2

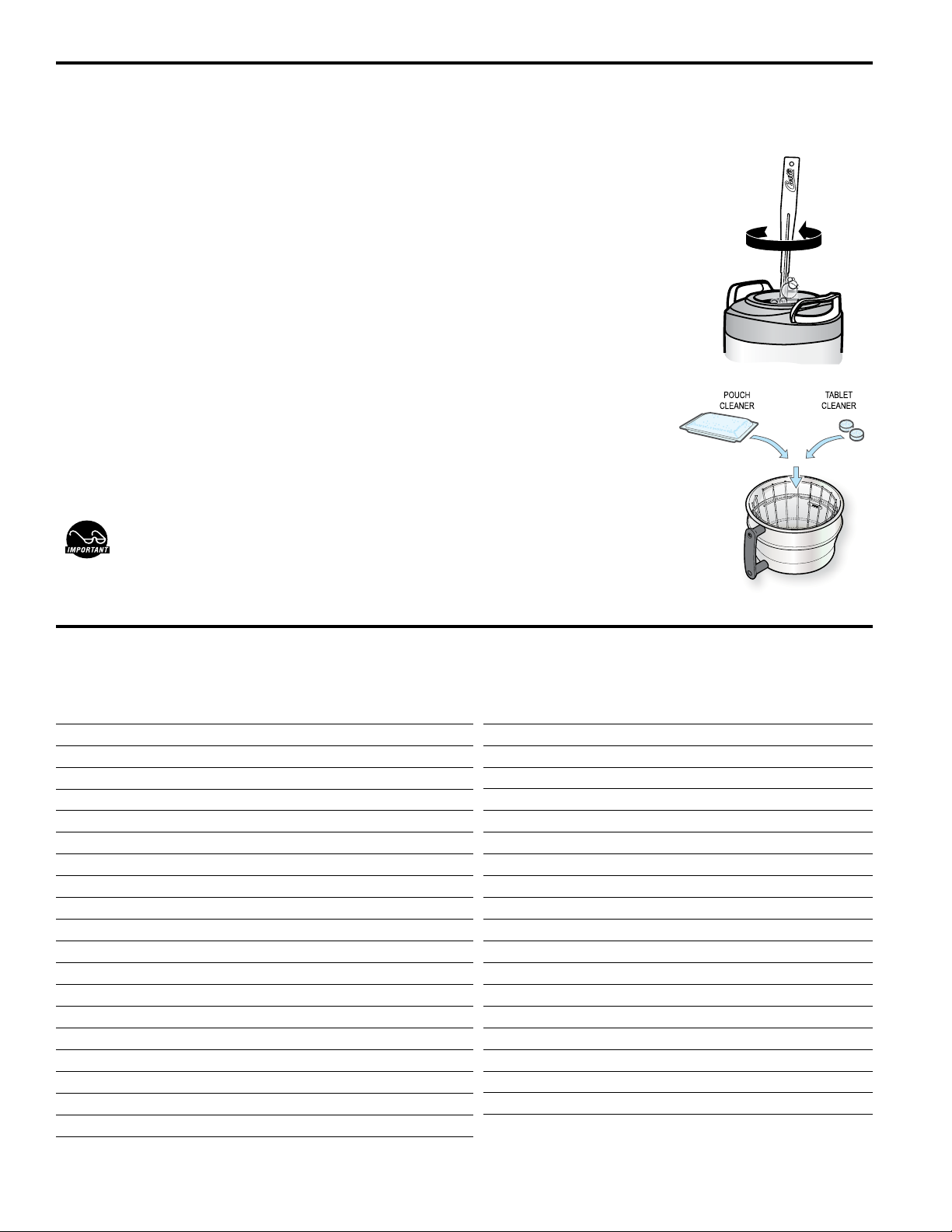

Cleaning Instructions

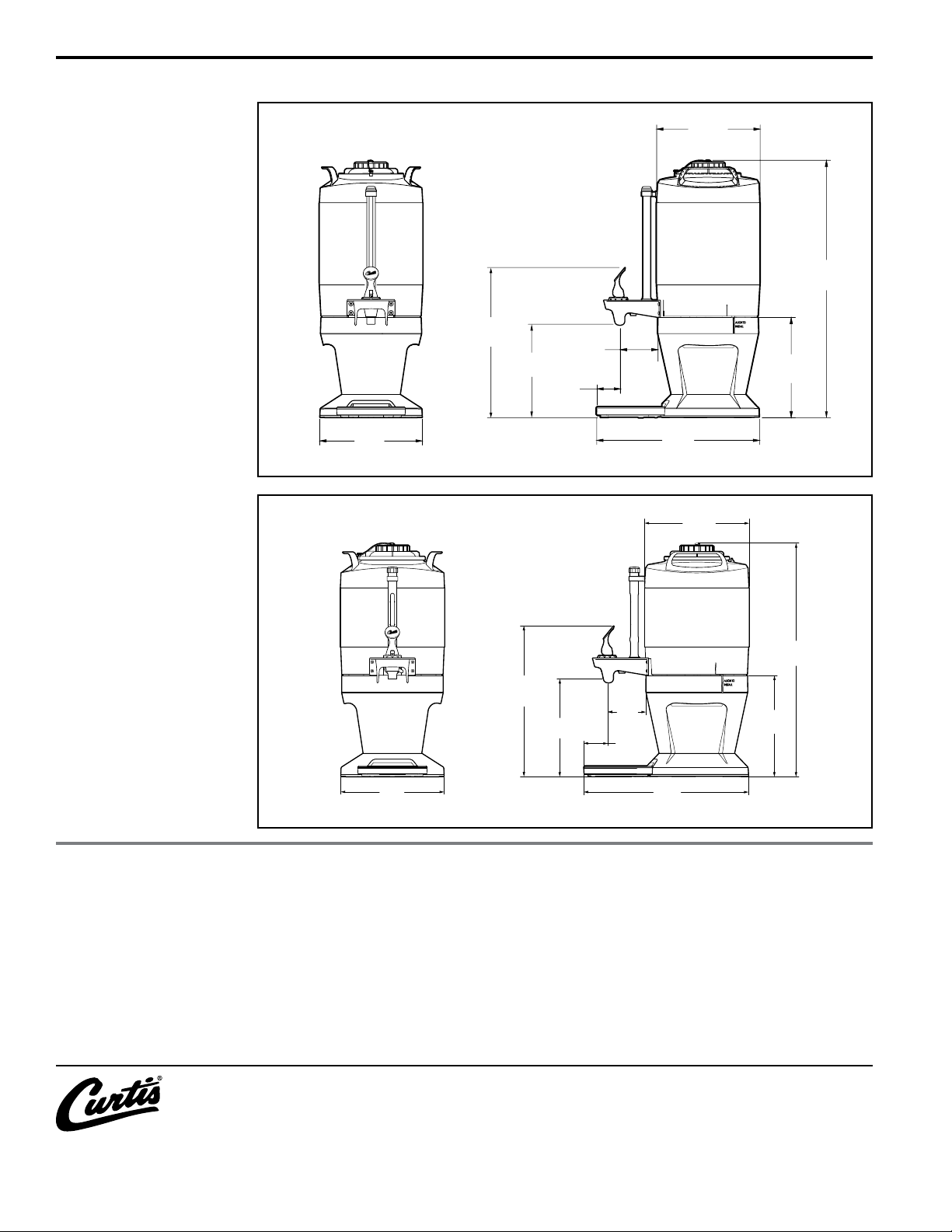

All parts are common between the 1 gallon and 1½ gallon servers, except where indicated by TXSG15 and TXSG01.

1. In a container, mix a mild detergent and warm water solution for cleaning the coffee server.

2. Discard old coffee from the coffee server.

3. Remove and clean the lid.

4. Clean inside the coffee server with a sponge brush soaked in detergent solution.

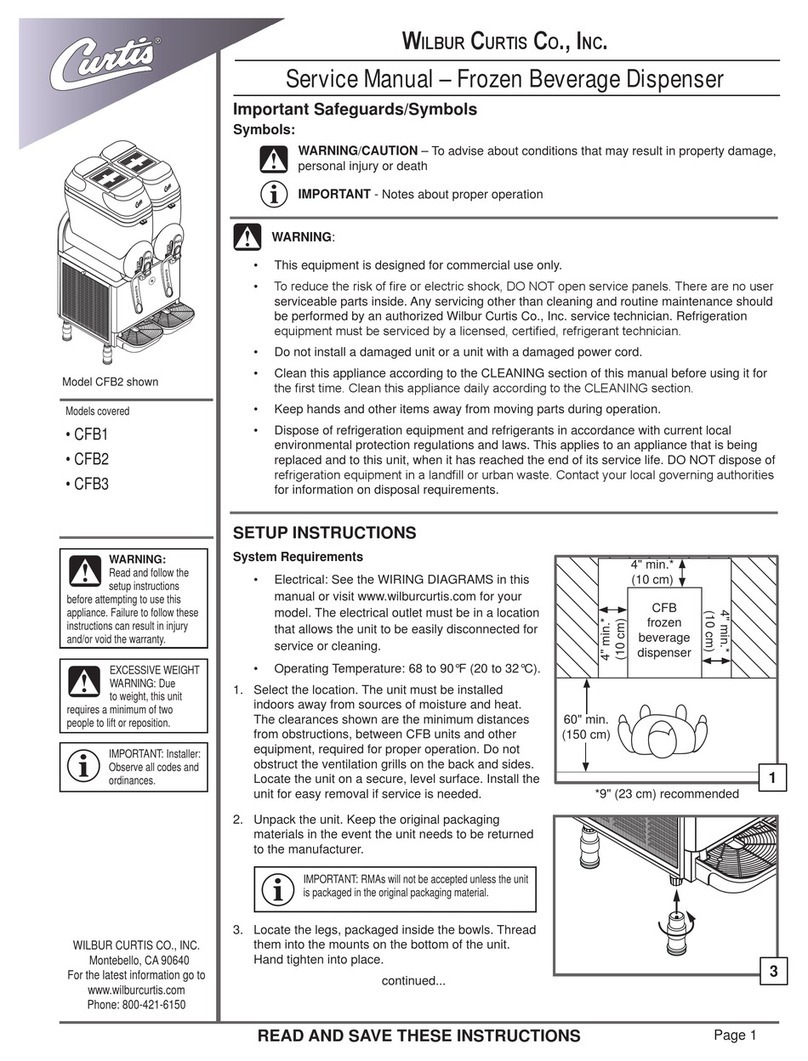

5. An easy way to remove mineral deposits from the brew cone and the coffee server is to

use a pouch or tablet cleaner.

a. Place two tablets or one pouch (refer to manufacturers’ recommendation) into the

brew cone.

b. Place the empty coffee server onto the brew deck.

c. Start a coffee brew cycle by pressing the Brew button on the electronic controller.

d. When the brew cycle has nished, allow the cleaning solution to sit in the coffee

server for a few minutes, then empty the coffee server.

6. Wipe the exterior surfaces with a sponge moistened with the detergent solution. Wipe

off coffee spots or stains.

7. Rinse the brew cone and coffee server with running water.

8. Dry the parts and return them to the coffee brewer.

TXSG Coffee Server Precautions:

Do not immerse coffee server in water.

Do not place in dishwasher.

Do not use harsh powders or cleansers containing chlorine.

Do not use a wire brush or pot scour to clean inside liner.

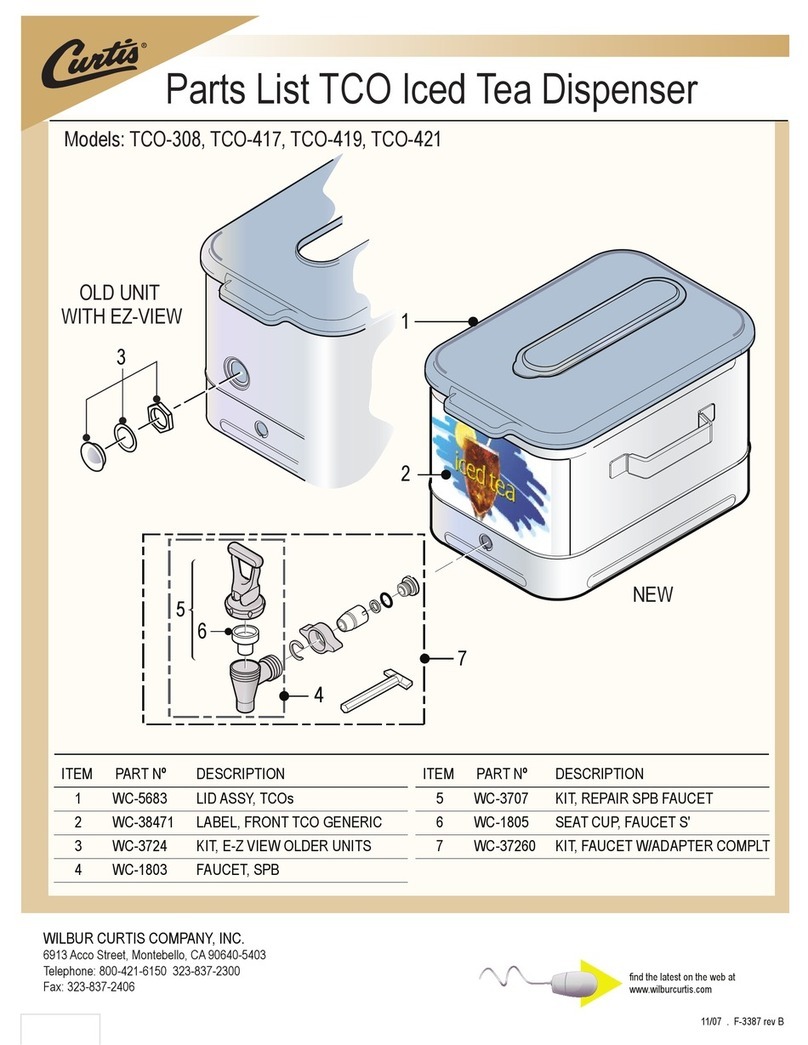

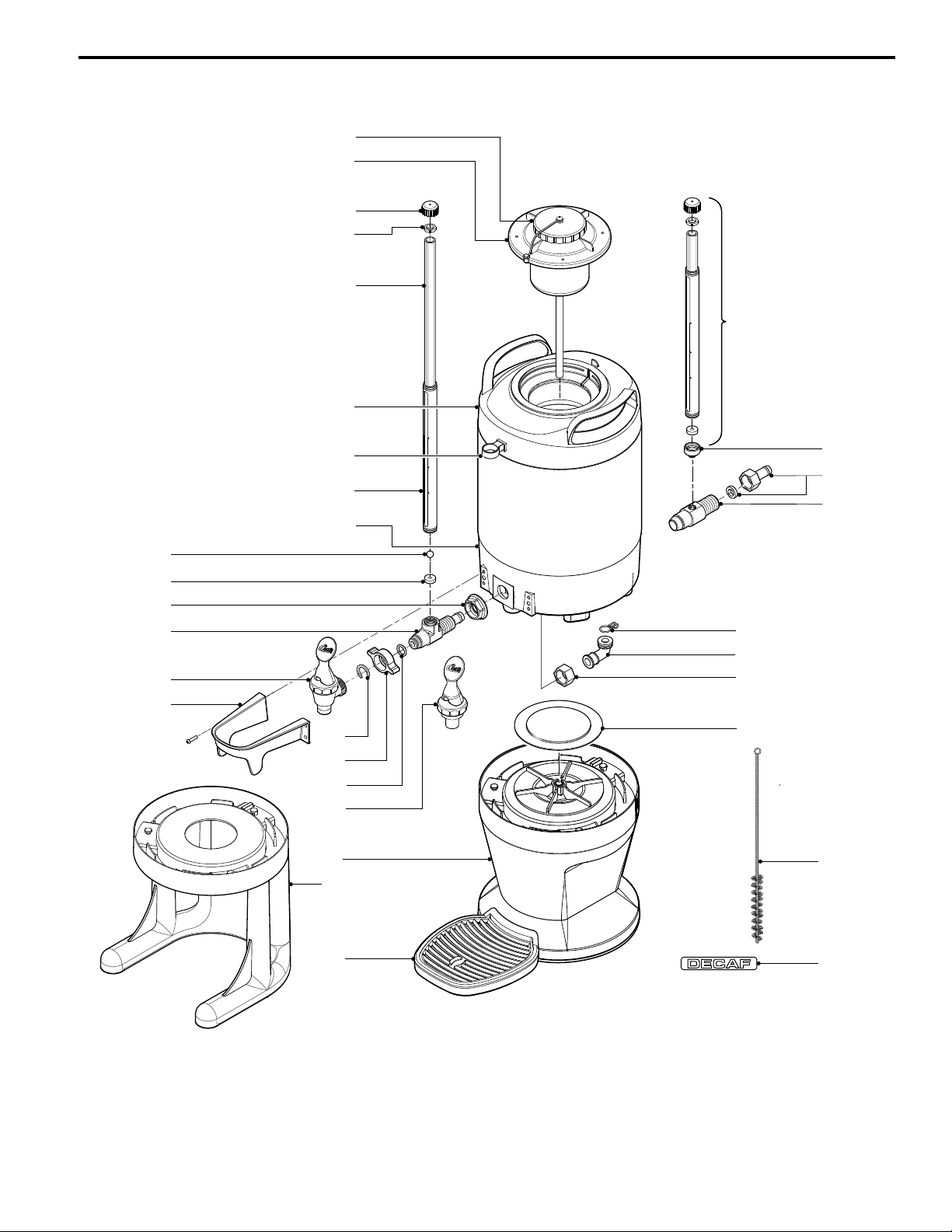

Illustrated Parts List

1

2

2A

3

4

5

5A

5B

6

7

8

8A

9

10

11

12

13

13A

14

WC-37387

WC-56025

WC-56024

WC-1949

WC-2005

WC-2027

WC-2025

WC-37396

WC-56028

WC-2063K

WC-2012-101

WC-2010-101

WC-56030

WC-32004

WC-2006

WC-1951

WC-1938-103K

WC-1938

WC-1841

KIT, CAP, TETHER & SCREW TXSG

LID ASSY, TXSG15

LID ASSY, TXSG01

CAP, SHIELD WITH VENT, PLASTIC

WASHER, SHIELD CAP 1/8”

GLASS, GAUGE 10” TXSG15

GLASS, GAUGE 8” TXSG01

KIT, GLASS GAUGE 10” 3PK TXSG15

TOP SERVER THREADED BLK

KIT, BRACKET, GAUGE GLASS RING

SHIELD, GAUGE GLASS 10” TXSG15

SHIELD, GAUGE GLASS 8” TXSG01

BOTTOM, PLASTIC BLACK SERVER

BALL, PLASTIC RESTRICTOR TXS

WASHER, .188 ID X .188 THK BTM

NUT, FLANGED, PLASTIC

KIT, SHNK, NUT & INST. TXSG 1GAL. & 1.5GAL

SHANK, PLASTIC (OLD UNITS)

FAUCET, ESP BLACK LOCKING

15

16

17

18

19

20

20A

21

22

23

24

25

26

27

28

28A

29

30

WC-64079

WC-1906

WC-1905

WC-4320

WC-3705

WC-56020

WC-56013

WC-61689

WC-43091

WC-2456

WC-4281

WC-58262

WC-37395

WC-2004-101

WC-29082

WC-29082K

WC-36076

WC-38281

GUARD, FAUCET TXSG ZINC

C’ RING .917 x .760 x .090

NUT, WING PLASTIC 1-1/32-14UNF

O-RING, ½” I.D.

KIT, FAUCET REPAIR

BASE ASSY SERVER STRAIGHT SIDE

BASE ASSY, SERVER (OPTIONAL)

DRIP, TRAY ASSEMBLY TLXS

CLAMP, WIRE HOSE

ELBOW, SILICONE STRT SIDE SRV

NUT, ½ – NPSM PLASTIC

COVER, BOTTOM WHITE PLASTIC

KIT, GAUGE ASSY 10” BLK TXSG15

SHIELD BASE GAGE BLACK (OLD UNITS)

FITTING, ½”-14 NPSF ASSY(OLD UNITS)

KIT, FIT., W/ SILICONE WASH (OLD UNITS)

BRUSH, GAUGE GLASS

LABEL, DECAF

INDEX № PART № DESCRIPTION

INDEX № PART № DESCRIPTION