Croplands SITREX FSP 100 User manual

USE AND MAINTENANCE

SITREX FSP 100/150 SPREADER

3

1-FOREWORD

This manual is an integral part of the machine and contains information necessary

for its operation and maintenance. Operators and maintenance staff are advised to

read the manual before using the machine or carrying out any maintenance.

This guide, or a copy of it, must always be kept in a convenient place for reference. It is

strictly forbidden to change its content and tear off pages. Additional illustrative leaflets

relative to new accessories or changes, and every updating of this guide must be at-

tached herewith.

The user’s guide must be kept for the entire working life of the spreader and must be

handed to all other users and future owners.

We recommend to contact the manufacturer for any further information about spare

parts and accessories.

2 - IDENTIFICATION LABELS

The identification label of the machine carrying all identification details is positioned on the

protective casing. Fig.1.

The labels in fig.2 are applied to the hopper, frame and casing as shown in fig.3

1 -Warning: before carrying out any maintenance, remove the ignition key from the tractor

and read the instruction and maintenance manual.

2 -Warning, remain at a distance to avoid anger from scattered product.

3 -Warning: read the instruction and maintenance manual carefully.

4 -Always use protective goggles and wear protective gloves.

5 -Warning: keep hands away from rotating parts while the machine is operating.

6 -This indicates the rotation speed in rpm.

Both the labels and the danger symbols must always be clean and in good condition; if

necessary, replace with other originals available on request from the manufacturer.

4

3 - WARRANTY

The manufacturer warrants new machinery to be free from defects in material and work-

manship at the time of delivery to the original purchaser if correctly set up and operated

according to this Operator's Handbook.

The manufacturer undertakes to repair or replace free of charge any defective part which

should be returned by the purchaser (freight prepaid) and found to be defective on in-

spection authorised by the manufacturer during the warranty period.

This warranty shall be valid for 12 (twelve) months from the delivery of the goods to the

original purchaser.

If the customer is unable to return the defective part to the manufacturer, the manufacturer

cannot be held responsible for any cost due for repair or replacement of any part of the

machine. He shall only supply the part(s) required for such repair and/or replacement.

The warranty shall be considered null and void when it is evident that the machine has

been improperly used or at least repaired without authorisation.

The manufacturer shall not be held responsible for any obligation or agreement reached

by any manufacturer employers, agents or dealers who do not comply with the above

warranty. The manufacturer cannot be held responsible for the subsequent damages.

This warranty replaces any other warranty, either explicit or implied, as well as any other

obligation of the manufacturer.

4 - DESCRIPTION OF THE MACHINE

This is a spreader with centrifugal action for dry or damp granular or non - granular materi-

als, to be towed by a tractor or self - propelled vehicle. The centrifugal action is generat-

ed by the rotation of a disc with four blades positioned on the circumference.

The machine is composed of: (fig.4):

1 spreading disc equipped with blades

2 frame with drawbar

3 loading hopper

5

5 - ACCIDENT PREVENTION REGULATIONS (how to avoid ac-

cidents)

• To avoid accidents, pay close attention to the warning notices affixed on the machine and

read this guide carefully.

• The use of the spreader is restricted to the functions, for which it has been designed and

which are described in the present guide. The manufacturer will not be held responsi-

ble for any damages to things or injuries to people caused by a wrong use of the

spreader.

• It is strictly forbidden to spread iron pieces, stones, gravel, glass and similar materials as

they may injure people and cause damages to things.

• Before starting the spreader, make sure all protection devices and guards are mounted

correctly.

• Make sure no bystanders (especially children) or animals are in the working area. This is

extremely important when the spreader is being used near public or easily accessible

roads.

• During work, wear close-fitting and laced-up garments, heavy safety shoes, safety gloves

and mask specially while spreading powdery fertilizers in windy weather.

• It is strictly forbidden to transport persons while the spreader is in operation or during

transfers.

• Note: when the spreader is attached to the tractor the blades are activated and start mov-

ing.

• After using the spreader, turn the engine off, apply the handbrake, lower the spreader to

the ground, disengage the P.T.O. and , if the hopper is still partially full, even the

product up in order to avoid accidental tipping.

• When travelling on public roads, connect the spreader to the tractor as described on

pag.12 of the present guide. A wrong connection may alter the vehicle stability. It is

necessary to abide by the national traffic code.

• We remind you that a careful operator is the best insurance against accidents.

6- USE OF THE MACHINE

It is possible to spread various types of fertilizers, seeds, salt and sand. The machine can

be attached to any type of self-propelled vehicle or tractor which is sufficiently powerful.

The quantity of the product scattered can be increased by means of the opening lever.

The quantity is increased by pushing the lever down and decreased by pulling it up. The

spread of the product is determined by the speed of the tractor.

6

YOU ARE ADVSED NOT TO:

. • load the hopper with wet products as these may clog the machine.

. • use the spreader to scatter stones or other dangerous materials.

. • dismantle safety devices and the covers protecting them.

. • transporting people is prohibited both while working and during transfers.

The fertilizer spreader must never be used by employees under the age of eighteen.

7-ASSEMBLING THE FERTILIZER SPREADER (Fig.5 )

A -Assemble shafts 3-4 and 5 on the transmission unit, with the same rotation direction as

shown in the drawing.

B -Fix the transmission unit 1 to the frame 2.

C -Fix the drawbar 6 to the frame 2.

D -Fix the tie-rod 7 and the casing P TO the frame 2.

E -Fit the disc 8 on the central transmission shaft.

F -Fix the fertilizer opening lever 9 to the bow on the frame 2.

G -Fit the space washer 10 on the unit axle .

H -Fix the wheels 11 to the unit axle.

I -Fit the agitator guide bushing 15 in the hopper cone, with the dosing disc, the sealing

washer and the snap ring. (N°12) .

L -Introduce the agitator 13 into the central hole in the hopper 14 and fix it to the shaft 5; fit

the casing 17 on the attachment holes of the hopper and fix the hopper to the frame 2.

M -Connect the opening tie-rod 16 to the dozer disc 8 and the opening lever 9.

8- FUNCTIONING OF THE MACHINE

HITCHING

The machine can be attached to any type of self-propelled vehicle or tractor which is suffi-

ciently powerful.

7

Position the tractor close to the machine, apply the handbrake and secure the drawbar to

the tractor using the special pin (Fig.6).

LOADING

Everytime the spreader has to be filled up it is advisable to check that there aren’t any for-

eign particles on the bottom that may obstruct the shutter.

REGULATING THE QUANTITY SUPPLIED

The quantity of product scattered can be increased or decreased by means of the opening

lever. The quantity is increased by pushing the lever downwards and decreased by pull-

ing it upwards, until the supply is shut off. (Fig.7)

DISC WITH ADJUSTABLE BLADES

According to the specific weight of the fertilizer to be spread, it is possible to direct the

blades by moving them in the special clamps from N° 1 to N° 5, to obtain even scattering

to the right and left. The blades are normally in position N° 3. By moving the blades to-

wards N° 1 the scattering range to the left of the driver is increased. By moving them to-

wards clamp N° 5 the scattering range to the right of the driver is increased. (Fig.8 )

9-ACCESSORIES

The fertilizer spreader can be equipped with the following accessories:

MANUAL TOWING KIT

This accessory allows the fertilizer spreader to be easily maneuvered once it has been de-

tached from the tractor. (Fig.9 )

SALT AND SAND SPREADER CONE

This is composed of a steel cone section with two adjustable side supports which hook on-

to the frame. By varying the height of the cone the scattering range is regulated, making

it possible to scatter the product over the area beneath the hopper. (Fig.10)

MECHANIC REMOTE CONTROL

For the regulation of the spread of the product from the driver’s seat of the tractor - Fig.11

8

10- MAINTENANCE

For efficient maintenance: disconnect the spreader from the tractor , clean the working ar-

ea and use suitable utensils suitable to the type of work that the spreader is used for.

After every 50 hours of work:

- Grease the wheel-hub by way of the special lubricator

-check that the screws are tight

-check the pressure of the tyres

11- STORAGE

At the end of each season, or in the event of long periods of disuse it is necessary to:

- Carefully clean the spreader and its discs of fertilizer.

-check transmission, distribution and regulation parts. Replace overused or damaged

parts.

-tighten all bolts.

-Grease well in order to avoid rusting.

-Park the machine in a closed area if possible and cover it, to protect it from damage

caused due to climatic conditions. Only the user will benefit when finding the machine

in optimal conditions after a period of disuse.

9

12 - TRANSPORTING THE MACHINE

The machine is supplied disassembled and packed in cardboard and polythene; therefore

read this instruction and maintenance booklet carefully.

Dispose of the packing properly in binds provided for this purpose.

13 - THECNICAL SPECIFICATIONS

OVERALL DIMENSION

Mod.

Height

Width

Wheight

Capacity

mm

mm

kg

l

FSP100

1000

850

46

100

FSP150

1050

850

61

143

TECHNICAL DATA

Required power (for all models)...........3 kW

Spreading range 4-8 m. (according to the speedy

and the type of fertilizer)

14 - DISPOSAL OF THE MACHINE

To protect the environment and to prevent people

from being harmed, do not throw away the spread-

er or its components, but have it demolished by an

authorized demolisher. The demolition should

comply to the laws regulating the country of the

demolisher.

10

11

12

13

FERTILIZER SPREADING TABLE (METRIC)

14

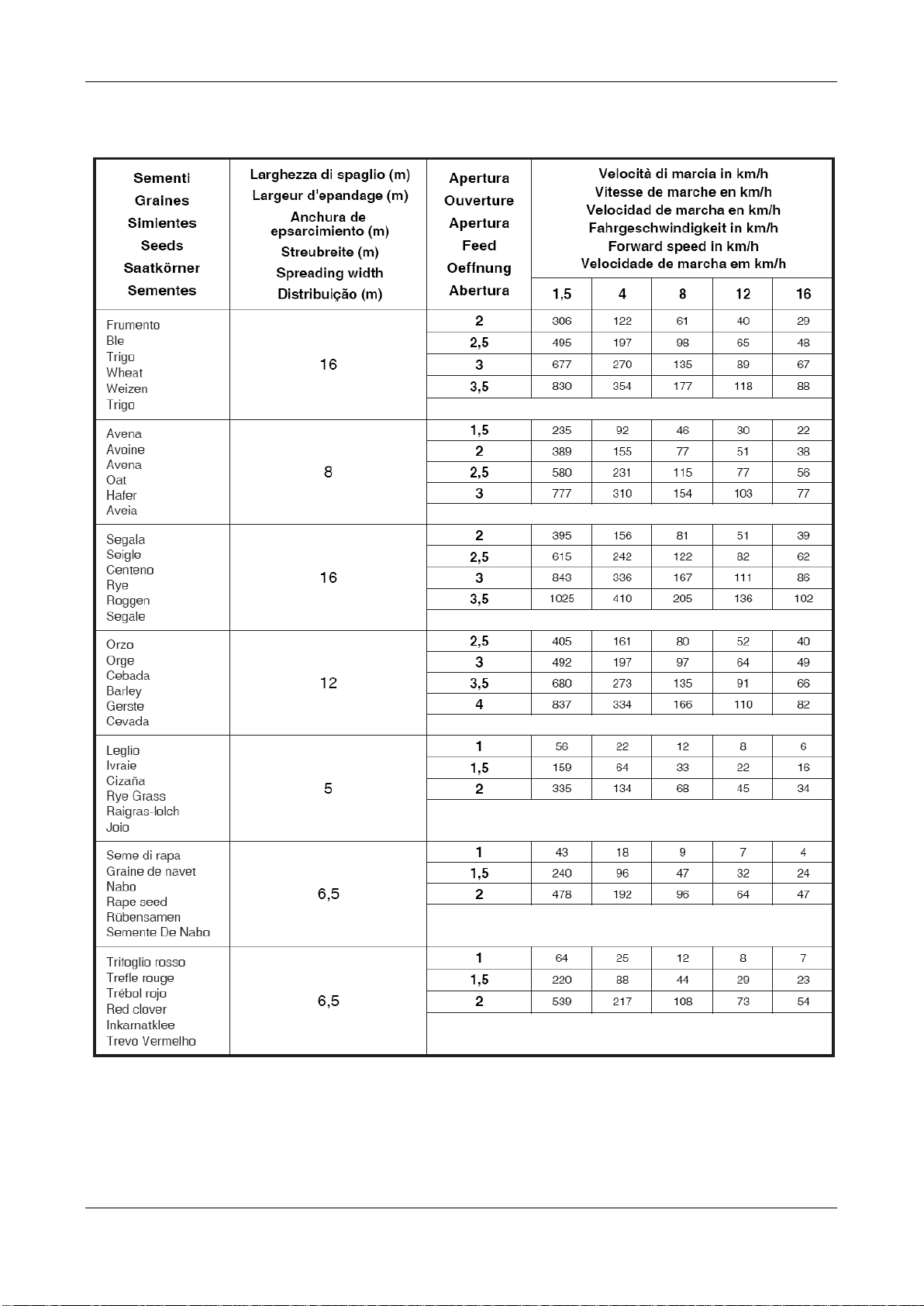

SEEDS SPREADING TABLE (METRIC)

15

FERTILIZER SPREADING TABLE (US)

SPREADING TABLE FOR FERTILIZER SPREADERS SERIES FSP

Lbs/acre OF FERTILIZER TO BE SPREAD WITH

FERTILIZER

SPREADING MPH/h

ENGINE R.P.M. AS IN COLUMN Mph/h

TYPE

RANGE

OPENING

(yards) 1,5 22,5 33,5 44,5 55,5 66,5 7

2,5 201 335 616 1016 1298 1601 1940 2343 2578 2899 3176 3573

COARSE-GRAINED

3,5 95 139 247 415 517 642 791 937 1030 1164 1294 1452

FERTILIZERS

15,5 552 70 129 205 260 321 393 473 525 602 662 745

635 54 86 139 176 219 260 324 343 401 433 492

7,5 21 35 64 107 134 171 201 241 259 299 347 375

2,5 467 799 1141 1459 1808 2014 2341 2582 2827 2990 3288

MEDIUM-GRAINED

3,5 176 330 468 599 740 827 947 1041 1143 1204 1334

FERTILIZERS

12 5105 171 236 303 376 418 479 526 582 610 672

673 113 163 199 253 286 326 355 401 415 457

7,5 54 82 116 155 189 207 246 268 295 312 341

2,5 177 289 491 558 1066 1344 1575 1896 2134 2451 2658 2959

FINE-GRAINED

3,5 85 122 204 341 441 552 649 773 866 1001 1086 1188

FERTILIZERS

9546 59 108 178 225 281 325 397 442 500 542 604

629 41 94 122 153 194 221 264 298 341 370 405

7,5 17 30 53 87 114 137 169 200 235 257 283 299

2,5 335 553 1021 1655 2046 2623 3065 3652 4088 4537 4975 5481

MEDIUM-CRYSTAL

3,5 117 222 435 670 827 1068 1237 1466 1643 1826 2000 2203

FERTILIZERS

6,5 569 113 211 334 422 541 623 740 832 920 1003 1107

645 77 142 226 284 369 421 497 554 615 674 738

7,5 30 54 102 173 211 278 322 368 414 461 503 557

2,5 278 760 1120 1658 2047 1869 2907 3391 4348

CALCIUM

3,5 111 304 459 680 820 1007 1174 1361 1529

CYANAMIDE

7,5 559 151 232 301 412 501 592 682 765

AND SIMILAR

637 101 150 221 276 337 393 455 509

7,5 26 79 113 169 207 254 293 341 381

2,5 144 573 937 1410 1804 2229 2643 3103 3401 3819 4095 4583

AMMONIUM

3,5 62 227 378 565 726 898 1054 1244 1366 1533 1643 1844

SULPHATE

7,5 529 116 191 285 367 450 526 624 680 785 820 922

623 74 124 192 244 299 353 424 458 515 551 794

7,5 15 59 95 145 182 225 266 321 341 383 416 459

2,5 2294 5106 6762 7024

THOMAS

4,5 3,5 580 1294 1708 1760

MEAL

5294 544 587 881

6198 433 301 591

16

SEEDS SPREADING TABLE (US)

SPREADING TABLE FOR SEEDS SPREADERS SERIES FSP

Lbs/acre OF SEEDS TO BE SPREAD WITH

SEEDS

SPREADING MPH/h ENGINE R.P.M. AS IN COLUMN Mph/h

RANGE

OPENING

(yards)

11,5 22,5 33,5 4

1273 442 604 740

2,5 109 176 241 316

WHEAT 12 554 87 120 158

7,5 36 58 79 105

10 26 43 60 79

1210 347 517 693

2,5 82 138 206 277

OAT 6,5 541 69 103 137

7,5 27 45 69 92

10 20 34 50 69

1352 549 752 914

2,5 139 216 300 366

RYE 12 572 109 149 183

7,5 45 73 99 121

10 35 55 77 91

1362 439 607 747

2,5 144 176 244 298

BARLEY 9 571 87 120 148

7,5 46 57 81 98

10 36 44 59 73

150 142 299

2,5 20 57 120

RYE GRASS 4511 29 61

7,5 720 40

10 514 30

138 214 426

2,5 16 86 171

TURNIP SEEDS 55 8 42 86

7,5 629 57

10 421 42

157 196 481

52,5 22 79 194

RED CLOVER 511 39 96

7,5 726 65

10 621 48

Zona Industriale-Viale Grecia, 8

06018 TRESTINA-(Perugia)-ITALY

Tel. +39.075.8540021-Telefax +39.075.8540523

e-mail: sitrex@sitrex.it www.sitrex.com

SPARE PARTS LIST

ASSEMBLY

USE AND MAINTENANCE

SITREX FS SPREADER

This manual suits for next models

1

Table of contents