CSE Universe Unidrive M600 User manual

Control User Guide

Unidrive M600

Universal Variable Speed AC drive for

induction and permanent magnet

motors

Part Number: 0478-0337-01

Issue: 1

Original Instructions

For the purposes of compliance with the EU Machinery Directive 2006/42/EC:

General information

The manufacturer accepts no liability for any consequences resulting from inappropriate, negligent or incorrect installation or

adjustment of the optional operating parameters of the equipment or from mismatching the variable speed drive with the motor.

The contents of this guide are believed to be correct at the time of printing. In the interests of a commitment to a policy of continuous

development and improvement, the manufacturer reserves the right to change the specification of the product or its performance, or

the contents of the guide, without notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means, electrical or mechanical

including photocopying, recording or by an information storage or retrieval system, without permission in writing from the publisher.

Drive firmware version

This product is supplied with the latest firmware version. If this drive is to be connected to an existing system or machine, all drive

firmware versions should be verified to confirm the same functionality as drives of the same model already present. This may also

apply to drives returned from an Emerson Industrial Automation Service Centre or Repair Centre. If there is any doubt please contact

the supplier of the product.

The firmware version of the drive can be checked by looking at Pr 00.050 {11.029}.

Environmental statement

Emerson Industrial Automation is committed to minimising the environmental impacts of its manufacturing operations and of its

products throughout their life cycle. To this end, we operate an Environmental Management System (EMS) which is certified to the

International Standard ISO 14001. Further information on the EMS, our Environmental Policy and other relevant information is

available on request, or can be found at

http://www.emersonindustrial.com/en-EN/controltechniques/aboutus/environment/Pages/environment.aspx

The electronic variable-speed drives manufactured by Emerson Industrial Automation have the potential to save energy and (through

increased machine/process efficiency) reduce raw material consumption and scrap throughout their long working lifetime. In typical

applications, these positive environmental effects far outweigh the negative impacts of product manufacture and end-of-life disposal.

Nevertheless, when the products eventually reach the end of their useful life, they must not be discarded but should instead be

recycled by a specialist recycler of electronic equipment. Recyclers will find the products easy to dismantle into their major component

parts for efficient recycling. Many parts snap together and can be separated without the use of tools, while other parts are secured

with conventional fasteners. Virtually all parts of the product are suitable for recycling.

Product packaging is of good quality and can be re-used. Large products are packed in wooden crates, while smaller products come

in strong cardboard cartons which themselves have a high recycled fibre content. If not re-used, these containers can be recycled.

Polythene, used on the protective film and bags for wrapping product, can be recycled in the same way. Emerson Industrial

Automations' packaging strategy prefers easily-recyclable materials of low environmental impact, and regular reviews identify

opportunities for improvement.

When preparing to recycle or dispose of any product or packaging, please observe local legislation and best practice.

REACH legislation

EC Regulation 1907/2006 on the Registration, Evaluation, Authorisation and restriction of Chemicals (REACH) requires the supplier

of an article to inform the recipient if it contains more than a specified proportion of any substance which is considered by the European

Chemicals Agency (ECHA) to be a Substance of Very High Concern (SVHC) and is therefore listed by them as a candidate for

compulsory authorisation.

For current information on how this requirement applies in relation to specific Emerson Industrial Automations' products, please

approach your usual contact in the first instance. Emerson Industrial Automations' position statement can be viewed at:

www.emersonindustrial.com/en-EN/controltechniques/aboutus/environment/reachregulation/Pages/reachregulation.aspx

Copyright © March 2016 Emerson Industrial Automation.

The information contained in this guide is for guidance only and does not form part of any contract. The accuracy cannot be guaranteed

as Emerson have an ongoing process of development and reserve the right to change the specification of their products without notice.

Control Techniques Limited. Registered Office: The Gro, Newtown, Powys SY16 3BE. Registered in England and Wales. Company

Reg. No. 01236886.

Moteurs Leroy-Somer SAS. Headquarters: Bd Marcellin Leroy, CS 10015, 16915 Angoulême Cedex 9, France. Share Capital: 65 800

512 €, RCS Angoulême 338 567 258.

Issue Number: 1

Drive Firmware: 01.13.01.00 onwards

For patent and intellectual property related information please go to: www.ctpatents.info.

How to use this guide

This guide is intended to be used in conjunction with the appropriate Power Installation Guide. The Power Installation

Guide gives information necessary to physically install the drive. This guide gives information on drive configuration,

operation and optimization.

There are specific safety warnings throughout this guide, located in the relevant sections. In addition, Chapter 1 Safety

information contains general safety information. It is essential that the warnings are observed and the information

considered when working with or designing a system using the drive.

This map of the user guide helps to find the right sections for the task you wish to complete, but for specific information,

refer to :

NOTE

Quick Start /

bench testing

Quick Start /

bench testing Familiarisation System designSystem design

Programming

and

commissioning

Programming

and

commissioning

Troubleshooting

1 Safety information

2 Product information

3 Mechanical installation

4 Electrical installation

5 Getting started

6 Basic parameters

7 Running the motor

8 Optimization

9 NV media card operation

11 Advanced parameters

12 Diagnostics

13 UL listing information

10 Onboard PLC

4Unidrive M600 Control User Guide

Issue Number: 1

Contents

1 Safety information .................................9

1.1 Warnings, Cautions and Notes .............................9

1.2 Electrical safety - general warning ........................9

1.3 System design and safety of personnel ................9

1.4 Environmental limits ..............................................9

1.5 Access ...................................................................9

1.6 Fire protection .......................................................9

1.7 Compliance with regulations .................................9

1.8 Motor .....................................................................9

1.9 Mechanical brake control ......................................9

1.10 Adjusting parameters ............................................9

1.11 Electrical installation ............................................10

1.12 Hazard .................................................................10

2 Product information ............................11

2.1 Introduction .........................................................11

2.2 Model number .....................................................11

2.3 Ratings ................................................................12

2.4 Operating modes .................................................13

2.5 Nameplate description ........................................14

2.6 Options ................................................................15

2.7 Drive features ......................................................17

3 Mechanical installation .......................18

3.1 Installing / removing option modules and

keypads ...............................................................18

4 Electrical installation ...........................21

4.1 24 Vdc supply ......................................................21

4.2 Communication connections ...............................22

4.3 Control connections ............................................23

4.4 Safe Torque Off (STO) ........................................28

5 Getting started .....................................30

5.1 Understanding the display ...................................30

5.2 Keypad operation ................................................30

5.3 Menu structure ....................................................32

5.4 Menu 0 ................................................................33

5.5 Advanced menus ................................................33

5.6 Changing the operating mode .............................35

5.7 Saving parameters ..............................................35

5.8 Restoring parameter defaults ..............................36

5.9 Parameter access level and security ..................36

5.10 Displaying parameters with non-default

values only ..........................................................37

5.11 Displaying destination parameters only ..............37

5.12 Communications .................................................37

6 Basic parameters .................................38

6.1 Menu 0: Basic parameters ..................................39

6.2 Parameter descriptions .......................................44

6.3 Full descriptions ..................................................46

6 Running the motor .............................. 59

6.1 Quick start connections ...................................... 59

6.2 Changing the operating mode ............................ 59

6.3 Quick start commissioning / start-up .................. 64

6.4 Quick start commissioning / start-up using

Unidrive M Connect (V02.00.00.00 onwards) .... 72

6.5 Diagnostics ......................................................... 76

7 Optimization ........................................ 77

7.1 Motor map parameters ....................................... 77

7.2 Maximum motor rated current ............................ 89

7.3 Current limits ...................................................... 89

7.4 Motor thermal protection .................................... 89

7.5 Switching frequency ........................................... 90

7.6 High speed operation ......................................... 90

7.7 CT Modbus RTU specification ........................... 92

8 NV Media Card Operation .................. 99

8.1 Introduction ........................................................ 99

8.2 NV Media Card support ...................................... 99

8.3 Transferring data .............................................. 100

8.4 Data block header information ......................... 101

8.5 NV Media Card parameters ............................. 102

8.6 NV Media Card trips ......................................... 103

9 Onboard PLC ..................................... 104

9.1 Onboard PLC and Machine Control Studio ...... 104

9.2 Benefits ............................................................ 104

9.3 Features ........................................................... 104

9.4 Onboard PLC parameters ................................ 105

9.5 Onboard PLC trips ........................................... 105

Unidrive M600 Control User Guide 5

Issue Number: 1

10 Advanced parameters .......................106

10.1 Parameter ranges and Variable minimum/

maximums: ........................................................109

10.2 Menu 1: Frequency / speed reference ..............120

10.3 Menu 2: Ramps .................................................124

10.4 Menu 3: Speed feedback and speed control ....127

10.5 Menu 4: Torque and current control ..................131

10.6 Menu 5: Motor control .......................................135

10.7 Menu 6: Sequencer and clock ..........................140

10.8 Menu 7: Analog I/O ...........................................144

10.9 Menu 8: Digital I/O ............................................148

10.10 Menu 9: Programmable logic, motorized

pot, binary sum and timers ................................152

10.11 Menu 10: Status and trips .................................158

10.12 Menu 11: General drive set-up .........................160

10.13 Menu 12: Threshold detectors, variable

selectors and brake control function .................162

10.14 Menu 13: Standard motion controller ................170

10.15 Menu 14: User PID controller ............................174

10.16 Menus 15, 16 and 17: Option module set-up ....177

10.17 Menu 18: Application menu 1 ...........................178

10.18 Menu 19: Application menu 2 ...........................178

10.19 Menu 20: Application menu 3 ...........................178

10.20 Menu 21: Second motor parameters ................179

10.21 Menu 22: Additional Menu 0 set-up ..................181

11 Diagnostics ........................................183

11.1 Status modes (Keypad and LED status) ...........183

11.2 Trip indications ..................................................183

11.3 Identifying a trip / trip source .............................184

11.4 Trips, Sub-trip numbers ....................................185

11.5 Internal / Hardware trips ....................................211

11.6 Alarm indications ...............................................211

11.7 Status indications ..............................................211

11.8 Programming error indications ..........................212

11.9 Displaying the trip history ..................................212

11.10 Behavior of the drive when tripped ...................212

12 UL Information ...................................213

12.1 UL file reference ................................................213

12.2 Option modules, kits and accessories ..............213

12.3 Enclosure ratings ..............................................213

12.4 Mounting ...........................................................213

12.5 Environment ......................................................213

12.6 Electrical Installation .........................................213

12.7 Motor overload protection and thermal

memory retention ..............................................214

12.8 Electrical supply ................................................214

12.9 External Class 2 supply ....................................214

12.10 Requirement for Transient Surge Suppression .214

12.11 Group Installation and Modular Drive Systems .214

12.12 cUL requirements for 575 V frame size 7 and 8 214

6Unidrive M600 Control User Guide

Issue Number: 1

EU Declaration of Conformity

This declaration is issued under the sole responsibility of the manufacturer. The object of the declaration is in conformity with the relevant Union

harmonization legislation. The declaration applies to the variable speed drive products shown below:

The model number may be followed by additional characters that do not affect the ratings.

The variable speed drive products listed above have been designed and manufactured in accordance with the following European harmonized

standards:

EN 61000-3-2:2014 Applicable where input current < 16 A. No limits apply for professional equipment where input power ≥1 kW.

These products comply with the Restriction of Hazardous Substances Directive (2011/65/EU), the Low Voltage Directive (2014/35/EU) and the

Electromagnetic Compatibility Directive (2014/30/EU).

G Williams

Vice President, Technology

Date: 15th February 2016

These electronic drive products are intended to be used with appropriate motors, controllers, electrical protection components and other

equipment to form complete end products or systems. Compliance with safety and EMC regulations depends upon installing and

configuring drives correctly, including using the specified input filters.

The drives must be installed only by professional installers who are familiar with requirements for safety and EMC. Refer to the Product

Documentation. An EMC data sheet is available giving detailed information. The assembler is responsible for ensuring that the end product

or system complies with all the relevant laws in the country where it is to be used.

Control Techniques Ltd

The Gro

Newtown

Powys

UK

SY16 3BE

Moteurs Leroy-Somer

Usine des Agriers

Boulevard Marcellin Leroy

CS10015

16915 Angoulême Cedex 9

France

Model number Interpretation Nomenclature aaaa - bbc ddddde

aaaa Basic series M100, M101, M200, M201, M300, M400, M600, M700, M701, M702, F300, H300, E200, E300, HS30, HS70,

HS71, HS72, M000, RECT

bb Frame size 01, 02, 03, 04, 05, 06, 07, 08, 09, 10, 11

c Voltage rating 1 = 100 V, 2 = 200 V, 4 = 400 V, 5 = 575 V, 6 = 690 V

ddddd Current rating Example 01000 = 100 A

e Drive format A = 6P Rectifier + Inverter (internal choke), D = Inverter, E = 6P Rectifier + Inverter (external choke),

N = 18P Rectifier + Inverter, T = 12P Rectifier + Inverter

EN 61800-5-1:2007 Adjustable speed electrical power drive systems - Part 5-1: Safety requirements - Electrical, thermal and energy

EN 61800-3: 2004+A1:2012 Adjustable speed electrical power drive systems - Part 3: EMC requirements and specific test methods

EN 61000-6-2:2005 Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity for industrial environments

EN 61000-6-4: 2007+ A1:2011 Electromagnetic compatibility (EMC) - Part 6-4: Generic standards - Emission standard for industrial

environments

EN 61000-3-2:2014 Electromagnetic compatibility (EMC) - Part 3-2: Limits for harmonic current emissions (equipment input current

≤16 A per phase)

EN 61000-3-3:2013

Electromagnetic compatibility (EMC) - Part 3-3: Limitation of voltage changes, voltage fluctuations and flicker in

public, low voltage supply systems, for equipment with rated current ≤16 A per phase and not subject to

conditional connection

Unidrive M600 Control User Guide 7

Issue Number: 1

EU Declaration of Conformity (including 2006 Machinery Directive)

This declaration is issued under the sole responsibility of the manufacturer. The object of the declaration is in conformity with the relevant Union

harmonization legislation. The declaration applies to the variable speed drive products shown below:

The model number may be followed by additional characters that do not affect the ratings.

This declaration relates to these products when used as a safety component of a machine. Only the Safe Torque Off function may be used

for a safety function of a machine. None of the other functions of the drive may be used to carry out a safety function.

These products fulfil all the relevant provisions of the Machinery Directive 2006/42/EC and the Electromagnetic Compatibility Directive (2014/30/EU).

EC type examination has been carried out by the following notified body:

TUV Rheinland Industrie Service GmbH

Am Grauen Stein

D-51105 Köln

Germany

Notified body identification number: 0035

The harmonized standards used are shown below:

EC type-examination certificate numbers:

01/205/5270.01/14 dated 2014-11-11

01/205/5387.01/15 dated 2015-01-29

01/205/5383.02/15 dated 2015-04-21

Person authorised to complete the technical file:

P Knight

Conformity Engineer

Newtown, Powys, UK

Control Techniques Ltd

The Gro

Newtown

Powys

UK

SY16 3BE

Moteurs Leroy-Somer

Usine des Agriers

Boulevard Marcellin Leroy

CS10015

16915 Angoulême Cedex 9

France

Model No. Interpretation Nomenclature aaaa - bbc ddddde

aaaa Basic series M300, M400, M600, M700, M701, M702, F300, H300, E200, E300, HS30, HS70, HS71, HS72, M000, RECT

bb Frame size 01, 02, 03, 04, 05, 06, 07, 08, 09, 10, 11

c Voltage rating 1 = 100 V, 2 = 200 V, 4 = 400 V, 5 = 575 V, 6 = 690 V

ddddd Current rating Example 01000 = 100 A

e Drive format A = 6P Rectifier + Inverter (internal choke), D = Inverter, E = 6P Rectifier + Inverter (external choke), N = 18P

Rectifier + Inverter, T = 12P Rectifier + Inverter

EN 61800-5-1:2007 Adjustable speed electrical power drive systems - Part 5-1: Safety requirements - Electrical, thermal and energy

EN 61800-5-2:2007 Adjustable speed electrical power drive systems - Part 5-2: Safety requirements - Functional

EN ISO 13849-1:2008 Safety of Machinery, Safety-related parts of control systems, General principles for design

EN ISO 13849-2:2008 Safety of machinery, Safety-related parts of control systems. Validation

EN 61800-3: 2004+A1:2012 Adjustable speed electrical power drive systems - Part 3: EMC requirements and specific test methods

EN 62061:2005 Safety of machinery, Functional safety of safety related electrical, electronic and programmable electronic control

systems

8Unidrive M600 Control User Guide

Issue Number: 1

G. Williams

Vice President, Technology

Date: 15th February 2016

Place: Newtown, Powys, UK

IMPORTANT NOTICE

These electronic drive products are intended to be used with appropriate motors, controllers, electrical protection components and other

equipment to form complete end products or systems. Compliance with safety and EMC regulations depends upon installing and

configuring drives correctly, including using the specified input filters.

The drives must be installed only by professional installers who are familiar with requirements for safety and EMC. Refer to the Product

Documentation. An EMC data sheet is available giving detailed information. The assembler is responsible for ensuring that the end product

or system complies with all the relevant laws in the country where it is to be used.

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor Optimization NV Media Card

Operation

Onboard

PLC

Advanced

parameters Diagnostics UL

Information

Unidrive M600 Control User Guide 9

Issue Number: 1

1 Safety information

1.1 Warnings, Cautions and Notes

A Note contains information which helps to ensure correct operation of

the product.

1.2 Electrical safety - general warning

The voltages used in the drive can cause severe electrical shock and/or

burns, and could be lethal. Extreme care is necessary at all times when

working with or adjacent to the drive.

Specific warnings are given at the relevant places in this Control User

Guide.

1.3 System design and safety of

personnel

The drive is intended as a component for professional incorporation into

complete equipment or a system. If installed incorrectly, the drive may

present a safety hazard.

The drive uses high voltages and currents, carries a high level of stored

electrical energy, and is used to control equipment which can cause

injury.

Close attention is required to the electrical installation and the system

design to avoid hazards either in normal operation or in the event of

equipment malfunction. System design, installation, commissioning/

start-up and maintenance must be carried out by personnel who have

the necessary training and experience. They must read this safety

information and this Control User Guide carefully.

The STOP and Safe Torque Off functions of the drive do not isolate

dangerous voltages from the output of the drive or from any external

option unit. The supply must be disconnected by an approved electrical

isolation device before gaining access to the electrical connections.

With the sole exception of the Safe Torque Off function, none of the

drive functions must be used to ensure safety of personnel, i.e.

they must not be used for safety-related functions.

Careful consideration must be given to the functions of the drive which

might result in a hazard, either through their intended behavior or

through incorrect operation due to a fault. In any application where a

malfunction of the drive or its control system could lead to or allow

damage, loss or injury, a risk analysis must be carried out, and where

necessary, further measures taken to reduce the risk - for example, an

over-speed protection device in case of failure of the speed control, or a

fail-safe mechanical brake in case of loss of motor braking.

The Safe Torque Off function may be used in a safety-related

application. The system designer is responsible for ensuring that the

complete system is safe and designed correctly according to the

relevant safety standards.

1.4 Environmental limits

Instructions in the Power Installation Guide regarding transport, storage,

installation and use of the drive must be complied with, including the

specified environmental limits. Drives must not be subjected to

excessive physical force.

1.5 Access

Drive access must be restricted to authorized personnel only. Safety

regulations which apply at the place of use must be complied with.

1.6 Fire protection

The drive enclosure is not classified as a fire enclosure. A separate fire

enclosure must be provided. For further information, refer to the relevant

Power Installation Guide.

1.7 Compliance with regulations

The installer is responsible for complying with all relevant regulations,

such as national wiring regulations, accident prevention regulations and

electromagnetic compatibility (EMC) regulations. Particular attention

must be given to the cross-sectional areas of conductors, the selection

of fuses or other protection, and protective ground (earth) connections.

The Power Installation Guide contains instruction for achieving

compliance with specific EMC standards.

Within the European Union, all machinery in which this product is used

must comply with the following directives:

Safety of Machinery 2006/42/EC.

Electromagnetic Compatibility (EMC) Directive 2014/30/EU.

1.8 Motor

Ensure the motor is installed in accordance with the manufacturer’s

recommendations. Ensure the motor shaft is not exposed.

Standard squirrel cage induction motors are designed for single speed

operation. If it is intended to use the capability of the drive to run a motor

at speeds above its designed maximum, it is strongly recommended that

the manufacturer is consulted first.

Low speeds may cause the motor to overheat because the cooling fan

becomes less effective. The motor should be installed with a protection

thermistor. If necessary, an electric forced vent fan should be used.

The values of the motor parameters set in the drive affect the protection

of the motor. The default values in the drive should not be relied upon.

It is essential that the correct value is entered in Pr 00.046 motor rated

current. This affects the thermal protection of the motor.

1.9 Mechanical brake control

The brake control functions are provided to allow well co-ordinated

operation of an external brake with the drive. While both hardware and

software are designed to high standards of quality and robustness, they

are not intended for use as safety functions, i.e. where a fault or failure

would result in a risk of injury. In any application where the incorrect

operation of the brake release mechanism could result in injury,

independent protection devices of proven integrity must also be

incorporated.

1.10 Adjusting parameters

Some parameters have a profound effect on the operation of the drive.

They must not be altered without careful consideration of the impact on

the controlled system. Measures must be taken to prevent unwanted

changes due to error or tampering.

A Warning contains information which is essential for

avoiding a safety hazard.

A Caution contains information which is necessary for

avoiding a risk of damage to the product or other equipment.

WARNING

CAUTION

NOTE

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor Optimization NV Media Card

Operation

Onboard

PLC

Advanced

parameters Diagnostics UL

Information

10 Unidrive M600 Control User Guide

Issue Number: 1

1.11 Electrical installation

1.11.1 Electric shock risk

The voltages present in the following locations can cause severe electric

shock and may be lethal:

AC supply cables and connections

Output cables and connections

Many internal parts of the drive, and external option units

Unless otherwise indicated, control terminals are single insulated and

must not be touched.

1.11.2 Stored charge

The drive contains capacitors that remain charged to a potentially lethal

voltage after the AC supply has been disconnected. If the drive has been

energized, the AC supply must be isolated at least ten minutes before

work may continue.

1.12 Hazard

1.12.1 Falling hazard

The drive presents a falling or toppling hazard. This can still cause injury

to personnel and therefore should be handled with care.

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor Optimization NV Media Card

Operation

Onboard

PLC

Advanced

parameters Diagnostics UL

Information

Unidrive M600 Control User Guide 11

Issue Number: 1

2 Product information

2.1 Introduction

Universal AC and servo drive

Unidrive M600 delivers maximum machine performance with sensorless induction and sensorless permanent magnet motor control, for dynamic and

efficient machine operation. An optional encoder port can be used for precise closed loop velocity applications and digital lock / frequency following.

Features

• Universal high performance drive for induction and sensorless permanent magnet motors.

• Onboard IEC 61131-3 programmable automation

• NV Media Card for parameter copying and data storage

• EIA 485 serial communications interface

• Single channel Safe Torque Off (STO) input

Optional features

• Select up to three option modules

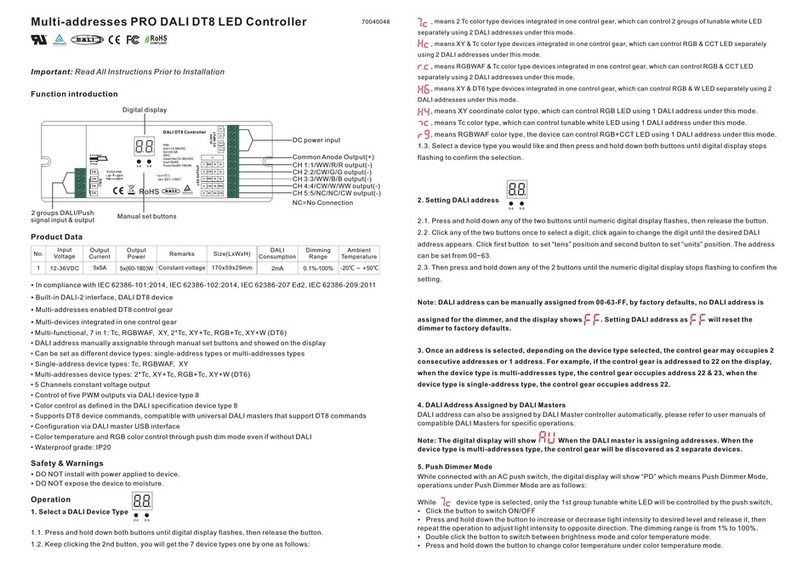

2.2 Model number

The way in which the model numbers for the Unidrive M600 range are formed is illustrated below:

Figure 2-1 Model number

* Only shown on Frame 9 to 11 identification label.

For simplicity, a Frame 9 drive with no internal choke (i.e. model 09xxxxxxE) is referred to as a Frame 9E and a Frame 9 drive with an internal choke

(i.e. model 09xxxxxxA) is referred to as a Frame 9A. Any reference to Frame 9 is applicable to both sizes 9E and 9A.

Identification Label

Electrical Specifications

Derivative

Unidrive M600

Product Line

Frame Size:

Voltage Rating:

Current Rating:

HeavyDuty current rating x10

Power Format:

Reserved

0

Optional Build

Customer Code

01 A B 1 00

Customer Code:

00 = 50 Hz

01 = 60 Hz

Reserved:

Conformal Coating:

0=Standard

IP/NEMA Rating:

1=IP20 /NEMA 1

BrakeTransistor:

B=Brake

Cooling:

A=Air

Documentation

1

Documentation:

0 - Supplied separately

1 - English

2 - French

3 - Italian

4 - German

5 - Spanish

2 - 200 V (200 - 240

- 400 V (380 - 480

- 575 V (500 - 575

- 690 V (500 - 690

±10 %)

4±

±

±

10 %)

5 10 %)

6 10 %)

Power

Format

M600 -03 4 00078 A

Configuration*

1

A - AC in AC out (with internal choke)

D - DC in AC out (Inverter)

C - AC in DC out (Rectifier)

E - AC in AC out (without internal choke)

Configuration:

1 - Standard

U - NoControl

M - Master

F- Follower

T- AC in AC out (12P rectifier plus inverter)

N = Nobrake

NOTE

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor Optimization NV Media Card

Operation

Onboard

PLC

Advanced

parameters Diagnostics UL

Information

12 Unidrive M600 Control User Guide

Issue Number: 1

2.3 Ratings

.

The drive is dual rated.

The setting of the motor rated current determines which rating applies -

Heavy Duty or Normal Duty.

The two ratings are compatible with motors designed to IEC60034.

The graph aside illustrates the difference between Normal Duty and

Heavy Duty with respect to continuous current rating and short term

overload limits.

Normal Duty Heavy Duty (default)

For applications which use Self ventilated (TENV/TEFC) induction

motors and require a low overload capability, and full torque at low

speeds is not required (e.g. fans, pumps).

Self ventilated (TENV/TEFC) induction motors require increased

protection against overload due to the reduced cooling effect of the fan

at low speed. To provide the correct level of protection the I2t software

operates at a level which is speed dependent. This is illustrated in the

graph below.

The speed at which the low speed protection takes effect can be

changed by the setting of Low Speed Thermal Protection Mode

(04.025). The protection starts when the motor speed is below 15 % of

base speed when Pr 04.025 = 0 (default) and below 50 % when

Pr 04.025 = 1.

For constant torque applications or applications which require a high

overload capability, or full torque is required at low speeds (e.g. winders,

hoists).

The thermal protection is set to protect force ventilated induction motors

and permanent magnet servo motors by default.

N

If the application uses a self ventilated (TENV/TEFC) induction motor

and increased thermal protection is required for speeds below 50 %

base speed, then this can be enabled by setting Low Speed Thermal

Protection Mode (04.025) = 1.

Operation of motor I2t protection

Motor I2t protection is fixed as shown below and is compatible with:

• Self ventilated (TENV/TEFC) induction motors

Motor I2t protection defaults to be compatible with:

• Forced ventilation induction motors

• Permanent magnet servo motors

Available output

current

Overload limit -

Heavy Duty

Maximum

continuous

current (above

50% base

speed) -

Normal Duty

Maximum

continuous

current -

Heavy Duty

Motor rated

current set

in the drive

Heavy Duty

- with high

overload capability

Normal Duty

Overload limit -

Normal Duty

NOTE

NOTE

Motor total

current (Pr 04.001)

as a percentage

of motor rated

current

Motor speed as a

percentage of base speed

100%

Max. permissible

continuous

current

100%

I t protection operates in this region

2

70%

50%15%

Pr = 0

Pr = 1

04.025

04.025

Motor total

current (Pr 04.001)

as a percentage

of motor rated

current

Motor speed as a

percentage of base speed

100%

Max. permissible

continuous

current

100%

I t protection operates in this region

2

70%

50%

Pr = 0

Pr = 1

04.025

04.025

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor Optimization NV Media Card

Operation

Onboard

PLC

Advanced

parameters Diagnostics UL

Information

Unidrive M600 Control User Guide 13

Issue Number: 1

2.4 Operating modes

The drive is designed to operate in any of the following modes:

Open loop mode

Open loop vector mode

Fixed V/F mode (V/Hz)

Quadratic V/F mode (V/Hz)

RFC - A

With position feedback sensor (requires optional SI-Encoder module)

Without position feedback sensor (Sensorless)

RFC - S

Without position feedback sensor (Sensorless)

Regen mode

2.4.1 Open loop mode

The drive applies power to the motor at frequencies varied by the user. The motor speed is a result of the output frequency of the drive and slip due

to the mechanical load. The drive can improve the speed control of the motor by applying slip compensation. The performance at low speed depends

on whether V/F mode or open loop vector mode is selected.

Open loop vector mode

The voltage applied to the motor is directly proportional to the frequency except at low speed where the drive uses motor parameters to apply the

correct voltage to keep the flux constant under varying load conditions.

Typically 100 % torque is available down to 1 Hz for a 50 Hz motor.

Fixed V/F mode

The voltage applied to the motor is directly proportional to the frequency except at low speed where a voltage boost is provided which is set by the

user. This mode can be used for multi-motor applications.

Typically 100 % torque is available down to 4 Hz for a 50 Hz motor.

Quadratic V/F mode

The voltage applied to the motor is directly proportional to the square of the frequency except at low speed where a voltage boost is provided which is

set by the user. This mode can be used for running fan or pump applications with quadratic load characteristics or for multi-motor applications. This

mode is not suitable for applications requiring a high starting torque.

2.4.2 RFC-A mode

Rotor Flux Control for Asynchronous (induction) motors (RFC-A) encompasses closed loop vector control with and without a position feedback

device.

With position feedback (requires optional SI-Encoder module)

For use with induction motors with a feedback device installed. The drive directly controls the speed of the motor using the feedback device to ensure

the rotor speed is exactly as demanded. Motor flux is accurately controlled at all times to provide full torque all the way down to zero speed.

Without position feedback (Sensorless)

Sensorless mode provides closed loop control without the need for position feedback by using current, voltages and key operating motor parameters

to estimate the motor speed. It can eliminate instability traditionally associated with open loop control such as operating large motors with light loads

at low frequencies.

2.4.3 RFC- S

Rotor Flux Control for Synchronous (permanent magnet brushless) motors (RFC-S) provides closed loop control without a position feedback device.

Without position feedback

For use with permanent magnet brushless motors without a feedback device installed.

Flux control is not required because the motor is self excited by the permanent magnets which form part of the rotor.

Full torque is available all the way down to zero speed, with salient motors.

2.4.4 Regen mode

For use as a regenerative front end for four quadrant operation.

Regen operation allows bi-directional power flow to and from the AC supply. This provides far greater efficiency levels in applications which would

otherwise dissipate large amounts of energy in the form of heat in a braking resistor.

The harmonic content of the input current is negligible due to the sinusoidal nature of the waveform when compared to a conventional bridge rectifier

or SCR/thyristor front end.

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor Optimization NV Media Card

Operation

Onboard

PLC

Advanced

parameters Diagnostics UL

Information

14 Unidrive M600 Control User Guide

Issue Number: 1

2.5 Nameplate description

Figure 2-2 Typical drive rating labels

* This label is only applicable to Size 7 and above.

Refer to Figure 2-1 Model number on page 11 for further information relating to the labels.

Date code format

The date code is split into two sections: a letter followed by a number. The letter indicates the year, and the number indicates the week number (within

the year) in which the drive was built.The letters go in alphabetical order, starting with A in 1991 (B in 1992, C in 1993 etc).

Example:

A date code of W28 would correspond to week 28 of year 2013.

Refer to

User Guide

Model

Frame

size

Voltage

HeavyDuty

current rating

Driveformat

M600-032 00050 A

Approvals

Input voltage

Output

voltage

HeavyDuty /

Normal Duty

power rating

Customer and

date code

Serial

number

Input

frequency

No.ofphases &

Typical input current for

Normal Duty rating

HeavyDuty /

Normal Duty rating

output current

M600-074-00660-A30/37kW STDV02

I/P 380-480V 50-60Hz 3ph74A

O/P 0-480V 3ph66/79A

Designed in UK

Made in U.K.

Serial No: 3000005001

No. of Input phase &

Input current

No. of Output phase

&

Output current

HeavyDuty/

Normal Duty Rating

ModelInput

frequency

HeavyDuty /

Normal Duty

power rating

Customer and

date code

Approvals

Serial number

Input

voltage

Output

voltage

Large label*

Key to approvals

CE approval Europe

RCM - Regulatory

Compliance Mark Australia

UL / cUL approval USA &

Canada

RoHS compliant Europe

Eurasian conformity Eurasia

Functional safety USA &

Canada

R

NOTE

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor Optimization NV Media Card

Operation

Onboard

PLC

Advanced

parameters Diagnostics UL

Information

Unidrive M600 Control User Guide 15

Issue Number: 1

2.6 Options

Figure 2-3 Options available with the drive

1. Keypad

2. Option module slot 1

3. Option module slot 2

4. Option module slot 3

5. CT USB Comms cable

6. Internal braking resistor

7. NV media card (* For further information refer to chapter 8 NV Media Card Operation on page 99).

8. KI-485 comms adaptor

8

Be aware of possible live terminals when inserting or removing the NV media card.

WARNING

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor Optimization NV Media Card

Operation

Onboard

PLC

Advanced

parameters Diagnostics UL

Information

16 Unidrive M600 Control User Guide

Issue Number: 1

All standard option modules are color-coded in order to make identification easy. All modules have an identification label on top of the module.

Standard option modules can be installed to any of the available option slots on the drive. The following tables shows the color-code key and gives

further details on their function.

Table 2-1 Option module identification

Type Option

module Color Name Further Details

Fieldbus

N/A KI-485 Adaptor

EIA 485 Comms Adaptor

EIA 485 Comms adaptor provides EIA 485 communication interface. This

adaptor supports 115 k Baud, node addresses between 1 to 16 and 8 1 NP M

serial mode.

Purple SI-PROFIBUS PROFIBUS option

PROFIBUS adapter for communications with the drive

Medium Grey SI-DeviceNet DeviceNet option

DeviceNet adapter for communications with the drive

Light Grey SI-CANopen CANopen option

CANopen adapter for communications with the drive

Beige SI-Ethernet

External Ethernet module that supports EtherNet/IP, Modbus TCP/IP and

RTMoE. The module can be used to provide high speed drive access, global

connectivity and integration with IT network technologies, such as wireless

networking

Yellow Green SI-PROFINET V2

PROFINET V2 option

PROFINET V2 adapter for communications with the drive

Note: PROFINET V2 replaces PROFINET RT.

Brown Red SI-EtherCAT EtherCAT option

EtherCAT adapter for communications with the drive

Automation

(I/O expansion) Orange SI-I/O

Extended I/O

Increases the I/O capability by adding the following combinations:

• Digital I/O

• Digital Inputs

• Analog Inputs (differential or single ended)

• Analog Output

• Relays

Feedback

Light Brown SI-Encoder Incremental encoder input interface module. Provides Closed loop Rotor

Flux Control for induction motors (RFC-A) on M600.

Dark Brown SI-Universal Encoder Additional combined encoder input and output interface supporting

Incremental, SinCos, HIPERFACE, EnDAT and SSI encoders.

Safety Yellow SI-Safety Safety module that provides an intelligent, programmable solution to meet

the IEC 61800-5-2 functional safety standard

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor Optimization NV Media Card

Operation

Onboard

PLC

Advanced

parameters Diagnostics UL

Information

Unidrive M600 Control User Guide 17

Issue Number: 1

Table 2-2 Keypad identification

Table 2-3 Additional options

2.7 Drive features

Figure 2-4 Features of the drive control section

Type Keypad Name Further Details

Keypad

KI-Keypad LCD keypad option

Keypad with an LCD display

KI-Keypad RTC LCD keypad option

Keypad with an LCD display and real time clock

Remote-Keypad RTC Remote LCD keypad option

Remote Keypad with an LCD display and real time clock

Remote-Keypad Remote LCD keypad option

Remote Keypad with an LCD display.

Type Option Name Further Details

Back-up

SD Card Adaptor SD Card Adaptor

Allows the drive to use an SD card for drive back-up

SMARTCARD SMARTCARD

Used for parameter back-up with the drive

www.controltechniques.com

Key

1. Keypad connection 2. Rating label 3. Identification label

4. Status LED 5. Option module slot 1 6. Option module slot 2

7. Option module slot 3 8. Relay connections 9. Control connections

10. Communications port 11. NV media card slot

1

2

3

4

5

6

7

8

9

10

11

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor Optimization NV Media Card

Operation

Onboard

PLC

Advanced

parameters Diagnostics UL

Information

18 Unidrive M600 Control User Guide

Issue Number: 1

3 Mechanical installation

3.1 Installing / removing option modules and keypads

Figure 3-1 Installation of an option module

Installing the first option module

Option module slots must be used in the following order: slot 3, slot 2 and slot 1 (refer to Figure 2-2 Features of the drive (size 3 to 10) on page 16 for

slot numbers).

• Move the option module in direction shown (1).

• Align and insert the option module tab in to the slot provided (2), this is highlighted in the detailed view (A).

• Press down on the option module until it clicks into place.

Installing the second option module

• Move the option module in direction shown (3).

• Align and insert the option module tab in to the slot provided on the already installed option module (4), this is highlighted in the detailed view (B).

• Press down on the option module until it clicks into place. Image (5) shows two option modules fully installed.

Installing the third option module

• Repeat the above process.

The drive has the facility for all three option module slots to be used at the same time, image (6) shows the three option modules installed.

Power down the drive before installing / removing the option module. Failure to do so may result in damage to the product.

CAUTION

NOTE

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor Optimization NV Media Card

Operation

Onboard

PLC

Advanced

parameters Diagnostics UL

Information

Unidrive M600 Control User Guide 19

Issue Number: 1

Figure 3-2 Removal of an option module

• Press down on the tab (1) to release the option module from the drive housing, the tab is highlighted in the detailed view (A).

• Tilt the option module towards you as shown (2).

• Totally remove the option module in direction shown (3).

Figure 3-3 Installation and removal of the KI-Keypad

To install, align the keypad and press gently in the direction shown until it clicks into position.

To remove, reverse the installation instructions.

N

The keypad can be installed / removed while the drive is powered up and running a motor, providing that the drive is not operating in keypad mode.

NOTE

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor Optimization NV Media Card

Operation

Onboard

PLC

Advanced

parameters Diagnostics UL

Information

20 Unidrive M600 Control User Guide

Issue Number: 1

3.1.1 Real time clock battery replacement

Those keypads which have the real time clock feature contain a battery to ensure the clock works when the drive is powered down. The battery has a

long life time but if the battery needs to be replaced or removed, follow the instructions below.

Low battery voltage is indicated by low battery symbol on the keypad display.

Figure 3-4 KI-Keypad RTC (rear view)

Figure 3-4 above illustrates the rear view of the KI-Keypad RTC.

1. To remove the battery cover insert a flat head screwdriver into the slot as shown (1), push and turn anti-clockwise until the battery cover is

released.

2. Replace the battery (the battery type is: CR2032).

3. Reverse point 1 above to replace battery cover.

Ensure the battery is disposed of correctly.

NOTE

Table of contents

Popular Controllers manuals by other brands

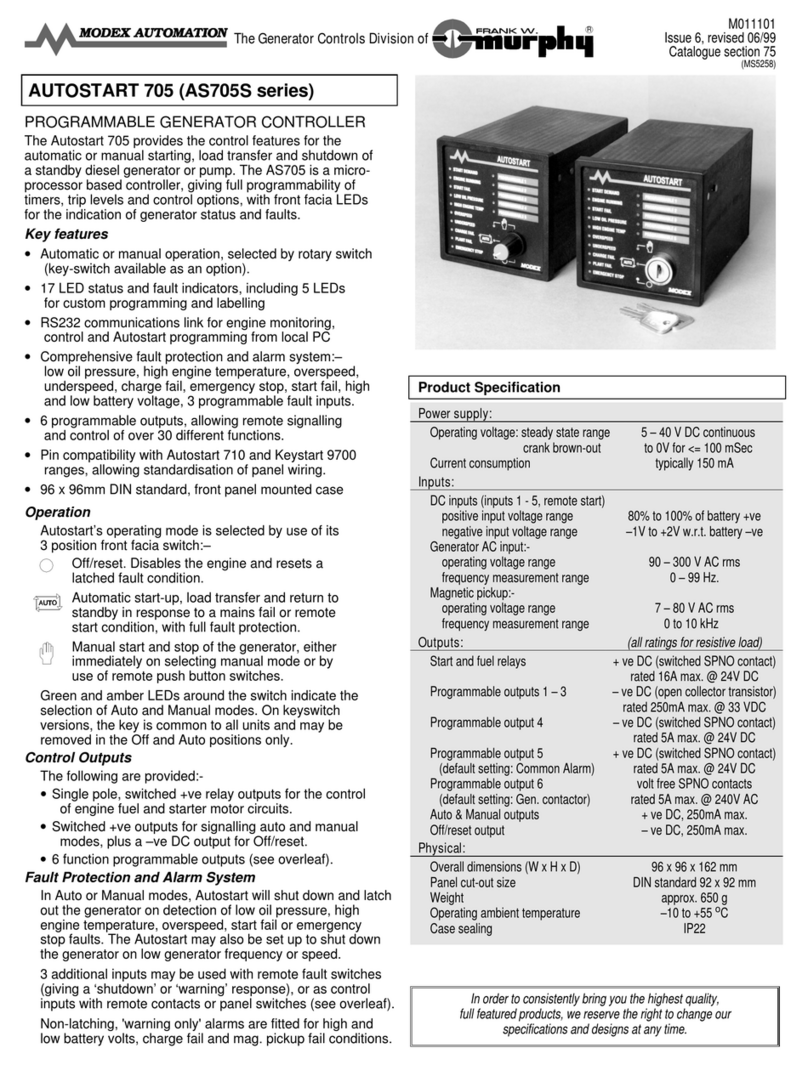

Murphy

Murphy Autostart 705 AS705S owner's manual

Zennio

Zennio Tecla 55 X Sign user manual

DT Research

DT Research DT122 Basic operation guide

elsner elektronik

elsner elektronik KNX R1-B4 compact 16 A Installation and adjustment

Chauvet

Chauvet COLORdash Batten-Hex 8 user manual

Evco

Evco EV8318 quick start guide