Crystal CHP075PX User manual

Please read and understand ALL the instructions

before installation and use.

-1-

This is for information purposes only as all our PX models are below the 7kgs threshold of R32Gas.

Regulation (EU) n° 517/2014 of 16/04/14 on fluorinated greenhouse gases and

repealing Regulation (EC) n° 842/2006

Leak checks

1. Operators of equipment that contains fluorinated greenhouses gases in quantities of 5 tons of CO2, equivalent or more and not

contained in foams shall ensure that the equipment is checked for leaks.

2. For equipment that contains fluorinated greenhouse gases in quantities of 5 tons of CO2equivalent or more, but of less than 50

tons of CO2equivalent: at least every 12 months.

Picture of the equivalence CO2

1. Load in kg and Tons amounting CO2.

Load and Tons amounting CO2

Frequency of test

From 7

to

75 kg load = from 5 at 50 Tons

Each year

Do not release R32 coolant liquid into the atmosphere. This is a fluoride greenhouse effect gas covered by the

Kyoto agreement with a global warming potential (GWP) = 675 - (see the European Community regulations on

fluoride greenhouse effect gases Regulation (EU) No 517/2014).

Concerning the Gas R32, 7.40kg amounting at 5 tons of CO2, commitment to check each year.

Training and certification

1. The operator of the relevant application shall ensure that the relevant personnel have obtained the necessary certification, which

implies appropriate knowledge of the applicable regulations and standards as well as the necessary competence in emission

prevention and recovery of fluorinated greenhouse gases and handling safety the relevant type and size of equipment.

Record keeping

1. Operators of equipment which is required to be checked for leaks, shall establish and maintain records for each piece of such

equipment specifying the following information:

a) The quantity and type of fluorinated greenhouse gases installed;

b) The quantities of fluorinated greenhouse gases added during installation, maintenance or servicing or due to leakage;

c) Whether the quantities of installed fluorinated greenhouse gases have been recycled or reclaimed, including the name and

address of the recycling or reclamation facility and, where applicable, the certificate number;

d) The quantity of fluorinated greenhouse gases recovered

e) The identity of the undertaking which installed, serviced, maintained and where applicable repaired or decommissioned the

equipment, including, where applicable, the number of its certificate;

f) The dates and results of the checks carried out;

g) If the equipment was decommissioned, the measures taken to recover and dispose of the fluorinated greenhouse gases.

2. The operator shall keep the records for at least five years, undertakes to carry out the activities for operators and shall

keep records for at least five years.

*Please note*:

-2-

12. WIFI function

ATTENTION: This manual includes all the necessary information the use and

installation of your heat pump .

1.

The installer must read the manual and attentively follow the instructions for

implementation and maintenance.

2.The installer is responsible for the installation of the product and should follow all the

instructions ANY errors due to an installation that does not follow the manual guidelines

will VOID the Warranty.

Any use that does not conform to its manufacturing purpose will be regarded as dangerous

and will VOID any Warranties.

for

Thank you for choosing our CHP-PX range for your swimming pool heat pump for your pool heating

needs, it will heat your water and keep the temperature constant when ambient temperatures are at

-20℃to 43℃. As long as the H/P unit purchased has been sized correctly to your specific

requirements, with adequate pool & plumbing, insulation and an insulated cover is used. Please

call supplier to discuss.

INDEX:

1. Specification

2. Dimension

3. Stock advice

4. Installation

5. Adjust the by-pass kit

6. Initial operation

7. Controller Operation

8. Electrical Wiring

9. Malfunction and Trouble shooting

10. Exploded view

11. Maintenance

WARNING :

Please always keep heat pump in well ventilated place and away from anything which could cause fire.

Do not braze or weld the pipe if there is refrigerant inside machine. Please do not charge the gas when in

a confined space.

Please always empty the water in the heat pump during winter time if not in use or when the ambient

temperature drops below 3℃, the Titanium Exchanger will be damaged by being frozen, in such cases,

your warranty will be VOID.

Please always turn off & isolate the power supply if you want to open the cabinet to reach inside the heat

pump.

Please keep the display controller in a dry area to protect the display controller from being damaged by

humidity, such damage will VOID the Warranty for the display.

The action of filling gas must be conducted by a professional with an R32 operating license.

-3-

1. Specification

Model

CHP075PX

CHP095PX

CHP115PX

CHP135PX

CHP165PX

CHP205PX

CHP255PX

CHP305PX

* Performance at Air 28℃, Water 28℃, Humidity 80%

Heating capacity

kW

7.5-2.3

9.5-2.4

11.5-2.9

13.5-3.2

17.1-3.7

20-4.6

25.5-5.9

30-6.7

Power

consumption

kW

1.19-0.15

1.51-0.15

1.83-0.18

2.14-0.2

2.76-0.23

3.28-0.29

4.18-0.37

4.91-0.42

C.O.P.

16-6.3

16-6.3

16-6.3

16-6.3

16-6.2

16-6.1

16-6.1

16-6.1

* Performance at Air 15℃, Water 26℃, Humidity 70%

Heating capacity

kW

5-2.1

6.8-2.2

8.2-2.3

10.1-2.4

12-3.2

15-3.9

19-4.8

23.5-5.5

Power

consumption

kW

1.11-0.26

1.45-0.28

1.74-0.29

2.15-0.3

2.55-0.4

3.19-0.49

4.04-0.6

5.0-0.69

C.O.P.

8-4.5

8-4.7

8-4.7

8-4.7

8-4.7

8-4.7

8-4.7

8-4.7

Voltage

V

220V-240V/50Hz or 60Hz/1PH

Rated current

A

5.0

6.7

8.2

9.5

11.5

14.9

18.6

22.3

Min. MCB fuse

A

16

16

16

25

25

30

30

40

Main cable

mm2

1.5

2.5

2.5

2.5

4

4

4

6

Advised pool volume

(with pool cover)

m³

11-26

12-34

14-62

16-65

24-86

54-118

63-132

70-182

Advised waterflux

m3/

h

2.6

2.9

3.8

4.2

4.7

5.2

8.2

10.3

Water pressure drop

Kpa

12

12

14

15

15

18

18

18

Water connection

mm

48.3/50

No. of Fan

1

2

Noise level(10m)

dB(

A

)

≤ 25

≤ 25

≤ 27

≤ 28

≤ 30

≤ 32

≤ 32

≤ 33

Noise level(1m)

dB

(A

)

32-45

32-46

33-46

34-48

34-48

35-50

35-50

36-52

* Dimension/ Weight

Net weight

kg

56

68

73

78

98

117

128

130

Gross weight

kg

68

73

78

83

113

135

146

148

Net dimension

mm

855*325*565

986*352*672

1040*355*895

1040*355*

1295

Packing

dimension

mm

925*417*616

1051*435*717

1140*480*917

1105*470*

1322

* Above data may be modified without notice.

-4-

2. Dimension (unit: mm)

2.1 Model: CHP075PX, CHP095PX

-5-

2.2 Model: CHP115PX, CHP135PX, CHP165PX.

2.3 Model: CHP205PX, CHP255PX

-6-

2.4 Model: CHP305PX.

-7-

3. Stock advice for R32 models

The warehouse should be bright, spacious, open, well ventilated, have ventilation

equipment and no fire source.

*VERY IMPORTANT* Heat pumps must be stored and transferred in a vertical position in its

original packaging. If this is not the case, the heat pump cannot be operated until a

minimum period of 24hrs has passed with the unit upright, before the unit can have the

electrical power turned on.

Smoking and the use of flames are prohibited near R32machine.

Water connections are not to be used as load bearing handles. The manufacturer does not accept

"ANY" responsibility for "ANY" damage to the water pipes.

4. Installation

4.1 Accessories list

Anti-vibration base, 4 pcs

Draining plug, 2 pcs

Water drainage pipes, 2 pcs

Winter Cover, 1 pc

Water connection assembly, 4 sets (2 sets 48.3mm, 2 sets 50mm )

-8-

4.2 Accessories Installation

Anti-vibration bases

1. Take out 4 Anti-vibration

bases

2. Install them on the bottom of

machine.

Note: Lift the heat pump to install the draining plug. Never

overturn the heat pump, it could damage the compressor.

Draining plug (NOT winter use

see further info regarding winter

use)

1. Install the draining plug under

the bottom panel

2. Connect with a water pipe to

drain out the water.

Water Inlet & outlet junction

1.Use the pipe tape to connect

the water Inlet & outlet junction

onto the heat pump.

2.Install the two joints like the

picture shows.

3. Screw them onto the water

Inlet & outlet junction.

NOTE: Please check for any shipping moved/damaged pipe work

etc. that is too close to other items that may cause vibration and

rubbing as this would be classed as shipping damage and "NOT"

a warranty issue.

Mains Cable wiring

1. Open the top cover of the

heat pump.

2.Connect the cables in the

correct terminal according to

electric diagram.

3. Please take note of length of

cable runs and possibly

upgraded cable requirement.

NOTE: Any damage caused or PCB`s damaged by doing this

will VOID the warranty.

Filtration pump wiring (Dry

contact)

1. Open the top cover of the

heat pump.

2. Connect the cables in the

correct terminal according to

electric diagram.

-9-

Dry contact timer connection

Timer

Dry contact pump connection

Water pump

-10

-

4.3 Installation of heat pump

(1) The heat pump must be installed by professional technicians, otherwise it may be damaged or

even broken.

(2) The unit is designed for outdoor location with good ventilation. Recirculation of cold discharge air

back into evaporator coil will greatly reduce heating capacity and efficiency of the unit, which will

void the compressor warranty.

(3) The unit can be installed almost anywhere in the outdoors. To get a good performance ,it needs

to meet the three factors :

a) Good ventilation

b) Stable and reliable power supply

c) Recycled water system

The difference from a gas water heater is, it should not bring environmental pollution or have

any installation problems in-windy areas.

(4) The unit should not be installed in a limited air ventilation area or placed in or near vegetation

that will block the air inlet.

These locations would deny the unit a continuous source of fresh air. When seasons change,

leaves maybe sucked onto the evaporator coil, thereby reducing its efficiency and impact on its

service life.

(5) For indoor installation, please request more instructions from your supplier and technicians.

(6) When a bypass is installed, flow should not exceed 30% of the nominal flow rate.

(7) Installer must make the water level higher than the circulation pump location. Unless a One-Way

Check Valve is used in the plumbing circuit.

(8) Typically, the pool heat pump unit should be installed aside a pool, less than 7.5 meters distance. But,

at least 2m away from the pool so a person cannot touch the pool and the heat pump at the same time,

as this would lead to electrical safety concerns.

(9) To get the best from the heat exchanger of the heat pump unit, it should be matched with the

nominal flow rate of water flow recommended in the specification sheet.

(10) We consider it good practice to place a discharge pipe in the lowest pipe to prevent freezing in

cold season. Put "T" fitting and ball valve to facilitate discharging the water in winter or emptying the

water out of the system to prevent freezing when the HP stops operating at the ambient

temperature below 3c, otherwise the unit may be damaged.

(11) It is suggested to install the quick adapter in front of the water in-out connection, which could

discharge water easily to prevent water freezing. This would be convenient for maintenance and

servicing.

(12) When the unit is running, there will be some condensation water discharged from the bottom.

For Summer Spring and Autumn use, please hold the drainage nozzle (accessory) into the hole

and clip well, then connect a pipe to drain the condensation water out. This tube and drain "IF"

used must be checked for blockages regularly as leaves and debris will block this.

-11 -

(13) The below picture shows the minimum required distances on each side of the heat pump.

*Absolute Minimum Clearance dimensions*

(14) If water pressure is over 10 KPA, or water flow rate is more than 11 cubic meters through

heat exchanger, it is necessary to install the by-pass pipe in water system.

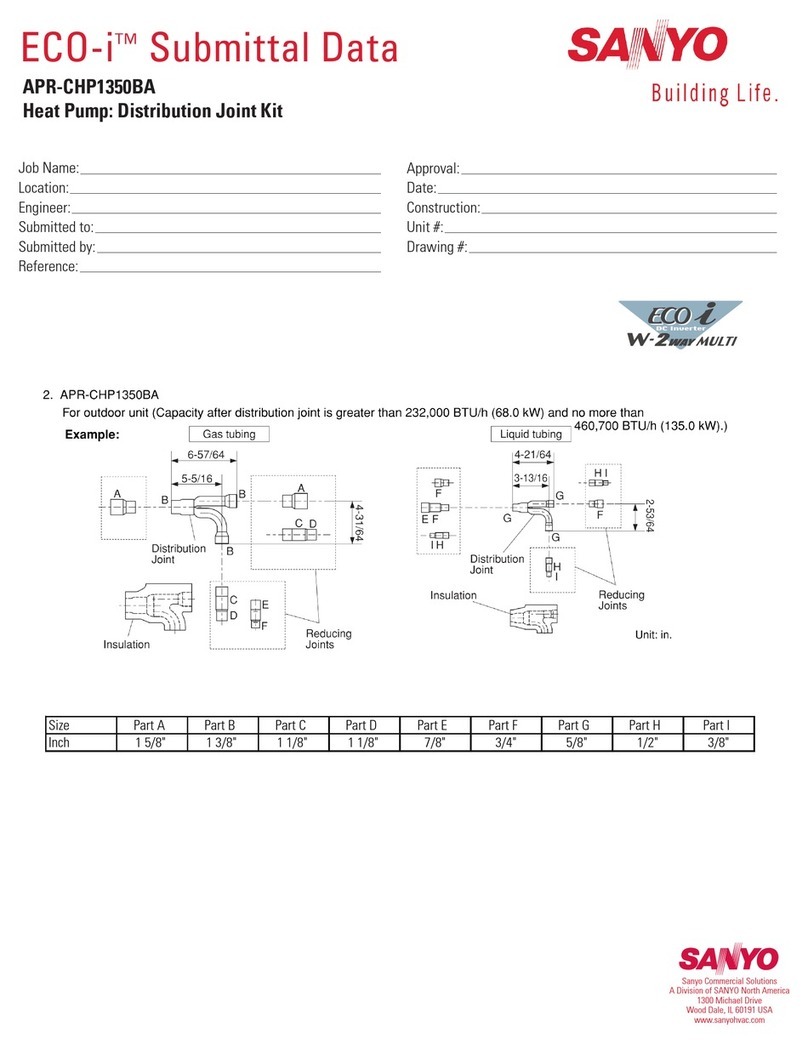

(15) Installation illustration

NOTE: The factory only provides the heat pump unit. The other items in the illustration are

necessary spare parts for the water system which are provided by users or installers.

ATTENTION:

Please follow these steps when operating for the first time :

1. Open the diversion heat pump valves to charge H/P with water and close the

by-pass valve (direct line)

2. Make sure that the pump and the water-in pipe have been filled with water.

Make sure there are no Air-Locks.

3. Start the unit

-12 -

(16) The location of a chemical introducer into your system is also critical to the heater’s life.

If an automatic chlorinator or brominator is used, it must be located downstream of the heater.

A "ONE" way check valve must be installed between the chlorinator and the heater to prevent

chlorine returning into the heat pump. (See below pictures)

-13 -

5. Adjusting the bypass

Use the following procedure to adjust the bypass:

1.Valve 1 wide open. Valve 2 & valve 3 closed.

2.

Slowly open valve 2 & valve 3 by half, then close the valve 1 slowly to increase the water flow to valve 2

& valve 3.

3.

If it shows‘ON` or `EE3’ on the display, it means the water flow into the heat pump is not enough, then

you need to adjust the valves to increase the water flow through the heat pump.

How to get the optimum water flow:

Please turn on the heat pump under heating function, firstly close the by-pass then open it slowly to start the

heat pump (the machine can't start running when the water flow is insufficient).

Continue to adjust the by-pass slowly, at this time check the Inlet water temp. & Outlet water temp., it will be

optimum when the difference is around 2 degree.

Drain out the water in winter for the units without drainage outlet in heat exchanger

Turn off the heat pump and be sure that it is disconnected from

power Turn off the water pump

-14 -

-Close the valves 1 and 2

-Open the valve 4

Allow water to drain out over a long period until the heat pump is fully drained.

NOTE: Close the valve 4 before turn on the heat pump.

6. Initial operation

Note: In order to heat the water in the pool (pond or hot tub), the filter pump must be running

to cause the water to circulate through the heat pump. The heat pump will not start up if the

water is not circulating.

After all connections have been made and checked, carry out the following procedure:

1) Switch on the filter pump. Check for leaks and verify that adequate water is flowing from and to

the swimming pool.

2) Connect power to the heat pump and press the On/Off button on the electronic control panel.

The unit will start up after the time delay expires (see below).

3) After a few minutes, check whether the air blowing out of the unit is cooler.

4) When the filter pump is turned off, the unit should also turn off automatically, if not, then adjust

the flow switch.

5) Allow the heat pump and the filter pump to run 24 hours a day until the desired water

temperature is reached. The heat pump will stop running at this point. After this, it will restart

automatically (as long as the filter pump is running) whenever the swimming pool water

temperature drops 2 degree below the set temperature.

Depending on the initial temperature of the water in the swimming pool and the air temperature, it

may take several days to heat the water to the desired temperature. A good swimming pool cover

can dramatically reduce the required length of time.

Water Flow Switch:

Your heat pump is equipped with a flow switch for protecting the HP unit running with adequate

water flow rate. The heat pump will turn on when the pool pump runs and shut the heat

pump off when the pool pump shuts off. If the pool water level is higher than 1m above or below

the heat pump’s automatic adjustment knob, your dealer may need to adjust its initial start up.

Time delay - The heat pump has a built-in 3-minute start-up delay to protect the circuitry and avoid

excessive contact wear. The unit will restart automatically after this time delay expires. Even a brief

power interruption will trigger this time delay and prevent the unit from restarting immediately.

Additional power interruptions during this delay period do not affect the 3-minute duration of the

delay.

Condensation

The air drawn into the heat pump is strongly cooled by the operation of the heat pump for heating

the pool water, which may cause condensation on the fins of the evaporator. The amount of

condensation may be as much as several litres per hour at high relative humidity. This is

sometimes mistakenly, regarded as a water leak.

-15 -

Pressure gauge display (R32)

Examine the pressure gauge which indicates the refrigerant gas pressure of the unit, the below

table shows the normal value of the gas pressure (R32) when the machine is in power off or running

conditions.

Unit Condition

Power Off

Ambient (℃)

-5~5

5~15

15~25

25~35

Water temp (℃)

/

/

/

/

Pressure gauge (Mpa)

0.59~0.85

0.85~1.18

1.18~1.59

1.59~2.1

Unit Condition

Running

Ambient (℃)

/

/

/

/

/

Water temp (℃)

10~15

15~20

20~25

25~30

30~35

Pressure gauge (Mpa)

1.1~1.6

1.3~1.8

1.5~2.1

1.7~2.4

1.9~2.7

7. Controller Operation

7.1 Guide for operation

7.2 The keys and their operations

7.2.1 button

Press to start the heat pump unit.

Press to stop the heat pump unit.

7.2.2 and button

Water temperature setting:

-16 -

Press or to set the water

Press and at the same time to check water in temperature, water out temperature

and set temperature.

7.2.3 button

Press to change the working mode, Powerful, silent and smart. The default mode is smart

mode.

7.2.4 button

Press for 2 seconds to enter secondary page.

Press and to select the functions and press to enter.

7.2.5 Heating/Cooling/Auto mode

Select and press to enter, press and to choose Heating/ Cooling/

Auto mode, press again to exit. The default mode is Heating mode.

Logic of auto mode:T1=Water inlet temperature /Tset= set temperature=28c

temperature.

-17 -

Parameter checking

and press to enter, press and to check d0-d11 value. Press

checking.

Code

Condition

Scope

Remark

d00

IPM mould temperature

0-120℃

Real testing value

d01

Inlet water temp.

-9℃~99℃

Real testing value

d02

Outlet water temp.

-9℃~99℃

Real testing value

d03

Ambient temp.

-30℃~70℃

flash if Real value<-9

d04

Frequency limitation code

0,1,2,4,8,16

Real testing value

d05

Piping temp.

-30℃~70℃

flash if Real value<-9

d06

Gas exhaust temperature

0℃~C5℃(125℃)

Real testing value

d07

Step of EEV

0~99

N*5

d08

Compressor running

frequency

0~99Hz

Real testing value

d09

Compressor current

0~30A

Real testing value

d10

Current fan speed

0-1200 (rpm)

Real testing value

d11

Error code for last time

All error code

Remark:

d4: Frequency limitation code,

0: No frequency limit;

1: Coil pipe temperature limit;

2: Overheating or overcooling frequency limit;

4: Drive Current frequency limit;

8: Drive voltage frequency limit;

16: Drive high temperature frequency limit

7.2.6

Select

to exit

-18 -

7.2.7 Parameter setting

Select and press to enter, press and to choose P0-P18 value and

press to set.

Note: Long press for 10s to set P8, P12, P13, P14, P15, P17, P18.

Code

Name

Scope

Defa

ult

Remark

P00

Mandatory defrosting

0-1

0

0: Default normal operation

1: Mandatory defrosting.

P03

Water pump

0-1

0

1:Always running;

0:Depends on the running of compressor

P07

Water temp. calibration

-9~9

0

Default setting: 0

P08

Adjustable for P9-P11

0~1

0

1: Adjustable for P9, P10, P11

0: Not adjustable for P9, P10, P11

P09

Compressor Frequency

18~110

50

Adjustable if P08=1

P10

Opening degree of EEV

0~470

350

Adjustable if P08=1

P11

Fan motor rotate speed

300~1000

500

Adjustable if P08=1

P12

Communication port of

modbus

0~5

0

Only available for HP with modbus

P13

ID NO. of modbus

protocol

1~88

9

Only available for HP with modbus

P14

Restore to factory

settings

0~1

0

0: Default

1: Restore to factory settings

(restore P00, P03, P07, P08, P09, P10, P11

to factory setting)

P15

Model code in modbus

Only available for HP with modbus

P16

Product code

/

/

Depend on the machine

P17

Modules selection

0~1

0

Only available for HP with modbus or wifi

1: Modbus module

0: Wifi module

P18

Mode

0~1

0

1: Heating only

0: Heating/Cooling/Auto mode

This manual suits for next models

7

Table of contents

Other Crystal Heat Pump manuals

Popular Heat Pump manuals by other brands

York

York YAZS022 installation manual

Heat Controller

Heat Controller VMH 09 Replacement parts

Bosch

Bosch BOVA Series installation instructions

STIEBEL ELTRON

STIEBEL ELTRON WPL 15 AS Operation and installation

Oasis

Oasis RAPID PRO RP14 Installation & user manual

EAS Electric

EAS Electric ETH220VMA instruction manual

Carrier

Carrier Puron IP24 owner's manual

Bryant

Bryant Legacy 547K 14 installation instructions

Grant

Grant Aerona3 HPID12R32 Installation and servicing instructions

Mitsubishi Electric

Mitsubishi Electric CITY MULTI PQHY- P216TSLMU-A1 quick start guide

Firefly

Firefly YASBP-56HL User manual, installation & operation

Hotjet

Hotjet MINI 5Ai installation manual