- 1 -

i3B_IBD5F REV4_0909

User Start-up Guide

MicroSD

Card slot

This equipment is suitable for use in Class I, Division 2,

Groups A, B, C and D or Non-hazardous locations only

WARNING: EXPLOSION HAZARD –

Do not disconnect

equipment unless power has been switched off or the area is known to

be non-hazardous.

AVERTISSEMENT - RISQUE D'EXPLOSION -

AVANT

DE DECONNECTOR L'EQUIPMENT, COUPER LE COURANT OU

S'ASSURER QUE L'EMPLACEMENT EST DESIGNE NON

DANGEREUX.

WARNING:

To avoid the risk of electric shock or burns, always

connect the safety (or earth) ground before making any other

connections.

WARNING:

To reduce the risk of fire, electrical shock, or physical

injury it is strongly recommended to fuse the voltage measurement

inputs. Be sure to locate fuses as close to the source as possible.

WARNING

:Replace fuse with the same type and rating to provide

protection against risk of fire and shock hazards.

WARNING

:In the event of repeated failure, do not replace the fuse

again as a repeated failure indicates a defective condition that will not

clear by replacing the fuse.

WARNING: EXPLOSION HAZARD –

Substitution of

components may impair suitability for Class I, Division 2

AVERTISSEMENT - RISQUE D'EXPLOSION -

LA

SUBSTITUTION DE COMPOSANTS PEUT RENDRE CE

MATERIAL INACCEPTABLE POUR LES EMPLACEMENTS DE

CLASSE 1, DIVISION 2

WARNING: EXPLOSION HAZARD

- BATTERIES MUST

ONLY BE CHANGED IN AN AREA KNOWN TO BE NON-

HAZARDOUS

AVERTISSEMENT - RISQUE D'EXPLOSION -

AFIN

D'EVITER TOUT RISQUE D'EXPLOSION, S'ASSURER QUE

L'EMPLACEMENT EST DESIGNE NON DANGEREUX AVANT

DE CHANGER LA BATTERIE

WARNING:

Battery May Explode If Mistreated. Do Not Recharge,

Disassemble or Dispose Of In Fire

WARNING:

Only qualified electrical personnel familiar with the

construction and operation of this equipment and the hazards involved

should install, adjust, operate, or service this equipment. Read and

understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in

severe bodily injury or loss of life.

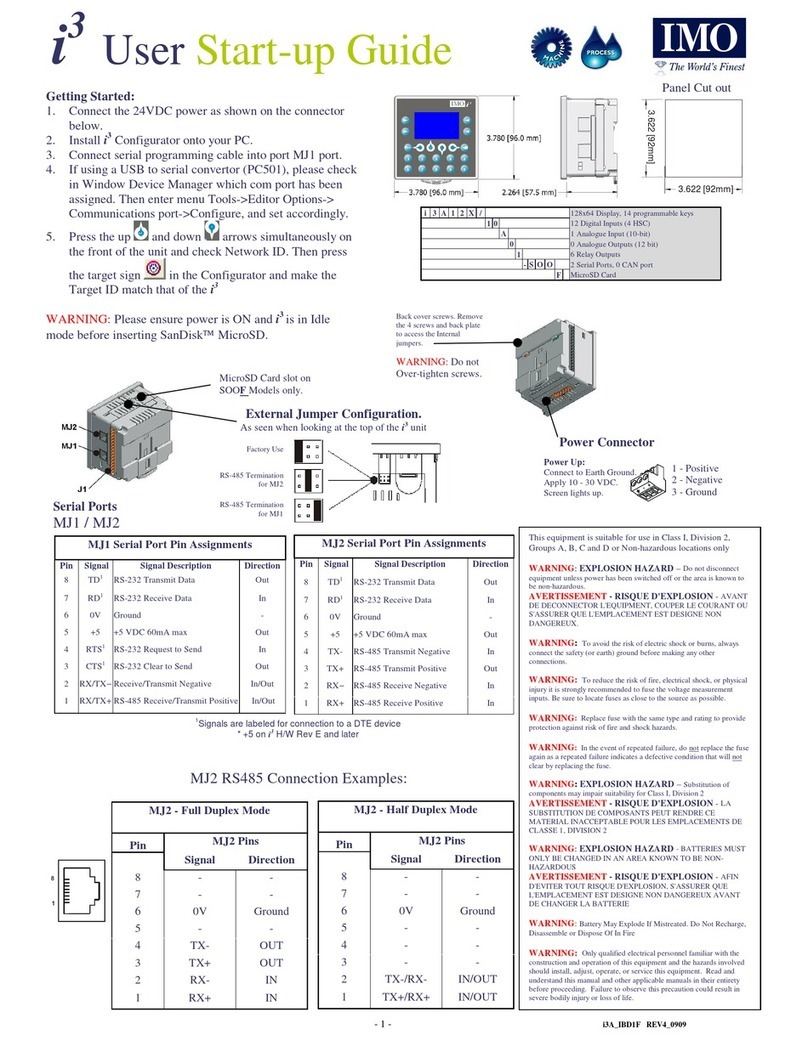

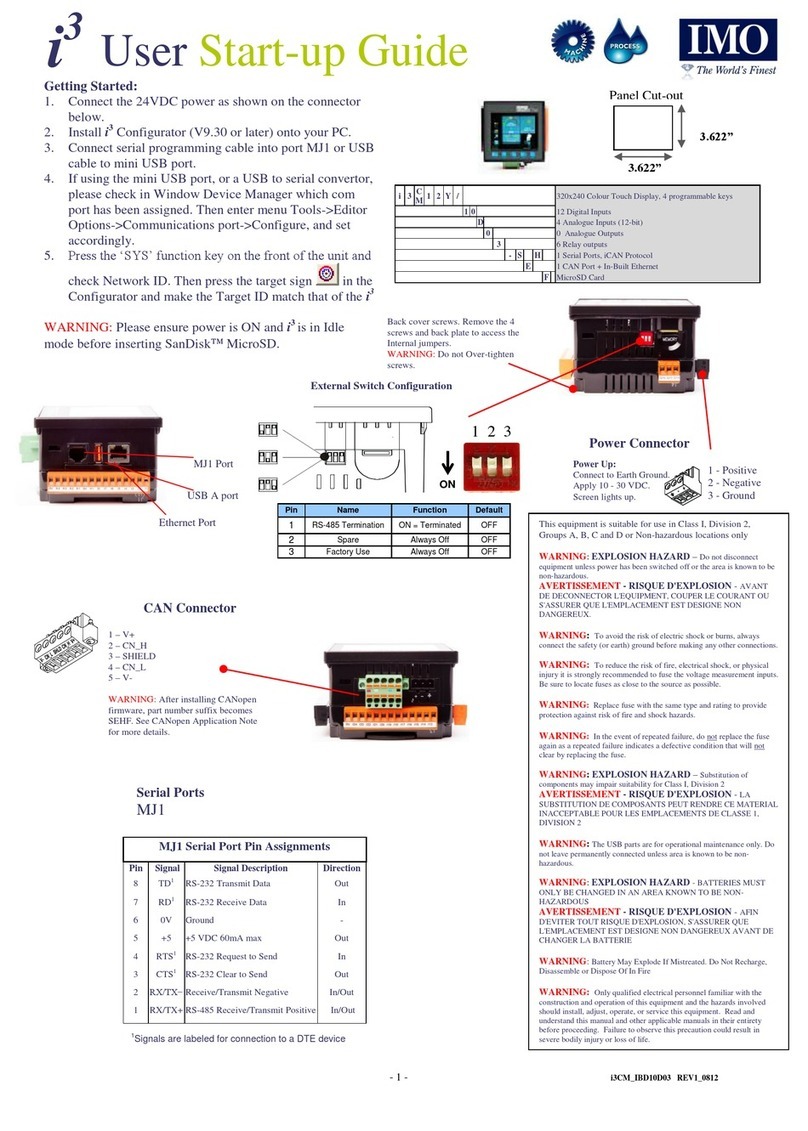

Getting Started:

1. Connect the 24VDC power as shown on the connector

below.

2. Install i

3

Configurator onto your PC.

3. Connect serial programming cable into port MJ1 port.

4. If using a USB to serial convertor (PC501), please check

in Window Device Manager which com port has been

assigned. Then enter menu Tools->Editor Options->

Communications port->Configure, and set accordingly.

5. Press the ‘SYS’ key on the front of the unit and check

Network ID. Then press the target sign in the

Configurator and make the Target ID match that of the i

3

WARNING: Please ensure power is ON and i

3

is in Idle

mode before inserting SanDiskMicroSD.

External Jumper Configuration.

As seen when looking at the top of the i

3

unit

DIPSW3: FACTORY USE

ONLY (tiny bootloader firmware

downloading). NOT FOR

DIPSW2: MJ2 Termination

(default – none)

DIPSW1: MJ1 Termination

(default – none)

Signals are labeled for connection to a DTE device

* +5 on i

3

H/W Rev E and later

MJ1 Serial Port Pin Assignments

Pin

Signal

Signal Description Direction

8 TD

1

RS-232 Transmit Data Out

7 RD

1

RS-232 Receive Data In

6 0V Ground -

5 +5 +5 VDC 60mA max Out

4 RTS

1

RS-232 Request to Send In

3 CTS

1

RS-232 Clear to Send Out

2 RX/TX−

Receive/Transmit Negative In/Out

1 RX/TX+

RS-485 Receive/Transmit Positive

In/Out

MJ2 Serial Port Pin Assignments

Pin

Signal

Signal Description Direction

8 TD

1

RS-232 Transmit Data Out

7 RD

1

RS-232 Receive Data In

6 0V Ground -

5 +5 +5 VDC 60mA max Out

4 TX- RS-485 Transmit Negative In

3 TX+ RS-485 Transmit Positive Out

2 RX− RS-485 Receive Negative In

1 RX+ RS-485 Receive Positive In

Serial Ports

MJ1 / MJ2

MJ2 - Full Duplex Mode

Pin MJ2 Pins

Signal Direction

8 - -

7 - -

6 0V Ground

5 - -

4 TX- OUT

3 TX+ OUT

2 RX- IN

1 RX+ IN

MJ2 - Half Duplex Mode

Pin MJ2 Pins

Signal Direction

8 - -

7 - -

6 0V Ground

5 - -

4 - -

3 - -

2 TX-/RX- IN/OUT

1 TX+/RX+ IN/OUT

MJ2 RS485 Connection Examples:

3.622 [92mm]

3.622 [92mm]

CAN Connector

1 – V+

2 – CN_H

3 – SHIELD

4 – CN_L

5 – V-

WARNING: After installing CANopen

firmware, part number suffix becomes

SCAF. See CANopen Application Note

for more details.

Back cover screws. Remove

the 4 screws and back plate

to access the Internal

WARNING: Do not Over-

tighten screws.

Power Connector

Power Up:

Connect to Earth Ground.

Apply 10 - 30 VDC.

Screen lights up.

1 - Positive

2 - Negative

3 - Ground

i

3

B

1

2

Y

/

160x128 Touch Display, 4 programmable keys

1

3

12 Digital Inputs (4 HSC + Universal Analogues)

C

2 Analogue Inputs (14-bit)

1

2 Analogue Outputs (12 bit)

4

12 Digital Outputs (2 PWM)

-

S

C

H

2 Serial Ports, 1 CAN port, iCAN Protocol

A

CANopen Protocol

F

MicroSD Card