Crystal ComboPump User manual

C R Y S T A L

engineering corporation

PN: 2909

9/2002

Page 1 of 4

ComboPump Instruction Sheet

Precision Pressure and Vacuum Hand Pump

Introduc-

tion

Thank you for purchasing a ComboPump. ComboPumps are

precision pressure

and

vacuum sources (depending on the

setting of the shuttle valve), that can be operated with one hand.

The built-in variable volume is pressure balanced, so it’s easy to

set the pressure precisely with just your fingertips, regardless of

how high the pressure is.

There are two pressure ports on top of the pump. Mount a

Digital Test Gauge or a 30 Series Pressure Calibrator directly on

top of the pump, connect the spare port directly to the device

being tested, and you have a complete field pressure calibra-

tion system.

All moving parts of the pump mechanism are protected from

damage and dirt. There are no exposed springs, piston rods,

etc. The body and handle are anodized aircraft grade

aluminum and all moving parts are high strength, corrosion-

proof plastics and metal. That’s why we are confident

your

ComboPump will provide many years of no-maintenance

service.

Specifications

Pressure Range:

PN: 2907 2000 kPa 20 bar 300 PSI

PN: 2908 3500 kPa 35 bar 500 PSI

Vacuum Range (Both models):

-85 kPa -0.85 bar -12.3 PSI -25″Hg

Connections

Two 1⁄8″Female National Pipe Thread (NPT

)

Weight

605g (1 lb., 5.3 oz.)

Dimensions

24mm (H) x 5mm (W) x 5mm (D) (9.5″H x 2″W x2″D)

Introduction

PN: 2909

9/2002

Page 2 of 4 PRESSURE is Our BUSINESSTM

Operating Instructions

The ComboPump is only for use with pneumatic systems. Do not use the

ComboPump with liquids of any kind. For safe and reliable operation please spend a

few minutes reading the following instructions.

WARNING

To prevent damage to the pump and possible injury, never connect the

ComboPump to a pressure source greater than 3500 kPa (500 PSIG, 35 bar).

Turn off, or isolate, all pressure-generating equipment from the pressure tap prior to

connecting the ComboPump.

NOTE: The operating pressure rating is printed on the pump body label on the

opposite side of the vent knob.

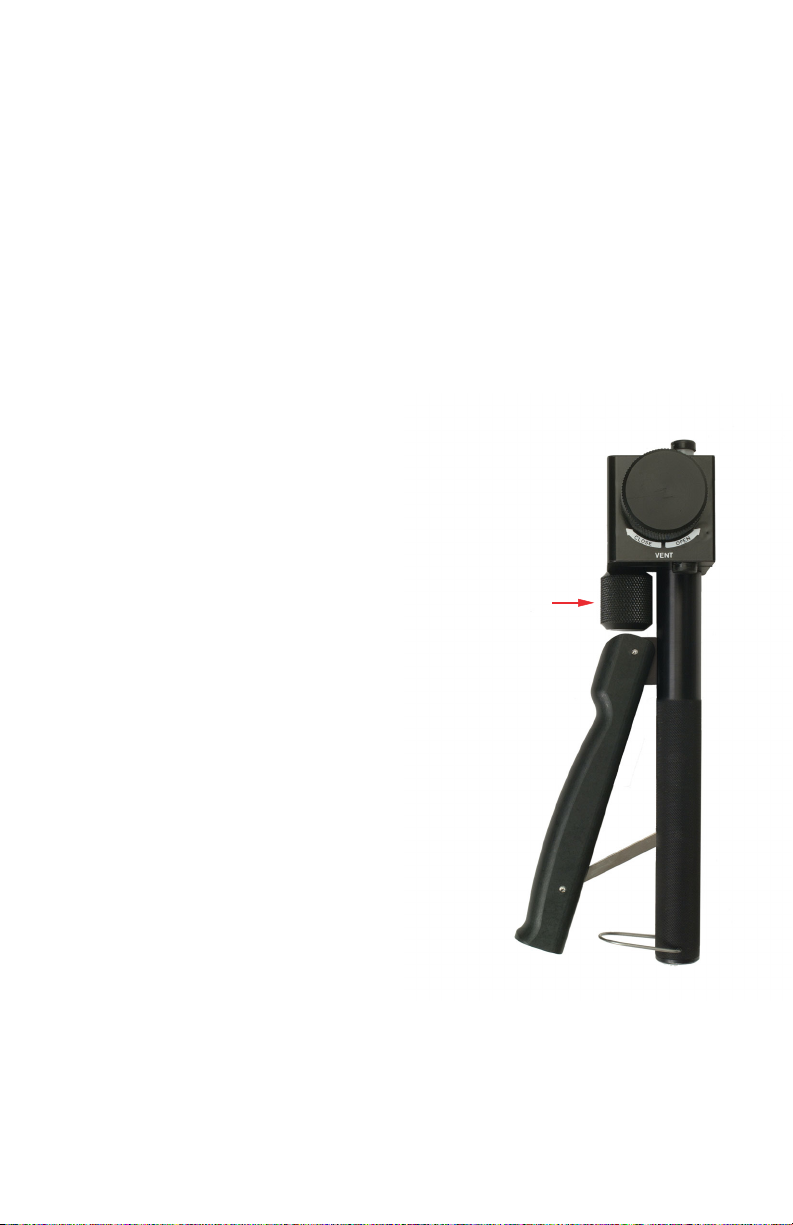

Shuttle Valve

Pressure Ports

Vent Knob

C R Y S T A L

engineering corporation

PN: 2909

9/2002

Page 3 of 4

1. Your ComboPump has two 1⁄8″NPT male pipe thread pressure ports. Always use

PTFE (polytetrafluoroethylene) tape on the threads of any pressure fittings

installed into the ComboPump. DO NOT USE liquid pipe sealing compounds

(such as “pipe dope”). Be careful not to over-tighten fittings.

CAUTION: Your fittings must have a pneumatic pressure rating of at least

5000 kPa (750 PSIG, 50 bar).

2. Connect the ComboPump to your test set-up. Select whether you want PRES-

SURE MODE (up position) or VACUUM MODE (pressed down position). Make

certain the valve is fully UP or fully DOWN.

3. Close the VENT KNOB by turning it fully clockwise. Don’t overtighten - fingertight

is enough.

4. You are now ready to perform your pressure or vacuum calibration. Squeeze the

ComboPump handle until you are close to the desired calibration

pressure or vacuum.

5. To make pressure or vacuum adjustments turn the variable

volume adjustment knob (the bottom knob next to the squeeze

handle) to set the precise the pressure or vacuum desired.

6. After the test is complete open the VENT KNOB to completely

release pressure or vacuum. The vent knob can also be used

to slowly bleed the system by opening it only a slight amount

and closing it once the pressure or vacuum is reached.

NOTE: Be sure to close the vent knob fully once the

system is fully vented, to prevent the knob from vibrating

loose when transporting the pump.

The ComboPump is covered by a 1 year warranty

against pressures leaks and defects in materials or

workmanship (see page 4). This warranty does not

cover physical abuse or misuse.

Contact the factory for all repair needs, regardless if

the ComboPump is covered by the warranty or not!

Repair or replacement of any parts must be performed only by

the factory, or a factory authorized representative. Do not attempt to

substitute parts or the warranty will be voided and damage to the pump or

personal injury may result. Remember:

Your safety comes first!

This is a high

pressure pump. Do not attempt your own repairs.

Variable Volume Knob

PN: 2909

9/2002

Page 4 of 4 PRESSURE is Our BUSINESSTM

Warranty

Crystal Engineering Corporation warrants the ComboPump to be free from defects in

material and workmanship under normal use and service for one (1) year from date of

purchase to the original purchaser. It does not apply when the product has been

misused, altered or damaged by accident or abnormal conditions of operation.

For in (or out) of warranty service, we can be reached at:

Phone .................... (805) 595-5477

Toll-Free ................ (800) 444-1850

Fax ......................... (805) 595-5466

Email ...................... service@crystalengineering.net

Web ....................... www.crystalengineering.net

If calling, have ready the model number, serial number, date of purchase and reason

for return. You will receive instructions for returning the device to Crystal Engineering.

Crystal Engineering will, at our option, repair or replace the defective device free of

charge and the device will be returned, transportation prepaid. However, if we

determine the failure was caused by misuse, alteration, accident or abnormal condi-

tion of operation, you will be billed for the repair.

CRYSTAL ENGINEERING CORPORATION MAKES NO WARRANTY OTHER THAN

THE LIMITED WARRANTY STATED ABOVE. ALL WARRANTIES, INCLUDING

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE, ARE LIMITED TO A PERIOD OF ONE (1) YEAR FROM

THE DATE OF PURCHASE. CRYSTAL ENGINEERING SHALL NOT BE LIABLE FOR

ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, WHETHER IN

CONTRACT, TORT OR OTHERWISE.

Note (USA only): Some states do not allow limitations of implied warranties or the

exclusion of incidental or consequential damages, so the above limitations or exclu-

sions may not apply to you. This warranty gives you specific legal rights and you may

have other rights which vary from state to state.

© 2002, Crystal Engineering Corporation

720 Aerovista Place, Suite B

San Luis Obispo, CA 93401-8701

Table of contents

Popular Water Pump manuals by other brands

SHIMGE

SHIMGE SQm Service manual

SFA

SFA SANIFOS 110 Installation and operating manual

Gasboy

Gasboy 61 Special installation instructions

Pentair

Pentair SHURFLO PIRANHA 375-116-10 quick guide

Grundfos

Grundfos DMH 25X Installation and operating instructions

EINHELL

EINHELL GC-DP 7035 LL Original operating instructions

SFA

SFA Sanicom FF03-P95 manual

Clarke

Clarke BIP1000 Operation & maintenance instructions

pumpa

pumpa BLUE LINE 3PVM Original instruction manual

Pentax

Pentax AQUADOMUS TRANSLATION OF ORIGINAL INSTRUCTIONS

Blue Angel

Blue Angel DF12VSM Operating instructions and parts manual

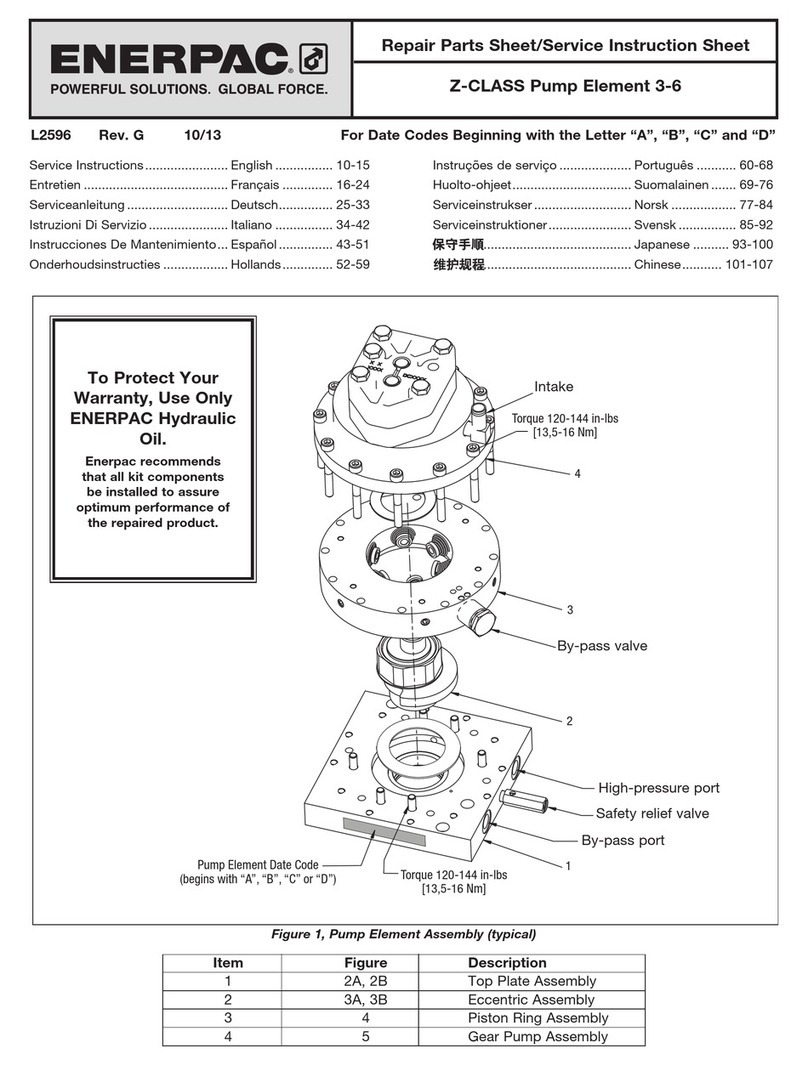

Enerpac

Enerpac DC8143900 Instruction and Repair Parts Sheet