Crystal Mini 40 User manual

INSTALLATION AND

USER MANUAL

for your heat pump

Crystal Mini 40

1

W

arning

2

works.

This heat pump contains a flammable refrigerant R32.

Any intervention on the refrigerant circuit is prohibited without a valid autho-

rization.

Before working on the refrigerant circuit, the following precautions are neces-

sary for safe work.

1. Work procedure

The work must be carried out according to a controlled procedure, in order to mini-

mize the risk of presence of flammable gases or vapors during the execution of the

2. General work area

All persons in the area must be informed of the nature of the work in progress. Avoid working in a confined

area. The area around the work area should be divided, secured and special attention should be paid to

nearby sources of flame or heat.

3. Verification of the presence of refrigerant

The area should be checked with a suitable refrigerant detector before and during work to ensure that

there is no potentially flammable gas. Make sure that the leak detection equipment used is suitable for

flammable refrigerants, ie it does not produce sparks, is properly sealed or has internalsafety.

4. Presence of fire extinguisher

If hot work is to be performed on the refrigeration equipment or any associated part, appropriate fire extin-

guishing equipment must be available. Install a dry powder or CO2 fire extinguisher near the work area.

5. No source of flame, heat or spark

It is totally forbidden to use a source of heat, flame or spark in the direct vicinity of one or more parts or

pipes containing or having contained a flammable refrigerant. All sources of ignition, including smoking,

must be sufficiently far from the place of installation, repair, removal and disposal, during which time a

flammable refrigerant may be released into the surrounding area. Before starting work, the environment

of the equipment should be checked to ensure that there is no risk of flammability. «No smoking» signs

must be posted.

6. Ventilated area

Make sure the area is in the open air or is properly ventilated before working on the system orperforming

hot work. Some ventilation must be maintained during the duration of the work.

7. Controls of refrigeration equipment

When electrical components are replaced, they must be suitable for the intended purpose and the appro-

priate specifications. Only the parts of the manufacturer can be used. If in doubt, consult the technical

service of the manufacturer.

The following controls should be applied to installations using flammable refrigerants:

- The size of the load is in accordance with the size of the room in which the rooms containing the

refrigerant are installed;

- Ventilation and air vents work properly and are not obstructed;

- If an indirect refrigeration circuit is used, the secondary circuit must also be checked.

- The marking on the equipment remains visible and legible. Illegible marks and signs must be corrected;

- Refrigeration pipes or components are installed in a position where they are unlikely to be exposed to a

substance that could corrode components containing refrigerant

8. Verification of electrical appliances

Repair and maintenance of electrical components must include initial safety checks and component

inspection procedures. If there is a defect that could compromise safety, no power supply should be

connected to the circuit until the problem is resolved.

Initial security checks must include:

•That the capacitors are discharged: this must be done in a safe way to avoid the possibility of sparks;

•No electrical components or wiring are exposed during loading, recovery or purging of the refrigerant

gas system;

•There is continuity of grounding.

T

hank you

3

Dear Customer,

Thank you for your purchase and for your confidence in our products.

These are the result of many years of research in the field of design and production of heat pumps

for swimming pools. Our aim is to provide you with an exceptional high performance quality product.

We have produced this manual with the utmost care so that you get maximum benefit from your

heat pump.

4

! PLEASE READ CAREFULLY

These installation instructions are an integral part of the product.

They must be given to the installer and retained by the user.

If the manual is lost, please consult the website:

The instructions and recommendations contained in this manual should be read carefully and

understood since they provide valuable information concerning the heat pump’s safe handling and

operation. Keep this manual in an accessible place for easy future reference.

Installation must be carried out by a qualified professional person in accordance with current

regulations and the manufacturer’s instructions. An installation error may cause physical injury

to persons or animals as well as mechanical damage for which the manufacturer can under no

circumstances be held responsible.

After unpacking the heat pump, please check the contents in order to report any damage.

Prior to connecting the heat pump, ensure that the information provided in this manual is compat-

ible with the actual installation conditions and does not exceed the maximum limits authorized for

this particular product.

In the event of a defect and/or malfunction of the heat pump, the electricity supply must be

disconnected and no attempt made to repair the fault.

Repairs must be undertaken only by an authorized technical service organization using original

replacement parts. Failure to comply with the above-mentioned clauses may have an adverse

effect on the heat pump’s safe operation.

Toguarantee the heat pump’s efficiency and satisfactory operation, it is important to ensure its

regular maintenance in accordance with the instructions provided.

If the heat pump is sold or transferred, always make sure that all technical documentation is

transmitted with the equipment to the new owner.

This heat pump is designed for heating a swimming pool/Hot Tub or Pond. Any other use mustbe

considered as being inappropriate, incorrect or even hazardous.

Any contractual or non-contractual liability of the manufacturer/distributor shall be deemed null

and void for damage caused by installation or operational errors, or due to non-compliance

with the instructions provided in this manual or with current installation norms applicable to the

equipment covered by this document.

Contents

5

1. General..........................................................................................................................................6

1.1 General Terms ofDelivery................................................................................................ 6

1.2 Safetyinstructions............................................................................................................ 6

1.3 Watertreatment ..............................................................................................................7

2. Description...................................................................................................................................8

2.1 Packagecontents ............................................................................................................8

2.2 Generalcharacteristics.....................................................................................................8

2.3 Technicalspecifications ...................................................................................................9

2.4 Unit dimensions.............................................................................................................10

2.5 Explodedview................................................................................................................11

3. Installation..................................................................................................................................12

3.1 Location ................................................................................................................................12

3.2 Installationlayout............................................................................................................13

3.3 Hydraulic connection.......................................................................................................13

3.4 Electricalconnection.......................................................................................................13

4. Use.......................................................................................................................................14

4.1 Controlpanel...................................................................................................................14

4.2 Operating modeselector.................................................................................................14

4.3 Heating Mode .................................................................................................................15

4.4 Cooling Mode .................................................................................................................16

4.5 Silent Mode.....................................................................................................................17

4.6 Auto Mode......................................................................................................................17

4.7 Status values and advancedsettings...............................................................................18

5.Operation.............................................................................................................................20

5.1 Operation........................................................................................................................20

6.Maintenance and servicing................................................................................................ 21

6.1 Maintenance, servicing and winter storage......................................................................21

7.Repairs................................................................................................................................ 22

7.1 Breakdowns and faults....................................................................................................22

7.2 List of faults. ...................................................................................................................23

8.Recycling ............................................................................................................................24

8.1 Recycling the heat pump................................................................................................24

A.Appendices........................................................................................................................................25

A.1 Wiring diagrams........................................................................................................................ 25

1. General

6

All equipment, even if shipped ‘free of carriage and packing’, is dispatched at the consignee’s own

risk.

The person responsible for receiving the equipment must carry out a visual inspection to identify

any damage to the heat pump during transport (refrigerant system, body panels, electrical control

box, frame). He/she must note down on the carrier’s delivery note any remarks concerning

damage caused during transport and confirm them to the carrier by registered letter within 48

hours.

The equipment must always be stored and transported vertically on a pallet and in its original

packaging. If it is stored or transported horizontally, wait at least 24 hours before switching it on.

During installation and servicing

Only a qualified person may undertake installation, start-up, servicing and repairs, in compliance

with current standards.

Before operating or undertaking any work on the equipment (installation, commissioning, usage,

servicing), the person responsible must be aware of all the instructions in the heat pump’s

installation manual as well as the technical specifications

Under no circumstances install the equipment close to a source of heat, combustible materials or

a building’s air intake.

If installation is not in a location with restricted access, a heat pump protective grille must be fitted

Toavoid severe burns, do not walk on pipework during installation, repairs or maintenance.

Toavoid severe burns, prior to any work on the refrigerant system, turn off the heat pump and wait

several minutes before placing temperature and pressure sensors.

Check the refrigerant level when servicing the heat pump.

Check that the high and low pressure switches are correctly connected to the refrigerant system

and that they turn off the electrical circuit if tripped during the equipment’s annual leakage

inspection.

Check that there is no trace of corrosion or oil stains around the refrigerant components.

WARNING :

Please

read

carefully

the

safety

instructions

before

using

the

equipment.

The

following

instructions

are

essential

for

safety

so

please

strictly

comply

with

them.

1.

2

Safety instructions

1.

1

General Terms of Delivery

1. General

7

During use

Toavoid serious injuries, never touch the fan when it isoperating.

Keep the heat pump out of the reach of children to avoid serious injuries caused by the heat

exchanger’s blades.

Never start the equipment if there is no water in the pool or if the circulating pump is stopped.

Check the water flow rate every month and clean the filter ifnecessary.

During cleaning

Switch off the equipment’s electricity supply.

Close the water inlet and outletvalves.

Do not insert anything into the air or water intakes or outlets.

Do not rinse the equipment with water

Rinse onlythe titanium with water

During repairs

Carry out work on the refrigerant system in accordance with current safetyregulations.

Brazing should be performed by a qualified welder.

When replacing a defective refrigerant component, use only parts certified by our technical

department.

When replacing pipework, only copper pipes conforming to Standard NF EN12735-1 may beused

for repairs.

When pressure-testing to detectleaks:

Toavoid the risks of fire or explosion, never use oxygen or dry air.

Use dehydrated nitrogen or a mixture of nitrogen andrefrigerant.

The low and high side test pressure must not exceed 42bar.

heat pumps for swimming pools can be used with all types of water treatmentsystems.

Nevertheless, it is essential that the treatment system (chlorine, pH, bromine and/or salt chlorina-

tor metering pumps) is installed after the heat pump in the hydraulic circuit.

To avoid any deterioration to the heat pump, the water’s pH must be maintained between

6.9 and 8.0.

1.3

W

ater treatment

2.

Description

8

ν Crystal Heat pump - Mini 40 Turbo R32

ν 2 hydraulic inlet/outlet connectors 32/38mm diameter

ν This installation and user manual

ν 4 anti-vibration pads

A heat pump has the following features:

CE certification and complies with the RoHS European directive

High performance with up to 90% energy savings compared to a conventional heating

system.

Clean, efficient and environmentally friendly R32 refrigerant

Reliable high output leading brand compressor.

Wide hydrophilic aluminum evaporator for use at low temperatures.

User-friendly intuitive control panel.

Heavy duty shell, anti-UV treated and easy to maintain.

Designed to be silent.

2.

2

General characteristics

2.

1

Package contents

2.

Description

9

Crystal Mini 40

Advised poolvolume

m³

20~25

Heating temperaturerange

℃

25~45

Cooling temperaturerange

℃

5~28

Auto mode temperature range

℃

5~43

Operatingrange

℃

-20~43

Air 26℃ Water 26℃

capacity(KW)

4.25~2.10

powerinput(KW)

0.73~0.18

Currentvalue(A)

3.24~0.79

COP

11.60~5.82

Air 15℃ Water 26℃

capacity(KW)

3.15~1.22

powerinput(KW)

0.75~0.18

Currentvalue(A)

3.26~0.79

COP

6.75~4.20

Air 35℃ Water 27℃

capacity(KW)

2.58~0.85

powerinput(KW)

0.75~0.68

Currentvalue(A)

3.26~0.21

EER

4.05~3.44

Air -15°C Water26℃

Capacity(KW)

1.42~0.55

Powerinput(KW)

0.713~0.171

Inputcurrent(A)

3.087~0.743

COP

3.22~1.99

Air -20°C Water26°C

Capacity(KW)

0.79~0.31

Powerinput(KW)

0.675~0.162

Inputcurrent(A)

2.913~0.704

COP

1.91~1.17

powersupply

220-240V / ~/50Hz

max powerinput

KW

1.5

max current

A

6.65

water flow-Min/Max

m³/h

0.9/3.6

Refrigerantvolume

R32/0.30kg

Min pressure/maxpressure

1.5/4.15MPa

unit netdimensions(mm)

400x280x385

packagedimensions(mm)

460x370x415

net weight kg

20

gross weightkg

22

noise at 10m

<35dB(A)

compressor brand

GMCC

Condensertype

TitaniumTube

water prooflevel

IPX4

Loss charge(mCE)

0.8

The technical specifications of our heat pumps are provided for information purposes only. We reserve the

right to make changes without prior notice.

2.

3

Technical specification

2.

Description

10

Dimensions in mm

Crystal Mini 40

A

385

B

420

C

290

D

52

E

180

2.

4

Unit dimensions

A

D

E

B

C

2.

Description

11

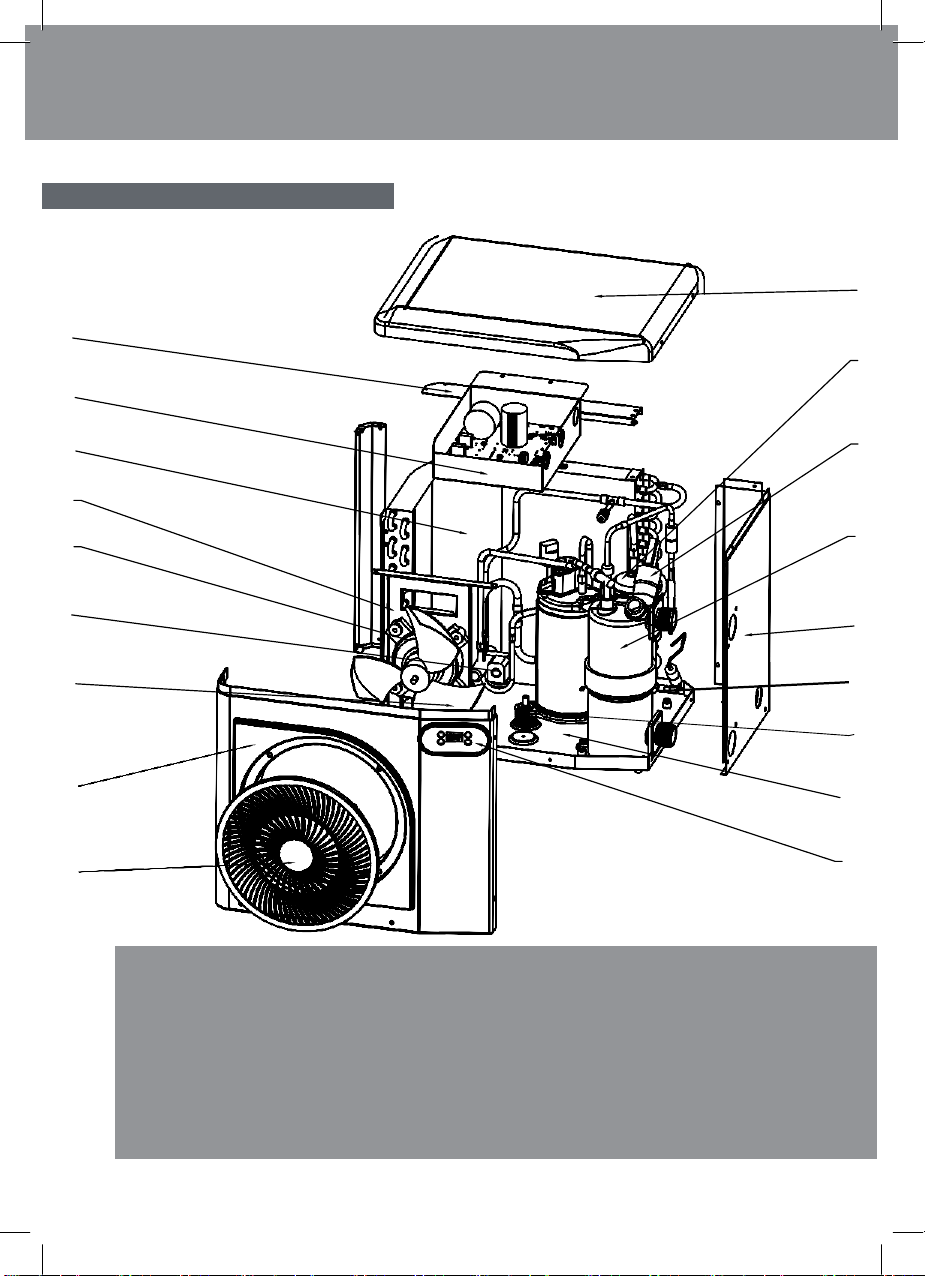

1. Fan protective grille

2. Front panel

3. Fan blade

4. 4-way valve

5. Fan motor

6. Fan support

7. Evaporator

8. Electrical control box

9. Mounting frame

10. Top panel

11. Compressor

12. Water Flow Switch

13. Heat exchanger

14.Left side panel

15. Electric base frame heating

16. Electric crankshaft heating

17. Base frame

18. Control panel

9

8

7

6

5

4

3

10

11

12

13

2

1

14

15

16

17

18

2.5

Exploding view

3. Installation

12

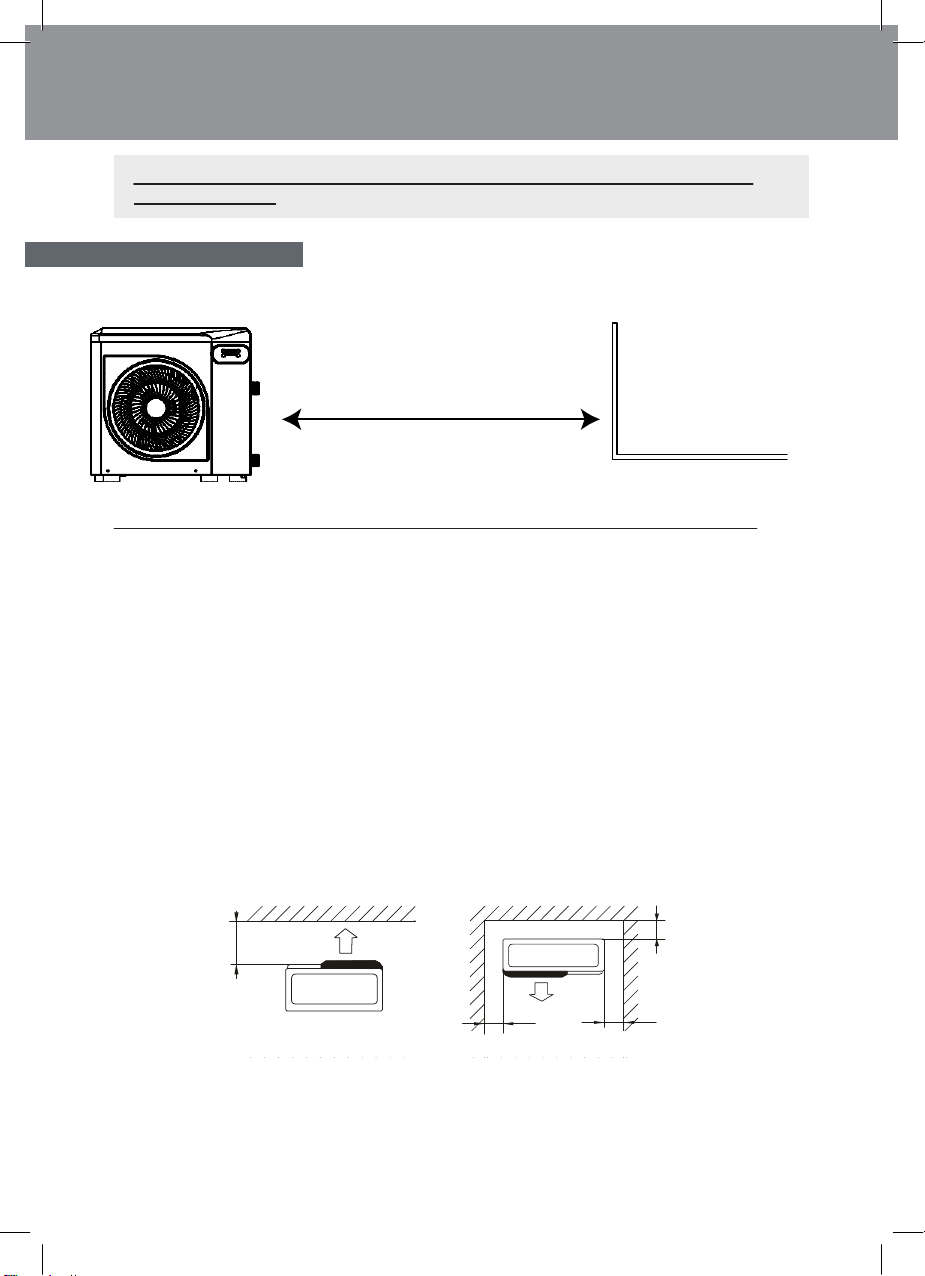

The heat pump should be located at least 2.5 meter away from the swimming pool.

Please comply with the following rules concerning the choice of heat pump location.

1. The unit’s future location must be easily accessible for convenient operation and maintenance.

2. It must be installed on the ground, laid ideally on a level concrete base . Ensure that the floor

is sufficiently stable and can support the weight of the unit

3. Check that the unit is properly ventilated, that the air outlet is not facing the windows of neigh-

boring buildings and that the exhaust air cannot return. In addition, provide sufficient space

around the unit for servicing and maintenance operations.

4. The unit must not be installed in an area exposed to oil, flammable gases, corrosiveproducts,

sulfurous compounds or close to high frequency equipment.

5. Toprevent mud splashes, do not install the unit near a road or track.

6. Toavoid causing nuisance to neighbors, make sure the unit is installed so that it is positioned

towards the area that is least sensitive to noise.

7. Keep the unit as much as possible out of the reach of children.

≥30

≥30

Dimensions in cm

Place nothing less than 1,50 m in front of the heat pump.

Leave 30 cm of empty space around the sides and rear of the heat pump.

Do not leave any obstacle above or in front of the unit!

Pool

>2.5m

3.

1

Location

The

heat

pump

is

very

easy

to

install,

only

water

and

power

need

to

be

connected

during installation.

≥

150

3. Installation

13

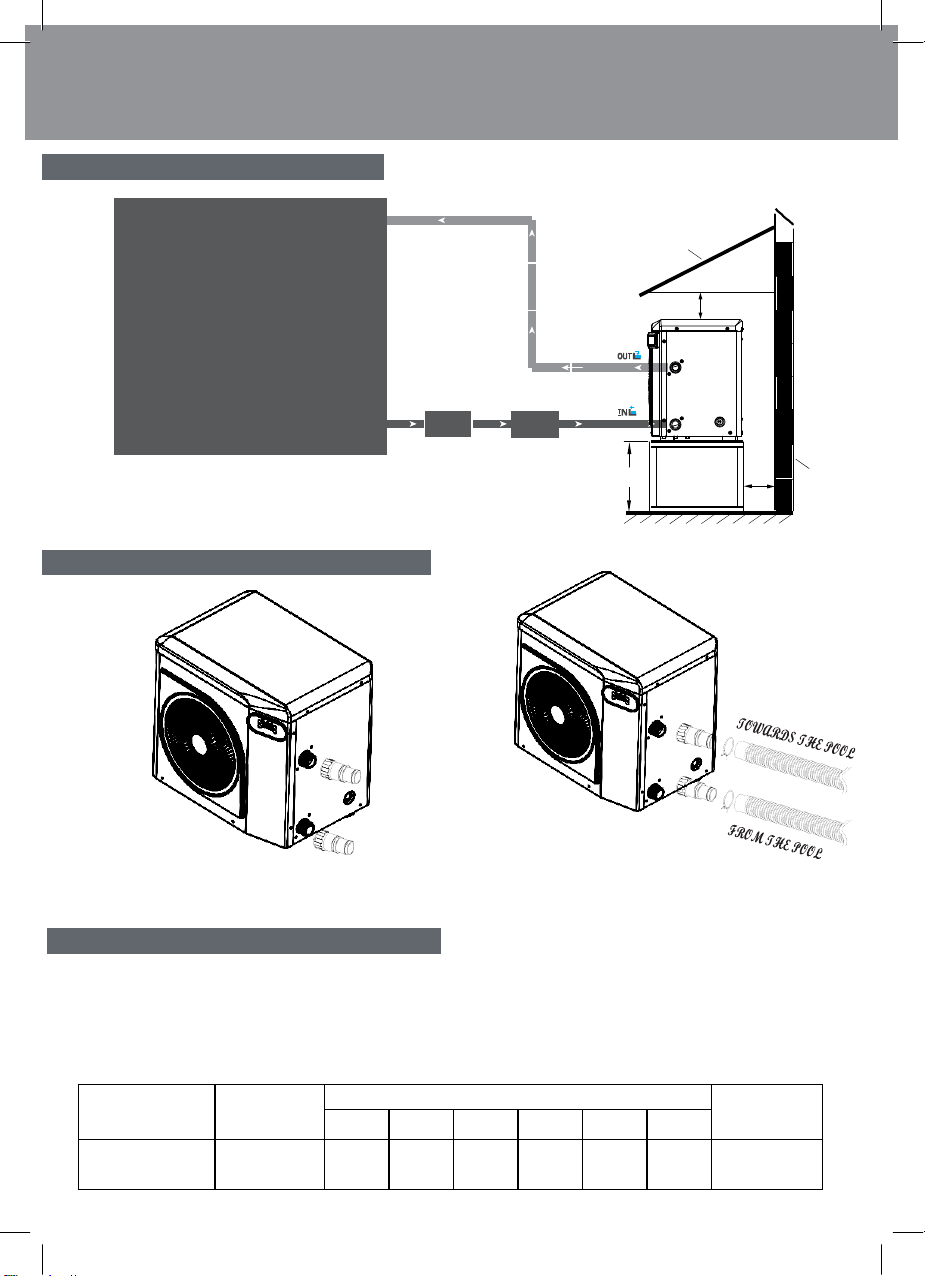

TOWARDS THE POOL

Snow tent

POOL

≥30cm

Filtration

Pump

FROM THE POOL

The filter located upstream of the heat pump must be regularly

backwashed so that the water in the system is clean, thus avoiding

the operational problems associated with dirt or clogging in the filter.

50-80cm ≥30cm

subgrade

wall

Step 1

Screw the connectors to the heat pump Step 2

Connect the water outlet pipe and the water intake pipe

The heat pump electrical plug integrates a 10mA differential circuit breaker.

Before connecting your heat pump, please ensure that the plug is

connected to the ground.

The filter pump should function at the same time as the heat pump.

Therefore, you need to connect them to the same electrical circuit.

Model

max current(A)

maximum length of the wire(m)

Refrigerant

2

1.0mm

2

1.5mm

2

2.5mm

2

4mm

2

6mm

2

10mm

Crystal Mini 40

6.65

36

52

88

142

213

371

R32

3.

4

Electrical connection

3.

3

Hydraulic connection

3.

2

Installation layout

4.

Use

14

1. Mode button

2. Heating mode indicator

3. Cooling/Defrost mode indicator

4. Silent mode indicator

5. Auto mode indicator

6. Wifi indicator

7. Increase Temp. button

8. Decrease Temp. button

9. ON/OFF button

Prior to setting your required temperature, you must first select an operating mode for your control

panel:

Heating Mode

Select the heating mode for the heat pump to heat

the water in your pool.

Cooling Mode

Select the cooling mode for the heat pump to cool

the water in your pool.

Silent Mode

Select the heating mode for the heat pump to heat

the water in your pool.

Auto Mode

automatic cooling or heating according to the set

temperature.

Wifi

Wifi function enabled

Before starting, ensure that the filtration pump is working and that water is circulating

through

the heat

pump.

4.2

erat

m

e

se

ect

r

4.1

12 3 4 5 6 7

9

8

4.

Use

15

Step 1 : Press to switch on yourpump.

Step 2 : Press to switch from onemode to another until the heating mode is displayed.

Step 3 : Using buttons and select the required

temperature. EXAMPLE:

If the current temperature is 18.8°C, default setting temperature is 27°required temperature is 30°

C.

Current water temperature Required water temperature

Useful information about how the heating modeoperates

When the incoming water temperature is less than or equal to the required temperature (set point

temperature) -X°C, the heat pump will switch to heating mode. The compressor will stop whenthe

temperature of the incoming water is greater than or equal to the required temperature (set point

temperature).

Temperature deviation value X setting

X : adjustable parameter from 1° to 18°C, default setting of temperature deviation value is 1°C.

(Parameter“P01”)

4.3

Heat

M

e

4.

Use

16

Step 1 : Press to switch on yourpump.

Step 2 : Press to switch from one mode to another until the cooling mode isdisplayed.

Step 3 : Using buttons and select the required temperature.

EXAMPLE :

If the current temperature is 30°C, default setting temperature is 27° required temperature is15°C.

Current water temperature Required water temperature

When the incoming water temperature is greater than or equal to the required temperature (set

point temperature) - X°C, the compressor will switch to cooling mode. The compressor will stop

when the temperature of the incoming water is less than or equal to the required temperature

(set point temperature).

Temperature deviation value X setting

X : adjustable parameter from 1° to 18°C, default setting of temperature deviation value is 1°C.

(Parameter“P01”)

Useful

information

about

how

the

cooling

mode

operates

4.4

Cooling

mode

4.

Use

17

Step 1 : Press to switch on yourpump.

Step 2 : Press to switch from one mode to another until the silent mode isdisplayed.

Step 3 : Using buttons and select the required temperature.

EXAMPLE :

If the current temperature is 18.8°C, default setting temperature is 27° required temperature is30°C.

Current water temperature Required water temperature

When the incoming water temperature is less than or equal to the required temperature (set point

temperature) -X°C, the heat pump will switch to heating mode. The compressor will stop whenthe

temperature of the incoming water is greater than or equal to the required temperature (set point

temperature).

Temperature deviation value X setting

X : adjustable parameter from 1° to 18°C, default setting of temperature deviation value is 1°C.

(Parameter“P01”)

Step 1 : Press to switch on yourpump.

Step 2 : Press to switch from one mode to another until the auto mode is displayed.

4.6

Auto

mode

Useful

information

about

how

the

silent

mode

operates

4.5

Silent

m

e

4.

Use

18

The system’s settings can be checked and adjusted via the control panel by following

these steps

Step 1 : Keep pressing 5 second Until all three LEDs flash simultaneously.

Step 2 : Press or for select the parameters.

Step 3 : Press for see the value.

Step 4 : Press again to return selection parameters or Press or digital flashing.

Step 5 : Press or to adjust the setting value.

Note, some settings cannot be modified. Consult the settings table for further information.

Step 6 : Press to set the newvalue.

Step 7 : Press to return to the mainscreen.

Parameter P01 The value of the parameter P01

WARNING: This operation is used to assist servicing and future repairs.

The default settings should only be modified by an experienced professional person.

4.7

at

s

va

es

a

a

va

ce

sett

s

4.

Use

19

Parameters table

N°

Description

Range value

Default

value

Comment

P01

Adjustment of temperature difference for restart

1~18°C

1°C

Actual data

P02

Reserved

/

/

/

P03

Reserved

/

/

/

P04

Settingtemperatureincoolingmode

5~28°C

27°C

Adjustable

P05

Settingtemperatureinheatingmode

25~45°C

27°C

Adjustable

P06

Dischargetemperatureprotect value

80~125°C

115°C

Adjustable

P07

Dischargetemperaturerecover value

50~100°C

95°C

Adjustable

P08

Compressor current protect

2-50A

Reserved

/

P09

Inlet water temperature compensation

50~100°C

95°C

Adjustable

P10

Reserved

/

/

/

P11

Defrosting mode activation timer

20~90 min

45min

Adjustable

P12

Defrostingmodecoilentrytemperature

-15~-1°C

-3°C

Adjustable

P13

Defrosting mode maximum duration

5~20min

8min

Adjustable

P14

Defrostingmodecoilexittemperature

1~40°C

20°C

Adjustable

P15

Defrostmodeambientandcoiltemperaturedifference

0~15°C

0°C

Adjustable

P16

Defrostingmode airentrytemperature

0~20°C

17°C

Adjustable

P17

EEV activation timer

20~90 sec.

45sec

Adjustable

P18

Heatingmodesuctionsupertemperaturesetvalue

-5~10°C

Reserved

/

P19

EEVactive-Dischargetemperatureprotect

70~125°C

Reserved

/

P20

EEVopening-Defrostingmode

20~450

Reserved

/

P21

EEV minimum opening

50~150

Reserved

/

P22

EEV mode selection

0 =Manual

1=Auto

Reserved

/

P23

EEVmanualmodeopening

20~450

Reserved

/

P24

Coolingmodesuctionsupertemperaturesetvalue

-5~10°C

Reserved

/

P25

ConstanttemperaturemodeFiltrationpumpstoptime

1~99min

45min

Adjustable

P26

ConstanttemperaturemodeFiltrationpumprunningtime

0~99min

5min

Adjustable

P27

CoolingEEVworkingmode

0=ambient

temperature

1=suctionsuper

temperature

Reserved

/

P28

Filtrationpumpworkingmode

0 =constant

temperature stop

1=constant

temperature running

1

Adjustable

P29

Maxwateroutlettempsetinheatingmode

25~45°C

43°C

Adjustable

4.7

at

s

va

es

a

a

va

ce

sett

s

Table of contents

Other Crystal Heat Pump manuals