Crossfire TRION 210 User manual

TRION 210

OWNER’S MANUAL

WARNING:

Read

Revision 2018-1-31

carefully and understand all ASSEMBLY AND OPERATION

INSTRUCTIONS before operating. Failure to follow the safety rules and other

basic safety precautions may result in serious personal injury.

“Danger” indicates an imminently hazardous situation which, if not avoided,

.

“Warning!” indicates a possible hazardous situation which, if not avoided, could

.

“Caution” indicates a possible hazardous situation which, if not avoided, may

.

“Note!” indicates a situation which implies a risk of impaired welding result

and damage to the equipment.

“Important!”

Utilisation for intended purpose only.

as defi

Safety signs.

pasted or painted cover.

Safety inspection.

regular intervals.

power sources.

Electric shock can kill. T

The input power circuit and machine internal circuits are also live

all metal parts touching the welding wire are electrically live. Incorrectly installed or

.

2

fl

AC welder with reduced open-load voltage.

.

fi

- IT and telecoms equipment

- IT and telecoms equipment

- W

-Mains supply

-W

-W

.

V

flame-resistant material (leather

fl

arc nor expose themselves to the arc rays or to hot spatter or material.

W

your health.

3

.

Wfi

supplied respirator.

W

confi

fi

fi

W

to prevent hazardous situations.

fire hazards or

overheat.

Wfl

position or in confined places.

when in a welding area.

fire. Remove

fi.

Do not weld where flfl

atmosphere may contain fl

gasoline).

fl

Keep a fi

contact tip when not in use.

4

fi

flame.

gas cylinder.

fittings

condition.

All

fi

good condition.

cylinder valve outlet.

V

Hot parts can burn.

Flying metal or dirt can injure eyes. When welding, chipping, wire

flying metal. It can hurt your

eyes.

Noise can damage hearing. Noise can be from some working equipments or

Moving parts can injure. .

fi

as drive rolls.

Have only qualifi

servicing and maintenance is fi.

5

duty cycle to use the machine.

Allow cooling period.

flow to unit.

.

fi

fication.

-T

6

î

î

peut entraî

Indique une situation qui implique un risque de perte de

fi fi

T

ûlures graves. Lorsque la machine est

fiî î fil et

fil de soudure sont

.

fi

Éfi

Connectez le câ

maintenance.

è é é

7

fil) semi-

T ûr

-

Alimentation secteur

Câ

Connectez le câ

ââ

Blindage

ûûler les yeux et la peau.

Tfl

T

non infl

La soudure peut produire

8

.

Travailler dans un espace confi.

T

fi fi

ûr.

Les étincelles de soudure et de coupe peuvent provoquer un incendie

ou une explosion. Lors de la soudure, assurez-vous que le circuit de

Assurez-vous que la zone est sûre avant toute soudure.

.

Connectez le câ

position ou dans des endroits confiT

fissures

fl

vapeurs infl

fi

pas ou ne les contourne pas.

9

É

.

fisant de personnes pour

Tfixant sur un

.

Gardez une distance sû

toute autre source de chaleur flammes.

â

ç

çus

T

û

avec la main nue ou la peau.

ûlures.

fi

soudure.

.

10

înement.

fi

î

utiliser la machine.

.

T

mise en œuvre pour la certifi

-T

normes pour le Canada et les É

11

Please read and save these instructions. Read through this owner’s manual carefully before using product.

Protect yourself and others by observing all safety information, warnings, and cautions. Failure to comply

with instructions could result in personal injury and/or damage to product or property. Please retain

instructions for future reference.

12

Operating Instructions and Parts Manual

MIG WELDER

Description

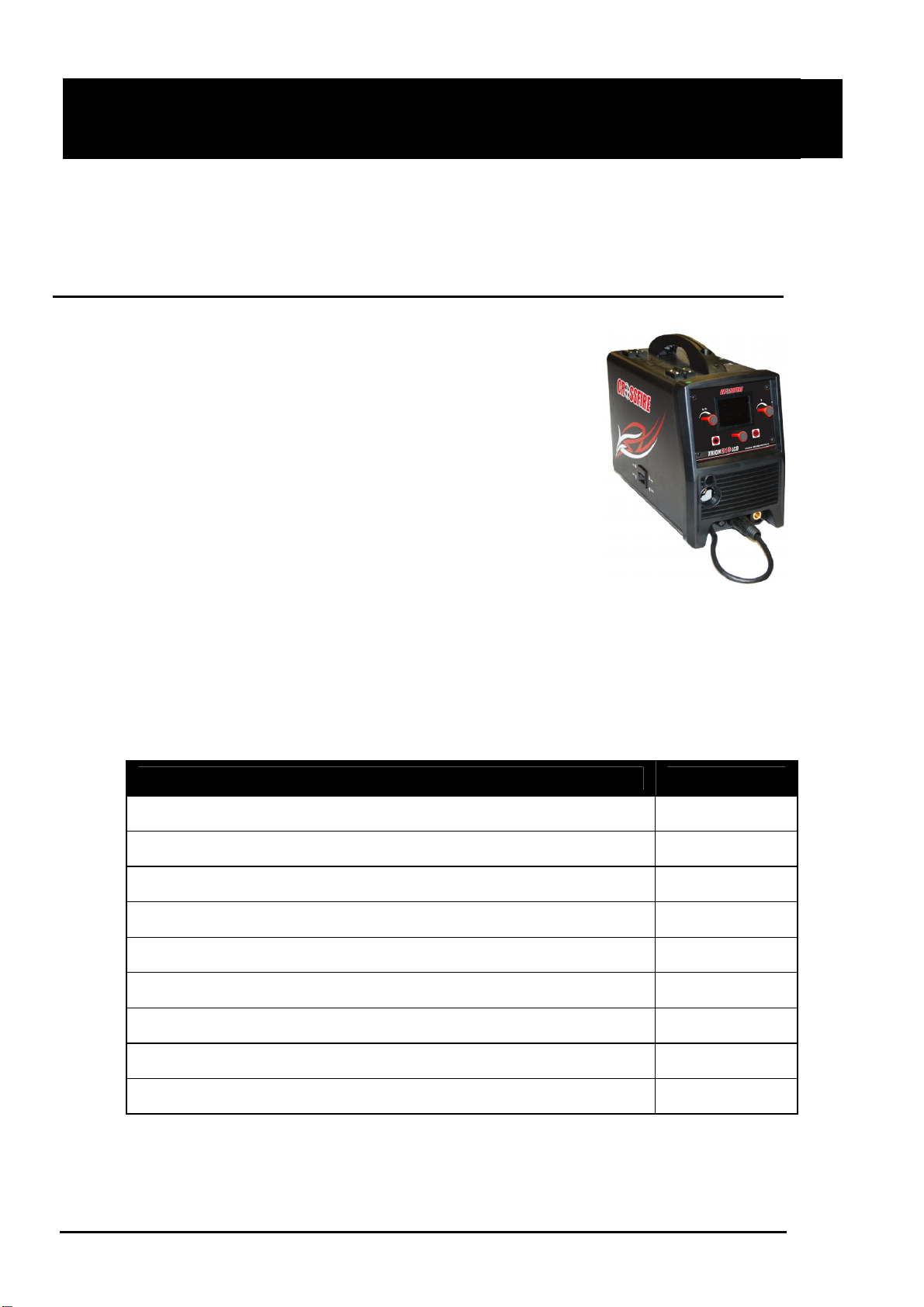

The TRION 210 is a multi-process DC inverter

welder, with LCD screen. This unit uses 1~Phase

120V or 230V, 50/60HZ AC power. A 15 amp

time delay fuse or circuit breaker is

recommended. The TRION 210 series is ideal for

Do-It-Yourself projects or for light maintenance.

MIG weld carbon steel, stainless steel , AlMg and

AlSi.

Unpacking

1.1 Remove cartons, bags or Styrofoam containing the welder and

accessories.

1.2 Check the contents with the packing list below.

ITEM QTY.

tinu1redleWGIMretrevnICD

scp1nugGIM

scp1pmalchtiwelbacgnidnuorG

Gas hose ф5.5 3m

tes1launaMs’rotarepO

Operating Instructions and Parts Manual

MIG/MMA WELDER

1.3 After unpacking unit, inspect carefully for any damage that may have

occurred during transit. Check for loose, missing, or damaged parts. Shipping

damage claim must be filed with carrier.

Operating Instructions and Parts Manual

Specifications and Dimension

Description Specification

012NOIRTledoM

Input power V 120(110~130)230(220~240)

Frequency Hz 50/60 50/60

Rated input current A 20 36

Rated input capacitance KVA 3.5 8.6

No-load voltage V 69 69

Rated working voltage V 18.5 24

MMA welding current A 10~70 10~180

LIFT Arc welding current A 10~90 10~180

MIG welding current A 40~90 40~200

Rated duty cycle % 40 20

Welding current(10min)A 40%@90 20%@200

10min/100% A 57 89

Efficiency η85%

Power factor Cosφ0.75

HssalcnoitalusnI

Enclosure protection IP 21S

Cooling type Fan cooled

Dimension L×W×H cm 73*32*48

Weight kg 18

13

Operating Instructions and Parts Manual

MIG/MMA WELDER

Removing from carton

1.1 Remove cartons, bags or Styrofoam containing the welder and accessories.

1.2 Check the contents with the packing list below.

Factory standard:EN60974-1

Optional accessories:Protective mask、tip、welding wire

GROUNDING CABLE

Use earth clamp to connect earth cable with work piece

MIG GUN

The welding wire is driven through the welding cable and MIG gun to the work piece.

It is attached to the drive system.

POWER SWITCH

In the “OFF” position no power is being supplied

In the “ON” position power is supplied to the main transformer and control circuit

14

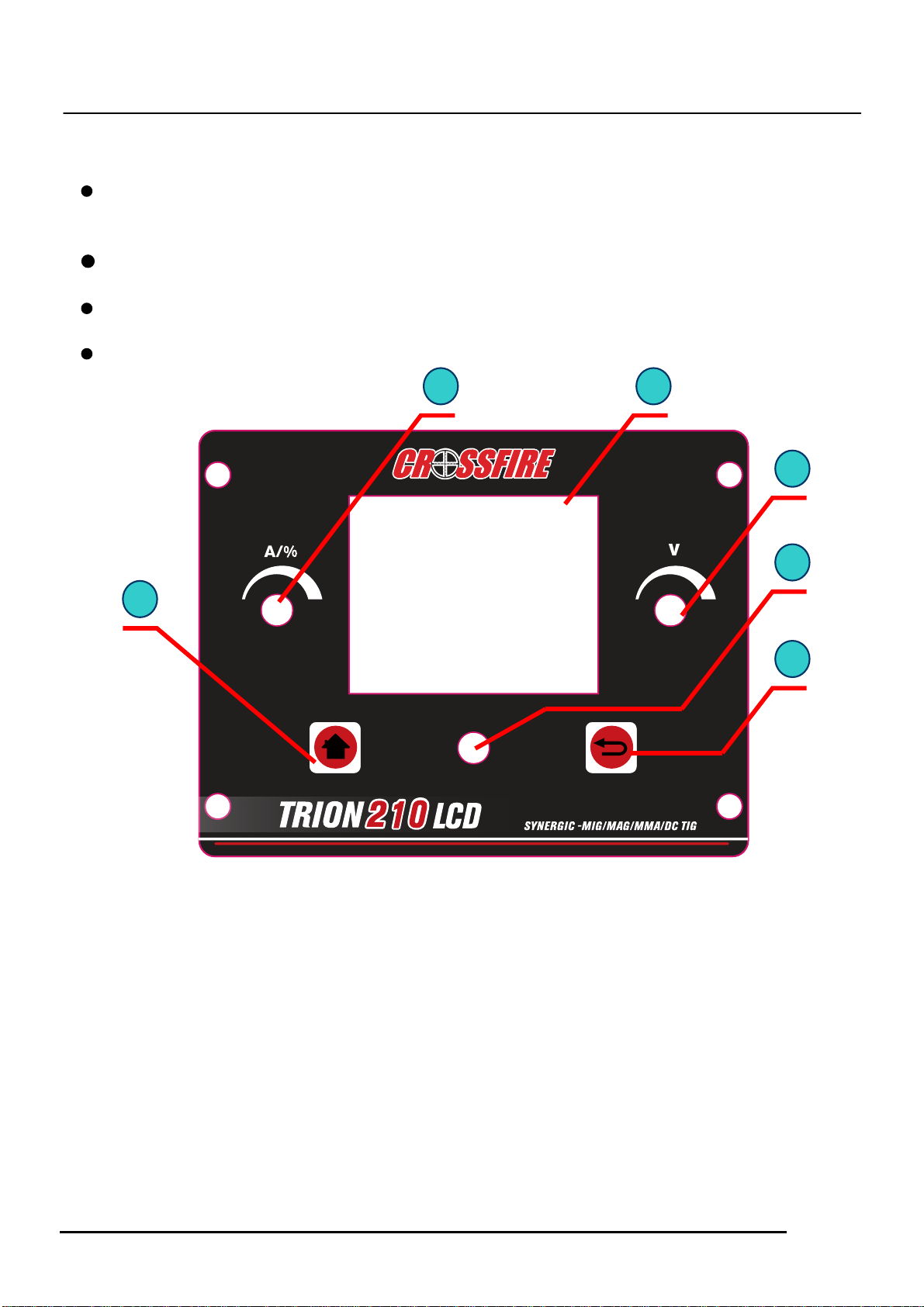

Know your Welder

Front Ctrl Panel

MIG Socket

Torch Polarity

Change Cable

Operating Instructions and Parts Manual

MIG/MMA WELDER

INPUT POWER CORD

The power cord connects the welder to the 120V/230 volt power supply. 14 amp

receptacle to supply power to the welder.

Torch Polarity Change Cable

To change the polarity of gun for kinds of core wire welding.

NAMEPALTE OF WELDER

The nameplate indicate the main electrical data of welder.

Front Ctrl panel

1. LCD: Shows all process from function selection to welding.

2. LEFT ADJUST KNOB: Allows user to adjust the current and wire feeding speed

accurately.

3. RIGHT ADJUST KNOB: Allows user to adjust the voltage accurately.

4. Home Key: Keep pressing home key, return to home page

5. Multi-function adjusting knob: For function selection; Press for confirming.

6. Return: Return to the previous step.

15

3

4

12

6

5

Operating Instructions and Parts Manual

MIG/MMA WELDER

Interface description

1. Multi-functions selection: Total 9 functions, 8 welding functions and 1 setting.

Adjusting multi-function knob for selecting, press for confirming

2. Output setup: Shows output connection under different welding mode, press

multi-function knob for confirming

3. Electrode/ Wire diameter selection:Adjusting multi-function knob to select

different electrode/wire diameter, press for confirming

16

Operating Instructions and Parts Manual

MIG/MMA WELDER

4. Material thickness: Adjusting multi-function knob to select different material

thickness, press for confirming

5. Welding display:Shows all selected parameters.

a. Under MIG welding, user can set wire feeding speed and voltage. Adjusting

Multi-function knob to set electro-inductance, press the knob to progress basic

parameter setting.

Note:

Note 1. Basic parameter setting including:gas pre flow, slow wire feeding, gas post flow, operating, load and save

function. there is also spool gun function under Al welding

Note2: In the green range of current and voltage, it means recommended parameter.

b. Under TIG welding, user can set current parameter;

17

Operating Instructions and Parts Manual

MIG/MMA WELDER

c. Under Stick welding, user can set current, arc force parameter and hot start.

6. Setting interface: It shows language setting, units setting, light setting,

information and recover setting.

7. Alarm interface:It shows the machine is overloaded and the internal temperature

is too high. Weld output will turn off automatically but the fan will still be working.

When the internal temperature is decreased, the alarm interface will turn off and

the machine will be ready to weld.

18

Operating Instructions and Parts Manual

MIG/MMA WELDER

Installation

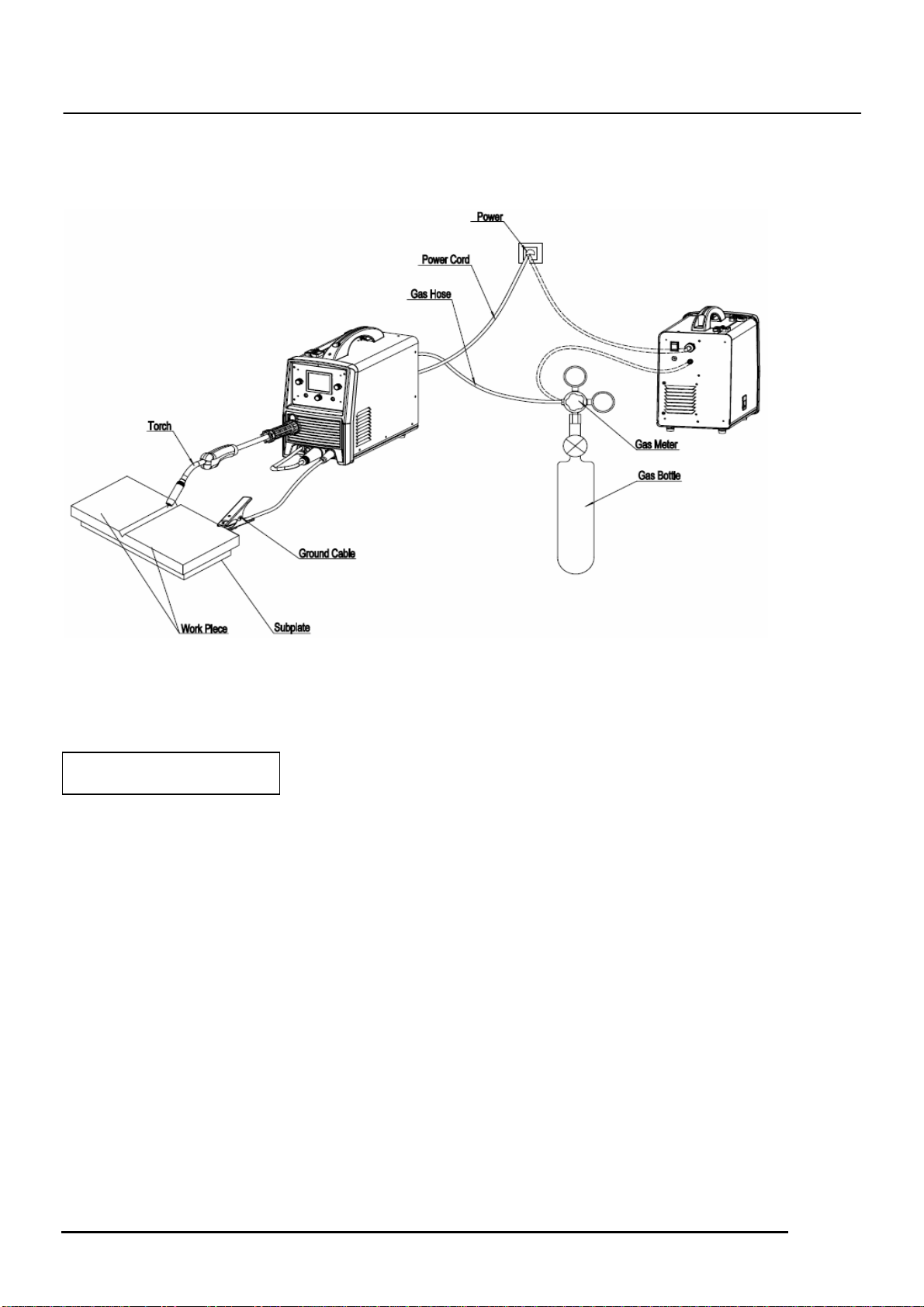

Outside Connection of the Machine

1. Power requirement

AC single phase 230V or 120V , 50/60HZ fused with a 15 amp time delayed fuse

or circuit breaker is required.

•High voltage danger from power source! Consult a qualified electrician for proper

installation of receptacle. This welder must be grounded while in use to protect

the operator from electrical shock.

• Do not remove grounding prong or alter the plug in any way. Do not use any

adapters between the welder’s power cord and the power source receptacle.

Make sure the POWER switch is OFF when connecting your welder’s power cord

to a properly grounded 120V/230Vac, 50/60Hz, single phase, 14 amp power

source.

2. Extension cord

During normal use an extension cord is not necessary. It is strongly

recommended that an extension cord should not be used because of the voltage

19

Operating Instructions and Parts Manual

MIG/MMA WELDER

drop they produce. This drop in voltage can affect the performance of the welder.

If you need to use an extension cord it must be a #12 gauge cord at the smallest.

-Do not use an extension cord over 25 ft. in length.

3. Setting up the work piece

3.1 Welding positions

There are two basic positions, for welding: Flat and Horizontal. Flat welding is

generally easier, faster, and allows for better penetration. If possible, the work

piece should be positioned so that the bead will run on a flat surface.

3.2 Preparing the Joint

Before welding, the surface of work piece needs to be free of dirt, rust, scale, oil

or paint. Or it will create brittle and porous weld. If the base metal pieces to be

joined are thick or heavy, it may be necessary to bevel the edges with a metal

grinder. The correct bevel should be around 60 degrees.

See following picture:

Based on different welding position, there are different welding joint, see following

images for more information

20

Table of contents

Other Crossfire Welding System manuals