Cromptons Spinna Winna User manual

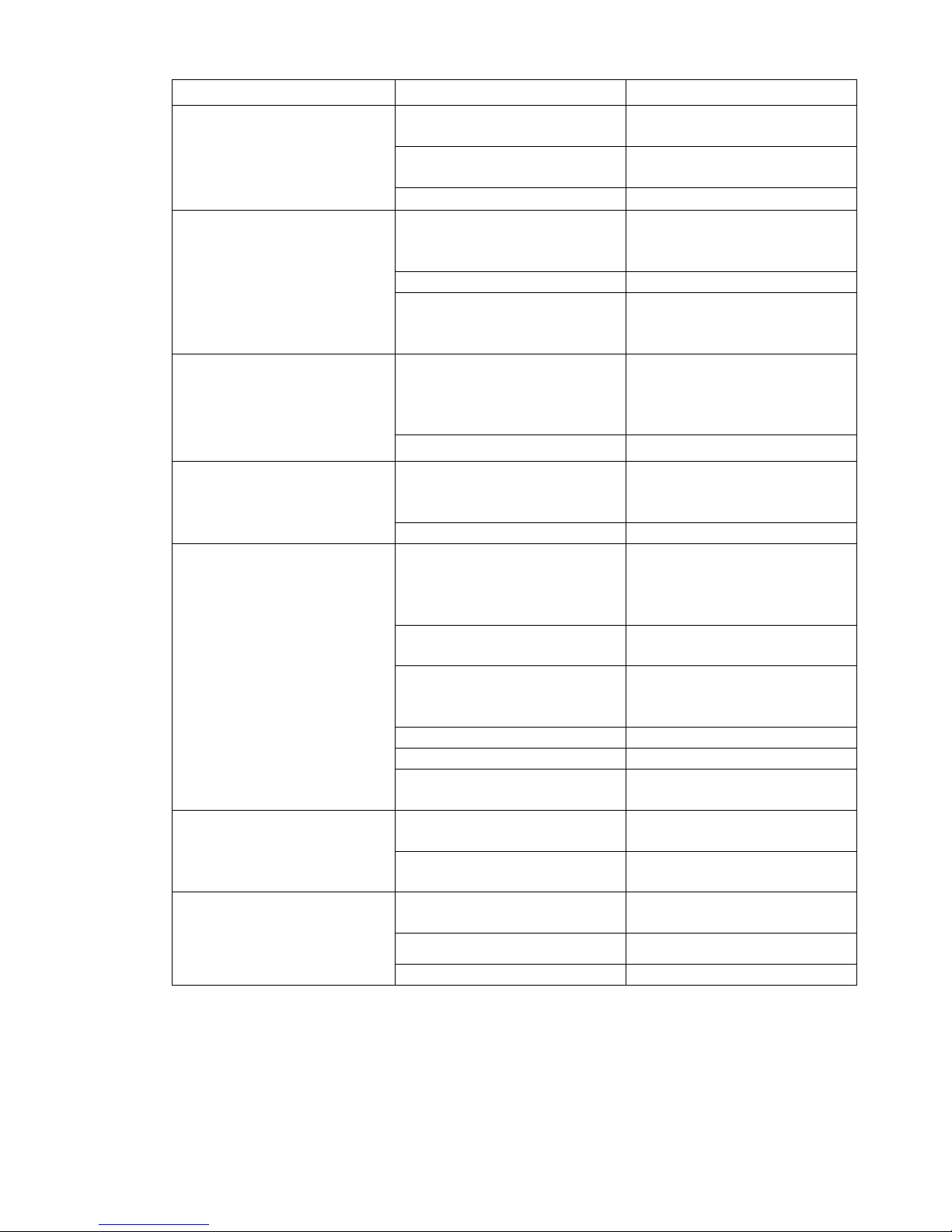

Table of contents

Other Cromptons Game manuals

Popular Game manuals by other brands

Radica Games

Radica Games Connectv Snowboarder 76044 instruction manual

Arachnid

Arachnid E5 instructions

NILS FUN

NILS FUN TDE03 user manual

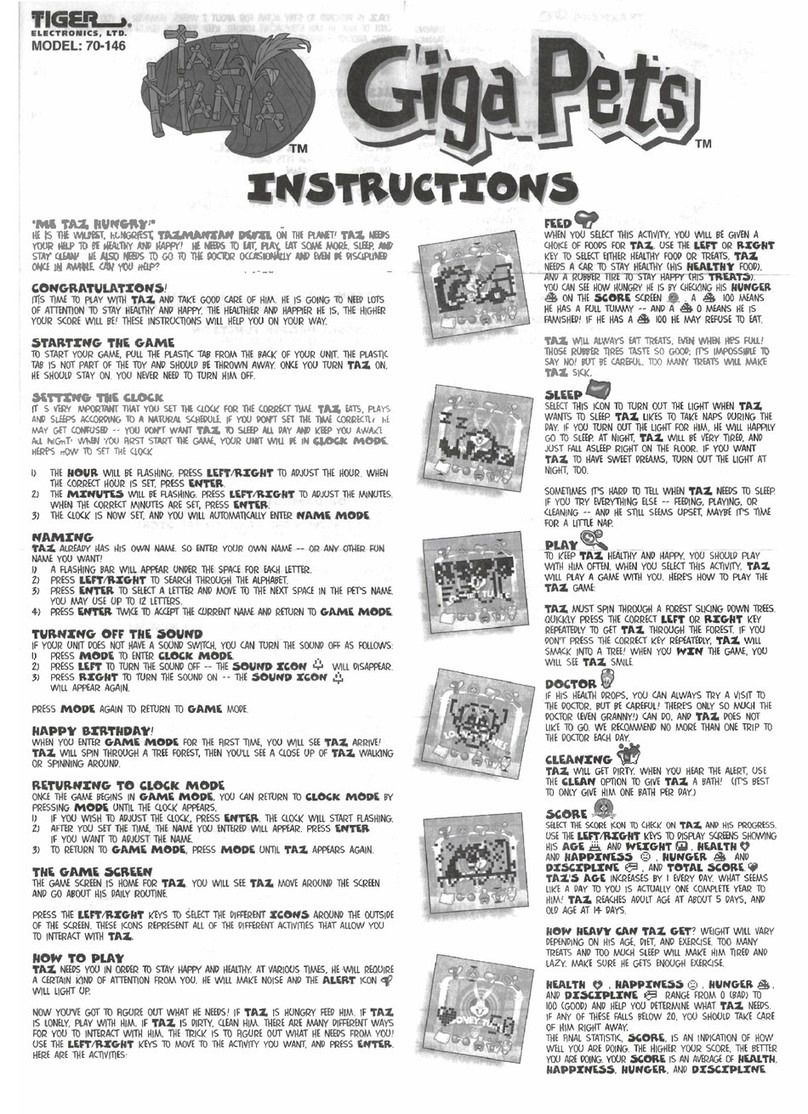

Tiger Electronics

Tiger Electronics GigaPets Taz Mania 70-146 instruction manual

Victory Tailgate

Victory Tailgate T8467 owner's manual

Entex

Entex Electronic Tennis user manual

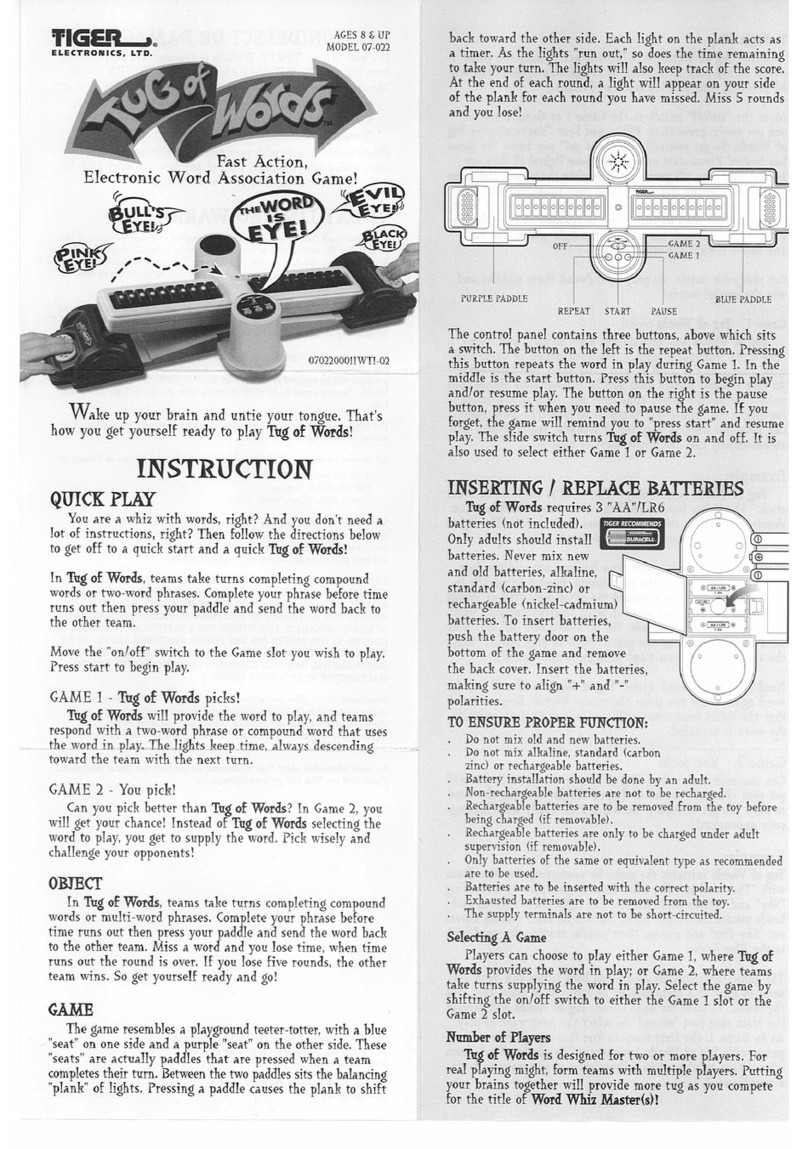

Tiger Electronics

Tiger Electronics Tug of Words 07-022 Instruction

Parker Brothers

Parker Brothers American Flag Game instructions

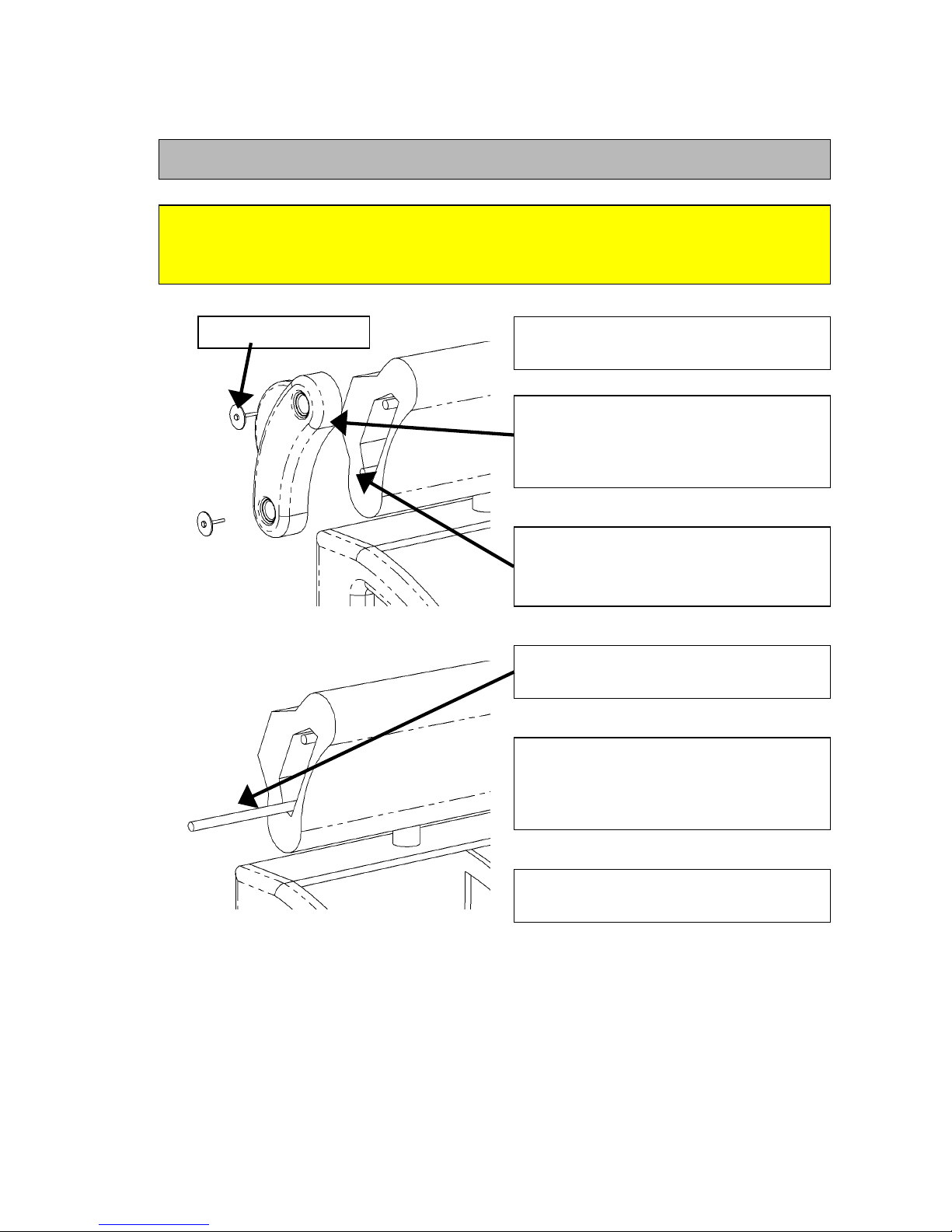

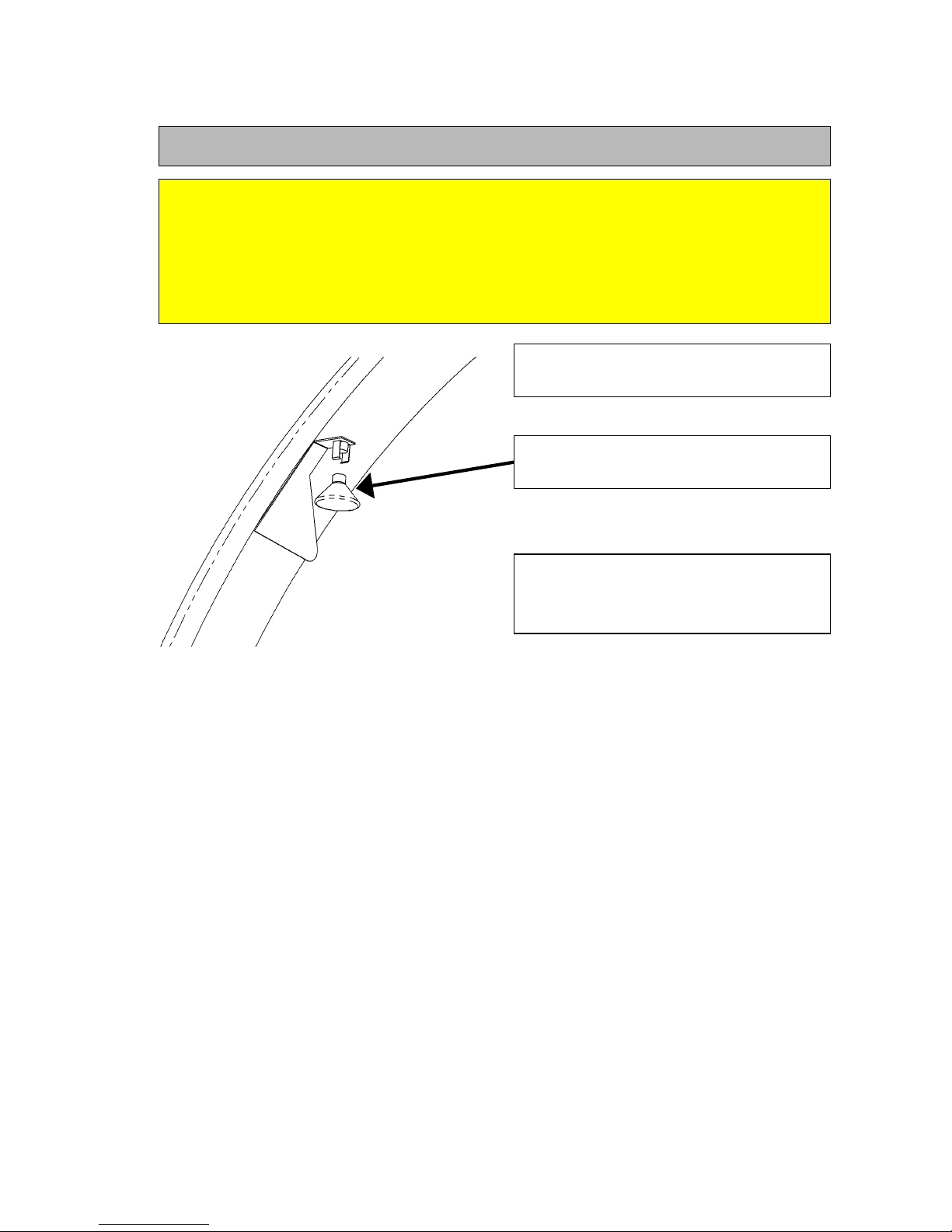

RHINO

RHINO Arcadw M01632F Assembly instructions and rules

Skil

Skil Games user manual

Costway

Costway TY557858 quick start guide

Coast to Coast

Coast to Coast FUN ZONE II user manual

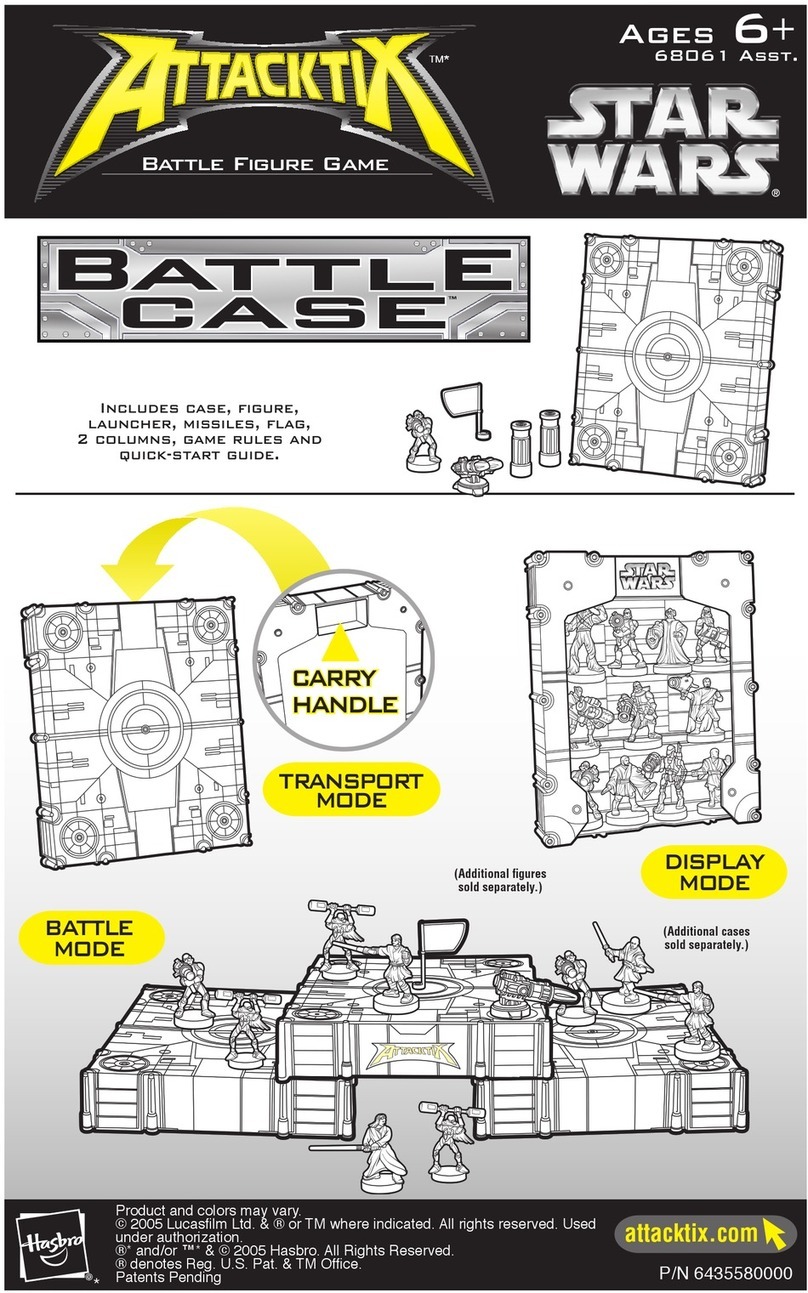

Hasbro

Hasbro Attacktix Battle Figure Game 68061 instruction manual

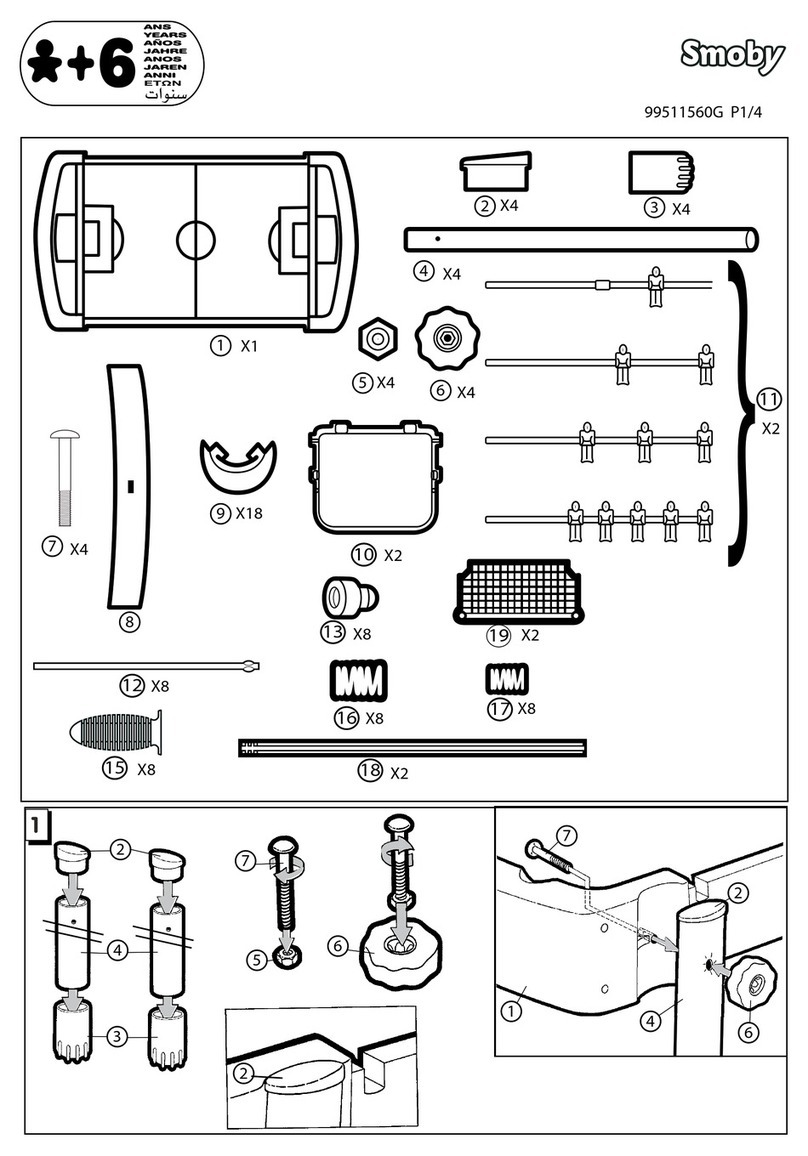

Smoby

Smoby BBF Challenger quick start guide

Tiger Electronics

Tiger Electronics Blue Diamonds 76-081 instructions

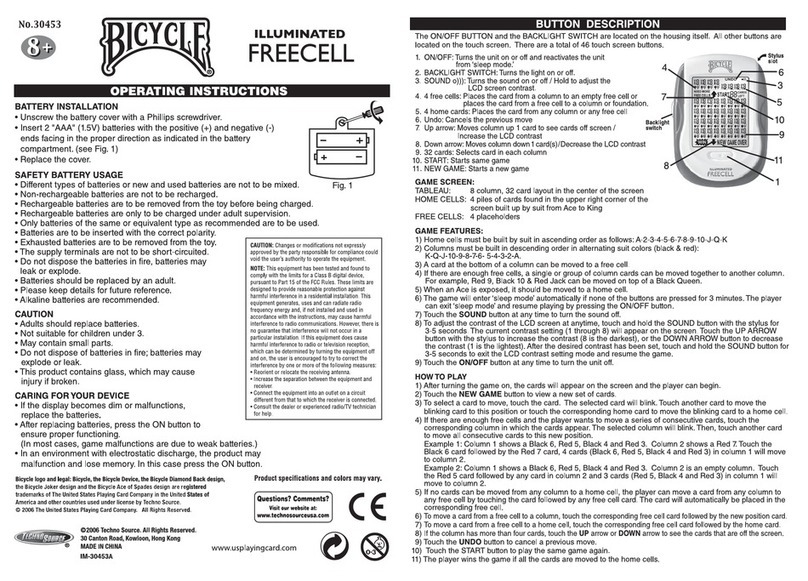

Techno Source

Techno Source Bicycle 30453A operating instructions

Sport Squad

Sport Squad STRIKE FOOSBALL Caliber SXF1002 Assembly instructions

Pentashot

Pentashot GLS 17 operating instructions