjust” key will scroll the value of the fourth

digit from 0 through to 9, the value will wrap from 9 round to

0.

Pressing the “>> Next” key advances the operation to the

“New Password Confirmed” and sets the fourth digit, in this

case to “3”.

New Password Confirmed.

Pressing “ Adjust” key will return to the “New/Change

Password”.

Pressing the “>> Next” key will advance to the Full Scale Set-

Up Screen.(See Section 5.2.1 Full Scale Current).

5.2 Set-Up Screens

Note: The Screens in sections 5.2.5 to 5.2.9 will be displayed in all units but will have no effect

on the operation of those units that do not have these options fitted.

5.2.1 Full Scale Current

The nominal Full Scale Current that will be displayed as the Line Currents. This screen enables

the user to display the Line currents inclusive of any transformer ratios, the values displayed

represent the Current in Amps.

Pressing the “>> Next” key accepts the present value and advances to the potential transformer

ratio menu. (See Section 5.2.2 Potential Transformer Ratio).

Pressing the “ Adjust” key will enter the “Full Scale Current

Edit” mode. This will scroll the value of the most significant

digit from 0 through to 9, unless the presently displayed

current transformer ratio together with the full scale voltage

value results in a maximum power of greater than 360

Megawatts in which case the digit range will be restricted, the

value will wrap from 4 round to 0. (0 to 9 for lesser significant

digits).

Pressing the “>> Next” key will advance to the next less

significant digit. (* Denotes that decimal point will be

flashing).

16

The “Maximum Power” restriction of 360 Megawatts refers to 120% of nominal current and

120% of nominal voltage, i.e. 250 Megawatts nominal system power.

When the least significant digit has been set, pressing the “>> Next” key will advance to the

“Full Scale Current Confirmation” stage.

The minimum value allowed is 1, the value will be forced to 1 if the display contains zero when

the “>> Next” key is pressed.

Full Scale Current Confirmation.

This screen will only appear following an edit of the full-scale

current.

If the scaling is not correct, pressing the “ Adjust” key will

return to the “Full Scale Current Edit” stage with the most

significant digit highlighted (associated decimal point flashing)

and the bottom line of the display will be blanked.

Pressing the “>> Next” key sets the displayed value and will

advance to the “Potential Transformer Ratio” menu. (See

Section 5.2.2 Potential Transformer Ratio).

5.2.2 Potential Transformer Ratio Primary Value

The nominal full scale voltage which will be displayed as the L1-N, L2-N and L3-N for a four wire

system or as L1-2, L2-3 and L3-1 in a three wire system. This screen enables the user to display

the line to neutral and line to line voltages inclusive of any transformer ratios, the values

displayed represent the voltage in kilovolts (note the x1000 enunciator).

Pressing the “>> Next” key accepts the present value and

advances to the “Demand Integration Time” menu. (See

Section 5.2.3 Demand Integration Time Edit).

Pressing the “ Adjust” key will enter the “Potential

Transformer Ratio Edit” Mode.

Initially all the digits of the current value will be flashing and

the decimal point position will be illuminated. This is to

indicate that initially the “multiplier” must be selected,

pressing the “ Adjust” key will move the decimal point

position to the right until it reaches ###.# after which it will

return to #.###.

Pressing the “>> Next” key will accept the present multiplier

(decimal point position) stop the digits flashing and advances

to the “Potential Transformer Digit Edit” mode.

17

Table of contents

Other Crompton Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Molecular Devices

Molecular Devices SPECTRAmax PLUS 384 Operator's manual

NoiseMeters

NoiseMeters CEL24 Series Quick user guide

Aalborg

Aalborg GFM 17 operating manual

Schmidt

Schmidt MST Series instruction manual

ABB

ABB MicroGuard solution user manual

PCB Piezotronics

PCB Piezotronics 3501B1260KG Installation and operating manual