CSE BIOMARINE BIOPAK 240 Revolution User manual

10

Breathing hoses do not need to be in straps on test apparatus 2

STATEMENTS OF FACT

BENCH BIOPAK 240-R CONTEST

1. Use only exact replacement parts in the configuration as specified by the

manufacturer. 8VHU%HQFKPDQ&DXWLRQVDQG/LPLWDWLRQV6SHFLDORU&ULWLFDO8VHU·V

Instructions)

2. The battery is to be changed in fresh air only. User/Benchman: Cautions and

/LPLWDWLRQV6SHFLDORU&ULWLFDO8VHU·V,QVWUXFWLRQV

3. MSHA approved for use with one of the following 9-Volt batteries only:

Eveready

Panasonic

Rayovac

Duracell

(Remote Monitoring System MSHA Electronic Approval Page)

4. Never substitute, modify, add or omit parts. User/Benchman: Cautions and

/LPLWDWLRQV6SHFLDORU&ULWLFDO8VHU·V,QVWUXFWLRQV

5. Prior to using the BioPak 240 Revolution it must be determined that the

user is medically fit. User/Benchman: Cautions and Limitations, Special or Critical

8VHU·VInstructions)

6. Always handle oxygen cylinders with care to prevent damage.

8VHU%HQFKPDQ&DXWLRQVDQG/LPLWDWLRQV6SHFLDORU&ULWLFDO8VHU·V,QVWUXFWLRQV

7. Do not open the cylinder valve in the presence of open flame, sparks or

high radiant heat. User/Benchman: Cautions and Limitations, Special or Critical

8VHU·V,QVWUXFWLRQV

8. Oxygen will enhance the combustion of other materials so that materials

that normally will not burn in air may burn in oxygen-rich atmospheres;

and, materials that do burn in air will burn more vigorously and at a

higher temperature in oxygen-rich atmospheres. User/Benchman: Cautions

DQG/LPLWDWLRQV6SHFLDORU&ULWLFDO8VHU·V,QVWUXFWLRQV

9. Oxygen will not cause materials to ignite without the presence of an

ignition source. User/Benchman: Cautions and Limitations, Special or Critical

8VHU·V,QVWUXFWLRQV

10. The use of an SCBA will add to the workload and stress of the user.

8VHU%HQFKPDQ&DXWLRQVDQG/LPLWDWLRQV6SHFLDORU&ULWLFDO8VHU·V,QVWUXFWLRQV

11. The BioPak 240 Revolution is suitable for respiratory protection entry

into and escape from oxygen deficient atmospheres with a temperature

as low as -5 degrees F (-5F) (-20C). (Users/Benchman Cautions and Limitations

RU&ULWLFDO8VHU·V,QVWUXFWLRQV

11

12. The BioPak 240 Revolution is approved when the oxygen cylinder is

fully charged with compressed medical or aviation grade oxygen at 3000

psi. 8VHU%HQFKPDQ&DXWLRQVDQG/LPLWDWLRQV6SHFLDORU&ULWLFDO8VHU·V,QVWUXFWLRQV

13. Allow the oxygen cylinder to cool after filling to determine the correct

pressure. 8VHU%HQFKPDQ&DXWLRQVDQG/LPLWDWLRQV6SHFLDORU&ULWLFDO8VHU·V

Instructions)

14. A foreign gas may cause cylinder corrosion. User/Benchman: Cautions and

/LPLWDWLRQV6SHFLDORU&ULWLFDO8VHU·V Instructions)

15. Always check for a current hydrostatic test date. User/Benchman: Cautions

DQG/LPLWDWLRQV6SHFLDORU&ULWLFDO8VHU·V,QVWUXFWLRQV

16. DOT requires carbon fiber wrapped aluminum cylinders be tested by an

approved facility on a 5-year cycle from the date of manufacture.

8VHU%HQFKPDQ&DXWLRQVDQG/LPLWDWLRQV6SHFLDORU&ULWLFDO8VHU·V,QVWUXFWLRQV

17. An unapproved facepiece will compromise the protection provided to

the user by the SCBA. User/Benchman: Cautions and Limitations, Special or

&ULWLFDO8VHU·V,QVWUXFWLRQV

18. A good facepiece seal is important to achieving full protection and proper

SCBA duration. User/Benchman: Cautions and Limitations, Special or Critical

8VHU·V,QVWUXFWLRQV

19. Users should conform to MSHA/NIOSH guidelines concerning facial hair and

the use of facemasks. (Users/Benchman Cautions and /LPLWDWLRQVRU&ULWLFDO8VHU·V

Instructions)

20. Replace the battery when the low battery alarm has activated, after 200 hours

of use or every 6 months whichever comes first.

(Benchman section 3.4)

21. The connectors of the monitoring device may only be connected to a Bio

marine BioPak 240R breathing Apparatus oxygen regulator, manifold

block and breathing chamber. User/Benchman: Cautions and Limitations,

6SHFLDORU&ULWLFDO8VHU·V,QVWUXFWLRQV

22. The fiber optic cable may only be connected to the BioPak 240R remote

gauge assembly. User/Benchman: Cautions and Limitations, Special or Critical

8VHU·V,QVWUXFWLRQV

12

23. Turn-Around maintenance procedures should be performed as soon as

possible after each use. (Benchman Section 3.1)

24. It is acceptable to leave the oxygen cylinder in place until after washing and

disinfecting has been completed. (Benchman Section 1.2)

25. Immediately after completion of BioPak use, remove the used CO2

scrubber canisters. (Benchman: Section 1.2

26. DO NOT submerge the Alarm Module during turn-around maintenance.

(Benchman: Section 1.3)

27. Do not allow any fluids to contact the in input port of the pressure

regulator. (Benchman: Section 1.3)

28. Use only cleaners and disinfectants that are approved by Bio marine.

(Benchman: Section 1.3)

29. If Cleaning is not immediately possible after each use, at a minimum remove

and discard the CO2 scrubber and moisture pad. (Benchman: Section 1.3)

30. Remove the oxygen cylinder making sure the seal washer remains in place and

install the regulator cover. (Benchman: Section 1.2)

31. Allow all components to remain wetted by the cleaning solution a minimum of

10 minutes. (Benchman: Section 1.3)

32. Thoroughly rinse all components in clean water to remove all disinfectant

solution. (Benchman: Section 1.3)

33. C.O.P.D. could limit or prevent the use of the BioPak 240 Revolution.

8VHU%HQFKPDQ&DXWLRQVDQG/LPLWDWLRQV6SHFLDORU&ULWLFDO8VHU·V,QVWUXFWLRQV

34. Place freeze forms onto a level surface in a freezer for a minimum of 8 hour

period at a temperature of 10 degrees F or less. (Benchman: Section 1.4)

35. If the optional magnetic wiper is utilized soak both chamois surfaces of the

wiper pieces with water. (User: Section 3.2)

36. The manual(s) are the minimum recommended procedures for maintaining

the BioPak 240R. (User/Benchman: Cautions and Limitations, Special or Critical

8VHU·V,QVWUXFWLRQV

37. Failure to follow the minimum procedures presented in the manual(s)

may violate government or agency approvals as well as void the

13

PDQXIDFWXUHU·VZDUUDQW\(User/Benchman: Cautions and Limitations, Special or

&ULWLFDO8VHU·V,QVWUXFWLRQV

38. To prevent mold growth remove the moisture control foam pads after each

use (Benchman: Section 1.3)

39. Do not pre-pack any BioPak that will be stored at temperatures at or below 32

degrees F. (Benchman: Section 1.12)

40. Pre-packing the BioPak 240 R with carbon dioxide scrubbers is only permitted

when utilizing Orbsorb carbon dioxide scrubber. (Benchman: Section 1.12)

41. Pre-packed carbon dioxide scrubbers may only be stored in the apparatus for

a maximum period of 1-year. (Benchman: Section 1.12)

42. Moisture control sponges must be installed dry when pre-packing the

BioPak. (Benchman: Section 1.12)

43. Apparatus that are pre-packed with the carbon dioxide scrubber shall be

stored within the specific storage temperature and humidity levels and must

be sealed air-tight in the apparatus. (Benchman: Section 1.12)

44. Failure to install the moisture pad will result in scrubber flooding and cause

elevated carbon dioxide levels in the inhalation gas. (Benchman: Section 1.12)

45. Users are not permitted to mix versions of the Orbsorb within a BioPak.

(Benchman: Section 1.12)

46. Install two carbon dioxide scrubber canisters into the breathing chamber

making sure that they are properly aligned and fully seated. (Benchman:

Section 1.12)

47. The alarm system battery shall be replaced after 200-hours of use, every 6-

months or after the alarm system low battery alarm flashes with

corresponding horn sounding. (Benchman: Section 3.4)

48. The oxygen cylinder must be fully charged to above 1500 psi to perform a

high pressure leak test. (Benchman: Section 2.6)

49. Use caution when installing the flow restrictor to insure that the O-ring does

not roll out of its gland. (Benchman: Section 3.5)

50. The Cylinder should be inspected regularly for signs of damage to the outer

14

wrapping. (Benchman: Section 3.3)

51. The Turn-Around Maintenance Tag should be attached to the apparatus in

a prominent location to show completion of all maintenance steps.

(Benchman: Section 1.1)

52. In addition to normal Turn-Around Maintenance, the SCBA shall be visually

inspected and pressure tested on a monthly basis if the apparatus is being

used at least once a month or is placed in long term storage. (Benchman Section:

2)

53. BioPaks that have been placed in long term storage should have the Long

Term Maintenance Procedure conducted every-6 months. (Benchman: Section 2)

54. The LED indication will cease when the pressure gauge reads less than 25 psi.

(Benchman: Section 1.10)

55. Never pry an O-ring from its glands with a screwdriver. Remove O-rings by

hand or with the pick tool provided in the service kit. (Benchman: Section 3.2)

56. Cristo-Lube and Dow-111 are the only lubricants approved for use in the

apparatus. (Benchman: Section 3.2)

57. Never lubricate the sealing washer that sits between the oxygen cylinder

and the pressure regulator. (Benchman: Section 3.2)

58. Cylinders that have been hydro-static tested shall be cleaned for high-pressure

oxygen service per national standards. (Benchman: Section 3.2)

59. Cylinders are to be retired from service 15-years after the date of

manufacture. (Benchman: Section 3.2)

60. The Alarm module will require replacement if any damage to the housing is

discovered. (Benchman: Section 3.)

61. If the flow does not meet the requirements of the table in the Bench Manual

the flow restrictor will need replacement. (Benchman: Section 1.8)

62. A good facemask seal is important to achieving full protection and

duration. (User/Benchman: Cautions and /LPLWDWLRQV6SHFLDORU&ULWLFDO8VHU·V

Instructions)

15

63. Personnel who intend to use protective breathing equipment in a

dangerous atmosphere must have the proper training, temperament and

experience. (User/Benchman: Cautions and Limitations, Special or &ULWLFDO8VHU·V

Instructions)

64. A clean shaven user will significantly increase the chances of achieving an

adequate face seal. (User/Benchman: Cautions and Limitations, Special or Critical

8VHU·V,QVWUXFWLRQV

65. The ongoing effectiveness and reliability of any protective breathing

HTXLSPHQWLVGHSHQGHQWXSRQWKHXVHU·VVWDQGDUGRIFDUHLQPDLQWDLQLQJ

the equipment. 8VHU%HQFKPDQ&DXWLRQVDQG/LPLWDWLRQV6SHFLDORU&ULWLFDO8VHU·V

Instructions)

66. The BioPak has been tested for intrinsic safety in methane-air mixtures

only. 8VHU%HQFKPDQ&DXWLRQVDQG/LPLWDWLRQV6SHFLDORU&ULWLFDO8VHU·V,QVWUXFWLRQV

67. The battery is to be changed in fresh air only. Do not change in hazardous

areas. (User/Benchman: Cautions and Limitations, SpeciaORU&ULWLFDO8VHU·V

Instructions)

68. The BioPak is a Self-Contained Closed Circuit Pressure Demand type

certified as Entry and Escape with a 4-hour duration. (Benchman: Section 6)

69. The constant Add is 1.8 liters average. (Benchman: Section 6)

70. The Demand Add flow is a minimum 80 liters per minute. (Benchman: Section 6)

71. The oxygen cylinder has a volume of 440 liters at 3000 psi. (Benchman: Section 6)

72. The BioPak breathing chamber has a Tidal Volume greater than 6

liters. (Benchman: Section 6)

73. For extreme temperature ranges, the BioPak should be configured with ice

coolers. When ambient temperatures are greater than 140 degrees F the

recommended duration is no more than 15 minutes and is limited by

human endurance. (Benchman: Section 6)

74. The emergency Add has a minimum flow rate of 80 liters per minute.

(Benchman: Section 6)

75. The BioPak operational conditions as it relates to relative humidity is 0 to

100%. (Benchman: Section 6)

16

76. BioPak weight fully charged is 34 pounds. (Benchman: Section 6)

77. Do not re-use CO2 scrubber chemical. (User/Benchman: Cautions and Limitations,

6SHFLDORU&ULWLFDO8VHU·V,QVWUXFWLRQV

78. The flow test results at 0-5280 feet at a cylinder pressure of 1500-2000 shall be 1.8-

2.4 liters per minute. (Benchman: Section 1.8)

79. During an alarm test the LED indication should turn to a flashing red with a

horn sounding when the pressure gauge reads between 650-1000 psi.

(Benchman: Section 1.10)

80. Do not allow oil, grease or other foreign materials to come in contact

with cylinder, cylinder valve or cylinder pressure regulator to prevent

possible ignition. (User/Benchman: Cautions and Limitations, Special or Critical

8VHU·V,QVWUXFWLRQV

81. The end of service life or low Oxygen alarm is a flashing red light and horn

sounding.

(User: Section 2.7)

82. The flashing blue light indicates an Ice Reminder. (User: Section 2.7)

83. The pressure gauge is protected against sudden loss of oxygen in the event of a

gauge line severing by a manual disconnect located at the gauge pass through

point of the housing. (User: Section 2.7)

84. A Pacemaker or other Cardiac Condition could limit or prevent the use of the

BioPak 240 Revolution. (User/Benchman: Cautions and Limitations, Special or Critical

8VHU·V,QVWUXFWLRQV

85. Breathing difficulties could limit or prevent the use of the BioPak 240

Revolution.

8VHU%HQFKPDQ&DXWLRQVDQG/LPLWDWLRQV6SHFLDORU&ULWLFDO8VHU·V

Instructions)

86. Claustrophobia or anxiety when wearing a SCBA could limit or prevent the

use of the BioPak 240 Revolution. (User/Benchman: Cautions and Limitations,

6SHFLDORU&ULWLFDO8VHU·V,QVWUXFWLRQV

87. The instructions provided by the USER and BENCHMAN manuals cannot

replace accredited training provided by qualified instructors in the proper

and safe use of Bio marine breathing apparatus. (User: Section 1.3)

88. X-Ray evidence of Pneumonia could limit or prevent the use of the BioPak 240

Revolution.

8VHU%HQFKPDQ&DXWLRQVDQG/LPLWDWLRQV6SHFLDORU&ULWLFDO8VHU·V

Instruction)

17

89. Epilepsy-Grand Mal or Petit Mal could limit or prevent the use of the BioPak

240 Revolution. 8VHU%HQFKPDQ&DXWLRQVDQG/LPLWDWLRQV6SHFLDORU&ULWLFDO8VHU·V

Instructions)

90. Use the ¼ inch hex driver from the service Kit to remove the flow restrictor.

(Benchman Section 3.5)

NOTE: The References listed above for the Statements of Facts

can be down loaded for free from Bio-PDULQH·VZHEVLWH.

18

BioPak 240 Revolution Complete

1 2

Cons. No. Designation

1 2

Cons. No. Designation

2 Upper Housing Assembly

3 Coolant Lid

4 Ice Canister

5 Breathing Hose

12 O2 Cylinder

13 Lower Housing Assembly

14 Harness Assembly

15 Ice Canister Freeze Form

19 Facemask Storage Plug

21 PCM Heat Exchanger

22 Moisture Absorbent Pad Set

19

Lower Housing

Ass

embly

1 2

Cons. No. Designation

1 2

Cons. No. Designation

1 Lower Housing Shell

2 Diaphragm Springs

3 External Oxygen Knob

7 Vent Spacer

12 Latch Foam Pad

16 Oxygen Cylinder Hold-Down Strap

18 Carrying Handle

20

Pneumatic

Ass

em

bl

y

1 2

Cons. No. Designation

1 2

Cons. No. Designation

1 Bypass Feed Tube

2 Bypass Return Tube

3 Oxygen Feed Tube

6 Bypass Valve Push Button

7 Bypass Valve

9 Oxygen Regulator Assembly

10 Remote Gauge Shut Off Assembly

11 Remote Gauge Assembly

12 Remote Gauge Feed Tube Assembly

21

Manifold

Ass

embly

1 2

Cons. No. Designation

1 2

Cons. No. Designation

1 Manifold Block w/ Pressure Switch

2 Constant Add Flow Restrictor Assembly

3 Swivel Elbow Fitting

22

Center Section Assembly

1 2

Cons. No. Designation

1 2

Cons. No. Designation

1 Lid O-Ring

2 Demand Feed Tube

4 Center Section Body Assembly

6 Constant Add Fitting

9 Demand Add Fitting

11 Demand Valve Gasket

12 Demand Valve Assembly

14 Flexible Diaphragm

15 Diaphragm Clamp

23

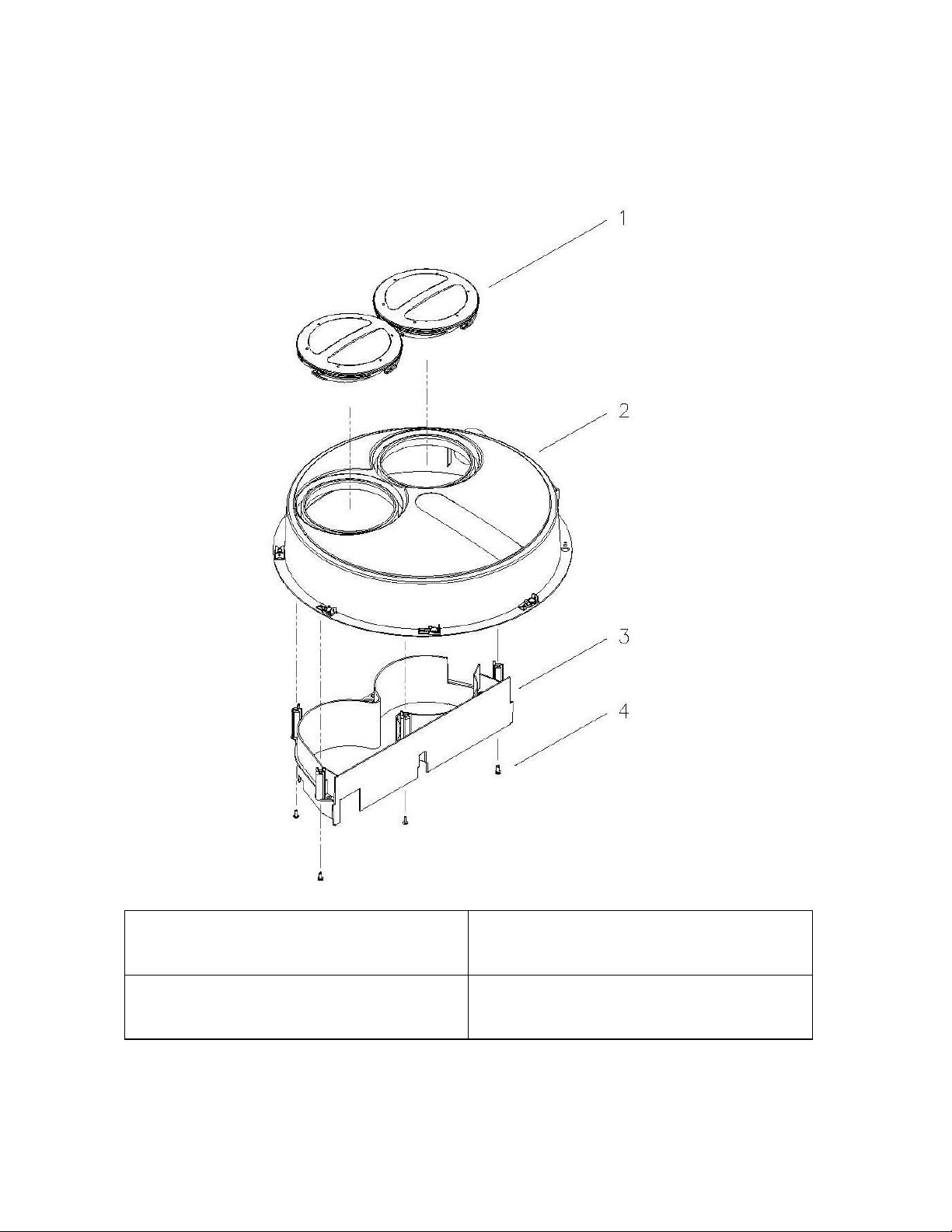

Center Section Lid Assembly

1 2

Cons. No. Designation

1 2

Cons. No. Designation

1 Coolant Lid

2 Center Section Lid

3 Flow Baffle

4 Self-Tapping Screws

24

Diaphragm

Ass

embly

1 2

Cons. No. Designation

1 2

Cons. No. Designation

1 Flexible Diaphragm

2 Vent Cap

3 Vent Body O-Ring

4 Vent Body

5 Vent Seat O-Ring

6 Vent Valve Spring

7 Vent Valve Seat

25

Breathing Hose

1 2

Cons. No. Designation

1 2

Cons. No. Designation

1 Breathing Hose

2 Worm Gear Hose Clamp

3 Stepless Ear Clamp

26

Ice Canister Freeze Form

1 2

Cons. No. Designation

1 2

Cons. No. Designation

1 Base Assembly

2 Freeze Tube

3 Top Plate

4 Wing Nut

27

Oxygen Cylinder Assembly

1 2

Cons. No. Desi

g

nation

1 2

Cons. No. Desi

g

nation

1 Green Cylinder

2 Exterior O-Ring

3 Valve Collar

4 Interior O-Ring

5 Valve Assembly

28

RMS Monitoring System

1 2

Cons. No. Designation

1 2

Cons. No. Designation

1 Battery Door

2 Battery Door Gasket

3 Battery Door Warning Label

5 9Vdc Battery

29

AV3500 F

ac

emas

k

-Com

pl

ete

Facemask

Ass

embly

5

13

4

10

1

7

2

3

12

9

6

8

ss

1 2

Cons. No. Desi

g

nation

1 2

Cons. No. Desi

g

nation

1 Interface Tube

2 Interface Gasket

3 Interface Fitting

4 Clip

5 Button

6 Cowling

7 Locking Pan Head Screw

8 Hose Adapter O-Ring

9 AV3500 Hose Adapter

10 Facemask Magnetic Wiper

12 Chin Condensation Pad

13 Lens

This manual suits for next models

1