CST Crydom HDC Series Assembly instructions

Rev. 062413

HDC Series

DC Load Solid State Contactors

FEATURES

PART NUMBER NOMENCLATURE

The HDC Series Solid State Contactors (SSCs) are designed for control of high power DC loads

such as brakes, clutches, coils, electro magnets, heaters, lamps, motors, solenoids, etc., where

long life and fast switching are required and traditional mechanical contactors or relays don’t

provide the required life, performance or service levels. The HDC Series offers the latest in DC

Solid State Power control by virtue of Crydom’s advanced high speed DC switching circuit for

on/off or PWM control (up to 1 KHz) utilizing optically isolated low dissipation FET outputs rated

at either 120 or 160 Amps at 48, 72 or 150 VDC Operating Voltage.

120 or 160 Amp DC Load Ratings @ 40ºC ambient w/heat sink

Single Pole Single Throw Normally Open operation (SPST/N.O.)

LED Input Status indicator standard

IEC 60947-4-1 Rated, UL & cUL

Required for valid part number

For options only and not required for valid part number

(A) See compatible accessories in TABLE 1.

(B) For maximum ratings use heat sink ratings shown in HDC series derating curves (see

product datasheet).

(C) Load can be wired to either terminal 1 or terminal 2. Proper polarity must be observed all

the time for the power supply and load.

(D) DC inductive loads must be diode supressed. Diode not included.

MOUNTING INSTRUCTIONS

Mounting on Heat Sink

Mounting on Panel

Please read all installation instructions before using your HDC Series Solid State Contactor (SSC).

Choose one of the two mounting options and follow the instructions.

Locate the panel section on which the HDC Series SSC will be mounted. Panel mount

surface must be clean, bare metal and provide adequate heat sinking capability. (B)

Be sure to use thermal pad or thermal compound between the SSC and the panel.

HDC Series Contactor mounting slots have a diameter of 0.2 in (5.0 mm). Four screws are

needed (not included) to mount the SSC onto panel. Choose screw length considering the

mounting surface and that HDC Series baseplate thickness is 0.125 in (3.2 mm).

Before applying full torque, tighten down all 4 screws until they contact the baseplate.

Then, tighten them to 20 in-lbs (2.2 Nm) starting with one immediately followed by the one

in the diagonally opposite corner. After the first 2 screws are completely tightened,

proceed tightening the remaining 2 screws.

Select adequate heat sink (see thermal derating curves).

Be sure to use thermal pad or thermal compound

between the SSC and the selected heat sink.

HDC Series Contactor mounting slots have a diameter of

0.2 in (5.0 mm). Four screws are needed (not included) to

mount the SSC onto heat sink (See fig. 1). Choose screw

length considering the mounting surface and that HDC

Series baseplate thickness is 0.125 in (3.2 mm).

Before applying full torque, tighten down all 4 screws

until they contact the baseplate. Then, tighten them to 20

in-lbs (2.2 Nm) starting with one immediately followed by

the one in the diagonally opposite corner. After the first 2

screws are completely tightened, proceed tightening the

remaining 2 screws.

fig. 1 HDC Series SSC

mounted on HS053 heat sink

(A)

(A)

For optimal thermal performance heat sink fins should be oriented vertically to promote

natural airflow.

(B)

Thermal pad

WIRING DIAGRAM

Series

Operating Voltage

60: 7-48 VDC

100: 7-72 VDC

200: 7-150 VDC

Control Voltage

A: 90-140 VAC

D: 4.5-32 VDC

Rated Load Current

120: 120 Amps

160: 160 Amps

A100 120

HDC

Thermal Pad

Blank: Not Included

H: Included

H

Wire Size

Maximum wire size capacity per terminal: Input 12 AWG (3.31 mm2) through

Quick Connect Terminals, Output 2/0 AWG (67.4 mm2). Choose wire gauge

according to actual load current. See TABLE 2.

Connections

First install Lug Terminal (Item 1 on fig.2) followed by Washer Int. Tooth-Lock

(Item 2 on fig.2) and finally Nut Hex (Item 3 on fig.2)

Transient Protection

An inductive load will produce harmful transient voltage when it is turned off. The more perfect the switch,

the larger the transient voltage. The MOSFET output is so nearly ideal switch that the transient voltages

produced by seemingly "non-inductive" loads can cause damage if not suppressed. Diodes should be fast

recovery type with PIV rated greater than twice the supply voltage.

Terminals

For maximum ratings, for 120 Amp models use Crydom lug terminal TRM3/0 or

other lug terminal with a diameter of 0.375 in (9.52 mm), 1 AWG (42.4 mm2) 75ºC

insulation wire installing capable.

For maximum ratings, for 160 Amp models use Crydom lug terminal TRM3/0 or

other lug terminal with a diameter of 0.375 in (9.52 mm), 2/0 AWG (67.4 mm2) 75ºC

insulation wire installing capable.

Important Considerations

WARNING! Do not try to unscrew Terminal Studs from Product.

Be sure to use input and output voltages within operating ranges.

LED indicates only input status. It does not represent output status.

Hardware Kit

TABLE 1. Accessories

Thermal Resistance

[ºC/W]

Heat Sink

Part No.

1.0

0.5

HS103 / HS103DR

HS053

HK1 TRM3/0

Thermal Pad

HSP-3

HSP-5

Lug Terminal

3

2

1

fig. 2 Lug Terminal

Connections

(C, D)

HDC200D160

4.5-32 VDC

INPUT

STATUS

- +

+/L1

-/L2

LOAD SIDE

160A 150VDC GENERAL USE UL508

SOLID STATE CONTACTOR

V

+

-

Load

( – ) ( + )

DC Input

HDC200A160

90-140 VAC

INPUT

STATUS

+/L1

-/L2

LOAD SIDE

160A 150VDC GENERAL USE UL508

SOLID STATE CONTACTOR

V

+

-

Load

( ) ( )

AC Input

Maximum Torque

lb in (N m)

Output Terminal

TABLE 2

HDC Series

Part No.

Torque

lb in (N m)

300 (33.9) 225 (25.4)

Wire Size for Max. Ratings

AWG (mm2)

1 (42.4)

2/0 (67.4)

HDCxxxx120x Nut Hex/Washer Int. Tooth-Lock

Combo Type 3/8”

HDCxxxx160x

HAZARD OF

ELECTRIC

SHOCK,

EXPLOSION,

OR ARC FLASH.

•Disconnect all

power before

installing or

working with

this equipment.

•Verify all

connections

and replace all

covers before

turning on

power.

Failure to follow

these

instructions will

result in death

or serious injury.

RIESGO DE

DESCARGA

ELECTRICA O

EXPLOSION.

•Desconectar

todos los

suministros de

energia a este

equipo antes

de trabajar

con este equipo.

•Verificar todas

las conexiones

y colocar todas

las tapas antes

de energizer

el equipo.

El

incumplimiento

de estas

instrucciones

puede provocar

la muerte o

lesiones serias.

RISQUE DE

DESCHARGE

ELECTRIQUE

OU EXPLOSION

•Eteindre

toutes les

sources

d'énergie de

cet appareil

avant de

travailler

dessus de cet

appareil

•Vérifier tous

connections, et

remettre tous

couverts en

olace avant de

mettre sous

De non-suivi de

ces instructions

provoquera la

mort ou des

lésions sérieuses

sérieuses.

GEFAHR EINES

ELEKTRISCHE

N SCHLAGES

ODER EINER

EXPLOSION.

•Stellen Sie

jeglichen

Strom ab, der

dieses Gerät

versorgt, bevor

Sie an dem

Gerät Arbeiten

durchführen

•Vor dem

Drehen auf

Energie alle

Anschlüsse

überprüfen

und alle

Abdeckungen

ersetzen.

Unterlassung

dieser

Anweisungen

können zum

Tode oder zu

schweren

Verletzungen

führen.

RISCHIO DI

SCOSSA

ELETTRICA O

DELL’ESPLOSI

ONE.

•Spenga tutta

l'alimentazion

e che fornisce

questa

apparecchiatu

ra prima del

lavorare a questa

apparecchiatu ra

•Verificare tutti

i collegamenti

e sostituire

tutte le coperture

prima della

rotazione

sull'alimentazi one

L'omissione di

seguire queste

istruz ioni

provocherà la

morte o di

lesioni serie

存在电击、

爆炸或电弧

闪烁危险

•

在操作此设

备之前请先

关闭电源。

若不遵守这些说明,

可能会导致严重的

人身伤害甚至死亡。

RISQUE DE DOMMAGE MATERIEL ET DE

SURCHAUFFE DU BOITIER

•Les panneaux latéraux du produit peuvent être

chauds. Laisser le produit refroidir avant de le

toucher.

•Respecter les consignes de montage, et

notamment les couples de serrage.

•Ne pas laisser pénétrer de liquide ni de corps

étrangers à l'intérieur du produit.

RISK OF MATERIAL DAMAGE AND HOT

ENCLOSURE

•The product's side panels may be hot, allow

the product to cool before touching.

•Follow proper mounting instructions including

torque values.

•Do not allow liquids or foreign objects to enter

this product.

Le non-respect de cette directive peut entraîner,

des lésions corporelles graves ou des

dommages matériels.

Failure to follow these instructions can result in

serious injury, or equipment damage.

La mancata osservanza di questa precauzione può

causare gravi rischi per l'incolumità personale o

danni alle apparecchiature.

Si no se respetan estas precauciones pueden

producirse graves lesiones, daños materiales.

Die Nichtbeachtung dieser Anweisung kann

Körperverletzung oder Materialschäden

zur Folge haben.

如不能正确执行这些操作说明,

极有可能造成严重人体伤害或者设备的损坏。

GEFAHR VON MATERIALSCHÄDEN UND

GEHÄUSEERHITZUNG

•Die Seitenwände können heiß sein. Lassen Sie

das Produkt abkühlen, bevor Sie es berühren.

•Beachten Sie die Montageanweisungen,

•Führen Sie keine Flüssigkeiten oder

Fremdkörper in das Produkt ein.

RISCHIO DI DANNI MATERIALI E D'INVOLUCRO

CALDO

•I pannelli laterali dell'apparecchio possono

scottare; lasciar quindi raffreddare il prodotto

prima di toccarlo.

•Seguire le istruzioni di montaggio corrette.

•Non far entrare liquidi o oggetti estranei in questo

apparecchio.

RIESGO DE DAÑOS MATERIALES Y DE

SOBRECALENTAMIENTO DE LA UNIDAD

•Los paneles laterales del producto pueden

estar calientes. Esperar que el producto se

enfríe antes de tocarlo.

•Respetar las instrucciones de montaje, y en

particular los pares de apretado.

•No dejar que penetren líquidos o cuerpos

extraños en el producto.

材料损坏和高温外壳的危险性

• 产品的一侧面板可能很热,在其冷却前请

不要触碰。

• 遵照正确的安装说明,包括扭矩值。

• 请勿让液体及其他异物进入本产品。

DANGER / PELIGRO / DANGER /GEFAHR / PERICOLO /

WARNING / AVERTISSEMENT / WARNUNG /ADVERTENCIA / AVVERTENZA / 警告

Rev. 062413

This manual suits for next models

24

Popular Control Unit manuals by other brands

Niles

Niles TVC-1 Installation & operation guide

Kontron

Kontron EPIC/CE user guide

Automationdirect.com

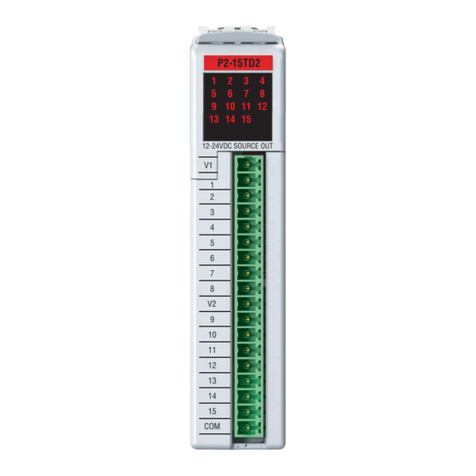

Automationdirect.com Productivity 2000 P2-15TD2 manual

Lenze

Lenze E84AYCIB Mounting instructions

SMA

SMA SWDMSI-10.BG1 installation manual

Spirax Sarco

Spirax Sarco 58 Installation and maintenance instructions

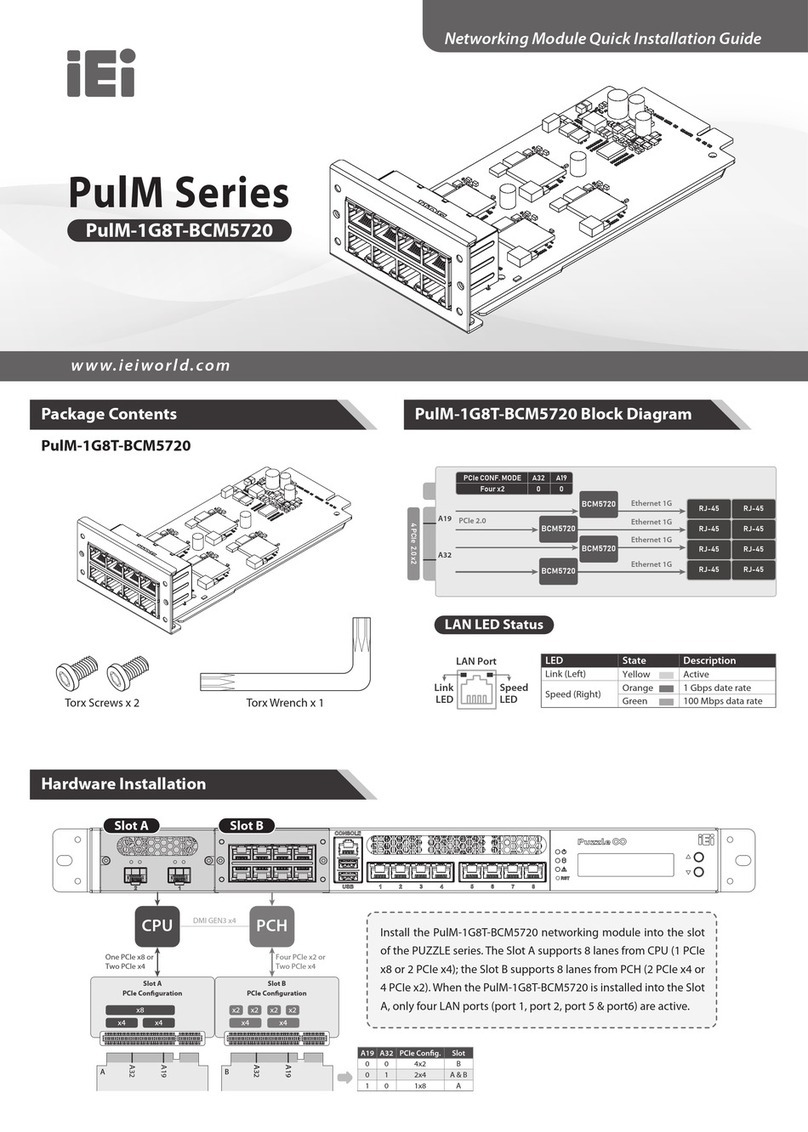

IEI Technology

IEI Technology PulM Series Quick installation guide

Villeroy & Boch

Villeroy & Boch Emotion Control Start-up and operation

KNX

KNX V3000 quick start guide

Honeywell

Honeywell NK295C installation instructions

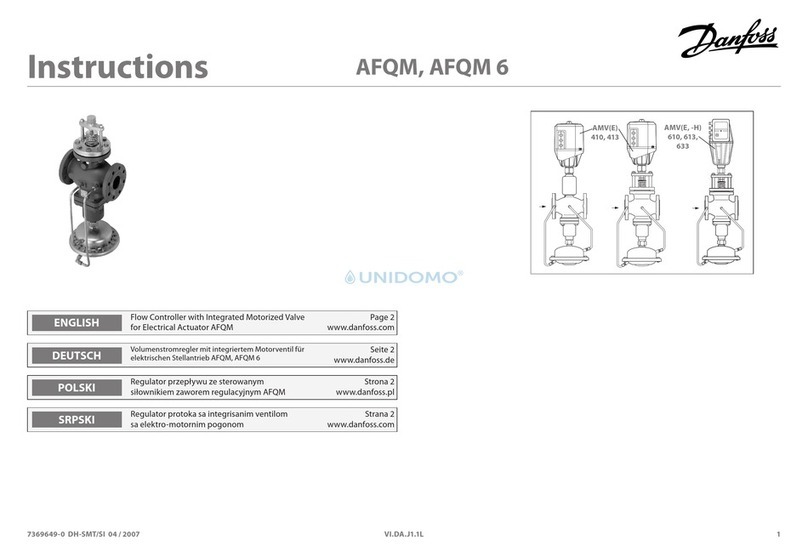

Danfoss

Danfoss AFQM instructions

B&B Electronics

B&B Electronics iMcV-DS3-LineTerm Operation manual