Enclosures

Walled enclosures.

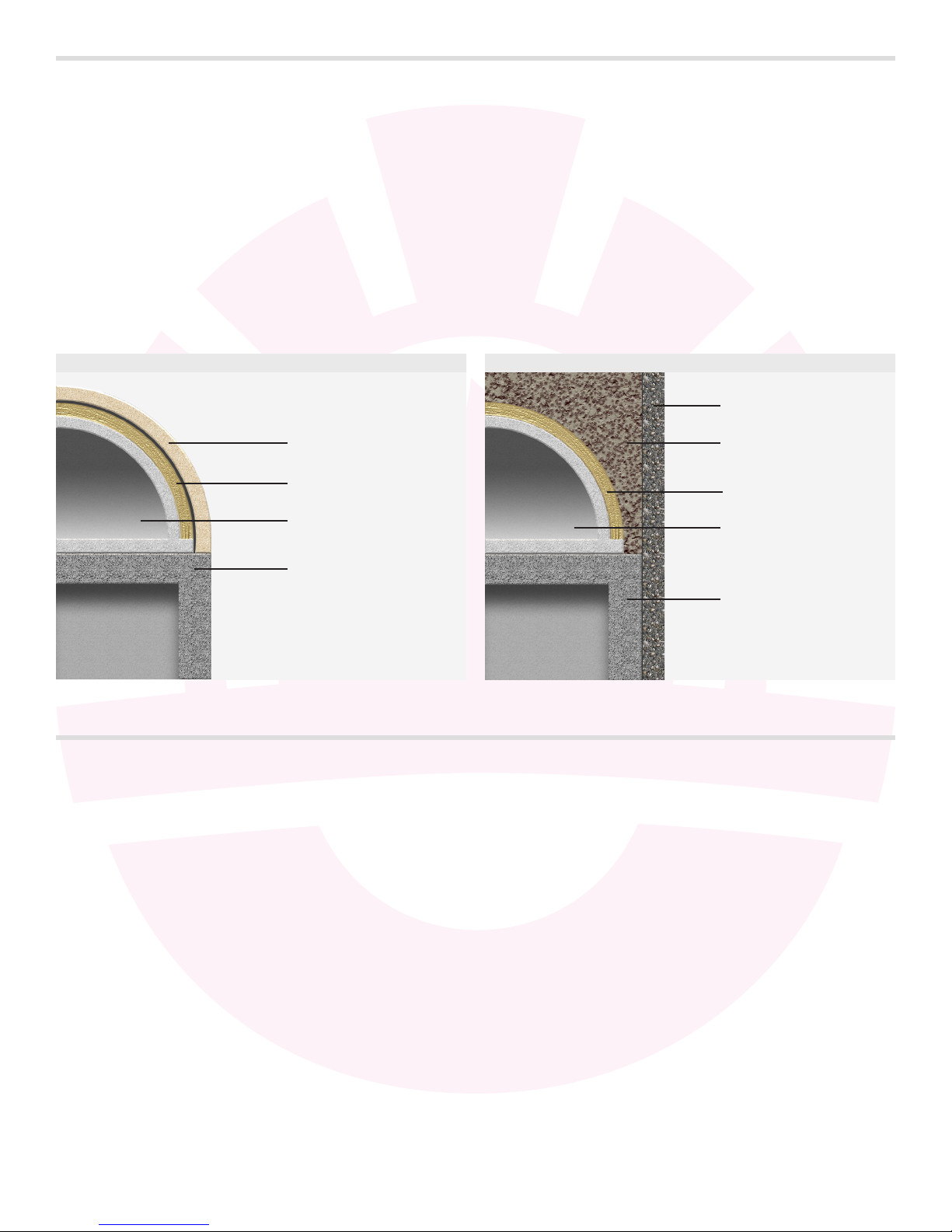

A walled enclosure is a classic and very beautiful way to nish your oven. Whatever style you choose, be sure to observe the

following safety rules:

1- Never use any combustible material in the enclosure. Wooden studs, plywood, drywall or any other combustible materials are

expressly forbidden, for they are a sure way to cause a re. The safest method is to build masonry walls with completely non-

combustible materials such as cement or ceramic blocks, bricks or stone.

2- Only completely non-combustible materials should be allowed to touch the oven kit. Metal studs and concrete boards are also

perfectly suitable, but then spaces between the oven kit (or any completely non-combustible material that touches it) and the

enclosure walls are mandatory. The minimum spacings should be 10 cm /4” from all sides, except the oven mouth and 35.5 cm

/ 14” from the top. Around the oven mouth, only completely non-combustible materials should be used, keeping a distance of

0.5 cm / 0.2” from it. That space may then be lled with weatherproof stucco. As to the hearth extension around the oven mouth,

keep a minimum of 76 cm / 30” to the sides of the mouth and 91 cm / 36” to the front of the mouth free from any combustible

material.

3- If you keep the wood in a space below the oven, be sure to leave at least 21.5 cm / 8½” between the bottom of the oven and

the top of the wood storage space. A covered container for the wood is better for avoiding any contact with ember or stray sparks.

Igloo enclosures.

If you opt for a smaller igloo-style enclosure, there are basically two ways of doing it:

1- You can cover the oven with a layer or two of insulating cement, spreading it directly on top of the insulation (the wire mesh

will hold the cement in place) or on top of a stucco lath layer. Proceed with a nishing layer of weatherproof stucco.

2- You can build a rebar frame around the oven kit and cover it with tied stucco lath, then cover the whole structure in a layer of

stucco 1.3 cm / ½” to 1.8 cm / ¾” thick. Follow with another layer of weatherproof stucco or paint.

Remember, these are general rules of thumb. Always comply rst to your local building codes!

The thermometer

Your Cuore

1000

+

Wood-Fired Oven comes with a bimetallic analog thermometer. It should be placed in the appropriate hole

above the oven mouth. For proper operation, the thermometer stem should protrude at least 4 cm / 1.5" inside the re chamber.

You may have to build an appropriate recess on the oven nishing so as to keep this recommended distance.

The thermometer needle will lock in place if the oven is heated above the maximum temperature. This will void the warranty.

IMPORTANT! Never try to bend the thermometer stem. This will ruin the thermometer.

If you do not wish to use this thermometer, simply ll the thermometer hole with refractory cement.

IMPORTANT! This oven should never, under any circumstances, be operated unnished and/or without a chimney. Remember,

water (by way of thermal shock) is a mortal enemy of wood-red ovens. So, if your oven is installed outdoors, it should be very

well encased and protected from rain and seeping water. For the same reason, never wash the inside of the oven. It is largely self-

cleaning.

Attention! Very important information! After the oven is nished, there must be a minimum 21-day curing time before

starting any re in the oven. Failure to do so may damage the oven and will result in loss of the warranty.

For additional tips and information on base and enclosure building, visit www.cuoreovens.com.

The Cuore

1000

+

operation manual is available for download from our website, under the Resources tab. Please be sure to read it

thoroughly before attempting to use the oven.