CSE Uniserve Unidrive M400 User manual

Control Quick Start

Guide

Unidrive M400

Part Number: 0478-0267-02

Issue: 2

Manufacturing Automation drive

Fast set-up and diagnosis with

real-text display, plus integrated

Machine Control Studio based

PLC

Unidrive M400 Control Quick Start Guide English Iss1.book Page 1 Tuesday, September 22, 2015 10:47 AM

Original Instructions

For the purposes of compliance with the EU Machinery Directive 2006/42/EC

This guide is intended to provide basic information required in order to set-up a drive to run a motor.

For more detailed installation information, please refer to the Unidrive M400 User Guide which is

available to download from:

http://www.emersonindustrial.com/en-EN/controltechniques/downloads/userguidesandsoftware/

Pages/downloads.aspx.

or

www.emersonindustrial.com/en-EN/leroy-somer-motors-drives/downloads/Pages/manuals.aspx.

Warnings, Cautions and Notes

Copyright © September 2015

Issue Number: 2

A Warning contains information which is essential for avoiding a safety hazard.

A Caution contains information which is necessary for avoiding a risk of damage to the

product or other equipment.

A Note contains information, which helps to ensure correct operation of the product.

This guide does not include safety information. Incorrect installation or operation of the

drive, could cause personnel injury or equipment damage. For essential safety

information, please refer to the Unidrive M400 User Guide or the safety booklet supplied

with the drive.

WARNING

CAUT IO N

NOTE

WARNING

Unidrive M400 Control Quick Start Guide English Iss1.book Page 2 Tuesday, September 22, 2015 10:47 AM

Unidrive M400 Control Quick Start Guide

Issue Number: 2

Contents

1 Safety information .......................................................................................4

2 Introduction ..................................................................................................6

2.1 Operating modes ..................................................................................................... 6

3 Options .........................................................................................................7

4 Control connections ....................................................................................8

4.1 Control terminal configurations and wiring ............................................................... 8

4.2 Safe Torque Off (STO) .......................................................................................... 14

5 Optional LCD keypad and display ...........................................................15

5.1 Saving parameters ................................................................................................ 16

5.2 Restoring parameter defaults ................................................................................ 16

6 Basic parameters (Menu 0) .......................................................................17

6.1 Menu 0: Basic parameters ..................................................................................... 17

6.2 Unidrive M400 parameter descriptions .................................................................. 22

7 Running the motor ....................................................................................41

8 Diagnostics ................................................................................................42

8.1 Alarm indications ................................................................................................... 46

9 NV Media Card Operation .........................................................................47

10 Machine Control Studio ............................................................................48

Unidrive M400 Control Quick Start Guide English Iss1.book Page 3 Tuesday, September 22, 2015 10:47 AM

4Unidrive M400 Control Quick Start Guide

Issue Number: 2

1 Safety information

1.1 Warnings, Cautions and Notes

1.2 Electrical safety - general warning

The voltages used in the drive can cause severe electrical shock and/or burns, and could be lethal.

Extreme care is necessary at all times when working with or adjacent to the drive. Specific warnings

are given at the relevant places in this guide.

1.3 System design and safety of personnel

The drive is intended as a component for professional incorporation into complete equipment or a

system. If installed incorrectly, the drive may present a safety hazard.

The drive uses high voltages and currents, carries a high level of stored electrical energy, and is used

to control equipment which can cause injury.

Close attention is required to the electrical installation and the system design to avoid hazards either

in normal operation or in the event of equipment malfunction. System design, installation,

commissioning/start-up and maintenance must be carried out by personnel who have the necessary

training and experience. They must read this safety information and this Guide carefully.

The STOP and Safe Torque Off functions of the drive do not isolate dangerous voltages from the

output of the drive or from any external option unit. The supply must be disconnected by an approved

electrical isolation device before gaining access to the electrical connections.

With the sole exception of the Safe Torque Off function, none of the drive functions must be

used to ensure safety of personnel, i.e. they must not be used for safety-related functions.

Careful consideration must be given to the functions of the drive which might result in a hazard,

either through their intended behavior or through incorrect operation due to a fault. In any application

where a malfunction of the drive or its control system could lead to or allow damage, loss or injury, a

risk analysis must be carried out, and where necessary, further measures taken to reduce the risk -

for example, an over-speed protection device in case of failure of the speed control, or a fail-safe

mechanical brake in case of loss of motor braking.

The Safe Torque Off function may be used in a safety-related application. The system designer is

responsible for ensuring that the complete system is safe and designed correctly according to the

relevant safety standards.

1.4 Environmental limits

Instructions in this guide regarding transport, storage, installation and use of the drive must be

complied with, including the specified environmental limits. Drives must not be subjected to

excessive physical force.

A Warning contains information which is essential for avoiding a safety hazard.

A Caution contains information which is necessary for avoiding a risk of damage to the

product or other equipment.

A Note contains information, which helps to ensure correct operation of the product.

WARNING

CAUT IO N

NOTE

Unidrive M400 Control Quick Start Guide English Iss1.book Page 4 Tuesday, September 22, 2015 10:47 AM

Unidrive M400 Control Quick Start Guide 5

Issue Number: 2

1.5 Access

Drive access must be restricted to authorized personnel only. Safety regulations which apply at the

place of use must be complied with.

1.6 Fire protection

The drive enclosure is not classified as a fire enclosure. A separate fire enclosure must be provided.

For further information, refer to the Drive User Guide.

1.7 Compliance with regulations

The installer is responsible for complying with all relevant regulations, such as national wiring

regulations, accident prevention regulations and electromagnetic compatibility (EMC) regulations.

Particular attention must be given to the cross-sectional areas of conductors, the selection of fuses

or other protection, and protective ground (earth) connections.

This guide contains instruction for achieving compliance with specific EMC standards.

Within the European Union, all machinery in which this product is used must comply with the

following directives:

2006/42/EC: Safety of machinery.

2004/108/EC: Electromagnetic Compatibility.

1.8 Motor

Ensure the motor is installed in accordance with the manufacturer’s recommendations. Ensure the

motor shaft is not exposed.

Standard squirrel cage induction motors are designed for single speed operation. If it is intended to

use the capability of the drive to run a motor at speeds above its designed maximum, it is strongly

recommended that the manufacturer is consulted first.

Low speeds may cause the motor to overheat because the cooling fan becomes less effective. The

motor should be installed with a protection thermistor. If necessary, an electric forced vent fan should

be used.

The values of the motor parameters set in the drive affect the protection of the motor. The default

values in the drive should not be relied upon.

It is essential that the correct value is entered in Pr 00.006 motor rated current. This affects the

thermal protection of the motor.

1.9 Mechanical brake control

The brake control functions are provided to allow well co-ordinated operation of an external brake

with the drive. While both hardware and software are designed to high standards of quality and

robustness, they are not intended for use as safety functions, i.e. where a fault or failure would result

in a risk of injury. In any application where the incorrect operation of the brake release mechanism

could result in injury, independent protection devices of proven integrity must also be incorporated.

1.10 Adjusting parameters

Some parameters have a profound effect on the operation of the drive. They must not be altered

without careful consideration of the impact on the controlled system. Measures must be taken to

prevent unwanted changes due to error or tampering.

Unidrive M400 Control Quick Start Guide English Iss1.book Page 5 Tuesday, September 22, 2015 10:47 AM

6Unidrive M400 Control Quick Start Guide

Issue Number: 2

1.11 Electrical installation

1.11.1 Electric shock risk

The voltages present in the following locations can cause severe electric shock and may be lethal:

• AC supply cables and connections

• Output cables and connections

• Many internal parts of the drive, and external option units

Unless otherwise indicated, control terminals are single insulated and must not be touched.

1.11.2 Stored charge

The drive contains capacitors that remain charged to a potentially lethal voltage after the AC supply

has been disconnected. If the drive has been energized, the AC supply must be isolated at least ten

minutes before work may continue.

2Introduction

M400 minimizes machine downtime with its optional intuitive advanced LCD Keypad that offers real-

text multi-language display for rapid set-up and superior diagnostics. Its onboard PLC with real-time

tasking can be used for simple logic control using Machine Control Studio programming software

(powered by CODESYS) to enhance drive application capability.

2.1 Operating modes

The drive is designed to operate in any of the following modes:

1. Open loop mode

Open loop vector mode

Fixed V/F mode (V/Hz)

Quadratic V/F mode (V/Hz)

2. RFC - A

2.1.1 Open loop mode

The drive applies power to the motor at frequencies varied by the user. The motor speed is a result of

the output frequency of the drive and slip due to the mechanical load. The drive can improve the

speed control of the motor by applying slip compensation. The performance at low speed depends

on whether V/F mode or open loop vector mode is selected.

Open loop vector mode

The voltage applied to the motor is directly proportional to the frequency except at low speed where

the drive uses motor parameters to apply the correct voltage to keep the flux constant under varying

load conditions.

Typically 100 % torque is available down to 1 Hz for a 50 Hz motor.

Fixed V/F mode

The voltage applied to the motor is directly proportional to the frequency except at low speed where a

voltage boost is provided which is set by the user. This mode can be used for multi-motor

applications.

Typically 100 % torque is available down to 4 Hz for a 50 Hz motor.

Quadratic V/F mode

The voltage applied to the motor is directly proportional to the square of the frequency except at low

speed where a voltage boost is provided which is set by the user. This mode can be used for running

fan or pump applications with quadratic load characteristics or for multi-motor applications. This

mode is not suitable for applications requiring a high starting torque.

Unidrive M400 Control Quick Start Guide English Iss1.book Page 6 Tuesday, September 22, 2015 10:47 AM

Unidrive M400 Control Quick Start Guide 7

Issue Number: 2

2.1.2 RFC-A mode

Sensorless mode provides closed loop control without the need for position feedback by using

current, voltages and key operating motor parameters to estimate the motor speed. It can eliminate

instability traditionally associated with open loop control such as operating large motors with light

loads at low frequencies.

3Options

Table 3-1 System Integration (SI) option module identification

Type Option module Color Name Further details

Fieldbus

Purple SI-PROFIBUS

See relevant option

module User Guide

Medium

Grey SI-DeviceNet

Light Grey SI-CANopen

Beige SI-Ethernet

Brown Red SI-EtherCAT

Automation

(I/O expansion) Orange SI-I/O

Unidrive M400 Control Quick Start Guide English Iss1.book Page 7 Tuesday, September 22, 2015 10:47 AM

8Unidrive M400 Control Quick Start Guide

Issue Number: 2

Table 3-2 Adaptor Interface (AI) option module identification

4 Control connections

For information on the default control connections, refer to the back cover of this guide. The

functionality of the control connections change depending on the setting of Pr 00.005.

4.1 Control terminal configurations and wiring

The setting of Pr 00.005 automatically sets the drive configuration.

Defaults are loaded before drive configuration changes are made.

Action will only occur if the drive is inactive, not in UU state and no User Actions are running.

Otherwise, the parameter will return to its pre altered value on exit from edit mode. All parameters

are saved if this parameter changes. are saved if this parameter changes.

Type Option module Name

Communications AI-485 Adaptor

Backup AI-Backup Adaptor

Backup AI-SMART Adaptor

00.005 Drive Configuration

RW Txt PT US

OL

Ú

AV (0), AI (1), AV Preset (2),

AI Preset (3), Preset (4),

Keypad (5), Keypad Ref (6),

Electronic Pot (7),

Torque Control (8), Pid Control (9)

ÖAV (0)

RFC-A

Value Text Description

0AV

Analog input 1 (voltage) Analog input 2 (voltage) selected by terminal (Local/

Remote)

1AI

Analog input 1 (current) or Analog input 2 (voltage) selected by terminal (Local/

Remote)

2 AV Preset Analog input 1 (voltage) or 3 presets selected by terminal

3 AI Preset Analog input 1 (current) or 3 presets selected by terminal

4Preset

Four presets selected by terminal

5Keypad

Keypad reference

6 Keypad Ref Keypad reference with terminal control

7 Electronic Pot Electronic Potentiometer

8 Torque Control Torque mode, Analog input 1 (current frequency reference) or Analog input 2

(voltage torque reference) selected by terminal

9 Pid Control PID mode, Analog input 1 (current feedback source) and Analog input 2 (voltage

reference source)

Unidrive M400 Control Quick Start Guide English Iss1.book Page 8 Tuesday, September 22, 2015 10:47 AM

Unidrive M400 Control Quick Start Guide 9

Issue Number: 2

Figure 4-1 Pr 00.005 = AV (50 and 60 Hz)

Figure 4-2 Pr 00.005 = AI (50 and 60 Hz)

1

2

3

4

0V

Voltage speed reference

input (AI 1+)

AI 1-

Voltage speed

reference input (AI 2)

5

6

7

8

0V

Analog output 1

(motor frequency)

+ 10 V output

Analog output 2

(motor active current)

9

10

11

Digital output

(zero frequency)

Unassigned

12

13

14

15

16

17

Run reverse

Run forward

Analog input 1/

input 2 select

+ 24 V output

Jog Forward

Unassigned

+ 24 V output

10k

10k

1

2

3

4

0V

Current speed reference

input (AI 1+)

AI 1-

Voltage speed

reference input (AI 2)

5

6

7

8

0V

Analog output 1

(motor frequency)

+ 10 V output

Analog output 2

(motor active current)

9

10

11

Digital output

(zero frequency)

Unassigned

12

13

14

15

16

17

Run reverse

Run forward

Analog input 1/

input 2 select

+ 24 V output

Jog Forward

Unassigned

+ 24 V output

10k

Current speed

reference input

Unidrive M400 Control Quick Start Guide English Iss1.book Page 9 Tuesday, September 22, 2015 10:47 AM

10 Unidrive M400 Control Quick Start Guide

Issue Number: 2

Figure 4-3 Pr 00.005 = AV Preset (50 and 60 Hz)

Figure 4-4 Pr 00.005 = AI Preset (50 and 60 Hz)

* Refer to Drive User Guide.

1

2

3

4

0V

Voltage speed reference

input (AI 1+)

AI 1-

Reference select

5

6

7

8

0V

Analog output 1

(motor frequency)

+ 10 V output

Analog output 2

(motor active current)

9

10

11

Digital output

(zero frequency)

Unassigned

12

13

14

15

16

17

Run reverse

Run forward

+ 24 V output

Jog Forward

Unassigned

+ 24 V output

10k

Reference select

Terminal 5 Terminal 14 Reference selected

0

0

1

1

0

1

0

1

Analog reference 1*

Preset speed 2*

Preset speed 3*

Preset speed 4*

1

2

3

4

0V

Current speed reference

input (AI 1+)

AI 1-

Reference select

5

6

7

8

0V

Analog output 1

(motor frequency)

+ 10 V output

Analog output 2

(motor active current)

9

10

11

Digital output

(zero frequency)

Unassigned

12

13

14

15

16

17

Run reverse

Run forward

+ 24 V output

Jog Forward

Unassigned

+ 24 V output

Current speed

reference input

Reference select

Terminal 5 Terminal 14 Reference selected

0

0

1

1

0

1

0

1

Analog reference 1*

Preset speed 2*

Preset speed 3*

Preset speed 4*

Unidrive M400 Control Quick Start Guide English Iss1.book Page 10 Tuesday, September 22, 2015 10:47 AM

Unidrive M400 Control Quick Start Guide 11

Issue Number: 2

Figure 4-5 Pr 00.005 = Preset (50 and 60 Hz)

* Refer to Drive User Guide.

Figure 4-6 Pr 00.005 = Keypad (50 and 60 Hz)

1

2

3

4

0V

Voltage speed reference

input (AI 1+)

AI 1-

Reference select

5

6

7

8

0V

Analog output 1

(motor frequency)

+ 10 V output

Analog output 2

(motor active current)

9

10

11

Digital output

(zero frequency)

Unassigned

12

13

14

15

16

17

Reference select

Run forward

+ 24 V output

Jog Forward

Unassigned

+ 24 V output

Run reverse

Terminal 5 Terminal 14 Reference selected

0

0

1

1

0

1

0

1

Preset speed 1*

Preset speed 2*

Preset speed 3*

Preset speed 4*

1

2

3

4

0V

Voltage speed reference

input (AI 1+)

AI 1-

5

6

7

8

0V

Analog output 1

(motor frequency)

+ 10 V output

Analog output 2

(motor active current)

9

10

11

Digital output

(zero frequency)

Unassigned

12

13

14

15

16

17

Analog input 1/

input 2 select

Run forward

+ 24 V output

Jog Forward

Unassigned

+ 24 V output

Run reverse

Voltage speed reference

input (AI 2)

When Pr 00.005 is set to Keypad, to run in

reverse:

•SetPr00.017 to On

The Keypad reference can now be set to a

negative frequency to run the motor in the

reverse direction.

Unidrive M400 Control Quick Start Guide English Iss1.book Page 11 Tuesday, September 22, 2015 10:47 AM

12 Unidrive M400 Control Quick Start Guide

Issue Number: 2

Figure 4-7 Pr 00.005 = Keypad Ref (50 and 60 Hz)

Figure 4-8 Pr 00.005 = Electronic Pot (50 and 60 Hz)

1

2

3

4

0V

Voltage speed reference

input (AI 1+)

AI 1-

5

6

7

8

0V

Analog output 1

(motor frequency)

+ 10 V output

Analog output 2

(motor active current)

9

10

11

Digital output

(zero frequency)

Unassigned

12

13

14

15

16

17

Analog input 1/

input 2 select

Run forward

+ 24 V output

Jog Forward

Unassigned

+ 24 V output

Run reverse

Voltage speed reference

input (AI 2)

1

2

3

4

0V

Voltage speed reference

input (AI 1+)

AI 1-

5

6

7

8

0V

Analog output 1

(motor frequency)

+ 10 V output

Analog output 2

(motor active current)

9

10

11

Digital output

(zero frequency)

Unassigned

12

13

14

15

16

17

UP

Run forward

+24Voutput

Jog Forward

Unassigned

+24Voutput

Run reverse

DOWN

When Pr 00.005 is set to Electronic Pot, the

following parameters may need to be

adjusted:

• Motorized pot up/down rate (s/100 %)

• Motorized pot bipolar select (0 =

unipolar, 1 = bipolar)

• Motorized pot mode: 0 = zero at power-

up, 1 = last value at power-up, 2 = zero

at power-up and only change when

drive is running, 3 = last value at power-

up and only change when drive is

running, 4 = zero at power-up and drive

disabled, only change when drive is

running.

Unidrive M400 Control Quick Start Guide English Iss1.book Page 12 Tuesday, September 22, 2015 10:47 AM

Unidrive M400 Control Quick Start Guide 13

Issue Number: 2

Figure 4-9 Pr 00.005 = Torque Control (50 and 60 Hz)

Figure 4-10 Pr 00.005 = PID Control (50 and 60 Hz)

* Refer to Drive User Guide.

1

2

3

4

0V

Current speed reference

input (AI 1+)

AI 1-

Torque reference

input (AI 2)

5

6

7

8

0V

Analog output 1

(motor frequency)

+ 10 V output

Analog output 2

(motor active current)

9

10

11

Digital output

(zero frequency)

Unassigned

12

13

14

15

16

17

Run reverse

Run forward

Torque mode select

+ 24 V output

Jog Forward

Unassigned

+ 24 V output

10k

Current speed

reference input

When torque mode is selected and

the drive is connected to an

unloaded motor, the motor speed

may increase rapidly to the

maximum speed (Pr 00.002 +10 %)

WARNING

1

2

3

4

0V

PID feedback

input (AI 1+)

AI 1-

5

6

7

8

0V

Analog output 1

(motor frequency)

+ 10 V output

Analog output 2

(motor active current)

9

10

11

Digital output

(zero frequency)

Unassigned

12

13

14

15

16

17

Run reverse

Run forward

PID enable

+ 24 V output

Jog Forward

Unassigned

+ 24 V output

4-20 mA PID

feedback input

0-10 V PID

reference input

PID reference

input (AI 2)

When Pr 00.005 is set to Pid, the following

parameters may need to be adjusted:

• PID proportional gain*

• PID integral gain*

• PID feedback invert*

• PID output upper limit (%)*

• PID output lower limit (%)*

Unidrive M400 Control Quick Start Guide English Iss1.book Page 13 Tuesday, September 22, 2015 10:47 AM

14 Unidrive M400 Control Quick Start Guide

Issue Number: 2

4.2 Safe Torque Off (STO)

The Safe Torque Off function provides a means for preventing the drive from generating torque in the

motor with a very high level of integrity. It is suitable for incorporation into a safety system for a

machine. It is also suitable for use as a conventional drive enable input.

The safety function is active when either one or both STO inputs are in the logic-low state as

specified in the control terminal specification. The function is defined according to EN 61800-5-2 and

IEC 61800-5-2 as follows. (In these standards a drive offering safety-related functions is referred to

as a PDS(SR)):

'Power, that can cause rotation (or motion in the case of a linear motor), is not applied to the motor.

The PDS(SR) will not provide energy to the motor which can generate torque (or force in the case of

a linear motor)'.

This safety function corresponds to an uncontrolled stop in accordance with stop category 0 of IEC

60204-1. The Safe Torque Off function makes use of the special property of an inverter drive with an

induction motor, which is that torque cannot be generated without the continuous correct active

behavior of the inverter circuit. All credible faults in the inverter power circuit cause a loss of torque

generation.

The Safe Torque Off function is fail-safe, so when the Safe Torque Off input is disconnected the drive

will not operate the motor, even if a combination of components within the drive has failed. Most

component failures are revealed by the drive failing to operate. Safe Torque Off is also independent

of the drive firmware.

The design of safety-related control systems must only be done by personnel with the

required training and experience. The Safe Torque Off function will only ensure the safety

of a machine if it is correctly incorporated into a complete safety system. The system must

be subject to a risk assessment to confirm that the residual risk of an unsafe event is at

an acceptable level for the application.

Safe Torque Off does not provide electrical isolation. The supply to the drive must be

disconnected by an approved isolation device before gaining access to power

connections.

It is essential to observe the maximum permitted voltage of 5 V for a safe low (disabled)

state of Safe Torque Off. The connections to the drive must be arranged so that voltage

drops in the 0 V wiring cannot exceed this value under any loading condition. It is strongly

recommended that the Safe Torque Off circuits be provided with a dedicated 0 V

conductors which should be connected to terminals 32 and 33 at the drive.

Figure 4-11 Frame 1 to 4 STO connections Figure 4-12 Frame 5 and above STO

connections

WARNING

WARNING

WARNING

32

0V

STO2

31

STO2

34

STO1

33

0V

ST01

Safe Torque

Off

35

0V

STO2 36

STO2

31

STO1

32

0V

ST01

Safe Torque

Off

Unidrive M400 Control Quick Start Guide English Iss1.book Page 14 Tuesday, September 22, 2015 10:47 AM

Unidrive M400 Control Quick Start Guide 15

Issue Number: 2

5 Optional LCD keypad and display

The keypad and display provide information to the user regarding the operating status of the drive

and trip codes, and provide the means for changing parameters, stopping and starting the drive, and

the ability to perform a drive reset.

Figure 5-1 Unidrive M400 keypad detail

(1) The Enter button is used to enter parameter view or edit mode, or to accept a parameter edit.

(2) The Navigation keys can be used to select individual parameters or to edit parameter values. In

keypad mode, the ‘Up’ and ‘Down’ keys are also used to increase or decrease the motor speed.

(3) The Start key is used to start the drive in keypad mode.

(4) The Stop / Reset key is used to stop and reset the drive in keypad mode. It can also be used to

reset the drive in terminal mode.

(5) The Escape key is used to exit from the parameter edit / view mode or disregard a parameter edit.

Frame 1 to 4

The 0 V terminals on the Safe Torque Off are isolated from each other and the

0 V common. On the size 2 110 V drives or when connecting single phase to a dual rated

200 V unit, the supply should be connected to L1 and L3.

Frames 5 and above

The 0 V terminals on the Safe Torque Off are not isolated from each other and the

0 V common.

The keypad is not supplied with the drive.

NOTE

NOTE

51

4

2

3

NOTE

Unidrive M400 Control Quick Start Guide English Iss1.book Page 15 Tuesday, September 22, 2015 10:47 AM

16 Unidrive M400 Control Quick Start Guide

Issue Number: 2

Table 5-2 Status indications

5.1 Saving parameters

When changing a parameter in Menu 0, the new value is saved when pressing the Enter button

to return to parameter view mode from parameter edit mode.

If parameters have been changed in the advanced menus, then the change will not be saved

automatically. A save function must be carried out.

Procedure

1. Select ‘Save parameters'* in Pr mm.000 (alternatively enter a value of 1001* in Pr mm.000)

2. Either:

• Press the red reset button

• Carry out a drive reset through serial communications by setting Pr 10.038 to 100

* If the drive is in the under voltage state (i.e. when the AI-Backup adaptor terminals are being

supplied from a +24 Vdc supply) a value of 1001 must be entered into Pr mm.000 to perform a save

function.

5.2 Restoring parameter defaults

Restoring parameter defaults by this method saves the default values in the drives memory. User

security status (00.010) and User security code (00.025) are not affected by this procedure).

Procedure

1. Ensure the drive is not enabled, i.e. terminal 31 & 34 is open or Pr 06.015 is OFF (0)

2. Select 'Reset 50 Hz Defs’ or 'Reset 60 Hz Defs' in Pr mm.000. (alternatively, enter 1233 (50 Hz

settings) or 1244 (60 Hz settings) in Pr mm.000).

3. Either:

• Press the red reset button

• Carry out a drive reset through serial communications by setting Pr 10.038 to 100

Upper row

string Description Drive output

stage

Inhibit The drive is inhibited and cannot be run. The Safe Torque Off

signal is not applied to Safe Torque Off terminals or is set to 0. Disabled

Ready The drive is ready to run. The drive enable is active, but the drive

inverter is not active because the final drive run is not active. Disabled

Stop The drive is stopped / holding zero frequency. Enabled

Run The drive is active and running. Enabled

Supply Loss Supply loss condition has been detected Enabled

Deceleration The motor is being decelerated to zero

frequency because the final drive run has been deactivated. Enabled

dc Injection The drive is applying DC injection braking. Enabled

Trip The drive has tripped and no longer controlling the motor. The trip

code appears in the lower display. Disabled

Under

Voltage

The drive is in the under voltage state either in low voltage or high

voltage mode. Disabled

Unidrive M400 Control Quick Start Guide English Iss1.book Page 16 Tuesday, September 22, 2015 10:47 AM

Unidrive M400 Control Quick Start Guide 17

Issue Number: 2

6 Basic parameters (Menu 0)

Menu 0 is used to bring together various commonly used parameters for basic easy set up of the

drive. All the parameters in Menu 0 appear in other menus in the drive. Menus 22 can be used to

configure the parameters in Menu 0.

6.1 Menu 0: Basic parameters

Parameter Range (Ú)Default (Ö)Type

OL RFC-A OL RFC-A

00.001 Minimum Reference

Clamp ±VM_NEGATIVE_REF_CLAMP1 Hz 0.00 Hz RW Num US

00.002 Maximum Reference

Clamp ±VM_POSITIVE_REF_CLAMP Hz 50Hz default: 50.00 Hz

60Hz default: 60.00 Hz RW Num US

00.003 Acceleration Rate 1 ±VM_ACCEL_RATE s/100 Hz 5.0 s/100 Hz RW Num US

00.004 Deceleration Rate 1 ±VM_ACCEL_RATE s/100 Hz 10.0 s/100 Hz RW Num US

00.005 Drive Configuration

AV (0), AI (1), AV Preset (2),

AI Preset (3), Preset (4),

Keypad (5), Keypad Ref (6),

Electronic Pot (7),

Torque Control (8),

Pid Control (9)

AV (0) RW Txt PT US

00.006 Motor Rated Current 0.00 to VM_RATED_CURRENT A Maximum Heavy Duty

Rating A RW Num RA US

00.007 Motor Rated Speed 0.0 to 80000.0 rpm

50Hz default:

1500.0 rpm

60Hz default:

1800.0 rpm

50Hz default:

1450.0 rpm

60Hz default:

1750.0 rpm

RW Num US

00.008 Motor Rated Voltage 0 to VM_AC_VOLTAGE_SET V

110V drive: 230 V

200V drive: 230 V

400V drive 50 Hz: 400 V

400V drive 60 Hz: 460 V

RW Num RA US

00.009 Motor Rated Power

Factor 0.00 to 1.00 0.85 RW Num RA US

00.010 User Security Status

Menu 0 (0), All Menus (1),

Read only Menu 0 (2),

Read only (3), Status Only (4),

No Access (5)

Menu 0 (0) RW Num ND NC PT

00.012 Input Logic Polarity Negative Logic (0) or

Positive Logic (1) Positive Logic (1) RW Txt US

00.015 Jog Reference 0.00 to 300.00 Hz 1.50 Hz RW Num US

00.016 Analog Input 1 Mode

4-20 mA Stop (-6),

20-4 mA Stop (-5), 4-20 mA Low (-4),

20-4 mA Low (-3), 4-20 mA Hold (-2),

20-4 mA Hold (-1), 0-20 mA (0),

20-0 mA (1), 4-20 mA Trp (2),

20-4 mA Trp (3), 4-20 mA (4),

20-4 mA (5), Voltage (6)

Voltage (6) RW Txt US

00.017 Bipolar Reference

Enable Off (0) or On (1) Off (0) RW Bit US

00.018 Preset Reference 1 ±VM_SPEED_FREQ_REF Hz 0.00 Hz RW Num US

00.025 User Security Code 0 to 9999 0 RW Num ND NC PT US

00.027

Power-up Keypad

Control Mode

Reference

Reset (0), Last (1), Preset (2) Reset (0) RW Txt US

00.028 Ramp Mode Select Fast (0), Standard (1),

Std boost (2), Fast boost (3) Standard (1) RW Txt US

00.029 Ramp Enable Off (0) or On (1) On (1) RW Bit US

Unidrive M400 Control Quick Start Guide English Iss1.book Page 17 Tuesday, September 22, 2015 10:47 AM

18 Unidrive M400 Control Quick Start Guide

Issue Number: 2

00.030 Parameter Cloning None (0), Read (1), Program (2),

Auto (3), Boot (4) None (0) RW Txt NC US

00.031 Stop Mode

Coast (0),

Ramp (1),

Ramp dc I (2),

dc I (3),

Timed dc I (4),

Disable (5)

Coast (0),

Ramp (1),

Ramp dc I (2),

dc I (3),

Timed dc I (4),

Disable (5),

No Ramp (6)

Ramp (1) RW Txt US

00.032

Dynamic V to F

Select / Flux

Optimization Select

0 to 1 0 RW Num US

00.033 Catch A Spinning

Motor

Disable (0), Enable (1),

Fwd Only (2), Rev Only (3) Disable (0) RW Txt US

00.034 Digital Input 5 Mode Input (0), Therm Short Cct (1),

Thermistor (2), Therm No Trip (3) Input (0) RW Txt US

00.035 Digital Output 1

Control 0 to 21 0 RW Num US

00.036 Analog Output 1

Control 0 to 14 0 RW Txt US

00.037 Maximum Switching

Frequency

0.667 (0), 1 (1), 2

(2), 3 (3), 4 (4), 6

(5), 8 (6), 12 (7),

16 (8) kHz

2 (2), 3 (3),

4 (4), 6 (5),

8 (6), 12 (7),

16 (8) kHz

3 (3) kHz RW Txt US

00.038 Autotune 0 to 2 0 to 3 0 RW Num NC US

00.039 Motor Rated

Frequency

0.00 to VM_SPEED_FREQ_REF_

UNIPOLAR Hz

50Hz: 50.00 Hz

60Hz: 60.00 Hz RW Num US

00.040 Number of Motor

Poles* Auto (0) to 32 (16) Auto 0 RW Num US

00.041 Control Mode

Ur S (0), Ur (1),

Fixed (2),

Ur Auto (3),

Ur I (4),

Square (5),

Fixed Tapered (6)

UrI (4) RW Txt US

00.042 Low Frequency

Voltage Boost 0.0 to 25.0 % 3.0 % RW Num US

00.043 Serial Baud Rate

300 (0), 600 (1), 1200 (2),

2400 (3), 4800 (4), 9600 (5),

19200 (6), 38400 (7), 57600 (8),

76800 (9), 115200 (10)

19200 (6) RW Txt US

00.044 Serial Address 1 to 247 1 RW Num US

00.045 Reset Serial

Communications Off (0) or On (1) Off (0) RW ND NC US

00.046

Brake Controller

Upper Current

Threshold

0 to 200 % 50 % RW Num US

00.047

Brake Controller

Lower Current

Threshold

0 to 200 % 10 % RW Num US

00.048

Brake Controller

Brake Release

Frequency

0.00 to 20.00 Hz 1.00 Hz RW Num US

00.049

Brake Controller

Brake Apply

Frequency

0.00 to 20.00 Hz 2.00 Hz RW Num US

00.050 Brake Controller

Brake Delay 0.0 to 25.0 s 1.0 s RW Num US

00.051

Brake Controller

Post-brake Release

Delay

0.0 to 25.0 s 1.0 s RW Num US

Parameter Range (Ú)Default (Ö)Type

OL RFC-A OL RFC-A

Unidrive M400 Control Quick Start Guide English Iss1.book Page 18 Tuesday, September 22, 2015 10:47 AM

Unidrive M400 Control Quick Start Guide 19

Issue Number: 2

* If this parameter is read via serial communications, it will show pole pairs.

00.053 Brake Controller

Initial Direction Ref (0), Forward (1), Reverse (2) Ref (0) RW Txt US

00.054

Brake Controller

Brake Apply Through

Zero Threshold

0.00 to 25.00 Hz 0.00 Hz RW Num US

00.055 Brake Controller

Enable

Disable (0), Relay (1),

Digital IO (2), User (3) Disable (0) RW Txt US

00.059 OUP Enable Stop (0) or Run (1) Run (1) RW Txt US

00.065

Frequency Controller

Proportional Gain

Kp1

0.000 to

200.000 s/rad 0.100 s/rad RW Num US

00.066 Frequency Controller

Integral Gain Ki1

0.00 to

655.35 s2/rad 0.10 s2/rad RW Num US

00.067 Sensorless Mode

Filter

4 (0), 5 (1), 6

(2), 8 (3), 12 (4),

20 (5) ms

4 (0) ms RW Txt US

00.069 Spin Start Boost 0.0 to 10.0 1.0 RW Num US

00.076 Action on Trip

Detection 0 to 31 0 RW Num ND NC PT US

00.077 Maximum Heavy

Duty Current Rating 0.00 to 9999.99 A RO Num ND NC PT

00.078 Software Version 0 to 999999 RO Num ND NC PT

00.079 User Drive Mode Open loop (1), RFC A (2) Open loop (1) RFC-A (2) RW Txt ND NC PT US

RW Read /

Write RO Read

only Num Number

parameter Bit Bit

parameter Txt Text string Bin Binary

parameter FI Filtered

ND

No

default

value

NC Not

copied PT Protected

parameter RA Rating

dependent US User save PS Power-down

save DE Destination

Parameter Range (Ú)Default (Ö)Type

OL RFC-A OL RFC-A

Unidrive M400 Control Quick Start Guide English Iss1.book Page 19 Tuesday, September 22, 2015 10:47 AM

20 Unidrive M400 Control Quick Start Guide

Issue Number: 2

Figure 6-1 Menu 0 logic diagram

2

5

Analog reference

Keypad reference

00.XXX

00.XXX

Key

Read-write (RW)

parameter

Read-only (RO)

parameter

Input

terminals

Output

terminals

X

X

X

X

The parameters are all shown in their default settings

00.018

Preset

Reference 1

Preset frequency

reference

14

0

5

00.017

00.015

Bipolar

Analog input 1 Analog

Input

1 Mode

15

Jog

Forward

Select

Jog

Reference

Analog input 1/

input 2 select

Analog input 2

Reference

Enable

AV

Pr

Pad

Pad.Ref

E. Pot

tor

Pid

6

7

8

9

01.015

Pr

set

01.050

>

1

01.050

00.005

Drive

Configuration

AI

AV.Pr

AI.Pr

1

2

3

4

00.016

Unidrive M400 Control Quick Start Guide English Iss1.book Page 20 Tuesday, September 22, 2015 10:47 AM

Table of contents

Popular Control Unit manuals by other brands

ZURN

ZURN AquaVantage ZH Series Installation, operation, maintenance and parts manual

elsner elektronik

elsner elektronik MSG1 compact Technical specifications and installation instructions

Emerson

Emerson Fisher 8540 instruction manual

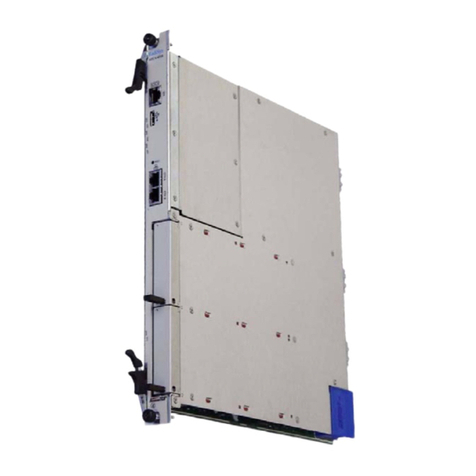

RadiSys

RadiSys PROMENTUM ATCA-4300 installation guide

Moxa Technologies

Moxa Technologies WAPN001 user manual

CRU

CRU WiebeTech Ditto quick start guide

CALEFFI

CALEFFI SATK series HIUs installation manual

BRAHMA

BRAHMA EG12 Series manual

MOGAS

MOGAS ASME Class 600 Installation, operation and maintenance manual

Warmworld

Warmworld DATATERM MK2 user guide

Motorola

Motorola 56F8346 user manual

Continental Refrigerator

Continental Refrigerator G12N410G1 user manual