351804-1 Rev. 100

COM5000-8 TECHNICAL MANUAL

TABLE OF CONTENTS

Section Description...............................................................................................................................Page

GENERAL .................................................................................................................................................v

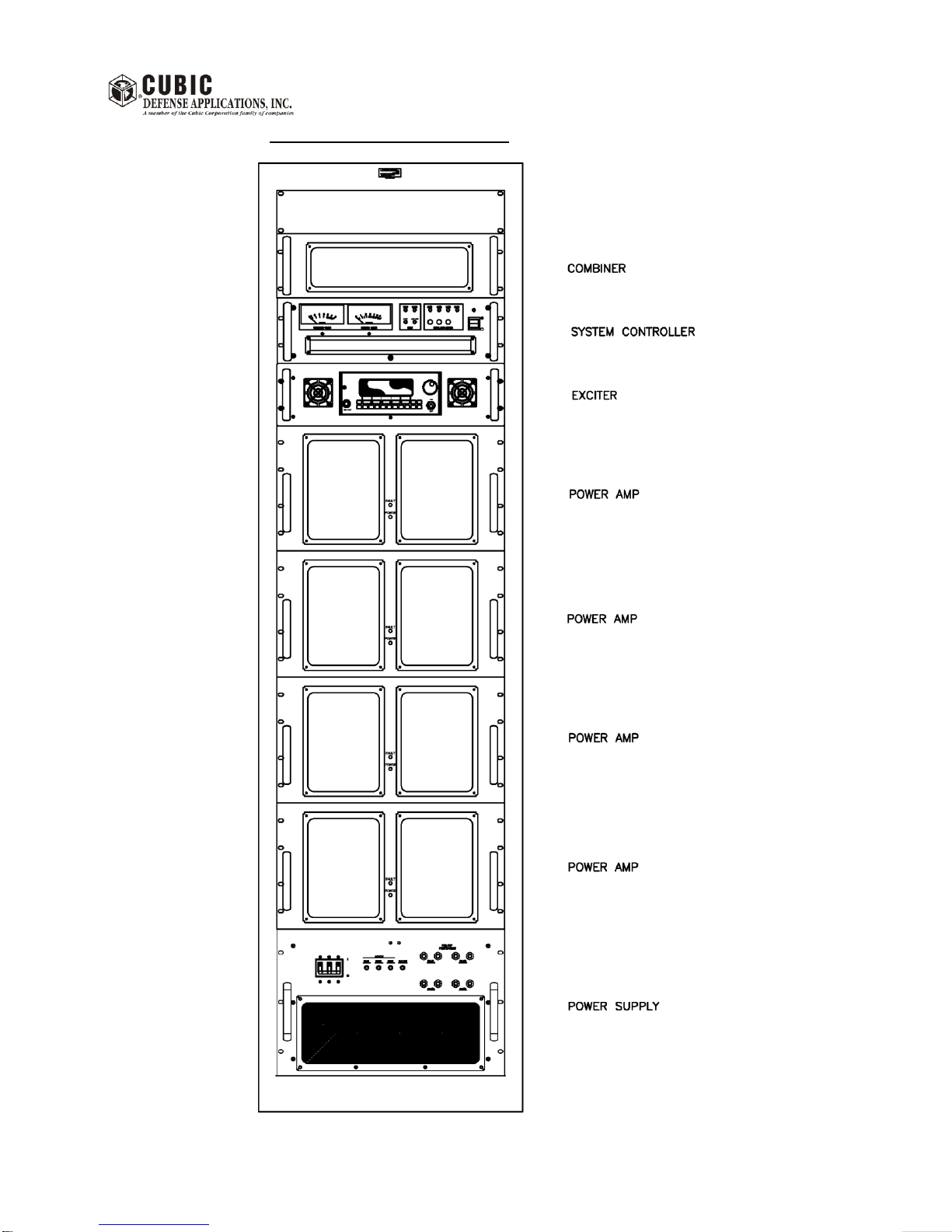

CONFIGURATION............................................................................................................................................v

5-kW TRANSMITTER PERFORMANCE SPECIFICATIONS (*) ....................................................................vi

SCOPE OF MANUAL.....................................................................................................................................vii

GENERAL SAFETY INFORMATION.............................................................................................................vii

CHAPTER 1 DESCRIPTION........................................................................................................................1

1. INTRODUCTION.....................................................................................................................1

1.1 GENERAL...............................................................................................................................1

1.2 FEATURES.............................................................................................................................1

CHAPTER 2 INSTALLATION......................................................................................................................2

2.1 GENERAL...............................................................................................................................2

2.1.1 Government Regulations ........................................................................................................2

2.1.2 Inspection................................................................................................................................2

2.1.3 General Installation .................................................................................................................2

2.1.4 Rack Cabinet Installation ........................................................................................................3

2.1.4.1 Module Removal .....................................................................................................................3

2.1.4.2 Rack Cabinet Mounting...........................................................................................................4

2.1.4.3 Reconnecting Cables To Modules..........................................................................................7

2.1.4.3.1 Power Supply Module Connections........................................................................................7

2.1.4.3.2 System Controller Module Connections..................................................................................8

2.1.4.3.3 Additional Module Connections...............................................................................................9

2.1.4.4 External Connections To The Transmitter............................................................................10

CHAPTER 3 OPERATION.........................................................................................................................11

3.1. INTRODUCTION...................................................................................................................11

3.2 CONTROLS AND DISPLAYS...............................................................................................11

3.2.1 Power Supply Module ...........................................................................................................11

3.2.2 PA Module.............................................................................................................................13

3.2.4 T-4180 Exciter Module..........................................................................................................16

3.3 TRANSMITTER SYSTEM OPERATION...............................................................................16

3.3.1 General..................................................................................................................................16

3.3.2 Operating The Transmitter....................................................................................................16

3.3.3 Transmitter External Control Protocol...................................................................................17

3.3.4 Continuous Bit Operation......................................................................................................17

CHAPTER 4 FUNCTIONAL DESCRIPTION .............................................................................................25

4.1 INTRODUCTION...................................................................................................................25

4.2 COM5000-8 SYSTEM...........................................................................................................25

4.3 1.25KW PA MODULE...........................................................................................................25

4.4 COMBINER MODULE...........................................................................................................28

4.5 SYSTEM CONTROLLER MODULE .....................................................................................28

4.6 POWER SUPPLY MODULE.................................................................................................30

CHAPTER 5 MAINTENANCE....................................................................................................................31

5.1 INTRODUCTION...................................................................................................................31

5.2 RECOMMENDED TEST EQUIPMENT.................................................................................31

5.3 PERIODIC MAINTENANCE..................................................................................................31