CROSSTEX SYCLONE Installation guide

Installation and

Operating Guide

For your safety, please read all instructions prior to installing, operating and servicing the Syclone™ Amalgam Separator.

Syclone™Amalgam Separator | Installation and operating guide

Table of contents

Warnings, Package Contents & Where to Install ..................1

Syclone Amalgam Separator Components............................ 1

Set-up & Installation.......................................................................2-3

Maintenance & Troubleshooting ............................................... 4

Replacement Canister Installation............................................5-6

Warning

The waste stream treated by the Syclone Amalgam Separator is

generated by a dental vacuum system and as such, may contain

concentrations of solid and soluble mercury and silver. Full collection

canisters should be handled, stored and disposed of according to

regulations applying to waste containing mercury.

Remember to wear safety protective gear such as gloves and safety

glasses or face shield when handling full Syclone™ Containers and

dispose of per local codes and regulations. All spills should be

considered as hazardous and handled in accordance with standard

hazardous materials (HAZMAT) handling procedures.

Where to install:

Instructions

• Choose an appropriate location for the installation of your

Syclone Amalgam Separator near your vacuum unit. Place in

an easily accessible location for replacement of collection

canister, somewhere between the treatment rooms and the

vacuum source.

• Do not connect to outlet of separating tank or water ring pump.

• To reduce the chance of backow into the amalgam separator,

please ensure that the amalgam separator outlet connection

is installed 4-6 inches above the inlet of the pump or tank.

Syclone Amalgam Separator components:

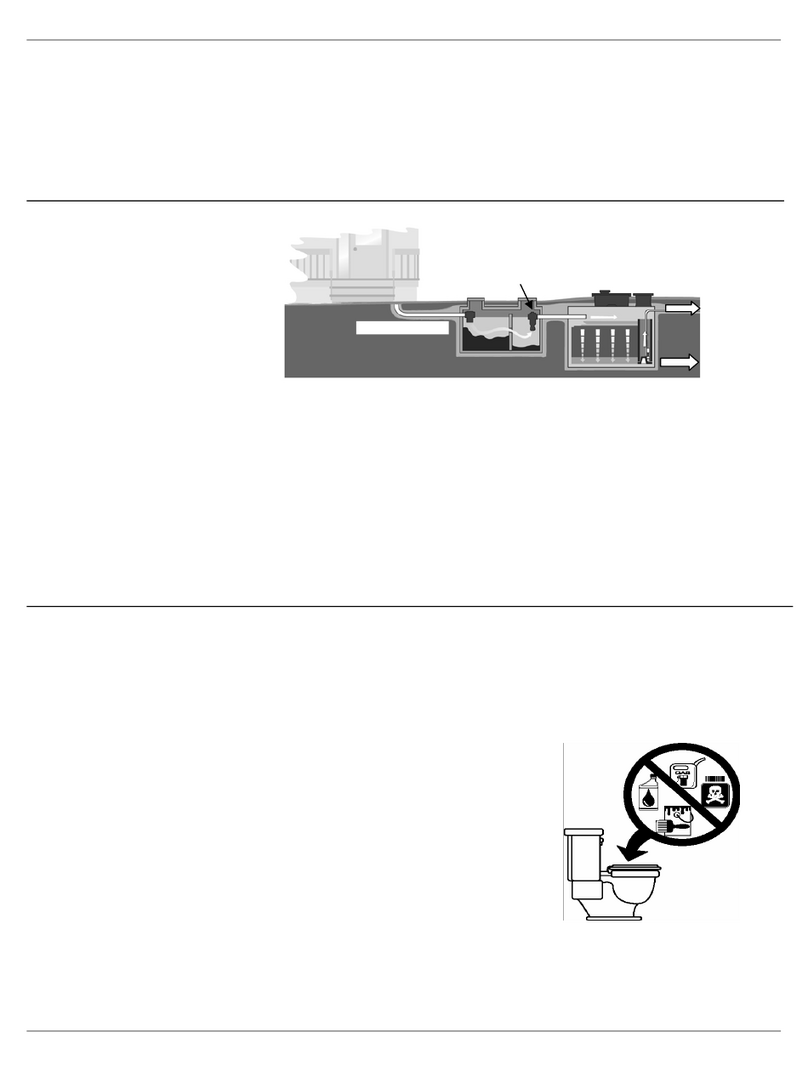

ab

e

d

Inlet (Chair) cRetaining Pins

Canister

Chamber

Flow in from treatment rooms

Flow out to pump inlet (wet vacuum unit) OR

to tank inlet (dry vacuum unit)

Drain Outlet (Pump)

e

d

g

g

b

c

a

f

f

Contents of the Syclone Amalgam Separator system:

• Installation and operating guide • (1) Canister

• (1) Amalgam separator top chamber • (1) Mounting Bracket

• Plumbing adapters, screws and washers • (2) Retaining Pins

Position the Syclone

Amalgam Separator

at least 4-6 inches

above the Syclone

outlet and

pump/tank inlet.

Canister Recycling.............................................................................7-8

Warranty & Part Numbers...............................................................9

Evacuation Line Cleaners & Amalgam Buckets ......................10

Visual Inspection Log.......................................................................12

Technical Installation Checklist .................................................... 13

1

Easy set-up and installation

Instructions:

• IMPORTANT: The unit should be

installed so that the outlet is 4-6 inches

higher than the tank or pump inlet.

• NOTE: Before installation, ensure

that lines are thoroughly ushed

with evacuation line cleaner, and

once complete, then the vacuum is

turned o.

• Use provided inlet and outlet

couplings.

• Do not glue plumbing to the Syclone™

Amalgam Separator inlet and outlet.

• Securely mount or support the

bracket.

• If mounting to a wall, use studs or wall

anchors for secure installation. Do not

mount directly into drywall.

• Write the installation date on the

collection container.

• Complete the product registration

form online at Crosstex.com/Syclone.

2

• Stud nder

• Level

• Heavy-duty wall anchors

• Screws

• Drill

• Phillips-head screwdriver

• Slotted screwdriver

• Measuring tape

• Pipe cutter

• Adapters and additional pipe (as

necessary)

• All items from the Syclone

Amalgam Separator box

It is recommended to keep these tools within arm’s reach during the installation:

Before installation, ensure that lines are

thoroughly ushed with evacuation line

cleaner, and once complete, then the

vacuum is turned o.

!

Find an appropriate location for the

Syclone Amalgam Separator

Secure the mounting bracket

• Generally installed close to the vacuum pump

• The Syclone Amalgam Separator outlet

should at least 4-6 inches higher than the

vacuum inlet

• Check for studs and mark one of the top corners

• If a stud is not available, wall anchors, plastic

standos, or similar ttings should be used

NOTE: Do not mount directly into drywall

• Attach the top corner of the mounting bracket

• Use level to conrm alignment

• Mark the rest of the pilot holes

• Drill pilot holes, install wall anchors if necessary

and use appropriate screws to secure the

mounting bracket

3

Attach the top chamber to pipes

• The outlet from the operatories should be installed to

the top inlet of the Syclone™ Amalgam Separator

• Measure the piping and cut

• Use one of the two couplings provided along with

adapters and additional pipe as necessary

• Connect to the vacuum via the system outlet on

the bottom using the other coupling provided

• Install adapters and additional pipe as necessary

• Be sure to tighten all connections to prevent leaking

NOTE: Depending on the conguration of the

pipes, you may need PVC adaptors to connect the

plumbing to the system (not provided with Syclone

Amalgam Separator)

Install the canister

• Fill the new canister with water

to help increase longevity of the

product

• Align the canister to the top

chamber and push up

• Secure the canister using the

retaining pins provided

Attach the top chamber

• Choose either left- or right-facing installation based

on layout

• Seat the prongs of the top chamber into the

corresponding slots on the mounting bracket

• Ensure that all the top and bottom ttings are fully

seated

• Use a Phillips-head screwdriver to tighten the screws

and washers provided for the bottom prongs of the

top chamber until snug

Easy set-up and installation (cont’d)

Final checks

• Turn on the vacuum and run water

through the system; check for leaks

• Write the installation date as well

as the maximum change date of 12

months on the canister label

• Attach the visual inspection log

• The unit is now ready for use

Maintenance and troubleshooting

Service & troubleshooting

The Syclone Amalgam Separator is designed to provide trouble-free service, with minimal attention. In the unlikely event of a

system-related problem please consult the troubleshooting and maintenance guide below.

Problem: Little or no vacuum at the handpiece.

• Check the sediment level of the container. Replace if full.

• Check the vacuum gauge.

If the vacuum gauge reads normally but there is little or no vacuum to the handpiece, there is probably a clog or a leak

between the handpiece and the Syclone Amalgam Separator. Further troubleshooting of the whole vacuum system may

be required. Please contact your preferred service technician or Crosstex Customer Support.

If the vacuum gauge reads lower than normal and you have a solid collection cup, check, clean or replace element/screen

if necessary. Check operation of the vacuum pump and listen for vacuum leaks. Check connections for breaks, cracks, kinks,

or loose clamps.

If the vacuum gauge reads lower than normal and you just replaced the canister, check the installation of the new canister. If

the vacuum is low there is a possibility that the O-rings on the canister did not seal into the receivers. Check the O-rings and

re-install per the installation procedure.

Problem: Water in the upper chamber of the system.

• Check the sediment level of the canister. Replace if full.

• Check the pH of the evacuation line cleaner; if below 6 or above 8, change canister and line cleaner.

• The transition from the upper chamber to the canister could be clogged.

Problem: Solids are at or above Full Line of canister.

• Change the canister. Inspect the top chamber for solids.

Problem: Top chamber contains some solids which has caused the system to back up.

• Turn on the vacuum.

• Remove the pins.

• Tilt the canister towards the outlet pipe to allow air into the top chamber.

• Place the canister back on and insert the pins.

Problem: Top chamber is full with solids which has caused the system to be in bypass.

There may be a reduction in suction and solids may be released into the waste stream.

• Replace top chamber.

• Do not discard the chamber; it must be recycled. Contact Crosstex Customer Service for additional support.

Maintenance

Line rinsing and vacuum line cleaners:

Cleaners should have these qualities:

Low-foaming, deodorizing, sanitizing

and pH between 6 and 8. Use of line

cleaners outside of this pH range will void

the warranty.

Dental vacuum systems:

Follow manufacturer’s instructions.

Note: It is recommended to rinse no

more than 5 rooms every 10 minutes.

Limit the total maximum ow to the

Syclone™ Amalgam Separator system

during rinsing to 1 liter per minute.

Rinsing too much or too rapidly can

overll the unit and could aect

eciency.

Canister replacement:

Follow instructions included with

the replacement canister. Check the

sediment level of the canister monthly.

Please see the Visual Inspection Log

located on page 12. Optional email

reminders are available when registering

the system for warranty at Crosstex.com/

Syclone.

4

This procedure should be performed only when

no patients are being worked on, as loss of

chairside vacuum may occur.

Leave the vacuum system running during the entire

canister change-out procedure.

• Full canisters should be handled and disposed

of according to applicable local, state, and

federal regulations.

• Remember to wear safety protective gear

such as gloves and safety glasses or face

shield when handling full Crosstex Syclone™

Canisters.

NOTE: If the system needs to be replaced,

it should be handled, sanitized, stored and

disposed of according to regulations applying to

hazardous waste containing mercury. Remember

to wear safety protective gear such as gloves and

safety glasses or face shield and dispose of per

local codes and regulations.

Before you begin: Examine the upper chamber of your Syclone

Amalgam Separator. If liquid is present, wait until it has drained into

the collection canister before proceeding.

Replacement canister installation

Hazardous Waste Warning

The waste stream treated by the Syclone™ Amalgam Separator is

generated by a dental vacuum system and as such, may contain

concentrations of solid and soluble mercury and silver. All spills should

be considered as hazardous and handled in accordance with standard

hazardous materials (HAZMAT) handling procedures.

Note: Crosstex oers a recycling program for the safe disposal/recycle

of full canisters. Contact your dental distributor to purchase a Syclone

Amalgam Separator Recycle Kit and replacement canister for the safe,

eco-friendly disposal of your full canister.

Purchase of the recycle kit also includes processing of the used canister

for recycling. Please visit the product webpage at Crosstex.com for

information on Syclone™ Canister Recycling. The used canister may never

be shipped to Crosstex International headquarters and must be sent to

a qualifying recycling facility.

Contents of the Syclone™ Replacement Canister

and Recycle Kit:

• Shipping box and cushions

• Instruction and recycling sheet

• (1) Replacement canister

• (2) O-rings (additional, added tting option)

• (3) Plugs

• (2) Cap seal

• (1) Zip-style disposal bag

• (1) Return shipping label sleeve

✓Don’t forget!

Save the shipping carton for storage of your full collection canister!

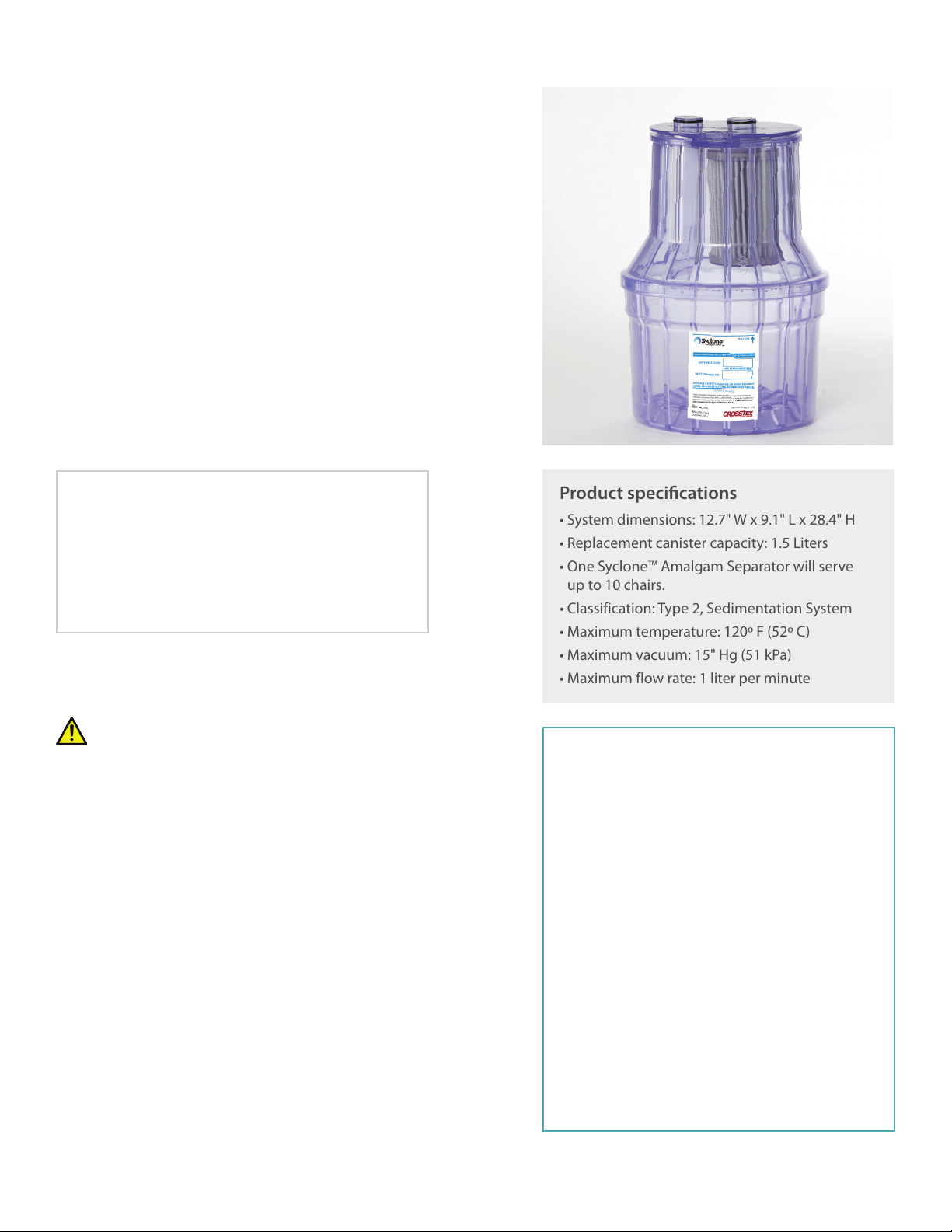

Product specications

• System dimensions: 12.7" W x 9.1" L x 28.4" H

• Replacement canister capacity: 1.5 Liters

• One Syclone™ Amalgam Separator will serve

up to 10 chairs.

• Classification: Type 2, Sedimentation System

• Maximum temperature: 120º F (52º C)

• Maximum vacuum: 15" Hg (51 kPa)

• Maximum flow rate: 1 liter per minute

Replacement canister:

Length: 10 ½"

Width: 9 ½"

Height: 12"

Weight: 4 lbs.

Shipping dimensions

Full system:

Length: 28"

Width: 19"

Height: 10"

Weight: 26 lbs.

5

6

1. Sanitize the vacuum system using the sanitization procedure established at your facility.

It is good practice to leave the vacuum pump running for 5 to 10 minutes every time the system is sanitized in order

to allow excess liquid time to evacuate the lines. Please note: record the vacuum gauge reading before removing the

canister. Its should be the same once the canister has been replaced.

2. With the vacuum system still running, remove the full canister from the unit as follows:

a. Open the zip-style bag (provided), remove all ttings from inside and slip the bag over the canister to be removed.

b. Support the canister with one hand while removing the retaining pins with the other hand. Tilt the canister to

release the element-side receiver rst (slotted pipe side – RIGHT side for right-handed installation or LEFT side for

left-handed installation) and then pull down to release the entire canister.

WARNING: Hold the bag securely in the unlikely event that the upper chamber may contain some residual liquid

that may drain during removal of the canister.

c. Decontaminate the contents of the collection canister by pouring 1:100 bleach solution into the canister (this is

done to stay compliant with DOT regulations on amalgam waste shipping).

d. Place the appropriate plugs into the inlet and outlet ttings of the full canister.

e. Place the plastic caps on top of the plugged inlet and outlet ttings of the full canister.

f. Squeeze out all excess air and zip the disposal bag closed.

Replacement canister installation (cont’d)

PPE information

Remember to wear safety protective gear such as gloves and safety glasses or face shield when handling

full Syclone™ Canisters.

3. With the vacuum system still running, install your new canister:

a. Fill the new canister with water before installation to help increase longevity

of the product. The canister can be installed only one way. Note the

alignment of the ttings on the canister with the receiver holes in the upper

unit.

b. Gently insert the ttings into the receiver holes. This can be accomplished

by rocking the canister slightly. The O-rings on the ttings should seat easily

into the upper unit receivers. (If the O-rings appear loose, exchange them for

the large-gauge O-rings included in the kit for a tighter t.)

c. Continue to push the canister into the top chamber until it is fully seated.

d. Insert the retaining pins into their holes until seated as per the gure on page 1.

e. The canister is now locked into place.

4. Fill out the information label:

a. Enter“Date Installed” on the new canister.

b. Enter the“Next Change Due”on the new canister, which should be 12

months from the installation date.

c. Note the vacuum gauge reading. The reading should be the same as before

the canister change.

Your canister must be changed every twelve (12) months or when sediment level reaches the Full Line; whichever occurs rst.

Check the sediment level of the canister monthly. If you would like to keep a written record of the visual inspection, please refer

to the chart on page 12.

Installing the replacement canister

Set up account

Check email

Set up a Crosstex DocHub account by accessing the

portal via the Syclone™ Amalgam Separator page

under “Product Warranty Registration.”

Enter the oce details on the rst step, ensuring

that all information is valid as this will be replicated

on the recycling certicates.

Check the email account entered in Step 1 for a

temporary password. Enter the temporary password.

You will be prompted to change the password to a

more memorable one that can be used for future

logins.

Crosstex DocHub

account set up

page

Verify address

Enter the business address of the oce. Ensure that

all information is valid as this will be replicated on

the recycling certicates. Verify the address and

select the UPS address that is pertinent to the oce.

You may override this feature if needed.

Enter serial number

Enter the valid serial number of your Syclone Amalgam

Separator. The serial number of the Syclone™ Canister

associated with the system should populate automatically.

Select the date installed and complete any pertinent

information on your preferred dealer. Opt-in to receive email

reminders to help stay compliant.

If you do not have a Syclone Amalgam Separator,

check

“No” on the rst question. Enter the serial number of your

amalgam separator and the valid serial number of the

Syclone™ Replacement Canister. Select the date installed and

complete any pertinent information on your preferred dealer.

Opt-in to receive email reminders to help stay compliant.

If

you have a canister from your current system that needs to

be recycled,

check yes for“Do you have a canister to return

from your original system?”. Enter the serial number of your

current canister in the eld provided. A UPS shipping label for

the current canister will be sent to the email associated with

the account.

Complete registration

Select “Complete Registration.”The processing may take a

few minutes. Once completed, you will be automatically

redirected to the dashboard. Use the dashboard to recycle

canisters, track returned canisters and view any recycling

certicates that have been generated. The Crosstex DocHub

dashboard Status and

Action columns

Final step for Crosstex

DocHub account setup

Canister recycling instructions

New users to Crosstex DocHub

7

Sign in

Print label

Prepare shipment

Track shipment

Deliver shipment

Use the Crosstex DocHub portal on the Syclone™

Canister Replacement Program page to generate

your label.

Sign in using the email and password associated

with the account. On the dashboard, select “Recycle

Canister” for the used canister you would like to

recycle.

On the next page, enter the serial number of the

new Syclone™ Replacement Canister. Check all

the information and hit“Request UPS Label.” No

payment information is required.

Note: Please use one UPS label per Syclone

Replacement Canister box.

Print the prepaid shipping label with tracking

information.

Check the email associated with the Crosstex

DocHub account for the UPS label. Print the

shipping label.

Recycle canister

page on Crosstex

DocHub

Example of

shipping label

Sample email from Crosstex DocHub with

attachment to print shipping label

Prepare the used canister for shipment and attach

the label to box using the return shipment label

sleeve.

Additional details on packaging the used canister

can be found in the Syclone Replacement Canister

Installation Guide.

After shipment, follow your package on Crosstex DocHub or with the tracking number provided from UPS. You will receive

your certicate once the canister has been received for recycling. Certicates may take up to 30 days to process from date

shipped to the recycler.

Deliver shipment within ten days to your UPS driver,

local UPS Store, UPS Drop Box or UPS Alliance (Oce

Depot or Staples).

Note: Purchase of the recycle kit includes processing

of the used canister for recycling. Please follow the

directions listed to ship the canister. Do not ship used

canisters to Crosstex. All used canisters must be sent

to a qualied recycling facility listed on the label.

SAMPLE

Canister recycling instructions

Returning users with Crosstex DocHub access

8

Warranty

System and Replacement Parts

Warranty

Syclone™ Amalgam Separators are warrantied against defects in material and workmanship for two (2) years from the date

of purchase. Syclone™ Replacement Canisters are warrantied for one (1) year from the date of purchase. During warranty

period Crosstex will at its sole discretion repair and/or replace products that prove to be defective at the original install

point with established proof of purchase.

Labor, transportation and recycling service charges are specically not included.

The Syclone Replacement Canister is warrantied for one (1) year when utilized on a compatible/compliant amalgam air/

water separator. Crosstex will honor all compatible/compliant amalgam air/water separator warranties.

Limitations of warranty

The warranty shall not apply to defects resulting from improper installation, maintenance, abuse, unauthorized

modication, or operation outside of the environmental specications for the product or damages that occur in shipping

due to improper repackaging of equipment for return to Crosstex. Crosstex specically disclaims the implied warranties of

merchantability and tness for a particular purpose.

Use of evacuation line cleaners having a pH less than 6 or greater than 8 will void these warranties.

Crosstex recommends the use of Sani Vac™ Evacuation System Cleaner, but other evacuation line cleaners with a pH

between 6 and 8 can also be used. The remedies provided herein are the buyer’s sole and exclusive remedies. Crosstex

shall not be liable for any direct, indirect, incidental or consequential damages, whether based on contract, tort or any

other legal theory. No other warranty is expressed or implied.

Note: If the Syclone Amalgam Separator is installed remotely from the dental center, a warning

signal alarm should be installed for monitoring capability.

9

Product ordering information:

Ref. # Description

AMLSYS Syclone™ Amalgam Separator System

AMLSYRC Syclone™ Replacement Canister and Recycle Kit

Sani Vac™ Evacuation System Cleaner

According to the American Dental Association (ADA) and regulators requiring

amalgam separators, oxidizing line cleaners should not be used with a functioning

amalgam separator because they can break down and release amalgam particles

into the wastewater*.

Cleaners containing bleach (chlorine bleach, sodium hypochlorite) should never

be used, as chlorine is known to cause mercury to be released from amalgam.

Regulators have also become aware of pH related to evacuation line cleaners. New

amalgam separator regulations now require the use of evacuation line cleaners with

a pH between 6 and 8.

Acidic (low pH) evacuation line cleaners have been known to hinder the operation

of amalgam separators. Basic (high pH) cleaners can cause premature wear on

materials used in amalgam separators. The use of Sani Vac™ Evacuation System

Cleaner with the Syclone™ Amalgam Separator system is recommended.

Although the 2003 CDC Dental Guidelines do not specify how often to clean

evacuation lines, they do suggest in the Saliva Ejector & Backow FAQ’s** to refer to

the manufacturer’s procedure for the appropriate cleaning and disinfection methods

of suction tubing. To maintain optional performance, Crosstex recommends routine

use of Sani Vac Evacuation System Cleaner (daily or after each patient) to prevent

sluggish lines, unnecessary downtime and/or costly line repairs.

Visit Crosstex.com for further details.

10

*www.epa.gov/eg/dental-euent-guidelines

**www.cdc.gov/oralhealth/infectioncontrol/faqs/saliva.html

Product ordering information:

Ref. # Description Quantity

JVAC Sani Vac™ Evacuation System Cleaner 1 gallon

11

Solid Amalgam Waste Disposal

As part of the EPA Dental Amalgam Rule, the Best Management

Practices (BMPs) outlines include recommendations to collect

and recycle solid amalgam waste. This includes contact and non-

contact amalgam, used amalgam capsules, extracted teeth with

amalgam, chairside traps and vacuum pump lters.

Be compliant with the recommended BMP with the Amalgam

Buckets from Crosstex. These can be used for safe and ecient

recycling of solid amalgam waste in the forms listed above. They

are UN certied and available in multiple sizes to best suit the

needs of the practice.

All Amalgam Buckets from Crosstex include pre-paid returns for

recycling and certicates of compliance, making it easy to stay

compliant.

Visit Crosstex.com/amalgambuckets for further details.

Product ordering information:

Ref. # Description Quantity

AMLB1 Amalgam Bucket 1.25 gallon 1 Each

AMLB2 Amalgam Bucket 2.5 gallon 1 Each

AMLB5 Amalgam Bucket 5 gallon 1 Each

Visual inspection log

For your convenience, we have provided a Visual Inspection Log for monthly reporting, which can be cut

out and axed to the system. Use this log to ensure proper operation and maintenance. Visually inspect

the canister monthly to determine the level of solid waste. Canister is replaced when solids reach the

Full Line or once a year, whichever comes rst.

Oce Name: ________________________________________________________________________

Serial Number of Syclone System: _______________________________________________________

Date of System Installation: ____________________________________________________________

Date (MM/DD/YYYY) Print Name Signature

SYCLONE INSPECTION LOG

12

13

Technical Installation Checklist for

Syclone™ Amalgam Separator

Step 1:

Step 4:

Step 6:

Step 2:

Step 5:

Step 3:

Step 7:

Locate the vacuum pump and

map out plan for installation

a. Check that vacuum is turned o

b. Syclone™ System should be

installed with the outlet higher

than the vacuum inlet by at

least 4-6 inches

Secure the Syclone Amalgam

Separator top chamber

a. Bottom ttings should be secured

to the mounting bracket with

provided screws and washers

Install replacement canister

a. Push into top chamber and

insert provided retaining pins

Unpack the Syclone Amalgam

Separator box and check that all

components are present

Attach top chamber to pipes

a. Measure where to cut piping

and make the cut

b. Install coupling to inlet and

add adaptors and additional

piping as necessary

c. Ensure that all joints are

tightened or glued

d. Repeat steps a-c for amalgam

separator outlet

Install the blue mounting bracket

a. Ensure that the bracket is level

and mark pilot holes’locations

b. If stud is available, use screws

to secure bracket to stud

c. If no stud is present, use wall

anchors and appropriate screws

to secure bracket to wall

Check system

a. Turn on vacuum and run water

through the system, checking

for leaks

b. Write installation date and next

change due date on canister

Stud nder

Level

Heavy-duty wall anchors

Screws

Drill

Phillips screwdriver

Slotted screwdriver

Measuring tape

Pipe cutter

Adapters and additional

pipe (as necessary)

All items from the Syclone

Amalgam Separator box

It is recommended to

keep these tools within

arm’s reach during the

installation:

Please read all instructions

in the Syclone Amalgam

Separator Installation

and Operating Guide prior

to installation.

!

Notes

14

Certied to ISO 11143

© 2019 Crosstex International, Inc. AMLSYS-IFU Rev. 4 - 3/19

For over 65 years, Crosstex has remained

dedicated to innovative, high-quality

solutions, services and education that ensure

maximum compliance and improve outcomes

for healthcare professionals and patients.

888.276.7783 | crosstex.com

All product names are trademarks of Crosstex International, Inc., a Cantel Medical company,

its aliates or related companies, unless otherwise noted.

Manufactured for: Crosstex International, Inc.

Corporate Office: 10 Ranick Road, Hauppauge, NY 11788-4209 USA

Website: www.crosstex.com E-mail: [email protected]

Other manuals for SYCLONE

1

Table of contents