CSL VARIVAC FC User manual

Copyright March 2001 – Steve Corkill

This manual subject to copyright and not to be copied without the express permission of Corkill Systems Limited

CSLVXXX-MANUAL-2013.DOC Page 1 June 5, 2013

Copyright March 2001 – Steve Corkill

This manual subject to copyright and not to be copied without the express permission of Corkill Systems Limited

CSLVXXX-MANUAL-2013.DOC Page 2 June 5, 2013

Varivac™

2013 Model

Instruction & Installer’s Manual

Contents

1. General Information

2. Mounting and wiring

3. Transducer Installation

4. LCP Keypad Operation and Parameter Editing

5. Motor Set Up and Automatic Motor Tuning

6. Auxiliary Equipment Setup

7. Vacuum Level Adjustment

8. Idle Speed Adjustment

9. Trouble Shooting

10. Common error messages

11. Help

12. Terms & Conditions of sale

Appendix A Installation Wiring Diagram

Appendix B Installation Layout

Appendix C Varivac Wiring Diagram

Copyright March 2001 – Steve Corkill

This manual subject to copyright and not to be copied without the express permission of Corkill Systems Limited

CSLVXXX-MANUAL-2013.DOC Page 3 June 5, 2013

1. General Information

The name “Varivac” is a protected Trademark belonging to Corkill Systems Limited,

unauthorised use of this name will lead to prosecution.

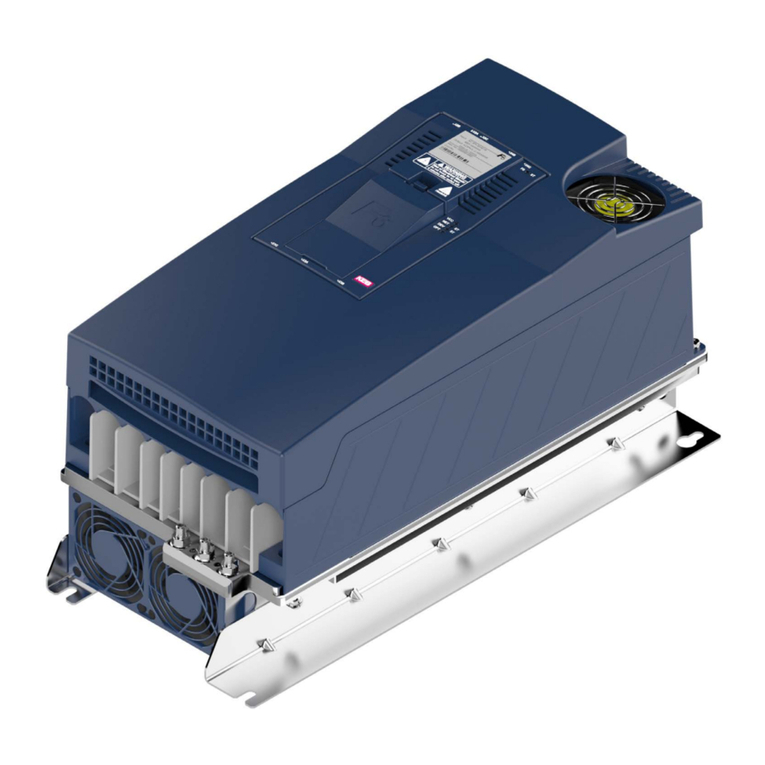

Varivac is available in standard motor sizes from 4 kilowatts to 30 kilowatts, model CSLV4B

has a 4 kilowatt capacity, CSLV5B is 5.5 kilowatt, etc.

A kit is available called the tandem kit witch will convert the VARIVAC into a Tandem pump

controller, this model controls two motors simultaneously and has individual motor circuit-

breakers to protect the motors. The Varivac should be sized for the combined rating of the

motors, e.g. 1 x 11Kw + 1 x 7.5Kw motor = 18.5Kw, therefore the model Varivac to be

ordered is a model CSLV18.5B and should be ordered with a tandem kit, part number

CSLVTANDEMKIT. Note; please specify sizes or current of motors when ordering the tandem

kit to ensure it is sent with the correct size motor overloads fitted.

Please note that not all sizes are available in single phase and dual phase units and the next

size up model may need to be purchased.

Tandem pump systems have been documented to be more economic to run with two motors

running, rather than switching one of the two motors off, plus the total reserve of the

combined motors is instantly available when required.

Cabling and Motor

The Varivac must be permanently wired on a dedicated circuit with protection according to the

controller specification sheet current ratings. The Varivac needs a continuous supply to

withstand its work environment (often damp and cold) and to allow for the ramp down function

to work correctly. If remote on/off switching is required, use the “remote start” terminals on the

Varivac.

Motor cables must be EMC type, 4 core screened with a dedicated earth conductor. This is an

essential factor in lowering the SCC in the plant.

This drive is C-Tick compliant and to comply with installation procedures metal glands must

be used on both the motor and controller. Example of a metal gland shown below.

If metal glands aren’t used, bond the screen using the supplied clamp at the Varivac. “Pigtail”

earths should be avoided at all times. The EMC cable screen must be bonded to earth at both

ends. Keep the motor tails as short as possible and clear of the incoming cable to prevent an

aerial effect. Use the following minimum sizes for 3 phase units, 2.5mm for up to 7.5Kw,

4.0mm for 11Kw and 15Kw, 6.0mm for 18.5Kw and over and on single phase units, 4mm for

up to 7.5Kw, 6mm for 15Kw and 15Kw, 8.0mm for 18.5Kw and over. Do not undersize cables,

larger is better to assist removal of RFI.

The above is also critical if cow ID systems are in use or being contemplated. The screen

should be retained over the cable as close as possible to the termination point (do not strip

the screen at the base of the switchboard and then run motor tails adjacent to other wiring -

the RFI effect will be transferred into any adjacent cables).

Copyright March 2001 – Steve Corkill

This manual subject to copyright and not to be copied without the express permission of Corkill Systems Limited

CSLVXXX-MANUAL-2013.DOC Page 4 June 5, 2013

The cable between the Varivac and Transducer is to be of minimum 0.2mm 2 core screened

twisted pair and not to be run parallel with heavy current carrying cables.

Belden type cable is preferred and we normally supply this with the Varivac. Earth the screen

at both ends and keep the tails as short as possible.

The power supply cable to the drive can be non screened TPS or similar cable, if the distance

to the drive is more than 15 metres, either step the above recommended cable size up or run

a separate large Earth conductor.

A Mains and RF filter is factory fitted internally in all controllers, this is normally adequate

however we recognize there are certain areas where this filter may not be sufficient to

suppress all radio interference, please contact us for more information if this is the case. The

filter system meets both Class I and Class II of the international standards that all controllers

are required to meet in Australasia for installation on networks containing either or both

commercial and residential installations.

Section 4 electrical installation of the FC300/FC200 Danfoss Operators Manual supplied with

this controller has more information regarding cabling and termination of VSDs, we strongly

recommend reading this section of this manual before commencing installation.

Some additional bonding may be required in order to remove RFI, talk to us if you think this

may be required.

The Low Voltage tolerance level with three phase controllers is 380 volts.

The Low Voltage tolerance level with single phase controllers is 198 volts

Voltage levels below this will cause nuisance tripping of the drive plus is likely to

cause damage to other electronic equipment in the dairy, contact your electrician or

network supplier if low voltage trips persist.

Copyright March 2001 – Steve Corkill

This manual subject to copyright and not to be copied without the express permission of Corkill Systems Limited

CSLVXXX-MANUAL-2013.DOC Page 5 June 5, 2013

2. Mounting and Wiring

Single Pump & Motor Combination

This system consists of one motor with one or more vacuum pumps attached.

1. Generally mount the Varivac adjacent the vacuum pump. The main factor in choosing

the Varivac location is keeping the EMC cable to the motor as short as possible.

2. Re-use the existing isolator normally at this point.

3. Remove power factor capacitor if connected (Varivac does this function).

4. Remove motor cable from the motor and re-terminate into the Varivac supply terminals

L1, L2 & L3 (L1 is the phase and L2 is the neutral on single phase units). Connect the

Earth to the screw/terminal provided.

5. Fit a new cable (EMC screened 4 core cable) from the Varivac terminals U,V,W to the

motor, in some models this is a plug – be sure to put the plug carefully back in to the

correct socket.

6. If the starter is at the switchboard and the farmer wishes to continue using the same

starter as previous to the Varivac installation, Remove the starter overload, connect the

incoming phases at the starter directly to the outgoing motor wires to keep power to the

Varivac continuously and then use this starter to switch the remote start terminals #5

& #6 to start and stop the Varivac. Any auxiliary equipment (pulsators/milk pump)

connected to this starter will then still be switched using the original contactor terminals.

7. If the farmer is happy to start at the Varivac, use terminals #12 and #13 to switch the

original starter or the attached auxiliaries – The maximum current through the sacrificial

relay is 5 Amp. If in doubt, use a driver relay.

8. If the starter is adjacent the pump, remove completely and switch any Auxiliary

equipment via terminals #12 and #13 in the Varivac – The maximum current through

the sacrificial relay is 5Amp.

9. If Star/Delta Starters are being replaced on three phase installations, connect motors

in 400 volt configuration, Delta on 400/600v motors and Star on 230/400v motors.

on single phase installations, connect motors in 230 volt configuration, Delta on

230/400v motors and Star on 110/220v motors –as a general rule configure the motor

in the same configuration as the intended supply voltage.

Check the motor name plate!.

Copyright March 2001 – Steve Corkill

This manual subject to copyright and not to be copied without the express permission of Corkill Systems Limited

CSLVXXX-MANUAL-2013.DOC Page 6 June 5, 2013

Tandem Pump & Motor Combination

This system consist generally of two motors wired separately each with one or more vacuum

pumps attached. These motors may be of different sizes, this does not matter!

1. Generally mount the Varivac close to the vacuum pumps. The main factor in choosing the

Varivac location is keeping the EMC cables to the motors as short as possible.

2. Re-use the existing isolators normally by the motors.

3. Remove power factor capacitors if connected (Varivac does this function).

4. Connect a new cable from a circuit-breaker or fuses sized to handle the combined

vacuum pump motors full load current to the Varivac.

5. Fit a new cable (EMC screened 4 core cable) from the Varivac terminals U,V,W to the motor

circuit breakers in the Tandem kit, and fit a new cable from the motor circuit breakers in the

Tandem kit to the motors. Set the correct motor currents on the overloads in the Tandem Kit.

6. If the starters at the switchboard are used to control auxiliary equipment, connect these to

terminals #12 and #13 in the Varivac – The maximum current through the sacrificial relay is

5Amp.

7. If the starters are adjacent the pump, remove completely and connect to the isolators.

8. If Star/Delta Starters are being replaced on three phase installations, connect motors in

400 volt configuration, Delta on 400/600v motors and Star on 230/400v motors.

on single phase installations, connect motors in 230 volt configuration, Delta on 230/400v

motors and Star on 110/220v motors –as a general rule configure the motor in the same

configuration as the intended supply voltage check the motor name plate!.

9. If the starter is at the switchboard and the farmer wishes to continue using the same starter

as previous to the Varivac installation, Remove the starter overload, connect the incoming

phases at the starter directly to the outgoing motor wires to keep power to the Varivac

continuous and then use this starter to switch the remote start terminals #5 & #6 to start and

stop the Varivac. Any auxiliary equipment (pulsators/milk pump) connected to this starter will

then still be switched using the original contactor terminals.

Copyright March 2001 – Steve Corkill

This manual subject to copyright and not to be copied without the express permission of Corkill Systems Limited

CSLVXXX-MANUAL-2013.DOC Page 7 June 5, 2013

3. Transducer Installation

General; mount the transducer as close to the cows as practical and possible, the sensing

face is VERY sensitive and easily damaged, be very careful with it.

Only mount the transducer in the Vacuum Interceptor when no other option is practical – it will

still work well but in high vacuum loss situations the vacuum at the cups will be lower than at

the transducer sensing face due to friction losses in the plant pipe work.

Herringbone Dairy – mount in the Hygienic Can as first choice or Milk Receiver as second

choice. The “Hygienic Can” can be drilled and a standard mounting kit used or insert in the

Milk Receiver, this will require the tri-clover fitting welded in (see photo).

NEVER mount the transducer as in the following picture.

This is a Very Bad location, which will cause all kinds of stability problems!!! The

transducer is mounted too close to the vacuum pump and welded directly into a very

small main air line.

Copyright March 2001 – Steve Corkill

This manual subject to copyright and not to be copied without the express permission of Corkill Systems Limited

CSLVXXX-MANUAL-2013.DOC Page 8 June 5, 2013

Rotary Dairy – mount as close as possible to the gland. Using a tee as in the installation

photos below moves the transducer out of direct air flow – this is good. There is often a spare

outlet in the gland, which is a good point to mount the transducer – beware of the transducer

being accidentally knocked by operators or moving pipe work. Where possible mount the

transducer upright to protect against moisture ingress.

Protect the transducer Belden cable through the duct with conduit or flexi-conduit as vibration

can crush the cable or rodents may chew it.

Connections:

Single pair screened Belden cable is supplied with the Varivac, connect the white to terminal

#1 at both the Transducer and the Varivac and Black to terminal #2 with the drain wire

connected to Earth at the Varivac end.

Avoid running the transducer cable parallel with high current and/or voltage cables as

interference can be induced into the cable. Make cables as short as possible inside the drive

and strip off the minimum of sheathing on the cable to lessen interference induced into the

cable. Ensure the cable always faces down from the gland, to prevent water running down the

cable from entering the transducer.

Copyright March 2001 – Steve Corkill

This manual subject to copyright and not to be copied without the express permission of Corkill Systems Limited

CSLVXXX-MANUAL-2013.DOC Page 9 June 5, 2013

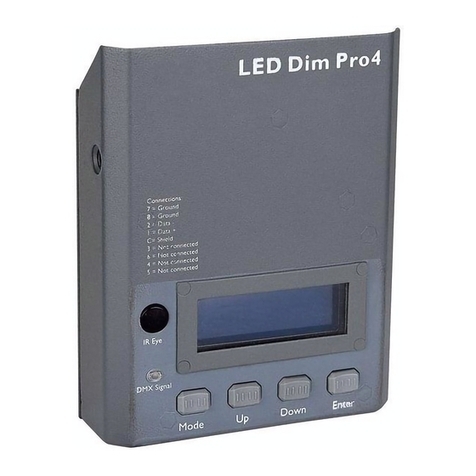

4. LCP Keypad Operation and Parameter Editing

Status Display To display the current operation of the drive and all status messages of the

Varivac, press the “Status” button. Press the “Status” button repeatedly to scroll through the

various states of the drive, to check operation of the drive and for diagnostics.

My personal menu To display the current user modifiable parameters of the drive press the

“Quick Menu” button on the front of the lcp followed by the “OK” key

My personal menu These are the user modifiable parameters that are used when setting

up the Varivac. These parameters include motor power, vacuum levels, automatic motor

adaptation, motor ramp times, low and high speed limits etc…

Pressing the up and down button will scroll through the various settings of the Varivac. These

are the settings that are used when commissioning the Varivac. All relevant settings are in

this menu to make it easy for anyone to install and set up a Varivac unit. Press the “OK”

button on any parameter to change its value. Once the right value is entered press the “OK”

button to store the value.

Current setup and setup in

edit

Current vacuum set

-

point

Status display

Current operation of d

r

ive and

warnings

Total

K

w used

R

unning hours

Current

parameter

Current parameter value

Copyright March 2001 – Steve Corkill

This manual subject to copyright and not to be copied without the express permission of Corkill Systems Limited

CSLVXXX-MANUAL-2013.DOC Page 10 June 5, 2013

5. Motor Set Up and Automatic Motor Tuning

Programming To make program changes press “Quick menu” key on the front of the LCP

followed by the “OK” key. Press the “Status” key to exit.

How to stop and start the drive while programming, to prevent unintentional starts

The drive can be stopped by pressing the “Off” key on the LCP. Press the “Auto on” key to

return the unit to run mode

Explanation of setups in the drive unit The drive contains four setups; milk/herd test

(setup 1), milk/herd test safety (setup 2), wash (setup3) and wash safety (setup 4).

In normal setups 1 and 3 the Varivac has the ability to over speed the motor to gain extra

reserve. This extra reserve assists in pulling up the bungs at the start of milking, and is

available any time vacuum problems arise.

The safety setups 2 and 4 prevent the motor from overloading. After running at high speed for

60 seconds the drive will jump back into a fail safe program and limit the speed of the motor.

How to edit a certain setup Select “My personal menu” from the “Quick menu” and press

the “Ok” key. Scroll down to parameter 011, press “Ok”, select the setup you wish to edit and

press the “Ok” key.

If the drive is in stop mode as explained in “How to stop and start the drive while

programming, to prevent unintentional starts” you can switch setups using the control switch

on the front of the drive but you can not switch into the safety setups.

Explanation of parameters in the quick menu The parameters in the quick menu are

dependant on which setup the drive is in. The setup is displayed in the top right corner as

explained in “LCP Keypad Operation and Parameter Editing”.

For example preset reference 2 will have no effect on the herd test vacuum if you edit in setup

3 or 4. The parameters can be edited in the same manor as explained in “How to edit a

certain setup”. Some of the settings cannot be modified when the drive is in run mode. To edit

these settings stop the drive as explained in “How to stop and start the drive while

programming, to prevent unintentional starts”.

Main Menu This menu is password protected, if it is necessary to access this menu

please phone Corkill Systems Limited for assistance.

Motor Set Up

With power on to the drive, press “Off” then “Quick Menu”.

Turn the selector switch on the drive to “Milk”, check and if necessary set the motor

parameters #120 through to #125 as above. All other set ups will automatically update.

While in “Milk”, turn on Parameter #129 “Auto Motor Adapt”. Press “Auto On” and the drive

will carry out the Auto Tuning function (not required if fitting a Tandem Kit). A message will be

displayed when tuning is complete. Turn selector switch to “Off” before pressing “Reset”. The

Varivac should be ready to use.

Copyright March 2001 – Steve Corkill

This manual subject to copyright and not to be copied without the express permission of Corkill Systems Limited

CSLVXXX-MANUAL-2013.DOC Page 11 June 5, 2013

Parameters in the Quick Menu

Parameter no#

011 Edit setup (The current setup being edited)

120 Motor power in Kw (from name plate data)

122 Motor voltage (from name plate data)

123 Motor frequency (50 Hz international motor or 60 Hz American motor)

124 Motor current (from name plate data)

125 Motor nominal speed (from name plate data)

126 Motor continuous rated torque (from name plate data) or 100%

129 Auto motor adapt function (for automatic tuning of motor)

139 Motor poles 2 poles for 2800rpm 4 for 1450 rpm and 6 for 960 rpm motor

190 Thermal overload setting (used for setting up tandem models)

310 Preset vacuum kPa

311 Jog speed in Hz (speed in test mode)

351 Ramp up speed

352 Ramp down speed

412 Motor low speed limit in Hz

414 Motor high speed limit in Hz

451 Warning current high( will indicate warning limit)

453 Warning speed high (used to set the speed limit when switching to and from

safety setups)

456 Warning feed back low (used to warn vacuum high and to set the low speed

running kit cut in vacuum)

1450 Disable RFI filter (for use with rcd protected circuits)

Parameter no# Setup 1 Setup 2 Setup 3 Setup 4

310.0 Milk vacuum

(kPa)

Milk safety

vacuum (kPa)

Wash vacuum

(kPa)

Wash safety

vacuum (kPa)

310.1 Herd test

vacuum (kPa)

Herd test safety

vacuum (kPa)

Not used Not used

351 Milk ramp up

time

Milk safety

ramp up time

wash ramp up

time

wash safety

ramp up time

352 Milk ramp up

time

Milk safety

ramp up time

wash ramp up

time

wash safety

ramp up time

Copyright March 2001 – Steve Corkill

This manual subject to copyright and not to be copied without the express permission of Corkill Systems Limited

CSLVXXX-MANUAL-2013.DOC Page 12 June 5, 2013

6. Auxiliary Equipment Setup

Switching auxiliary equipment via the Varivac

For remote switching of auxiliary equipment use the sacrificial Relay contacts on DIN rail

terminals #12 and #13. This is a programmable clean set of contacts to operate pulsators

cooler pumps etc...

Warning - this relay will switch up to 400 volts do not load to more than 5 amps !!

Using the Danfoss relay #2 directly is not recommended. No warranty will be recognised if

this relay has been overloaded.

The relay is factory programmed to operate whenever the drive is running. It can be

programmed to operate on a variety of different functions using parameter 540 in the quick

menu.

Another option is to use a 24 VDC driver relay and connect the coil across terminal #20 on

the Danfoss drive and the start signal from the DIN terminal #8, this gives an independent

clean set of contacts for auxiliary equipment.

The power supply within the drive is rated at 120mA and can only drive a maximum of two

Omron GSR1/2 type relays (there are spare din rail mounts to attach up to two relays within

the drive). The drive will not drive a contactor directly and severe damage will result to the

control card/smps if the power supply is overloaded. No warranty will be recognised if the

control card is damaged as a result of overloading.

Switching Varivac to Wash via remote

For remote switching of the Varivac to “WASH” join the DIN rail terminals #6 & #10 together

using the remote switch.

Switching Varivac to start via remote

For remote starting of the Varivac join the DIN rail terminals #5 & #6 together using the

remote switch or existing spare contact on plant start contactor.

Auxiliary wiring connections recommendations

To avoid interference we recommend using screened cable (like the Belden transducer cable

supplied with the Varivac) to connect the Varivac to auxiliary equipment or vice versa.

For interfacing with 230 or 400 volt controls, use slave relays and low voltage screened

Belden or equivalent cable to bring back switch signals to the Varivac. Remember to earth

both ends of the cable screen.

Make cables as short as possible inside the drive and strip off the minimum of sheathing on

the cable to lessen interference being induced into the cable.

Copyright March 2001 – Steve Corkill

This manual subject to copyright and not to be copied without the express permission of Corkill Systems Limited

CSLVXXX-MANUAL-2013.DOC Page 13 June 5, 2013

7. Vacuum Level Adjustment

Setting the air regulator(s)

There are two basic types of air regulators; remote sensing and the standard type. Remote

sensing types have a long pipe attached to the air regulator and to a sensor. The sensor is

mounted on the main vacuum line above the pit in herringbone sheds or close to the gland in

rotary sheds. All air regulators have an adjustment screw that is used to set the vacuum level

in the plant. The remote types have the adjustment at the sensor. Partial disassembly of

some types is necessary. Usually the setting screw is contained within a rubber or plastic cap

on the top or side, and in the center of the device. Some types have a locking nut or screw to

stop vibration altering the adjustment.

To read the plant vacuum level setting, run the Varivac in “TEST” mode and check the

existing vacuum level on the gauge within the shed. Take a note of this setting.

After locating the adjustment screw for the air regulator, adjust the air regulator(s) one at a

time by turning the screw until the vacuum is set between four and six kPa above the vacuum

level as noted above.

Setting the Varivac vacuum level

If the type of shed was stated when ordering, the Varivac will be preset for the following:

Rotary sheds; Milk – 43kPa, Wash – 42kPa, Herd Test – 44kPa.

Herringbone sheds; Milk – 46kPa, Wash – 45kPa, Herd Test – 47kPa.

If no shed was stated, the settings will be as for a rotary shed.

Note that commonly sold vacuum gauges are very rarely accurate. The above settings are

factory calibrated to the transducer supplied with the Varivac. If your gauge reads different to

the above settings it is very likely the gauge is inaccurate.

To adjust the vacuum level from these preset levels; Start the drive in the mode you wish to

adjust the vacuum for, and press “Quick menu” followed by “Ok”. Scroll to Parameter #310

“preset reference” and press “Ok”. Select the reference you wish to adjust (zero for milk/wash

and one for herd test) and press “Ok”. The drive will display the vacuum level, use the keys to

adjust, and press “Ok” to store the setting.

8. Idle Speed adjustment

Water Ring Vacuum Pumps

Run the plant up to vacuum with the selector in “MILK” and then open one cluster.

Close the cluster and listen to the pump while observing the plant vacuum level, the vacuum

level may rise slightly at this point, this is normal.

If the pump hunts (vibrates and races up and down violently), go to Parameter #412 and

raise the setting until the pump just stops hunting (a collapsing water ring causes this effect).

For older 1:1 driven pumps this is normally in the range of 30 – 35 Hz. With close coupled

pumps such as Siemens, Robuschi or Flomax WRC series this setting will generally be

between 25 and 30Hz.

If the pump does not hunt but the vacuum rises significantly (more than 2kPa), lower the

Parameter #412 settings to just above the water ring collapse position. Different models of

water ring pumps have different minimum speeds depending on required plant vacuum level,

plate adjustment, incoming water temperature and pump scaling or wear.

Set Parameter #412 to this setting in “WASH” and “HERD TEST” setups as well.

Copyright March 2001 – Steve Corkill

This manual subject to copyright and not to be copied without the express permission of Corkill Systems Limited

CSLVXXX-MANUAL-2013.DOC Page 14 June 5, 2013

The factory maximum speed setting is 55 Hz. This can be adjusted by opening clusters until

the top speed is reached (this can be seen on the screen, press the “Status” button if

required). The speed can be raised or lowered by changing Parameter #414. Set the

maximum speed so that the kilowatt reading is approximately 15% above the nameplate

rating. The Varivac will only allow this overload for 60 seconds, after which it will switch to a

safety mode with a maximum speed of 50 Hz until the clusters are closed again.

Blower and Oil Vane Vacuum Pumps.

Run the plant up to vacuum with the selector in “MILK” the vacuum level may rise slightly at

this point. If the vacuum level rises, lower the minimum speed of the pump using Parameter

#412 until the vacuum level returns to the normal milking level.

Set Parameter #412 to this setting in “WASH” and “HERD TEST” setups as well.

The factory maximum speed setting is 55 Hz. This can be adjusted by opening clusters until

the top speed is reached (this can be seen on the screen, press the “Status” button if

required). The speed can be raised or lowered by changing Parameter #414. Set the

maximum speed so that the kilowatt reading is approximately 15% above the nameplate

rating. The Varivac will only allow this overload for 60 seconds, after which it will switch to a

safety mode with a maximum speed of 50 Hz until the clusters are closed again.

Low speed running problems in pumps and the low speed running kit.

High speed or high performance types of vacuum pumps may clatter or lose their water ring

when running at extreme low speeds. This happens when all clusters are closed and no air is

admitted to the plant. This is normal for these pumps and will stop when the cups are placed

on the cows and some air is being admitted to the plant.

The effect is caused by the vanes or water within the pump dropping as there is not enough

centrifugal force to hold them out when there is no air coming into the plant.

This can be overcome by increasing the minimum speed of the pump such that it minimizes

the clatter or hunting and doesn’t increase the vacuum too much at idle.

Incorrectly adjusted water ring pumps can hunt severely. Sometimes all that is required is a

small end plate adjustment. This is a sensitive adjustment and should only be carried out by

someone who understands this procedure.

If a smooth idle speed cannot be achieved, a special low speed running kit is available. This

kit will bleed air into the plant in relation to the minimum effective speed of the pump. The kit

is fully adjustable as to where and when the valve opens and closes, and is also adjustable as

to how long the valve takes to open.

Contact Corkill Systems Limited if you think this kit may be required (an additional charge will

apply for this kit).

9. Trouble Shooting

Drive won’t start.

Cause: Remote start not wired properly, drive is in “Local Stop”, overloads tripped (tandem

models only).

Remedy: Check to see if overloads are tripped (tandem models only) reset if necessary and

set them to the correct current rating for the motors.

Check to see if remote start is wired correctly by placing a wire link between the remote start

terminals.

The drive may show local stop on the display. Press “Auto on” on the control panel of the

Danfoss Drive.

Copyright March 2001 – Steve Corkill

This manual subject to copyright and not to be copied without the express permission of Corkill Systems Limited

CSLVXXX-MANUAL-2013.DOC Page 15 June 5, 2013

Drive won’t speed up in variable speed modes

Cause: Internal reference set points are set incorrectly. Break in transducer cabling or

transducer wired incorrectly into Varivac.

Remedy: Check to see if Varivac is working by temporarily shorting terminals #1 and #2.

Drive should speed up indicating that there is a fault with the reference adjustment or

transducer. In the main display use the up or down button to check the transducer current on

terminal #54, if the current is zero then there is an open circuit in the transducer cabling or the

wiring of the transducer plug.

If the current is at or above 4mA then the transducer connections are inverted or the vacuum

adjustment simply needs adjusting to the correct vacuum level in the plant, see “Set Up and

Automatic Motor Tuning”.

Drive won’t slow down in Milk/Wash/Herd Test

Cause: Short in transducer cabling. Air regulator set to close to Varivac and is drawing air.

Plant not gaining vacuum due to pump loss of prime (water ring only), or major air leak.

Remedy: Check for air leaks. Check air regulator setting. Check pump water supply. If the

plant has some vacuum, check the vacuum level setting.

In the main display use the up or down button to check the transducer current on terminal

#60. If the current is 20mA, there is a short circuit fault in the transducer cabling or the wiring

of the transducer plug.

Drive won’t switch between modes (set ups)

Cause: Drive is forced into a setup.

Remedy: Check that the drive switches between setups by switching the selector switch.

The number of the set up (mode) will show in the top right corner of the LCP screen.

Setup #1 = Milk; Setup #3 = Wash, setups #2 and #4 are safety setups only if the vacuum

pump is run overloaded for more than 60 seconds.

If the drive doesn’t switch between setups, select “multi setup” for parameter #010.

Drive draws excessive kilowatts and trips out.

Cause: Maximum speed set to high. Pumps being over-driven or overseas spec motor.

Remedy: Lower the top speed if necessary or change the belt pulley ratio.

Some motors draw more current then specified on the name plate at New Zealand supply

rating, especially on multi volt European motors. Lower the top speed a little to reduce the

current it will draw.

10. Common Error Messages.

WARNING/ALARM 4 Phase fault (MAINS PHASE LOSS).

Cause: A phase is missing on the supply side or the mains voltage imbalance is too high.

This message can also appear if there is a fault in the input rectifier of the frequency

converter.

Remedy: Check if all 3 Phases are present at the Varivac. If these are OK, check other 3

Phase equipment in the Dairy shed to make sure your power supply to the Dairy shed is OK.

Turn off the Varivac completely for 40 sec then back on. You might need to press “Reset”,

followed by “Auto On” on the Danfoss Drive.

WARNING 6 Voltage warning low (DC LINK VOLTAGE LOW).

Cause: The intermediate circuit voltage (DC) is below the under voltage limit of the control

system. The incoming voltage to the Varivac is too low for it to operate.

Remedy: There could be a fault with the power lines. The voltage will need to be returned to

normal for the Varivac to operate

WARNING/ALARM 9 Inverter Overload (INVERTER TIME).

Copyright March 2001 – Steve Corkill

This manual subject to copyright and not to be copied without the express permission of Corkill Systems Limited

CSLVXXX-MANUAL-2013.DOC Page 16 June 5, 2013

Cause: The electronic, thermal inverter protection reports that the frequency converter is

about to trip because of an overload (current too high for too long). The counter for the

electronic, thermal inverter protection gives a warning at 98% and trips and enters alarm state

at 100%. The frequency converter cannot be reset until the counter is below 90%.

The fault is that the frequency converter is overloaded by more than 100% for too long.

Remedy: Too many cups open for too long, too many ramps due to a flushing pulsator in

“Milk” when the Varivac should be in “Wash”. Incorrect motor data has been put into the drive.

Turn off the Varivac completely for 40 sec then back on. You might need to press “Reset”,

followed by “Auto On” on the Danfoss Drive.

WARNING/ALARM 13 Over current (OVERCURRENT).

Cause: The inverter peak current limit (160% of the rated current) has been exceeded. The

warning will last approx 1 – 2 seconds, after which the frequency converter will trip and enter

alarm state.

Remedy: Turn the frequency converter off and check whether the motor shaft can be turned

and whether the motor size matches the frequency converter.

Too many cups open for too long, excessive air emissions, incorrect motor data has been put

into the drive. Turn off the Varivac completely for 40 sec then back on. You might need to

press “Reset”, followed by “Auto On” on the Danfoss Drive.

ALARM 14 Earth fault (EARTH FAULT).

Cause: There is a discharge from the output phases to earth. Either the motor or the cable to

the motor has a short to earth, or a drive output IGBT may be shorted.

Remedy: Make sure no power factor capacitor is fitted to the motor. An Electrician will have

to check if the short is in the motor, cable or drive. Turn off the Varivac completely for 40 sec

then back on. You might need to press “Reset”, followed by “Auto On” on the Danfoss Drive.

ALARM 16 Short-circuit (CURR.SHORT CIRCUIT):

Cause: There is a short circuit on the drive output. This could be in the cable, isolator, motor

terminals or windings or a drive output IGBT may be shorted.

Remedy: An Electrician will have to check if the short is in the motor, cable isolator or drive.

Disconnect the drive at the motor output terminals and turn the Varivac back on to prove the

controller is OK. Turn off the Varivac completely for 40 sec then back on. You might need to

press “Reset”, followed by “Auto On” on the Danfoss Drive.

Copyright March 2001 – Steve Corkill

This manual subject to copyright and not to be copied without the express permission of Corkill Systems Limited

CSLVXXX-MANUAL-2013.DOC Page 17 June 5, 2013

11. Help!!!

A full list of warnings and alarms are listed at the rear of the Danfoss Operating Instructions

supplied with the Varivac. Please check these and take note of the Error Code before phoning

for assistance. We need to know the code in order to help you.

The Varivac has a 24 month warranty; this warranty does not cover water or physical damage

and is for free replacement of components. The parts sent will be charged for, until the faulty

parts are returned to Corkill Systems for evaluation and credit.

Labour, travelling or any subsequent loss will not be paid or subsidised. If you have a

problem, please phone as soon as possible for assistance to minimise the time spent fault

finding. Please state that you have a Varivac problem and have any Error Codes available.

In the interests of improvement and clarity, we welcome any suggestions regarding this

manual or the Varivac product.

Any problems, anytime, anywhere,

Phone (06) 761 7531 (International Code ++64 6 7617531)

Fax (06) 761 7336,

Email; info@corkillsystems.co.nz

Web; www.corkillsystems.co.nz

Corkill Systems Limited

5 Tasman Street, PO Box 16

Opunake 4616

Taranaki

New Zealand

This product is manufactured to NZ Electrical Standard AS/NZS 3000:2007.

It has been tested and is safe to be used when installed as per our installation

instructions.

Visit www.corkillsystems.co.nz for product compliance documentation.

Copyright March 2001 – Steve Corkill

This manual subject to copyright and not to be copied without the express permission of Corkill Systems Limited

CSLVXXX-MANUAL-2013.DOC Page 18 June 5, 2013

12. TERMS AND CONDITIONS OF SALE

GENERAL

All quotations, orders and contracts for the sale or supply of goods or services by Corkill Systems Limited shall unless, otherwise agreed in

writing, be subject to the following terms and conditions:

1. ORDERS

All orders are made and accepted on the terms and conditions here stated. Order cancellations are subject to terms agreed as at time of

cancellation.

2. PRICES Prices quoted remain firm for 30 days but beyond that time prices may be adjusted.

3. DELIVERY

Delivery dates given by Corkill Systems Limited are approximate and rely on prompt receipt of all necessary information regarding

the order. Corkill Systems Limited will use their best effort to meet the estimated date but will not be held liable for any delay due to

circumstances arising in the industry generally or within Corkill Systems Limited work due to delay in receipt of supplies from sub-

contractor or any other circumstances beyond Corkill Systems Limited control. No liability will be taken for any late deliveries

unless delivery date has been guaranteed by Corkill Systems Limited in writing. Otherwise Corkill Systems Limited will use its best

endeavour to meet delivery dates.

4. DELIVERY CHARGES

Unless otherwise agreed in writing or at the discretion of Corkill Systems Limited, all freight will be charged to the Purchaser’s

account.

5. RETURN OF GOODS

No goods may be returned without prior written approval of Corkill Systems Limited and may be subject to a restocking fee.

Approval will be contemplated by Corkill Systems Limited only in circumstances where:

5.1 Advice of any proposed return is given within 30 days following the date of the invoice.

5.2 Transportation and other costs for return are prepaid by the Purchaser

5.3 Goods to be accompanied by a copy of Corkill Systems Limited Packing Slip or Invoice

5.4 Goods to be accompanied by a written explanation of reasons for return.

5.5 Corkill Systems Limited may charge for handling, inspection, disassembly or reconditioning stock items.

5.6 Units manufactured, modified or imported as special or unique units will only be accepted for credit

less the cost of converting the unit back to a standard saleable unit.

6. TERMS OF PAYMENT

All goods shall be paid for on the 20th day of the month following delivery. Corkill Systems Limited may at any time require full or

part payment in advance of delivery and the purchaser shall not be entitled to any damages or compensation arising from such

requirement. Goods on time payment shall be subject to the conditions on the Time Payment contract in addition to the terms

contained within this document.

7. PRODUCT SAFETY

Corkill Systems Limited products are supplied and manufactured to high standards but no electrical equipment is failsafe within

itself. When risk to person or property may be involved a fail-safe device should be an integral part of the equipment, the entire

responsibility for which rests with the Purchaser.

8. OWNERSHIP OF GOODS

The goods shall remain the property of Corkill Systems Limited until they have been fully paid for. Risk shall pass to the purchaser

on delivery. The purchaser will insure the goods. The purchaser acknowledges that it is in possession as agent and bailee for

Corkill Systems Limited and owes a fiduciary duty to Corkill Systems Limited until such time as legal and equitable title shall

transfer. The purchaser’s right to possession of unpaid goods shall terminate on demand by Corkill Systems Limited, which may

enter or authorise an agent to enter the purchaser’s premises to recover the goods.

9. PRODUCT WARRANTY

Provided that the product has been subjected to normal and proper use only, all new products supplied by the company are

warranted to be free from defects in materials and workmanship from the date of shipment to the Purchaser either for one year or

the Manufacturers warranty term subject to the following conditions:

10.1 All electrical equipment to be installed and commissioned by qualified trade-persons.

10.2 Adequate measures to be taken against moisture and/or mechanical damage.

10.3 Recommended cabling procedures and/or circuitry protection must be provided.

10.4 Suitable overload protection be provided and installed where required.

10.5 All faulty components to be returned to Corkill Systems Limited before a credit can be made.

In the event of equipment failure, all faulty components will be repaired or replaced free of charge, consequential loss/equipment

damage and/or labour and/or travelling will not be subsidised. Any unauthorised dismantling, repair or modification voids this

warranty.

10. LIABILITY UNDER WARRANTY

Corkill Systems Limited liability under this warranty or any other warranty whether express or implied in law or fact shall be limited

to the repair or replacement of defective material and workmanship and in no event shall Corkill Systems Limited be liable for

consequential or indirect damages.

11. GOVERNING LAW This agreement shall be construed according to the laws of New Zealand.

Copyright March 2001 – Steve Corkill

This manual subject to copyright and not to be copied without the express permission of Corkill Systems Limited

CSLVXXX-MANUAL-2013.DOC Page 19 June 5, 2013

VARIVAC Installation Data Sheet

Customer Name.................................................................. Installation Date......................................

Postal Address.......................................................................................................................................

Delivery Address....................................................................................................................................

Phone ...................................... Fax......................................... Mobile.................................................

Email....................................... Purchased from....................................................................................

----------------------------------------------------------------------------------------------------------------------------

Installer Business Name........................................................................................................................

Installer Technician Name....................................................................................................................

Postal Address.......................................................................................................................................

Delivery Address....................................................................................................................................

Phone ...................................... Fax......................................... Mobile.................................................

Email....................................

----------------------------------------------------------------------------------------------------------------------------

-

VARIVAC Model #......................... Serial #....................................................VLT Model....................

Manufacture Date..........................Program................................................Software Version..................

Tested by.........................................................................Signed...............................................................

----------------------------------------------------------------------------------------------------------------------------

--

Shed Type...................................................................................Shed Size...............................................

Master Vacuum Pump Type...................................................... Model..................................................

Slave Vacuum Pump Type...........................Model..........................Starter Type.....................................

VARIVAC Mounting position................................... Transducer Mounting position..............................

(ie switchboard/machine room/store) (ie Interceptor/Sanitary Can)

Check Valve installed on Master Pump Inlet / Exhaust Y / N Slave Pump Inlet / Exhaust Y /

N

Master Pump Motor Make.................................................Model.........................................Kw...............

RPM.......................................Nominal Voltage...................................Amps.............................Hz............

Auto Motor Adaption done ...Y / N Program uploaded to LCP..... Y / N

Installer Name.............................................................................. Signed.................................................

for any concerns or comments, please note separately and fax with this form

Copyright March 2001 – Steve Corkill

This manual subject to copyright and not to be copied without the express permission of Corkill Systems Limited

CSLVXXX-MANUAL-2013.DOC Page 20 June 5, 2013

SWITCH BOARD

VARIVAC

USE EMC/CBS FLEX

MOTOR

SHEILDED BELDEN CABLE FOR REMOTE START.

EARTH BOTH ENDS

OUT TO AUX

L1 L2 L3 U V W

1 2 3 4 5 6 7 8 9 10 11 12 13

SHEILDED BELDEN CABLE FOR

TRANSDUCER.

EARTH BOTH ENDS

SLAVE START RELAY

EXISTING PLANT START

CONTACTOR

TERMINALS #12 AND 13 ARE CLEAN CONTACTS FOR

PULSATORS ETC…

CORKILL SYSTEMS Ltd

5 Tasman St, PO Box 16

OPUNAKE, TARANAKI. NEW ZEALAND

Ph (06) 761 7531 Fax (06) 761 7336

INSTALLATION WIRING DIAGRAM FOR

VARIVAC

TM

2008 MODEL

25 March 2008

CSLVXXX-INSTALL-WIRING-2008.pub

Table of contents