UNIT INSTALLATION

EXPLOSION HAZARD

Do not apply flame or steam to a refrigerant

cylinder. If heat is needed to change faster,

partially immerse the cylinder in warm water.

> A cyclinder should never contain more than 80%

of liquid refrigant.

> Add only R-410A to an R-410A cylinder.

It operates at much higher presures than R-22.

Service equipment used with R-410A must be

listed.

>Do not use a cylinder as a platform or roller.

Always store a cylinder in a cool, dry place.

ELECTRICAL SHOCK HAZARD

> Ensure power source is OFF or disconnected at

main panel before opening any electrical boxes.

Failure to comply may cause serious injury or

death.

>It is imperative that the components of this

system are properly grounded to minimize any

electrical shock hazard and / or personal injury.

REFRIGERANT SAFE HANDLING

Because refrigerants are heavier than air, they can

push out oxygen from your lungs or from

enclosed spaces. To avoid death or difficulty

breathing, take the following precautions:

1- You should never sniff a refrigerant

2- No refrigerant should ever be purged into an

enclosed space or room. By law, all refrigerants

must be reclaimed.

3- If you suspect an indoor leak, you must

thoroughly ventilate the area before you begin

work.

4- If you do get contact with liquid refrigerant,

wear gloves and goggles to avoid frostbite or

blindness. If liquid refrigerant does get in your

eyes or on your skin, seek medical attention

immediately.

5- Refrigerant can cause poisonous gas to be

released if it is burned.

6- Always follow EPA regulations.

Read these instructions completely and then plan all connections

which must be made to the unit including ducting, condensate

drain line, seawater inlet and outlet hoses, electrical power

connection, location of control, and seawater pump placement, to

assure easy access for routing and future servicing for both

chilled water and air handler units.

Installation and servicing of this system can be hazardous due to

system pressure and electrical components. When working on this

equipment, always observe precautions described in the literature,

tags and labels attached to the unit. Follow all safety codes.

Wear safety glasses and work gloves and place a fire extinguisher

close to work area.

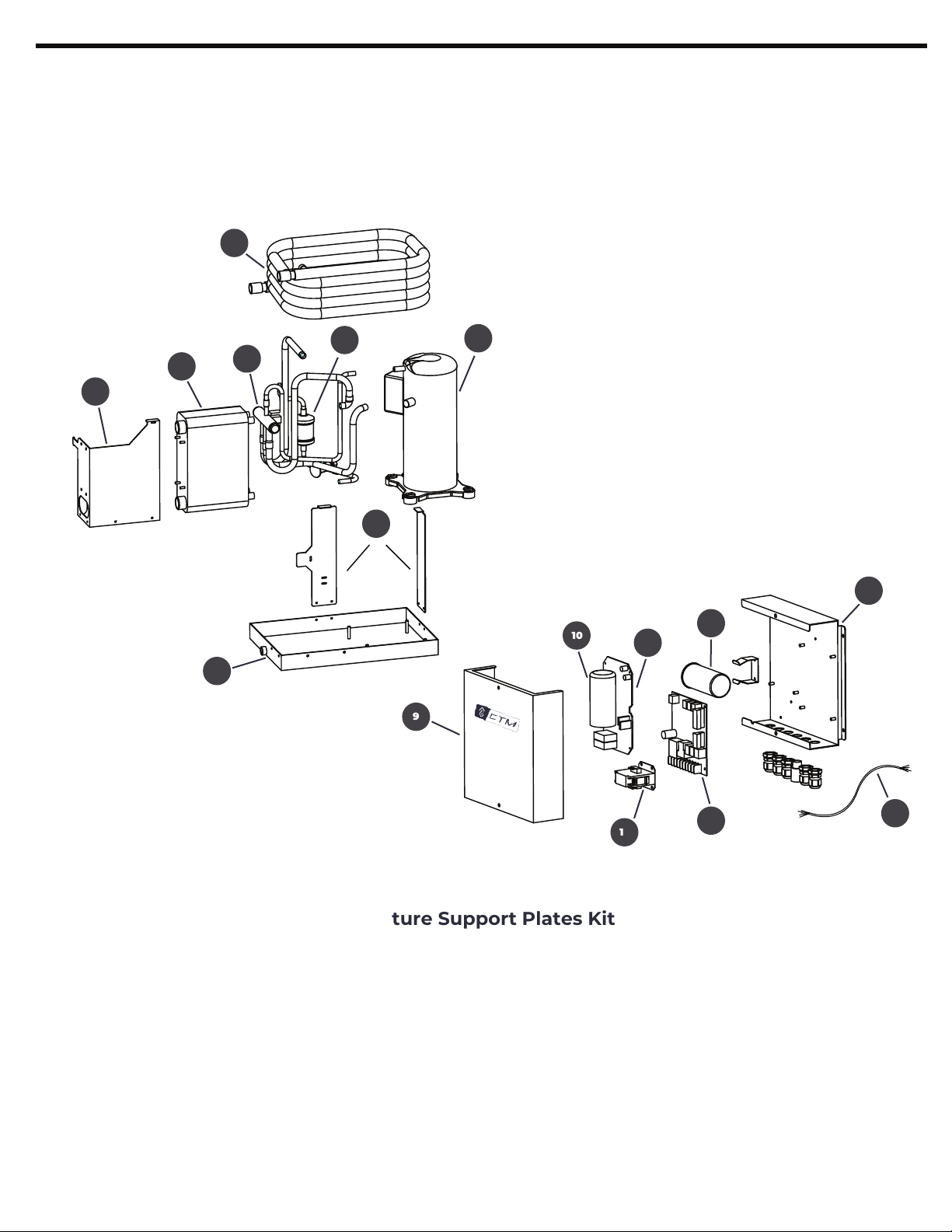

MOUNTING THE CHILLED WATER SYSTEM AND THE ELECTRICAL BOX

CHILLED WATER SYSTEM ELECTRICAL BOX

Pay attention to signalling symbols

throughout this manual with important

information.

Some sections of this instructions manual have QR

codes that you can easily scan with your Smartphone.

They generally contain tutorial videos following the

instructions in this manual or additional information.

Refer to the illustrations throughout

this manual for guidance.

Some pages have a boxed section on the right to

indicate potential physical injury hazards and

potential damages to the units. It’s important to

read, understand and obey safety instructions.

5

CTM Marine Chilled Water Systems Installation & User Manual

1 - The chiller unit is usually installed in the engine room.

Make sure to install the chiller unit in a horizontal surface strong

enough to hold the unit when the boat is in motion, choose a location

where it will be dry and able to be serviced easily. Allow at least between

3 - 4 feet (0.9 - 1.2m) of space around the unit and at least 3 feet (0.9 m)

above the unit.

2 - The control panel or electrical box which contains all the controls to

operate the chiller should be installed on a dry and flat horizontal or

vertical surface where it could be accessed easily for installation and

servicing. Make sure the location of the control panel is free of water

spray and moisture.