CS Yachts CS36T User manual

CS36T

Owner’s Manual

CS YACHTS LTD., 79 Bramsteele Road

Brampton, Ontario, Canada. L6W 3K6

CS36T Owner’s Manual Page 2

Contents

1 INTRODUCTION ......................................................................................................................................... 5

2 SPECIFICATIONS AND DIMENSIONS - CS 36T ............................................................................................... 6

2.1 DIMENSIONS .................................................................................................................................................... 6

2.2 CLEARANCE AND SHIPPING DIMENSIONS ................................................................................................................ 6

2.3 TANKAGE ......................................................................................................................................................... 7

2.4 SAIL PLAN DIMENSIONS ...................................................................................................................................... 7

3 CONSTRUCTION ......................................................................................................................................... 8

3.1 HULL .............................................................................................................................................................. 8

3.2 DECK/HULL CONNECTION ................................................................................................................................... 8

3.3 DECK .............................................................................................................................................................. 8

3.4 STEERING AND RUDDER ...................................................................................................................................... 8

3.5 BALLAST .......................................................................................................................................................... 8

4 RIGGING .................................................................................................................................................... 9

4.1 GENERAL ......................................................................................................................................................... 9

4.2 SPARS ............................................................................................................................................................. 9

4.3 TUNING ........................................................................................................................................................... 9

4.3.1 Tuning at the Dock or While Moored ..................................................................................................... 10

4.3.2 Tuning While Sailing .............................................................................................................................. 11

5 POWER PLANT AND TRANSMISSION ......................................................................................................... 12

5.1 ENGINE ......................................................................................................................................................... 12

5.2 EXHAUST SYSTEM ............................................................................................................................................ 12

5.3 TRANSMISSION ............................................................................................................................................... 12

5.4 PROPELLER SHAFT ........................................................................................................................................... 12

5.4.1 Propeller Shaft Alignment ...................................................................................................................... 13

5.4.2 Coupling ................................................................................................................................................. 13

5.4.3 Stuffing Box ............................................................................................................................................ 13

5.5 PROPELLERS ................................................................................................................................................... 14

5.5.1 Installation of Propeller ......................................................................................................................... 14

5.5.2 Propeller Alignment ............................................................................................................................... 14

5.5.3 Removal of Propeller .............................................................................................................................. 14

6 FUEL SYSTEM ............................................................................................................................................ 16

6.1 FUEL TANK ..................................................................................................................................................... 16

6.2 FUELING ........................................................................................................................................................ 16

6.3 FUEL GRADE .................................................................................................................................................. 16

6.4 FUEL TANK CONDENSATION .............................................................................................................................. 16

7 ELECTRICAL ............................................................................................................................................... 17

CS36T Owner’s Manual Page 3

7.1 BATTERIES ..................................................................................................................................................... 17

7.2 ALTERNATORS ................................................................................................................................................ 17

7.3 ELECTRONICS .................................................................................................................................................. 17

7.4 MASTHEAD FITTINGS ....................................................................................................................................... 18

8 THROUGH HULL AND DECK FITTINGS ......................................................................................................... 19

8.1 HOW TO INSTALL THROUGH HULL FITTINGS ......................................................................................................... 19

8.2 HOW TO INSTALL DECK FITTINGS ........................................................................................................................ 19

9 ENGINE CONTROLS AND OPERATIONS ....................................................................................................... 20

9.1 STARTING AND OPERATING A DIESEL ................................................................................................................... 20

9.2 ENGINE SHUTDOWN ........................................................................................................................................ 21

10 MAINTENANCE ......................................................................................................................................... 22

10.1 GELCOAT ....................................................................................................................................................... 22

10.1.1 Gelcoat Repairs .................................................................................................................................. 22

10.2 CARE OF HATCHES AND PORTS ........................................................................................................................... 23

10.3 TEAK............................................................................................................................................................. 24

10.4 BOTTOM OF THE HULL ..................................................................................................................................... 24

10.5 LIFELINES, PULPITS AND STANCHIONS .................................................................................................................. 25

10.6 WINCHES, BLOCKS AND HANDLES ....................................................................................................................... 25

10.7 STANDING RIGGING ......................................................................................................................................... 25

10.8 RUNNING RIGGING .......................................................................................................................................... 26

10.9 STEERING ...................................................................................................................................................... 26

10.10 ENGINE ..................................................................................................................................................... 27

10.11 ELECTRICAL AND ELECTRONICS....................................................................................................................... 27

10.12 UPHOLSTERY .............................................................................................................................................. 28

11 SAFETY EQUIPMENT .................................................................................................................................. 29

11.1 FIRE EXTINGUISHERS ........................................................................................................................................ 29

11.2 LIFE JACKETS .................................................................................................................................................. 29

11.3 LIFE BUOYS .................................................................................................................................................... 29

11.4 SAFETY HARNESSES ......................................................................................................................................... 29

11.5 LIFELINES ....................................................................................................................................................... 29

11.6 DINGHY AND LIFE RAFT .................................................................................................................................... 30

11.7 FLASHLIGHTS .................................................................................................................................................. 30

11.8 SAFETY FLARES ............................................................................................................................................... 30

11.9 FOG SIGNALS AND RADAR REFLECTORS ............................................................................................................... 30

11.10 ANCHOR ................................................................................................................................................... 30

12 LAUNCHING AND STORAGE PROCEDURES ................................................................................................. 31

12.1 PRIOR TO LAUNCH CHECK LIST ........................................................................................................................... 31

12.2 AFTER LAUNCH CHECK LIST ............................................................................................................................... 31

12.3 STEPPING THE MAST ........................................................................................................................................ 31

CS36T Owner’s Manual Page 4

13 WINTER LAY-UP AND STORAGE ................................................................................................................. 34

13.1 UN-STEPPING THE MAST .................................................................................................................................. 34

13.2 HAULING-OUT AND SLING LOCATION .................................................................................................................. 35

13.3 CRADLE SUPPORT ............................................................................................................................................ 35

13.4 WINTERIZING PROCEDURE ................................................................................................................................ 35

13.5 HEAD AND HOLDING TANK................................................................................................................................ 36

13.6 FRESHWATER PRESSURE SYSTEM ........................................................................................................................ 37

13.7 BILGE PUMP .................................................................................................................................................. 38

13.8 GATE VALVES ................................................................................................................................................. 38

13.9 BATTERIES ..................................................................................................................................................... 38

13.10 UPHOLSTERY .............................................................................................................................................. 38

13.11 DECK HARDWARE ....................................................................................................................................... 38

13.12 LOCKERS AND ENCLOSURES ........................................................................................................................... 39

14 WARRANTY .............................................................................................................................................. 40

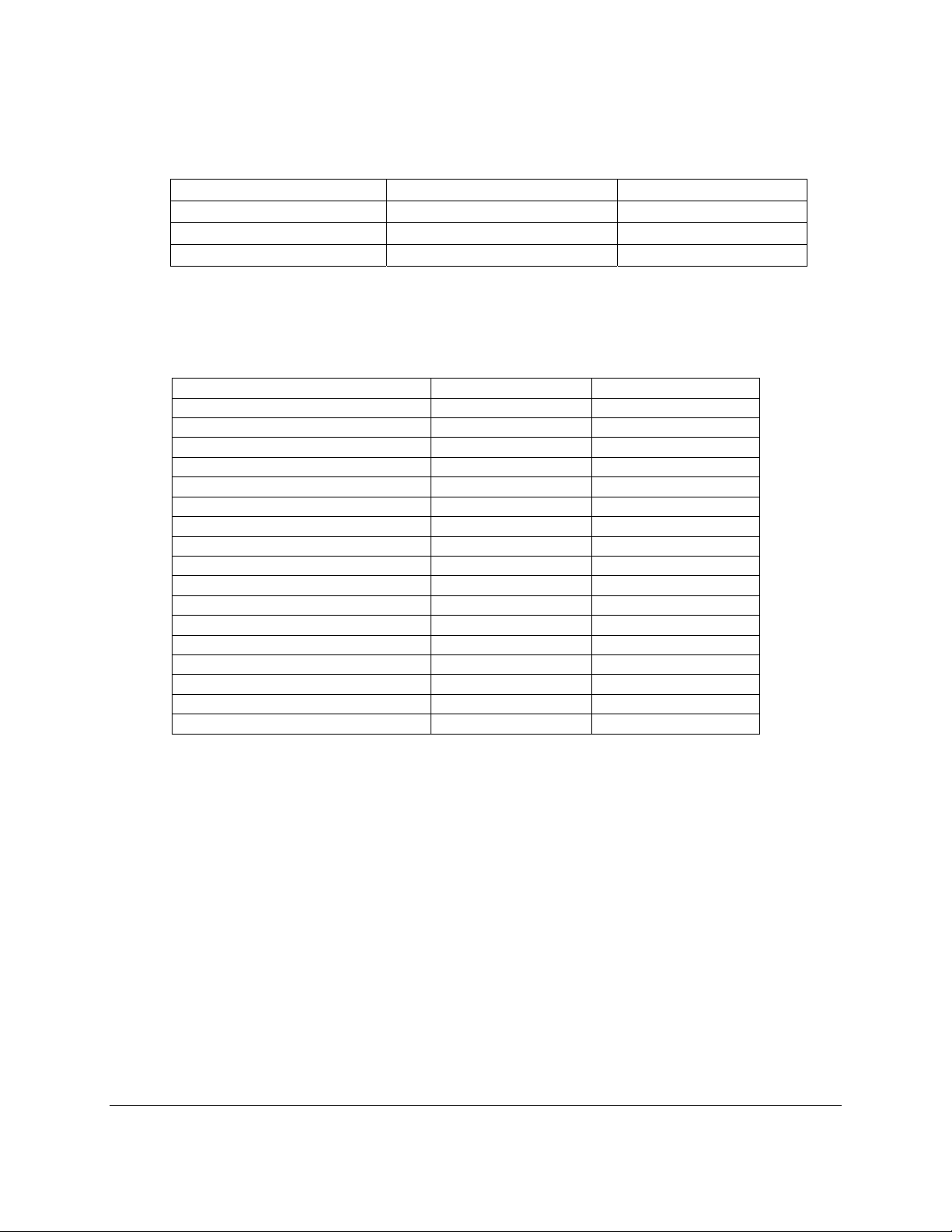

15 TABLES ..................................................................................................................................................... 41

TABLES

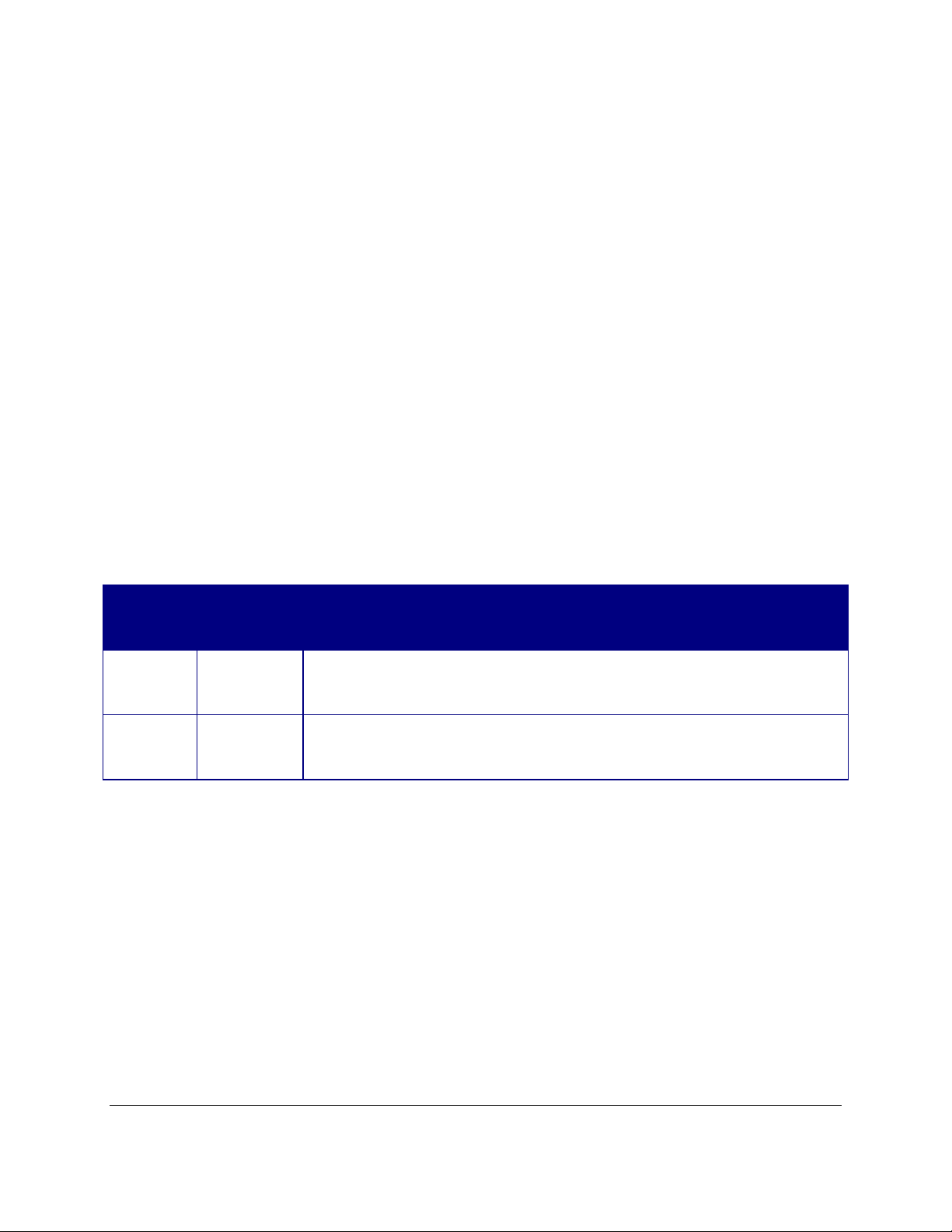

TABLE 1 LUBRICANTS, COOLANTS AND FILTERS ....................................................................................... 41

TABLE 2 ELECTRICAL LIGHT BULB REPLACEMENT ..................................................................................... 41

TABLE 3 TANK CAPACITIES, TOILET, STOVE AND FAUCET TYPES .................................................................. 42

TABLE 4 STAINLESS STEEL AND RIGGING COMPONENTS ............................................................................ 42

TABLE 5 STANDING RIGGING .............................................................................................................. 43

TABLE 6 RUNNING RIGGING ............................................................................................................... 44

TABLE 7 BLOCKS .............................................................................................................................. 45

TABLE 8 BACKSTAY PRELOAD LIMITS .................................................................................................... 45

TABLE 9 ENGINE AND PROPELLER ........................................................................................................ 45

CS36T Owner’s Manual Page 5

1 INTRODUCTION

This manual will help you to know your CS 36T (Traditional)Yacht. Read your manual carefully as well as

the manufacturer’s components manuals supplied with your yacht.

It is most important to familiarize yourself thoroughly with all aspects of operating and maintaining your

yacht in a safe and efficient manner.

If any questions remain that you cannot solve, your CS dealer will be only too pleased to clarify them.

If you find your yacht equipped with different gear from what is shown in your manual, it is usually due

to our continuing effort to upgrade and improve our line of yachts. Any new piece of equipment will be

usually equal or better.

We will therefore keep you informed through your dealer of any changes or improvements that have

been made relating to your particular yacht.

On taking delivery of your yacht, fill in the warranty card or change of ownership card and be sure to

read and understand the CS warranty. Return the card to CS Yachts as soon as possible.

Date Version

Number Description

Feb2010 “CS30Manual.pdf” appeared w/o illustrations.

28Oct2019 V2 Converted to Word 2016, partially edited for grammar, spelling and layout.

Contents need updating. Converted to PDF Acrobat 6.x

CS36T Owner’s Manual Page 6

2 SPECIFICATIONS AND DIMENSIONS - CS 36T

2.1 Dimensions

L.0.A. 36'- 6" 11.13 m

L.W.L. 29'- 3" 8.92 m

Beam 11'- 6" 3.50 m

Draft, Deep 6'- 3" 1.90 m

Draft, Shoal 4' - 11" 1.52 m

Displacement 15,500 lbs. 7,021 kg.

Ballast Keel, Deep 6,500 lbs. 2,944 kg.

Ballast Keel, Shoal 6,650 lbs. 3,012 kg.

2.2 Clearance and Shipping Dimensions

Masthead to waterline (excluding

antenna, etc.) 52' - 10" 16.11 m

Pulpit to waterline (mast lowered) 6’- 7" 2.00 m

Height overall in shipping cradle, Deep

draft 12' - 1" 3.68 m

Height overall in shipping cradle, Shoal

draft 10' - 10" 3.30m

Shipping weight in cradle with spars

approx. 16,300 lbs. 7393 kg.

Mast length 54' - 5" 16.58 m

Mast section 5.3" x 7.9" 127 x 205 mm

CS36T Owner’s Manual Page 7

2.3 Tankage

Freshwater 82 Imp. Gals. 372 L

Waste holding 32 Imp. Gals. 145 L

Fuel 35 Imp. Gals. 159 L

Battery capacity 2 x 112 Amp. Hrs.

2.4 Sail Plan Dimensions

I 49.0' 14.94 m

J 15.0' 4.57 m

LP 22.5' 6.86 m

P 42.75' 13.03 m

E 12.75' 3.88 m

SPL 15.0' 4.57 m

SL 48.68' 14.84 m

SMW 27.0' 8.23 m

Main Sail 272 sq. ft. 25.26 sq. m

No.1 Genoa- heavy 551 sq. ft. 51.18 sq. m

No.1 Genoa- light 551 sq. ft. 51.18 sq. m

No. 2 Genoa 492 sq.' ft. 45.70 sq. m.

No. 3 Genoa 391 sq. ft. 36.32 sq. m.

Jib 270 sq. ft. 25.08 sq. m.

Storm Jib 104 sq. ft. 9.66 sq. m.

Spinnaker approx. 1,200 sq. ft 111.48 sq. m.

Sail Area -100% Foretriangle 640 sq. ft. 59.36 sq. m.

Sail Area - Actual with #1-150% 822 sq. ft. 76.45 sq. m.

CS36T Owner’s Manual Page 8

3 CONSTRUCTION

3.1 Hull

The hull of the CS 36 yacht is a one-piece fiberglass molding. The hull is hand laid up with the finest

materials available and reinforced at key points of stress. The CS 36 is made even stronger by a molded

spline and girder section down the center of the yacht.

The stresses of the mast and keel are accepted by this module giving the yacht exceptional integrity. The

boot top and top accent strip are permanently molded into the hull.

3.2 Deck/Hull Connection

On assembly, the top of the hull flange is capped with a soft butyl rubber gasket. The deck is fastened

with stainless steel through bolts to the hull flange.

Upon tightening the bolts, the butyl compound is forced into remaining crevices.

Should a leak develop at the deck/hull joint the through bolts in the area may be tightened, ensuring

that the bolt does not turn while tightening the nut.

3.3 Deck

The deck and cockpit is a single-unit fiberglass molding surfaced with gelcoat. The deck and horizontal

section is molded in a sandwich of end grain balsa to give additional stiffness. A non-skid finish is molded

into the working areas of the deck.

3.4 Steering and Rudder

The yacht is fitted with pedestal steering and wheel, a radial driver turned by the wheel through a cable

system, clamped to the rudder post and through bolted.

The stainless rudder stock is a two-point attachment system. It is housed in a bearing gland which is

through bolted to a mounting flange integral with the hull laminate. The lower end of the stock is

supported by a lower bearing through bolted to the skeg.

3.5 Ballast

The keel of your CS Yacht is lead alloyed with antimony for added strength and cast to close tolerances.

The keel is through-bolted with oversize 316 stainless steel bolts that have been cast into the lead. The

tensile strength of these bolts is greater than 7,000 lbs. Each of the 12 bolts is capable of carrying the

keel by itself. Eight of the 12 bolts are double-lugged. These bolts are also embedded at various depths

in the lead keel itself. (See dwg. No. 9)

CS36T Owner’s Manual Page 9

4 RIGGING

4.1 General

It is important to understand the principles involved in order to do an effective job of mast tuning.

Standing rigging refers to fixed lengths of stainless-steel wire or rod supporting the mast. If they offer

fore and aft support, they are called forestay and backstay. If the support is principally transverse, they

are called shrouds.

4.2 Spars

The mast on your CS .36 is supported by three sets of shrouds. Those running from the masthead to

deck are known as upper or cap shrouds.

Intermediate shrouds, fixed at the inner end of the upper shrouds, run through the tip of the lower

spreaders to the chain plates.

Two sets of lower shrouds are fitted, known as forward and aft lowers. Lower shrouds, led to chain

plates forward and aft of the mast centerline, provide some fore and aft support.

To reduce the large tensile forces in the shrouds and compressive load in the mast, the upper and

intermediate shrouds are led over spreaders. The upper spreaders lead the shrouds out from the mast

and provide a deflection of approximately 12°, which is considered ideal. However, the shrouds impart a

side load, acting horizontally along the spreader. The intermediates take some of this load off the mast

at the upper spreader, while the lower shrouds do the same at the lower spreader.

It is obvious that the more standing rigging that is used transversely and longitudinally, the stiffer the rig

will be, allowing a smaller mast section, thus reducing windage.

However, the French-made Isomat spars used by CS, together with the standing rigging described above

provide a very good balance of strength and simplicity.

4.3 Tuning

Tuning involves adjusting the tension of shrouds and stays so that the mast will remain straight under

various sailing conditions and when moored.

Tuning involves two phases: (a) Tuning at the dock or while moored; (b) Fine tuning while sailing.

CS36T Owner’s Manual Page 10

4.3.1 Tuning at the Dock or While Moored

All turnbuckles should be equipped with toggles at their base as supplied be CS Yachts to eliminate any

bending load on the swage and turnbuckle threads, including both ends of the forestay.

Start tuning the mast by ensuring that the mast is in the center of the boat, perpendicular to the

transverse waterline. The mast is set in the forward setting at the mast step. At this point the rubber

mast collar should be set into the mast partners between the mast and deck. This is a tight fit and can be

accomplished best by fitting the collar into place as the mast is being lowered onto the mast step. If the

collar just fits into the fiberglass mast partners with the mast heel casting 2"-3" away from the mast

step, the collar will fit perfectly.

Since boats often do not level at dock due to uneven load distribution of the accommodation plan and

internal weights, slacken all shrouds fully by loosening the turnbuckles. Take the main halyard and lead

the shackle end to a point on the starboard toe rail. Adjust the tension on the halyard so that the end of

the shackle just touches the toe rail, then cleat the halyard. Move the shackle to the same location on

the port toe rail; the end of the shackle should just touch the rail. Lightly take up on the turnbuckles on

the upper shrouds until the mast has been centered.

Now, starting at the lower shrouds, tighten their turnbuckles evenly. Repeatedly sight up the mast track

to ensure that you are not deflecting the lower part of the mast in any direction.

Next, tighten the intermediates, again, ensuring that the mast remains straight, then do the same on the

uppers. When you are sure that the mast is straight, start at the lowers and tighten each pair of shrouds

evenly, by counting the number of turns applied to each. Tighten until the turnbuckles become difficult

to turn.

The mast should now be checked for rake. Rake is the angle, either forward or aft, from vertical.

Forward rake is to be avoided.

In calm conditions, if possible, hang a weight on the main halyard shackle and suspend it just above the

deck. The distance from the aft face of the mast to the halyard represents the amount of rake and

should be approximately 8"-10".

Rake is adjusted by moving the masthead in the required direction by use of the turnbuckles on the

backstay and forestay.

If your yacht is fitted with a furling gear on the forestay, it may be necessary to adjust the length of the

forestay by the use of link plates.

Backstay tension should be high, to minimize forestay sag, without imparting too much fore and aft

bend in the mast.

CS36T Owner’s Manual Page 11

4.3.2 Tuning While Sailing

Select a day with steady winds, around 10 knots. When sailing close-hauled, sight up the luff groove of

the mast. If the mast falls off to leeward in the middle section, luff up and tighten up on the windward

lower and intermediate turnbuckles as necessary, noting the amount of adjustment. Tighten the

leeward lower and intermediate turnbuckles by the corresponding amount. Sail close hauled on the

other tack and check the luff-groove again. Repeat this adjustment as necessary.

Your rig is now basically tuned. As you become more familiar with the yacht and her rig you may want to

do some find tuning. This may involve changing the amount of rake to optimize weather helm, or

imparting a limited amount of mast bend, by adjusting the relationship between the fore and aft lower

shrouds.

Remember that with a new boat the rig will "settle” and some stretch will take place. It may be

necessary to recheck and repeat the tuning sequence. Ensure that all turnbuckles are pinned or locked

when tuning is finished.

CS36T Owner’s Manual Page 12

5 POWER PLANT AND TRANSMISSION

5.1 Engine

A Westerbeke W30 or W33 with Paragon hydraulic gearbox close-coupled to a Walter RV1O V- drive

with 2:1 reduction ratio. For full details of the engine please refer to Westerbeke Technical manual sent

out with every CS 36. Read this manual carefully.

An air exhaust blower is fitted to exhaust hot air from the engine compartment. It starts and stops when

the key is turned to “on" from the "run" position. The air is exhausted via flexible trunking through a

vent on the after side of the cockpit coaming.

5.2 Exhaust System

The exhaust system on the CS 36 utilizes a "pot" type muffler. At engine running condition an auxiliary

water pump draws water through the intake port, circulates it through the heat exchanger and thence

into the muffler. The water mixes with the exhaust gases in the muffler and is discharged overboard

through the exhaust port at the aft port side of the hull.

NOTES RE: EXHAUST VENT: To prevent water being sucked back into the engine when shut down, a vent

is fitted into the exhaust manifold elbow and piped to a 90° elbow fitting in the starboard topsides.

Under certain load conditions, cooling water will flow through the vent and be discharged overboard.

On a regular basis check that this is happening; no water indicates the pipe of fitting is blocked and

needs clearing.

The raw or saltwater in the heat exchanger lowers the temperature of the engine coolant circulated

through the engine block with the engine water pump.

This coolant consists of a 50% ethylene glycol and 50% freshwater solution and protects the internal

system down to -32°F (-35°C) This solution should be used at all times for engine corrosion protection

and should be checked for its strength before winter lay-up.

5.3 Transmission

All necessary data and information about the transmission are fully detailed in the engine manual. To

avoid damage to the gears and increase clutch life, the engine should always be at idle speed when

shifting into forward or reverse gear.

5.4 Propeller Shaft

The propeller shaft is supported at the inboard end by the shaft coupling and at the outboard end by a

P-Bracket containing a bearing for 1" diameter shaft. It is retained in the P-Bracket by two socket type

CS36T Owner’s Manual Page 13

set screws. Check this bearing for wear at every fit-out. A zinc sacrificial anode is fitted on the shaft

ahead of the P-Bracket to protect the shaft and propeller from corrosion. The anode should be

inspected on a regular basis and renewed when required. The shaft passes through the hull at the

stuffing box.

5.4.1 Propeller Shaft Alignment

The propeller shaft is carefully aligned with the engine prior to delivery of a yacht. However, each time

the boat is launched, this alignment should be checked, especially if there is excessive vibration when

the engine is running, or loss of engine speed is evident.

Check the alignment in the following sequences: (a) remove the bolts on the shaft coupling adjacent to

the transmission box; (b) support the weight of the shaft and coupling and slide the coupling faces

together by hand; and, (c) use a feeler gauge or a piece of metal stock of .003" maximum thickness to

check that the gauge is gripped firmly and completely around the entire circumference of the coupling

faces.

If the feeler gauge does not pull evenly around the entire coupling, misalignment is evident. This can be

corrected by adjusting the engine legs until the coupling faces match evenly. Rotate the shaft 1800 and

again check the alignment. Should it still be out of line it could indicate a bent shaft. The shaft must then

be removed and straightened or replaced.

5.4.2 Coupling

The shaft is keyed to the half coupling and is retained in the half coupling by a set screw which is wired

up at plant to ensure it cannot back off. Check the wire and tightness of the coupling bolts at every fit-

out.

If there is any reason to suspect misalignment between the engine and the propeller shaft, have a

competent service yard check the alignment and correct if necessary. Some telltale signs are excessive

vibration, unreasonable wear at the packing gland and P-bracket bearing.

5.4.3 Stuffing Box

The stuffing box is located at the inboard end of a fiberglass tube passing through the hull. The stuffing

box should be inspected on a regular basis. The fiberglass tube and the stuffing box are connected by

means of a flexible rubber held in place by hose clamps. If there is only a slight drip no adjustment

should be made to avoid seizure. If the leak is excessive, the packing glands may be tightened by

loosening the lock nut and tightening the gland nut slightly (roughly a quarter turn), then tightening the

lock nut again.

NOTE: The rubber tubing at the stuffing box must be inspected yearly. It should be replaced every 2

years. The gland packing nut should never be over tightened. The idea is for the gland to drip slowly

when running under power, with no drip when the shaft is not turning.

CS36T Owner’s Manual Page 14

Should the stuffing box continue to leak after tightening down the gland nut and after several hours of

engine operation, a new stuffing box packing may be necessary.

The Teflon-coated asbestos packing can be replaced by unscrewing the gland nut and winding three

turns of 1/4" tallowed flax packing around the shaft in the direction of the nut installation. Replace the

gland nut again and tighten just until the leak stops, and finally tighten the lock nut. Should any leaks

still persist, a bent or scored shaft may be the problem and should be investigated.

5.5 Propellers

NOTE: Depending upon which type of propeller is fitted, at fit-out check that all split pins through

retaining nuts are in place and are sound. (see table 9)

A two-bladed, solid bronze propeller is standard on your yacht. This unit is the better choice for cruising

purposes. For racing sailors, the optional folding propeller is superior, offering the least amount of drag.

5.5.1 Installation of Propeller

Ensure the base of the propeller is free from dirt and any corrosion. The end of the shaft should be

cleaned and any burrs on the shaft or keyway must be removed. Place the propeller on the shaft with

both propeller and shaft keyways in line.

The key should fit tightly at the sides but with a 0.1" (2 1/2mm) clearance at the top. Do not force the

key in since it may shift the propeller off center.

5.5.2 Propeller Alignment

Ensure proper propeller alignment which can be checked by clamping a piece of metal or wood to the

propeller strut which just touches the edge of one propeller blade. When rotating the shaft by hand any

variance in the track will be noted by either striking the indicator with the next blade or showing a gap.

If the propeller indicates such a condition it should be checked and balanced by your dealer or any

marine yard familiar with this type of work.

5.5.3 Removal of Propeller

For both solid and folding propellers, a propeller puller is required which can be purchased at any

marine dealer.

Procedure for Removal of a Martec Folding Propeller

1. Remove all cotter pins from pivot bar for blades and shaft. Save cotter pins if possible.

CS36T Owner’s Manual Page 15

2. Pull pivot bar from the blades. Some propellers are tapped for a bolt on one end of the

3. pivot bar. Thread a bolt into this end of the pivot bar and pull same by means of bolt. On others

the bar can be tapped out with a drift punch and hammer.

4. This applies to both types of propellers. Remove shaft nut which is counter sunk inside the

propeller hub on folding propellers and exposed on solid props. For removal of the shaft nut on

the folding prop, a 1/2" square drive handle with extension is required and a socket for the

standard prop.

5. When removing the propeller, leave the prop retaining nut in place 1 to 2 turns loose from the

tight position for protection of the threads. The puller shaft should never bear directly on the

end of the propeller shaft. Since it bears on the propeller retaining nut, a brass aluminum or

copper spacer should be used for protection of the nut.

6. The puller must be installed straight and centered carefully in order to utilize its maximum

effectiveness. The claws of the wheel puller should be placed behind the prop hub.

Procedure for Removal of a Gori Folding Propeller

If a Gori folding propeller has been installed, the procedure is similar, but Allen screws are used in lieu of

cotter pins.

CS36T Owner’s Manual Page 16

6 FUEL SYSTEM

6.1 Fuel Tank

The fuel tank is filled via a deck filling plate marked "Fuel" on the starboard side alongside the cockpit.

After filling ensure that the plate is screwed in firmly to prevent any water seepage into the fuel. The

fuel withdrawal exits from the top of the tank on the center line. A tank vent is installed with the pipe

connected to a 90° vent elbow through the hull at the top of the transom. The fuel supply is piped to the

engine via a primary CAV Filtrap 120 Sedimentary filter. The secondary filter is engine mounted. The

sedimentary filter is designed to trap the larger solid particles and water droplets and should be drained

off periodically through the drain plug in the base. For instructions on bleeding the fuel system, refer to

the Westerbeke Technical Manual. On more recent models, a Groco water separator is used and is

engine mounted.

6.2 Fueling

Extinguish all open flames aboard the yacht before opening the fuel inlet cap No person should be

smoking and all electrical circuits including the main electrical switch should be turned off. The fuel hose

nozzle must be touching the metal deck plate to ground static electricity. After completion of the

refueling, close the inlet cap tightly and wash down any spills with freshwater. Open all hatches and

operate the blower for at least five minutes. An air vent is located on the transom which connects to the

fuel tank.

6.3 Fuel Grade

For the CS 36T use number 2 diesel fuel.

6.4 Fuel Tank Condensation

If the fuel tank is kept topped up, condensation in the tank will be minimized.

CS36T Owner’s Manual Page 17

7 ELECTRICAL

The yacht is wired for both 12V and 110V systems.

Wiring harnesses and connections, including the main switch panel, are installed as high in the interior

of the yacht as possible, reducing the exposure to water. See wiring diagram of your commissioning set.

See also Diagrams No. 26 (white print), No. 14 and No. 15 of the mast lighting system and VHF hook-up.

7.1 Batteries

The battery box is located near the engine under the chart table bench (quarter berth). The explosion-

proof 4-position main battery switch is located at the starboard side of the companionway (OFF, ONE,

BOTH, TWO).

The switch activates the #1 and #2 battery or both batteries will operate in parallel.

Do not turn this switch to "OFF" while the engine is running, since serious damage to the charging

system could result.

Most engine manufacturers do not recommend that batteries be changed with this switch while the

engine is running. But CS Yachts installs a splitter and therefore it is safe to switch to the alternate

battery while the engine is running.

The professional mariner battery charger is fully automatic and so when connected to a dockside AC

supply, it is quite safe to have the AC/DC converter switch on and the yacht left unattended. Charging

current is routed to the batteries through a splitter. This device acts as a one-way gate, allowing the

alternator to charge both banks of batteries, but preventing any reverse current flow between batteries.

Note that the alternator will charge both banks of batteries irrespective of the position of the battery

master switch. In other words, you can charge the batteries with AC power even with the master switch

in the "OFF" position.

7.2 Alternators

The Westerbeke engine is equipped with a standard alternator as described in the engine manual

7.3 Electronics

Most yacht owners add various electronic equipment such as depth sounders, logs, speedometers, all of

which require through hull fittings.

Equipment such as VHF, SSB, R.D.F., wind indicators, relative wind indicators and Loran radar usually

require masthead fittings. Most problems with the instruments are caused by faulty installation and

should be done in most instances by a specialist.

CS36T Owner’s Manual Page 18

Provide separate fused circuits for each electronic piece of equipment feeding off the yacht's

12V electric system. Radios and high amperage equipment should be wired directly to the battery and

fused near the battery. All equipment should be installed according to the manufacturer's

recommendations.

7.4 Masthead Fittings

The installation for additional masthead fittings should be done according to manufacturer's

recommendations. All cables leading from the masthead should be color coded, should come out at the

foot of the mast, and be provided with quick connectors in order to facilitate easy disconnecting when

un-stepping the mast.

Keep all connectors and junction as high as possible off the hull bottom, including electronic equipment,

to prevent them from coming in contact with water.

CS36T Owner’s Manual Page 19

8 Through Hull and Deck Fittings

8.1 How to Install Through Hull Fittings

1. Consult with your local marine dealer for correct positioning of the through hull.

2. Drill a hole to accommodate the size of the through hull fitting.

3. For strength purposes, provide a small back-up plate, such as marine plywood with the same

hole diameter. Line up the holes and embed the back-up plate in sealer, allow to dry and glass

into place using mat and resin.

4. Install through hull fitting.

8.2 How to Install Deck Fittings

1. Ensure that deck reinforcement is provided where additional winches are to be located such as

winch island mounts.

2. The cabin ceiling panels are removable and access holes to be drilled through the wood panel

ceiling for access to bolts securing the winch.

3. Winches usually do not require back-up plates but flat washers, lock washers and nuts are

required. All penetrating bolts for winches, tracks and cleats should be embedded with silicone

sealant.

4. All deck fittings which are under load, such as, chain plates and inboard genoa tracks, should be

checked annually for leaks and resealed with marine sealant if leaks are detected.

CS36T Owner’s Manual Page 20

9 ENGINE CONTROLS and OPERATIONS

Engine Controls - the throttle and gear shift levers are mounted on the steering pedestal-- throttle to

starboard, shift to port. The stop pull is mounted alongside the engine instrument panel. For instructions

on engine starting, see Westerbeke Technical Manual, page 17 for W3- and page 8 for W33

Engine Instruments - consists of a standard Westerbeke panel comprising of tachometer, oil pressure

gauge, water temperature, ammeter and start. In addition, CS Yachts fit a rheostat switch for the

binnacle compass and manual pull stop for engine shutdown. Owners should refer to these instruments

when the engine is running. Operating figures are laid down in the Westerbeke Technical Manual.

9.1 Starting and Operating a Diesel

1. Turn the main battery switch to either #1 or #2 position. (Do not- use the "BOTH" position

unless both sets of batteries are low. When the batteries are unevenly charged, selecting

"BOTH" will result in the more highly charged battery discharging into the lower one. When

engine is not running switch to ONE or TWO for DC services and keep one battery fully charged

for starting the engine.

2. Check that engine water intake valve is open.

3. Check that gear shift lever is in neutral and fuel throttle is half open.

4. Push in key and hold for approximately 5-time clicks (15-20 seconds), then turn key fully

clockwise and start the engine.

5. Check that the oil pressure gauge registers (50-70 PSI); check the exhaust port for water

discharge of engine coolant. If oil pressure gauge does not register or water is not being

discharged, shut down engine immediately.

6. While the engine is warming up, monitor oil pressure and water temperature gauges. If normal

operation is not indicated, shut down engine and consult the manual for trouble shooting

suggestions

7. Close throttle until engine idles at low (approximately 800-1000 RPM) before moving gear lever

into forward or reverse position.

8. With folding propellers, excessive vibration may occur when the engine is put in forward gear.

This is usually caused by one blade of the propeller not opening. When this occurs, slow down

the engine, shift gear into reverse and accelerate engine. This usually opens the propeller. Slow

the engine down to idle and shift into forward gear.

9. It is advisable to let the engine warm-up to full operating temperature (175-19OF) before

Table of contents