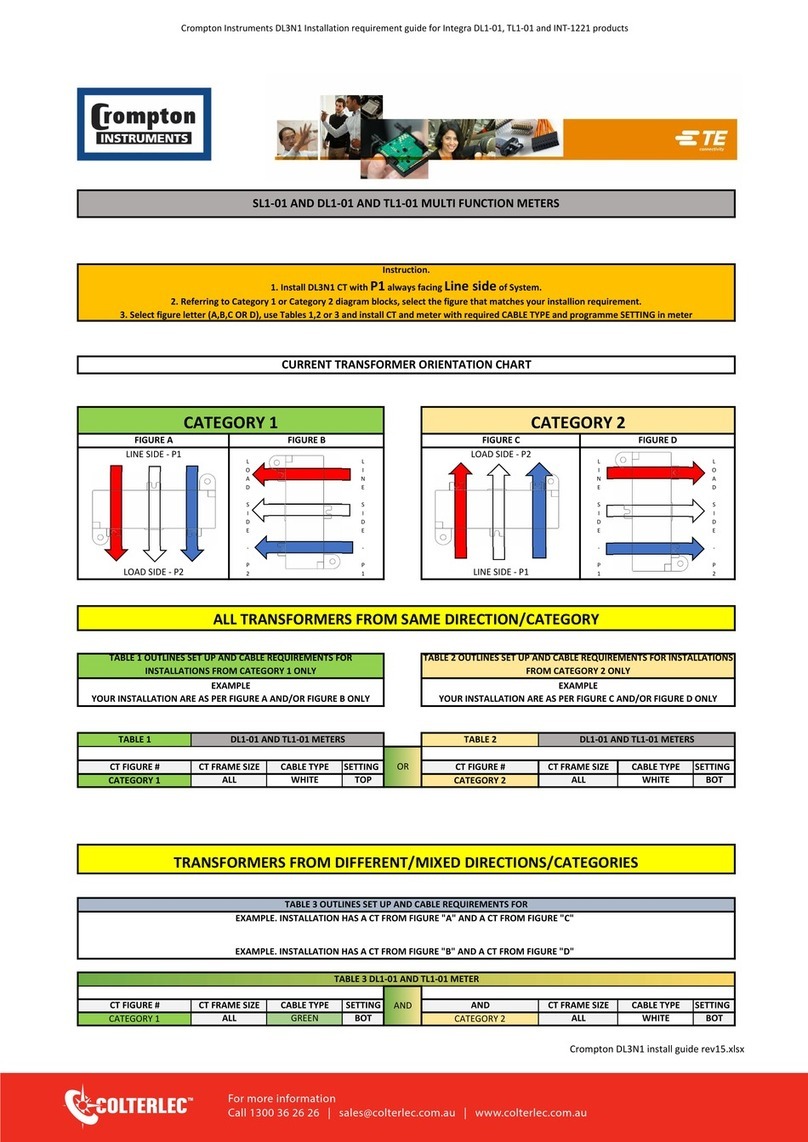

Crompton 264 Series User manual

Crompton • www.crompton-instruments.comMay 27, 2005 Crompton Bar Digital DS (NK2) Page 1

Smart Tricolor or mono-color digital bargraph with a Universal Header Selectable

Input, an optional isolated analog output and up to four fully programmable set

points, for monitoring, measurement, and control applications.

• A Tricolor or mono color (red or green), 101 segment high

brightness bargraph. Optional vertical or horizontal format.

• Red 4-digit LED display with range between –1999 to

9999 (12000 counts). Optional green digital display.

• Front panel LED annunciators provide indication of set-

point status.

• Two 10 Amp Form C, and two 5 Amp Form A relays available.

•

Auto-sensing AC/DC power supply. For voltages between

85-264 V AC / 110-370 V DC (Z) or 18-48 / 18-72 V AC / DC (Y).

• Optional isolated 16 bit analog output. User or factory

scalable to 4 to 20 mA, 0 to 20 mA or 0 to 10 V across

any desired digital span from ± one count to the full scale

range of – 1999 to 9999 (12000 counts).

• Optional NEMA-4 front cover.

•

Automatic averaging (16 sample moving average with eight

count replacement window to speed up display response).

• 24 V DC excitation is available to power external 4/20 mA

transmitters.

General Features Specifications

Input Specs: ..............Depends on

range and function selected

A/D Converter:...........14 bit single slope

Accuracy:...................±(0.05% of reading + 2 counts)

Temp. Coeff.: .............100 ppm/°C (Typical)

Warm up time:...........2 minutes

Conversion Rate: ......10 conversions per second (Typical)

Digital Display:..........

4 digit 0.31" LED red (std), green (optn)

Range

–1999 to 9999 counts.

Bargraph Display:.....

101 segment 4” red vertical (std),

green or tricolor (optn), horizontal (optn)

Polarity:......................Assumed positive. Displays – negative

Decimal Selection:....Front panel button selectable, X•X•X•X•

Positive Overrange:..Bargraph and top segments of digital

display flash.

Negative Overrange:.First segment of bargraph and bottom

segments of digital display flash.

Relay Output: ............Two 5 Amp Form A relays and Two

10 Amp Form C relays.

Analog Output:..........Isolated 16 bit user scalable mA or V

1: (volts out)............. 0-10 V DC @ 500 Ωor higher resistance

2: (mA out) ..............

4-20 mA @ 0 to 500Ωmax loop resistance

Power Supply:...........AC/DC Auto sensing wide range supply

Y..............................

18-48 VAC / 18-72 VDC @ 2.5W max 4.2W

Z (std).....................

85-265 VAC / 95-370 VDC @ 2.5W max 4.2W

Operating Temp.:.......0 to 60°C

Storage Temp: ...........–20°C to 70°C

Relative Humidity: ....95% (non condensing)

Case Dimensions:.....

3/32 DIN (Bezel 36Wx144Hmm)

Depth behind bezel 135 mm (5.32")

Plus 16 mm (0.63”) for connectors

Weight:.......................9.5 oz., 12 oz when packed

• The bargraph can display,

full scale, any desired por-

tion of the digital reading.

•

Bargraph center zero func-

tion.

•

Four programmable set-

points.

• Setpoint 1 has delay-on-

make and delay-on-break

plus a special “pump on

pump off” mode that cre-

Software Features

ates a Hysteresis Band

between SP1 and SP2.

• Relay activation can be

selected to occur above

(hi) or below (Lo) each set-

point.

• Digital display blanking.

• Decimal point setting.

• Four-level brightness con-

trol of the bargraph and

digital display.

Ordering Code

UNIVERSAL PROCESS INPUT

**: Custom Input

1: 0 ~ 1mA

2: 4 ~ 20mA

3: 0 ~ 1V

4: 1 ~ 5V

5: 0 ~ 5V

ANALOG OUTPUT

_: Custom Output

_: 0 ~ 10V

_: 4 ~ 20mA

_: 0 ~ 20mA

RELAYS

DTV: No Relays

DTT: Two 10A Form C Relays

DTF: Two 10A Form C Relays

and Two 5A Form A Relays

POWER SUPPLY

A: 85 ~ 264V AC

110 ~ 370V DC

B: 19 ~ 36V AC/DC

COLOR

RD: Red Bargraph

GN: Green Bargraph

YL: Yellow Bargraph

: Tricolor Bargraph

DISPLAY

VS: Vertical

HS: Horizontal

264 SERIES

of

101 Segment Bargraphs

with Digital Display

Crompton • www.crompton-instruments.comPage 2 May 27, 2005 Crompton Bar Digital DS (NK2)

Front Panel Buttons

Program Button

The

P

button is used to move from one program step to the next.

Controls and Indicators

When pressed at the same time as the button, it initiates the

calibration mode. When pressed at the same time as the

button, it initiates the setpoint setting mode.

Up Button

When in the operational display, pressing the button allows you

to view the setting of setpoint 1.

When setting a displayed parameter during programming, the

button is used to increase the value of the displayed parameter.

Down Button

When in the operational display, pressing the button allows you

to view the setting of setpoint 2.

When setting a displayed parameter during programming, the

button is used to decrease the value of the displayed parameter.

Front Panel LED Display

Relay Activation

The Relay Activation LEDs indicate the alarm status. They are

labeled from bottom to top: SP1, SP2, SP3, SP4.

Digital LED Displays

The digital LED displays are used to display the meter input

signal readings. They also display the programming settings

during programming.

Setpoint Indication

The position of setpoints on the bargraph display are indicated by

an ON or OFF segment depending on whether the bargraph display

is below or above the setpoint.

0

10

30

50

70

20

40

60

80

4

3

2

1

P

SP

101 Segment

Bargraph

Optional Program

Lockout Switch

(located behind

faceplate)

Relay Activation LED (SP4)

Relay Activation LED (SP3)

Relay Activation LED (SP2)

Relay Activation LED (SP1)

UP Button

PROGRAM

Button

DOWN

Button

4 Digit LED

Display

Setpoint

indicated

by an OFF

Segment

Setpoint

indicated

by an ON

Segment

To remove setpoint

indication, set to a

value below bLo

This symbol represents the

OPERATIONAL DISPLAY.

This is the PROGRAM button.

This is the UP button.

This is the DOWN button.

When a button is shown, press and release

it to go onto the next step in the direction

indicated by the arrow. When an alterna-

tive dotted line is shown, this indicates that

an alternative logic branch will be followed

when a particular option is present.

When two buttons are shown side by

side and enclosed by a dotted line, they

must be pressed at the same time then

released to go onto the next programming

step.

If an X appears through a digit, it means

that any number displayed in that digit is not

relevant to the function being explained.

P

[Span]

[10000]

P

P

[LLLL]

[LhLh]

[hLhL]

When the

and

buttons are shown

together, the display value can be increased

by pressing and releasing the

button

or decreased by pressing and releasing the

button.

When the

and

buttons are shown

with two displays, either display can be

selected by pressing and releasing the

or

buttons.

When two displays are shown together

with bursts, this indicates that the display is

toggling (flashing) between the name of the

function and the value.

Text or numbers shown between square

brackets in a procedure indicate the pro-

gramming code name of the function or the

value displayed on the meter display.

When there are more than two display selec-

tions they are shown in brackets below the

first display and are also selectable by press-

ing and releasing the

or

buttons.

A dotted line enclosing an entire logic dia-

gram indicates that programming branch

will appear only when a particular option is

present.

To explain software programming procedures, logic diagrams are

used to visually assist in following the programming steps. The

following symbols are used throughout the logic diagrams to

represent the buttons and indicators on the meter:

Programming Conventions

Crompton • www.crompton-instruments.comMay 27, 2005 Crompton Bar Digital DS (NK2) Page 3

Operational Display

MAIN MENU

SETPOINT

VIEW ONLY MODE

SETPOINT

VIEW ONLY MODE

Set points cannot

be changed

in the SETPOINT

VIEW ONLY MODE.

Example

Bargraph Center Point

Display Selection (cto)

This branch will

only appear if

the analog

output option

is installed

Digital Display ON/OFF

Selection (diSP)

Sub-menu MODE

Calibration Mode

Calibration

Input

Calibration

Output

Calibrate Analog

Output Lo

Calibrate Analog

Output Hi

Select the Digital

Reading at which

the Analog Output

Hi (chi) will occur

Select the Digital

Reading at which

the Analog Output

Lo (cLo) will occur

This branch will only appear

if the analog output option

is installed

DIGITAL SPAN SELECTION

FOR ANALOG RANGE OUTPUT

See Page 6

DIGITAL DISPLAY ON/OFF

See Page 6

BARGRAPH CENTER POINT

DISPLAY MODE SELECTION

See Page 6

TWO POINT ANALOG OUTPUT

RANGE SETTING AND CALIBRATION

See Page 7

Set the Decimal

Point (dp)

Bargraph Display

Scale Lo Range

Setting (bLo)

Bargraph Display

Scale hi Range

Setting (bhi)

Display

Brightness (br)

1 Dimmest

2 Dim

3 Bright

4 Brightest

[X•XXX]

[XX•XX]

[XXX•X]

[XXXX•]

[XXXX]

DECIMAL POINT AND

BRIGHTNESS SELECTION

See Page 5

DIGITAL SPAN SELECTION

FOR BARGRAPH DISPLAY

See Page 5

Select the

desired

reading for

the applied

Lo input signal

Select the

desired

reading for

the applied

hi input signal

Any new settings

are canceled and

previous settings

are retained

Err. Indicates

unsuccessfull

calibration

Goes directly

to Zero setting

if Analog Output

is not installed

TWO POINT DIGITAL

CALIBRATION MODE

See Page 4

[orAn]

[rEd]

NOTE: Will only

appear if a tricolor

display is installed

[orAn]

[rEd]

[orAn]

[rEd]

[orAn]

[rEd]

[orAn]

[rEd]

BARGRAPH COLOR

PROGRAMMING MODE

See Page 9

SETPOINT SETTING AND

RELAY CONFIGURATION MODE

See Page 8

[LhLh]

[hLhL]

[hhhh]

Set Setpoint 1 (SP1)

Delay-on-Make (doM)

Delay-on-Break (dob)

0 to 9999 seconds

Relays Activation [rLYS]

(H) High the relay

energizes when the

setpoint is exceeded

(L) Low the relay

energizes below the

setpoint.

Setpoints Indication

is from left to right

SP1, SP2, SP3, SP4

Hysteresis [hYSt]

When hYSt is selected ON, and SP2 is

set at a value higher than SP1, the SP1

relay will operate in a special "pump on

pump off" Hysteresis mode. SP2 acts as

the upper limit and SP1 acts as the lower

limit of the Hysteresis Band.

For filling applications, rLYS should be set

to LhLh. SP1 will then activate for inputs

less than the SP1 setpoint, and remain ON

until the SP2 setpoint is reached.

For emptying applications, rLYS should

be set to hhhh. SP1 will then activate for

inputs greater than the SP2 setpoint, and

remain ON until the SP1 setpoint is reached.

Tricolor Bargraph

The tri-color bargraph is designed

like a traffic light, to display either

red, orange or green, but only one

color at a time. The color to be

displayed is selected in two ways.

The first step is to select the color

to be displayed when the bar is

“below” whichever set point is set

to the lowest position.

The second step is to select the

color to be displayed when the bar

is above each specific setpoint,

regardless of the order or position

to which the set points are set.

However, if two or more setpoints

with differently specified colors are

positioned at the same set point

value, the color specified for the

set point with the highest

identifying number will be

displayed. When setpoints are set

to the same value, the SP4 color

overrides the SP3 color, the SP3

color overrides the SP2 color, and

the SP2 color overrides the SP1

color.

Setpoint 2 (SP2)

Setpoint 3 (SP3)

NOTE: [dom] [dob]

Functions are only

available for SP1

0 to 9999 seconds

Setpoint 4 (SP4)

+

–

4.00

+

–

20.00

Software Logic Tree

Software Version is Displayed on Power-up

When power is applied, all segments of the bargraph and digi-

tal display light up for 3 seconds. The version number of the

installed software is then displayed for 2 seconds, after which,

the operational display indicates the input signal.

These are intelligent meters with a hierarchical software struc-

ture designed for easy programming and operation, as shown

below in the software logic tree.

15 Second Program Timeout

Except for ZERO and SPAN settings in the Two Point Digital

Calibration Mode and the Analog Output Range Setting and

Calibration Mode (cLo and chi), the meter has a 15 second

program timeout. If no buttons are pressed for 15 seconds in

any of the other programming sequences, the meter will exit the

programming mode and return to the operational display. Any

program changes that were made prior to pressing the

P

but-

ton in the preceding step will not be saved.

Crompton • www.crompton-instruments.comPage 4 May 27, 2005 Crompton Bar Digital DS (NK2)

STEP A Enter the Calibration Mode

1)

Press the

P

and buttons at the same time. Display toggles

between [CAL] and [oFF].

2) Press the or button. Display changes from [oFF] to [on].

3)

Press the

P

button. Display toggles between [CAL] and [out].

Note: If at this point, the display skips directly to STEP C and toggles between

[SPAn] and the previous [SPan] setting, the software is detecting that the

optional analog output hardware is NOT installed.

STEP B

Select Two Point Digital Calibration of Input Signal

1) Press the or button to select CAL [iP] for input signal calibration.

2) Press the

P

button. Display toggles between [ZEro] and the previ-

ous zero setting.

STEP C Set the Meter’s Low Input Signal Reading on the Digital Display

1) Apply a zero or low signal to the meter. (Positive or negative val-

ues are allowed).

2) Using the and buttons, adjust the meter display to the desired

reading for the applied low input signal.

3) Press the

P

button. Display toggles between [SPAn] and the pre-

vious span setting.

STEP D Set the Meter’s High Input Signal Reading on the Digital Display

1) Apply a high input signal to the meter.

2) Using the and buttons, adjust the digital display to the

desired reading for the applied high input signal.

3) Press the

P

button.

The Digital Calibration Procedure is now complete.

If the digital calibration was successfully completed, the menu branches

to the Digital Span Selection for Bargraph Display (see page 5), and the

display flashes [bhi] and the previous setting.

ERROR Indicates Unsuccessful Calibration

If the calibration was unsuccessful, the display indicates [Err], the new

calibration settings just entered will not take effect and the previously

stored setting will remain.

The three most likely causes of an error during

calibration are:

1.

The full scale and zero signals were too similar. The full scale signal must be

at least 1000 counts greater than the zero or low input signal (positive and

negative values are allowed).

2. The scaling requirement exceeded the digital display span capability

of the meter (12,000 counts between –1999 to 9999).

3. No input signal present, or incorrect input signal connections.

This mode enables the meter to be calibrated by applying a zero or low input signal, entering the desired reading for that signal, then

applying a high input signal, and then entering the desired reading for that signal. The meter then automatically calculates and pro-

grams in the requisite scale factor, within the following parameters.

1. Positive and negative signals may be applied, but the difference between the low and the high signal inputs must be at least 1000

counts or Err will be indicated.

2. Positive and Negative values for the desired reading can be entered, but the scale factor created can not exceed the Digital Display

Span capability of the meter which is 12,000 counts between –1999 to 9999.

3. The internal Signal Span is limited to 3 V DC between – 1 V DC to + 2 V DC. Any outputs from an Input Signal Conditioning module

that exceed these limits will cause the meter to indicate overrange regardless

of the Digital Display Span scaled.

Note: Many input signal conditioners have provisions for analog calibration and

scaling. If the meter is digitally set to read zero with a zero input (shorted input),

and to read 1000 with a 1.000 V input, any pre-calibrated analog signal con-

ditioner, with an output that does not exceed – 1 V to + 2 V, will read correctly

without any further calibration when it is inserted in the meter.

Two Point Digital Calibration Mode

MAIN MENU

Operational Display

Sub-menu

MODE

STEP A Calibration

Mode

STEP B Calibration

Mode

STEP C Zero

STEP D Span

Err. Any new setting

canceled and previous

settings are retained

To Digital Span Selection for

Bargraph Display Page 5

cAL out/iP branch will only

appear if the analog output

option is installed, otherwise

cAL on goes directly to ZEro

setting

TWO POINT DIGITAL

CALIBRATION MODE

To Digital Span Selection

for Bargraph Display

See Page 6

To Two Point Analog

Output Range Setting

and Calibration

See Page 7

Crompton • www.crompton-instruments.comMay 27, 2005 Crompton Bar Digital DS (NK2) Page 5

Example

Example

From Two Point

Digital Calibration

Mode See Page 4

STEP A

STEP B

STEP C

STEP D

See Example Above

of Bargraph Display

Scale Range

To Digital Span Selection

for Analog Range Output or

Bargraph Center Point

Display Mode Selection

on Page 6

DIGITAL SPAN SELECTION

FOR BARGRAPH DISPLAY

[X•XXX]

[XX•XX]

[XXX•X]

[XXXX•]

[XXXX]

DECIMAL POINT AND

BRIGHTNESS SELECTION

STEP A Enter the Calibration Sub Menu Mode

1) Press the

P

and buttons at the same time. Display toggles

between [CAL] and [oFF].

2) Press the

P

button. Display toggles between [bhi] and the

previous setting.

STEP B Set the Digital Span of the Bargraph Display

(See example

above)

1) Using the and buttons, adjust the display to the desired

high parameter reading, e.g. 6000 counts.

2) Press the

P

button. Display toggles between [bLo] and the

previous setting.

3) Using the and buttons, adjust the display to the desired

low parameter reading, e.g. 4000 counts.

4) Press the

P

button. Display changes from [4000] to [dP].

STEP C Set the Decimal Point

1) Using the and buttons, adjust the display to the desired

decimal point setting.

2) Press the

P

button. Display toggles between [br] and the

previous brightness setting.

STEP D Set the Bargraph and Digital Display Brightness

1) Using the and buttons, adjust the display to the desired

brightness setting (4 is the brightest setting).

2) Press the

P

button. Display toggles between [Anhi] and the

previous [Anhi] setting.

Note: If at this point, the display skips directly to STEP G and toggles

between [Cto] and [oFF], the software is detecting that the optional analog

output hardware is NOT installed.

Digital Span Selection For Bargraph Display

Decimal Point and Brightness Selection

Bargraph does not light up for

Input Signals up to 3999 counts

Bargraph lights up for Input

Signals above 4000 counts

No bargraph

display

Digital display Digital display

%

100

0

10

30

50

70

90

20

40

60

80

4

3

2

1

P

SP

Bargraph display

ends at

6000 counts

Bargraph display

starts at

4000 counts

At 5000 counts

the bargraph display

will be at midpoint

%

100

0

10

30

50

70

90

20

40

60

80

4

3

2

1

P

SP

Example of Setting the Digital Span of the Bargraph Display

to be Different than the Digital Display Range

The bargraph can be set to display full scale (0-101 bars) any portion

of the digital reading from a minimum of 100 counts to a maximum of

12,000 counts. This provides higher resolution bargraph indication for

those applications where the normal operating input signal range is less

than the desired full scale display range of the digital display.

For Example:

If the full scale range of the meter has been set from -1999 to

9999 (0-12,000 counts), but the normal operating range of the

input signal is between 4000 & 6000. The bargraph high param-

eter [bhi] can be set to 6000 and the bargraph low parameter [bLo]

can be set to 4000.

This means that although the meter could digitally display a signal

from -1999 to 9999 (0-12,000 counts), the bargraph display only

begins to function at a reading of 4000, and reaches full scale

indication at a reading of 6000. Although the digital display will

continue reading up to 9999 before indicating overrange, the bar-

graph display will indicate its overrange by flashing for readings

above 6000.

Crompton • www.crompton-instruments.comPage 6 May 27, 2005 Crompton Bar Digital DS (NK2)

5000

Center

Point

Single

Bar Lit

0

2500

5000

Center

Point

0

2500

4000

As signal

increases

0

5000

Center

Point

2500

1000

As signal

decreases

+ 1 V

Center

Point

Single

Bar Lit

- 1 V

0 V

+ 1 V

Center

Point

- 1 V

0 V

0.800

As signal

increases

+ 1 V

- 1 V

0 V

Center

Point

-0.800

As signal

decreases

Example of Using the Center Point Bargraph Display Mode

with a Unipolar Input

If the meter's full scale range is set to 5000 counts, the midpoint would be

2500 counts. If a signal of 2500 counts is applied only one segment at the

2500 count mark will light up. If a signal of 4000 counts is applied the seg-

ments between the center segment (2500 counts) and the 4000 count mark

light up.

If a signal of 1000 counts is applied, the segments between the center seg-

ment (2500 counts) and the 1000 count mark will light up.

Example of Using the Center Point Bargraph Display Mode

with Bipolar Signal Inputs

The meter may also be calibrated to display symmetrical bipolar signals such

as ± 1 V or ± 10 V. When the center point display mode is selected, it will then

function as a center zero meter. When positive signals are applied, the bar

will go up from the center point, and when negative signals are applied, the

bar will go down from the center point.

STEP E Selecting the [Anhi] Digital Value for Analog High Output

1) Using the and buttons, adjust the display to the desired

digital value at which the [chi] Calibrated Analog High output will

occur. For digital readings outside the digital span selected, the

analog output will linearly rise above the value set for chi, up to the

maximum analog output capability. However, the analog output will

not go lower than the calibrated value set for cLo (see below).

2) Press the

P

button.

Display toggles between [AnLo] and previous

[AnLo] setting.

STEP F Selecting the [AnLo] Digital Value for Analog Low Output

1) Using the and buttons, adjust the display to the desired

digital value at which the [cLo] Calibrated Analog Low output will

occur. For Digital readings outside the Digital Span selected, the

analog output will not go lower than the calibrated value set for cLo.

2) Press the

P

button. The display toggles between [cto] and [oFF].

Note: Any two digital span points from –1999 to 9999 can be selected. The digital

values for [Anhi] analog high and [AnLo] analog low can be reversed to provide a 20 to

4mA output. The digital span selected can be as small as two counts, when using the

analog output to function as a Control or Alarm Driver. Small digital spans will cause

the high resolution 16 bit D to A to increment digitally in stair case steps.

See Two Point Analog Output Range Setting and Calibration at the top of the next

page.

Digital Span Selection for Analog Range OutputDigital Span Selection for Analog Range Output

Bargraph Center Point Display Mode Selection

STEP G

Bargraph Center Point Mode Selection (See example above)

1) To select bargraph center point mode, press the or

button. Display changes from [oFF] to [on].

2) Press the

P

button. Display toggles between [diSP] and [on]

or [oFF].

STEP H Digital Display ON/OFF Selection

1) To set the display to [oFF], press the or button. Display

toggles between [diSP] and [oFF].

2) Press the

P

button. The display exits the calibration mode

and returns to the operational display. Only the bargraph

display is on and the digital display is off.

If the digital display is selected to be off, pressing any button to

make programming changes or to view setpoints activates the digital display.

When the procedure is complete, the digital display will then automatically

switch off.

The Display/Bargraph settings are now complete.

Operational Display

STEP G

STEP H

See Example of Bargraph

Center Point Display Mode

Selection Above

From Digital Span Selection

for Analog Range Output Above

or Direct From Decimal Point

and Brightness Selection Page 5

if Analog Output Option is Not Present

BARGRAPH CENTER POINT

DISPLAY MODE SELECTION

STEP E

STEP F

This branch will only

appear if the analog

output option is installed

To Bargraph Center

Point Display Mode

Selection Below

From Decimal Point and

Brightness Selection

See Page 5

DIGITAL SPAN SELECTION

FOR ANALOG RANGE OUTPUT

Crompton • www.crompton-instruments.comMay 27, 2005 Crompton Bar Digital DS (NK2) Page 7

Operational Display

Sub-menu

MODE

STEP A Calibration

Mode

STEP B Calibration

Mode

STEP E

Calibrate

Analog

Output

Lo

STEP F

Calibrate

Analog

Output

Hi

Will only appear if the analog

output option is installed

To Digital Span Selection

for Bargraph Display

See Page 5

To Two Point Digital

Calibration Mode

See Page 4

Operational Display

TWO POINT ANALOG OUTPUT

RANGE SETTING AND CALIBRATION

+x

–x

4.00

+x

–x

20.00

Determine if the Analog Output Selection Header is in the 4 to 20mA (0-20mA) position or

the 0 to 10VDC position. If necessary, the module may have to be removed and the header

position changed (see Component Layout below).

Note: Always disconnect power from the meter before removing the analog output module

to adjust the mA or Volts output selection header and reinstalling it. When power is recon-

nected, the meter’s software will automatically detect the presence or absence of the analog

output module.

STEP A Enter the Calibration Mode

1)

Press the

P

and buttons at the same time. Display toggles between [cAL]

and [oFF].

2) Press the or button. Display changes from [oFF] to [on].

3) Press the

P

button. Display toggles between [cAL] and [out] input calibration.

Note: If at this point the display skips directly to toggle between Zero and the previous Zero

setting, the software is detecting that the optional analog output hardware is NOT installed.

STEP B Enter the Two Point Analog [ouT] Output Range Setting and Calibration Mode

1)

Press the

P

button. Display toggles between [cLo] and an internal scale factor.

STEP E Set or Calibrate [cLo] the Low Analog Value of the Analog Output Range

1)

Connect a multimeter to analog output pins 4 and 5 (see Rear Panel Pinouts

on page 10). Using the and buttons, adjust the analog output to the desired

low value as measured on the multimeter. cLo may be adjusted to any value from

–0.3 mA to 18 mA (mA output selected) or from –0.6 V to 8 V (volt output select-

ed). However, the output of cLo must always be less than the value selected for

chi. If a reversed analog output is desired, the values selected to establish the

Digital Span can be reversed (see top of page 6). For digital readings outside the

Digital Span selected, the analog output will not go any lower than the calibrated

value set for cLo. However, the analog output will linearly rise above the value set

for chi, up to the the maximum analog output capability (see chi below).

2)

Press the

P

button. Display toggles between [chi] and an internal scale factor.

STEP F Set or Calibrate [chi] the High Analog Value of the Analog Output Range

1) Using the and buttons, adjust the analog output to the desired high

value as measured on the multimeter display. chi may be adjusted to any

value from 18 mA to 24 mA (mA output) or from 8 V to 10.3 V (volt output).

However, the value must be higher than the value selected for cLo. For digital

readings outside the Digital Span selected, the analog output will linearly rise

above the value set for chi, up to the maximum analog output capability.

2) Press the

P

button. The meter exits the calibration mode and returns to

the operational display.

Note: The analog output range established by the values selected for cLo and chi will

occur, automatically scaled, between the two digital values selected for AnHi and AnLo.

However, the analog output can linearly rise above the chi value set for digital readings

outside the digital span selected. See Digital Span Selection on page 6.

Two Point Analog Output Range Setting and CalibrationTwo Point Analog Output Range Setting and Calibration

Component Layout

High Voltage

Transformer is Grey

Low Voltage

Transformer is Black

-+

~

~

+

+

+

+

+

+

ON/OFF

EXT 24V

2V

5V

10V

20V

Custom

VOLTS

AMPS

2mA

20mA

Custom

LOCK

ON

OFF

Optional Analog

Output Module

4 to 20 mA (0 to 20 mA)

Selection Position

0 to 10 V DC

Selection Position

Selection Header

Optional Analog Output Module

Display

Board (Front)

Relay

Activation

LEDs

Bargraph

Segments

Digital Display

Programming

Buttons

100

0

10

30

50

70

90

20

40

60

80

4

3

2

1

P

SP

SP3

SP1

SP4

SP2

Optional 16 Bit Isolated Analog Output Module

4 to 20 mA

(

0 to 20 mA

)

S

election Positio

n

0

to 1

0

V D

C

S

election Positio

n

Analog Output

S

election Heade

r

Note: Always disconnect power from the meter before removing the ana-

log output module to adjust the mA or Volts output selection header and

reinstalling it. When power is reconnected, the meter’s software will auto-

matically detect the presence or absence of the analog output module.

Crompton • www.crompton-instruments.comPage 8 May 27, 2005 Crompton Bar Digital DS (NK2)

Operational Display

SETPOINT SETTING

AND RELAY

CONFIGURATION MODE

STEP A

STEP B

STEP C

STEP D

No [doM] or [dob]

No [doM] or [dob]

STEP E

STEP F

STEP G

STEP H

To Step I of Setpoint

Setting and Relay

Configuration Page 9

The following programming steps are required to enter the setpoint values and config-

ure the relay functions in a meter with four relays using four setpoints. Generally if less

than four relays are installed, the setpoints without relays are operational in software for

tri-color control or display only purposes. To remove unwanted setpoint indications, set

them to 9999 or -1999 depending on the relay activation mode selected.

STEP A Enter the Setpoint Mode

1) Press the

P

and buttons at the same time. Display toggles

between [SP1] and the previous SP1 setting.

STEP B Set Setpoint 1 (SP1)

1) Using the and buttons, adjust the display to the desired SP1 value.

2) Press the

P

button. Display toggles between [doM] and the previous

[doM] setting.

STEP C Set the SP1 Delay-on-Make (doM) Delay Time Setting

1)

Using the and buttons, adjust the display to the desired [doM]

value (0 to 9999 seconds). The reading must continuously remain in an

alarm condition until this delay time has elapsed before the relay will make

contact (energize).

2) Press the

P

button. Display toggles between [dob] and the previous

[dob] setting.

STEP D Set the SP1 Delay-on-Break (dob) Delay Time Setting

1)

Using the and buttons, adjust the display to the desired [dob] value

(0 to 9999 seconds). The reading must continuously remain in a non-

alarm condition until this delay time has elapsed before the relay will break

contact (de-energize).

2) Press the

P

button. Display toggles between [hYSt] and the previous

[hYSt] setting.

STEP E Select the Hysteresis (hYSt)

1)

Using the and buttons, select the Hysteresis to be ON or OFF.

2) Press the

P

button. Display toggles between [SP2] and the previous

SP2 setting.

Note: When hYSt is selected ON, and SP2 is set at a value higher than SP1, the SP1 relay

will operate in a special "pump on pump off" Hysteresis mode. SP2 acts as the upper limit

and SP1 acts as the lower limit of the Hysteresis Band on the SP1 relay.

For filling applications:

rLYS should be set to LhLh (see step I). The SP1 relay and SP1 LED Annunciator will

then activate for inputs less than the SP1 setpoint, and remain ON until the SP2 setpoint is

reached.

For emptying applications:

rLYS should be set to hhhh (see step I). The SP1 relay and SP1 LED Annunciator will then acti-

vate for inputs greater than the SP2 setpoint, and remain ON until the SP1 setpoint is reached.

STEP F Set Setpoint 2 (SP2)

1) Using the and buttons, adjust the display to the desired SP2 value.

2) Press the

P

button. Display toggles between [doM] and the previous

[doM] setting.

STEP G Set Setpoint 3 (SP3) (No [doM] or [dob])

1) Using the and buttons, adjust the display to the desired SP3 value.

2) Press the

P

button. Display toggles between [SP4] and the previous

SP4 setting.

STEP H Set Setpoint 4 (SP4) (No [doM] or [dob])

1)

Using the and buttons, adjust the display to the desired SP4 value.

2) Press the

P

button. Display toggles between [rLYS] and the

previous relay setting.

Please Continue On Next Page.

Setpoint Setting and Relay Configuration Mode

Crompton • www.crompton-instruments.comMay 27, 2005 Crompton Bar Digital DS (NK2) Page 9

[LhLh]

[hLhL]

[hhhh]

STEP I

STEP J

STEP K

STEP L

STEP M

STEP N

[orAn]

[rEd]

NOTE: Will only

appear if a tricolor

display is installed

[orAn]

[rEd]

[orAn]

[rEd]

[orAn]

[rEd]

[orAn]

[rEd]

BARGRAPH COLOR

PROGRAMMING MODE

Operational Display

Operational Display

From From Step H of

Setpoint Setting and Relay

Configuration Page 8

For safety, the tri-color bargraph is designed like a traffic light, to display either

red, orange or green, but only one color at a time. The color to be displayed is

selected in two ways.

First (Step J) is to select the color to be displayed, when the bar is “below*”,

whichever set point is set to the lowest position.

Second (Steps K, L, M, and N) is to select the color to be displayed when the

bar is above each specific set point, regardless of the order or position to which

the set points are set.

However, if two or more setpoints with differently specified colors are positioned

at the same set point value, the color specified for the set point with the highest

Identifying number will be displayed. When set points are set to the same value,

the SP4 color overrides the SP3 color, the SP3 color overrides the SP2 color, and

the SP2 color overrides the SP1 color.

STEP J Select Bargraph Color when the bar is BELOW* the Setpoint that

is set to the lowest position

1) Using the and buttons, select the desired bargraph color [grn],

[oran] or [red]

2) Press the

P

button. Display toggles between [CSP1] and the

previous color setting.

STEP K Select Bargraph Color when the bar is ABOVE* SP1 Setpoint

1) Using the and buttons, select the desired bar graph color [grn],

[oran] or [red]

2) Press the

P

button. Display toggles between [CSP2] and the

previous color setting.

STEP L Select Bargraph Color when the bar is ABOVE* SP2 Setpoint

1) Using the and buttons, select the desired bargraph color [grn],

[oran] or [red]

2) Press the

P

button. Display toggles between [CSP3] and the

previous color setting.

STEP M Select Bargraph Color when the bar is ABOVE* SP3 Setpoint

1) Using the and buttons, select the desired bargraph color [grn],

[oran] or [red]

2) Press the

P

button. Display toggles between [CSP4] and the

previous color setting.

STEP N Select Bargraph Color when the bar is ABOVE* SP4 Setpoint

1) Using the and buttons, select the desired bargraph color [grn],

[oran] or [red]

2) Press the

P

button. The meter exits the setpoint mode and returns

to the operational display.

The Bargraph Color programming mode is now complete.

STEP I Set Relay Activation mode [rLYS]

(H) High the relay energizes when the setpoint is exceeded. (L) Low the

relay energizes below the setpoint. The setpoint is indicated from left to

right SP1, SP2, SP3, SP4.

1) Using the and buttons, adjust the reading on the display to

the desired relay settings: [LLLL], [LhLh], [LLhh], [hhhh].

2) Press the

P

button.

If a mono-color red or green display is installed then the Setpoint Relay Programming

Mode is now complete and the meter returns to the operational display.

If a tricolor bargraph display is installed then the Bargraph Color Programming

Mode will be entered and display toggles between [CoL] and the previous setting.

Color selection menu will be displayed.

Setpoint Setting and Relay Configuration Mode Continued

Bargraph Color Programming Mode

1 2 3 4

SP

P

*Note: For horizontal display formats BELOW*

should be read as, “to the left” and ABOVE*

should be read as, “to the right”.

Crompton • www.crompton-instruments.comPage 10 May 27, 2005 Crompton Bar Digital DS (NK2)

Functional Diagram

2

3

7

1

5

4

8

9

10

11

12

13

14

15

NO3

COM 1 & 3

NO1

NC1

NO4

COM 2 & 4

NO2

NC2

Input HI

24V Excitation

Input LO

-

+

Display

Driver

Multiplexer

and

Buffer

Amplifier

Micro

Processor

1M

0.1

1.25V

Ref Hi

+ 24 V DC

24 V Excitation

Select

20V

10V

5V

2V

GND

Range Select

+ 5 V

— 5 V

14 Bit

Single

Slope

A to D GND

+ 5 V

GND

+ 5 V

+ 5 V

Relay

Activation

LEDs

Bargraph

Segments

Digital Display

Programming

Buttons

GND ON OFF

ON

OFF

Isolated 16 Bit Sigma Delta D to A

Select HeadermA V

MOV’s

10A

5A + 5 V

SP3

PROGRAM

LOCK

+ 5 V

SP1

MOV’s

10A

5A + 5 V

SP4

+ 5 V

SP2

AC Neutral, - DC

AC Line, + DC

AC/DC Power Input

Volts

Amps

+15 V DC

Analog Output

FN-RR-S141 Neko

100

0

10

30

50

70

90

20

40

60

80

4

3

2

1

P

SP

Excitation Return

Custom

Custom

20mA

2mA

NTC

EMI Filter

Isolated

Switching

Supply -5 V DC

+5 V DC

+24 V DC

ISO

GND

GND

+15 V DC

ISO

GND

Connector Pinouts

Rear Panel Pinout Diagram

This meter uses screw terminals for all input and output

connections.

COM

1&3

NO3 NC1

SP3

COM

2&4

NC2

NO4

SP4

NO1

SP1

NO2

SP2

1 2 3 4 56 7 8 9 10 11 12 13 14 15

AC

Neutral

AC

Line

+ DC - DC

or

Input HI

24V Exc

Input Lo

-

+

Analog

Output

Pin Descriptions

Input Signal – Pins 1 to 3

Pin 1 Input HI

Pin 2 24V EXC

Pin 3 Input Lo

Analog Output – Pins 4 to 5

Pin 4 Analog Output +

Pin 5 Analog Output –

Pins 6 to 13 – Relay Output Pins

Pin 6 SP3 NO. Normally Open 5 Amp Form A.

Pin 7 SP1/3 COM. Common for SP1 and SP3.

Pin 8 SP1 NC. Normally Closed 10 Amp Form C.

Pin 9 SP1 NO. Normally Open 10 Amp Form C.

Pin 10 SP4 NO. Normally Open 5 Amp Form A.

Pin 11 SP2/4 COM. Common for SP2 and SP4.

Pin 12 SP2 NC. Normally Closed 10 Amp Form C.

Pin 13 SP2 NO. Normally Open 10 Amp Form C.

Pins 14 to 15 – AC/DC Power Input

Pin 14 AC line or +DC. Power input. The standard power is 85

to 265VAC or 95 to 370VDC. Optional power supply of

18 to 48VAC or 18 to 72VDC power is also available.

Pin 15 AC neutral or -DC. Power input. The standard power is

85 to 265VAC or 95 to 370VDC. Optional power supply

of 18 to 48VAC or 18 to 72VDC power is also available.

WARNING: AC and DC input signals and power sup-

ply voltages can be hazardous. Do Not connect live wires

to screw terminals, and do not insert, remove or handle

screw terminals with live wires connected.

!

(+) (—)

POWER

—

+

INPUT

HI

INPUT

LO

ANALOG

OUT

24V

Exc

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Crompton • www.crompton-instruments.comMay 27, 2005 Crompton Bar Digital DS (NK2) Page 11

Typical Application Circuits and Connection Instructions

SINGLE CHANNEL 4 to 20 mA DC:

with External 24V DC Excitation.

SINGLE CHANNEL 4 to 20 mA DC:

Multiplexer

and

Buffer

Amplifier

Micro

Processor

1M

0.1

1.25V

Ref

+ 24 V DC

Exc. Return

24 V Excitation

Select

GND

+ 5 V

— 5 V

14 Bit

Single

Slope

A to D GND

+ 5 V

GND

+ 5 V

+ 5 V

GND

ON

OFF

Isolated 16 Bit Sigma Delta D to A

Select HeadermA V

Amps

Volts

+15 V DC

1

2

3

4

5

Analog Output

(Isolated)

Input Hi

External

Loop

Supply

4-20 mA

Transmitter

Input Lo

+

—

Other devices can be

added to the loop.

4-20mA Iso-An- Out.eps

Custom

20V

10V

5V

2V

Custom

20mA

2mA

Voltage

Range Select

Current

Range Select

+_

Multiplexer

and

Buffer

Amplifier

Micro

Processor

1M

0.1

1.25V

Ref

+ 24 V DC

Exc. Return

24 V Excitation

Select

GND

+ 5 V

– 5 V

14 Bit

Single

Slope

A to D GND

+ 5 V

GND

+ 5 V

+ 5 V

GND

ON

OFF

Isolated 16 Bit Sigma Delta D to A

Select HeadermA V

Amps

Volts

+15 V DC

1

2

3

4

5

4-20mA Iso-An- Out.eps

with 24V Excitation provided by the Bargraph

Custom

20V

10V

5V

2V

Custom

20mA

2mA

Voltage

Range Select

Current

Range Select

Input Hi

4-20 mA

Transmitter

+24V Exc

Other devices can be

added to the loop.

Analog Output

(Isolated)

+

–

SINGLE CHANNEL DC Volts:

Multiplexer

and

Buffer

Amplifier

Micro

Processor

1M

0.1

1.25V

Ref

+ 24 V DC

Exc. Return

24 V Excitation

Select

Custom

20V

10V

5V

2V

Custom

20mA

2mA

GND

Voltage

Range Select

Current

Range Select

+ 5 V

— 5 V

14 Bit

Single

Slope

A to D GND

+ 5 V

GND

+ 5 V

+ 5 V

GND

ON

OFF

Isolated 16 Bit Sigma Delta D to A

Select HeadermA V

Amps

Volts

+15 V DC

1

2

3

4

5

4-20mA Iso-An- Out.eps

Input Hi

DC V

Analog Output

(Isolated)

Input Lo

+

—

Example shown is with the Isolated Analog Output Option.

Example shown is with the Isolated Analog Output Option.

Select appropriate range of 2V, 5V, 10V or 20V. (Custom ranges also available).

Example shown is for 10V DC with Isolated Analog Output option.

Crompton • www.crompton-instruments.comPage 12 May 27, 2005 Crompton Bar Digital DS (NK2)

STEP A Prepare the Panel

1) Cut a hole in the panel to suit the panel cutout. See

Case Dimensions for panel cutout sizes.

STEP B Fit the Meter

1) Turn both mounting screws counterclockwise to allow

for the thickness of the panel.

2) Make sure that both lugs on the mounting screws are

flush with the edge of the bargraph case.

3) Push the bargraph into the panel cutout from the front

of the panel.

4) Push and turn the mounting screws in a clockwise

direction until they are tight.

STEP C Connect the Cables

1) Connect all input cables to the connector pins (see

Connector Pinouts for details).

2) Connect the power cables to the connector pins (see

Connector Pinouts for details).

Bezel NEMA-4X Lens Cover

36mm (1.42")

144mm (5.67")

Rear View

35mm (1.38")

Base

O-ring

Gasket

Cover

Removable

Key-lock

Panel

Safety

Catch

Part #: OP-N4/144T36

This cover is designed to be dust and water

proof to NEMA-4 standards. The lens cover

consists of a base and cover with a cam hinge

and key-lock locking device.

An O-ring, or Neoprene gasket forms a seal

between the base and the panel. The cam hinge

holds the cover from closing when opened until

pushed closed. A safety catch keeps the cover

closed even when the key is removed and the

key hole can be used to attach a safety seal clip,

preventing unauthorized opening.

Top View

9mm (0.35")

139mm

(5.47")

139mm

(5.47")

135mm (5.32")

160mm (6.3")

16mm (0.63")

Neko Case Dimensions

Lug in flush

position

Lug in

tightened

position

Panel

Mounting

Screw Panel

Case Dimensions

Installation Instructions

WARNING

AC and DC power supply voltages are hazardous.

Make sure the power supply is isolated before

connecting to the bargraph.

!

Crompton Instruments Ltd.

Freebournes Road

Witham

CM8 3AH

Essex

Tel: 01376 512601 • Fax: 01376 500860

Crompton Instruments Inc.

1640 Airport Road #109

Kennesaw, GA 30144

Tel: 770-425-8903 • Fax: 770-423-7194

Table of contents

Other Crompton Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

HP

HP 1660 Series Training guide

Reliance

Reliance Simpliport 180 Installation, operation & maintenance instructions

Z-bolt

Z-bolt BTG-10G instruction manual

ALAT UJI

ALAT UJI M5-012 user guide

Conrad

Conrad 13 02 30 operating instructions

FMC Technologies

FMC Technologies INVALCO 64908265 Installation & operation manual