Sensing the world ·Leading the change

9

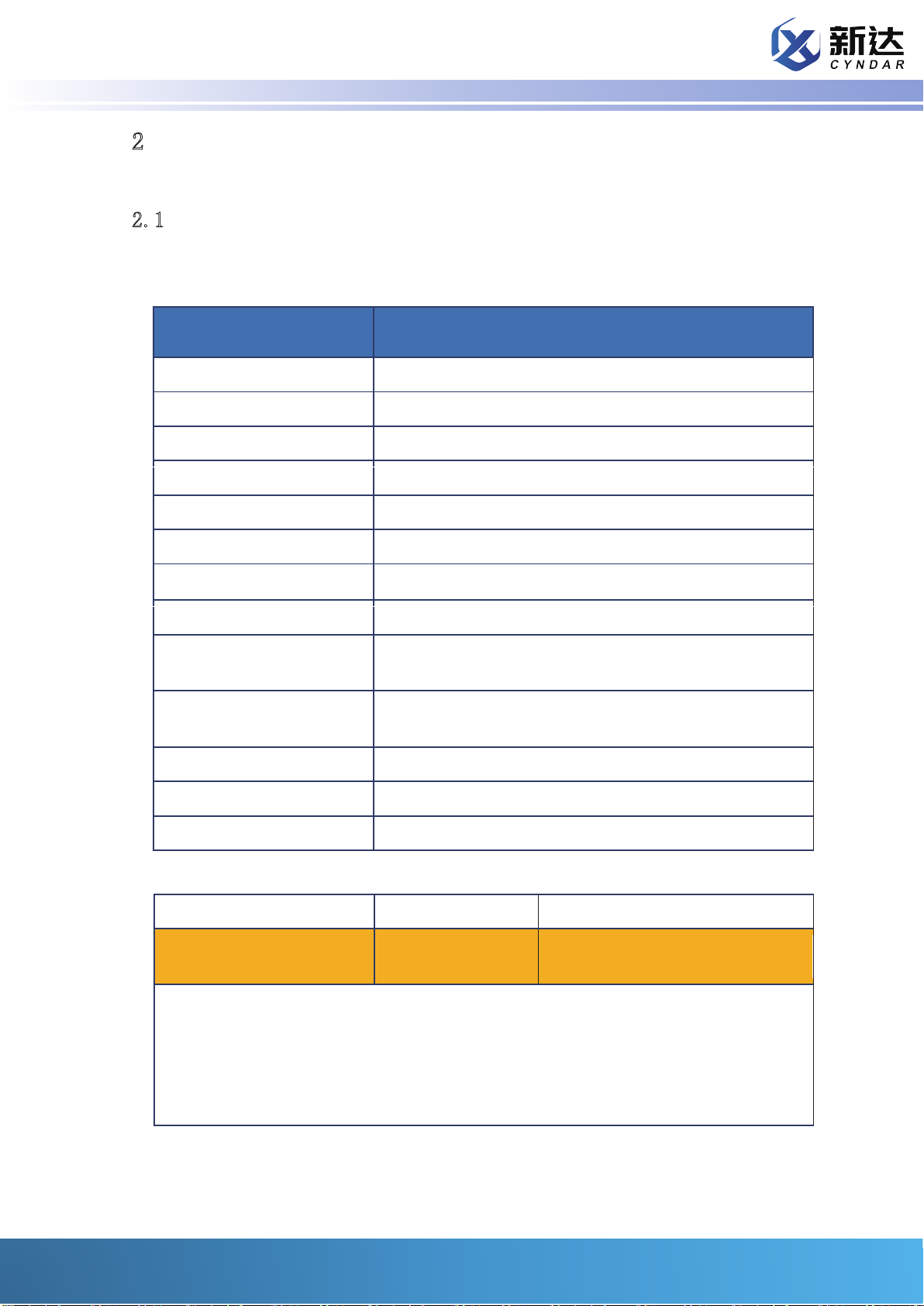

2.4

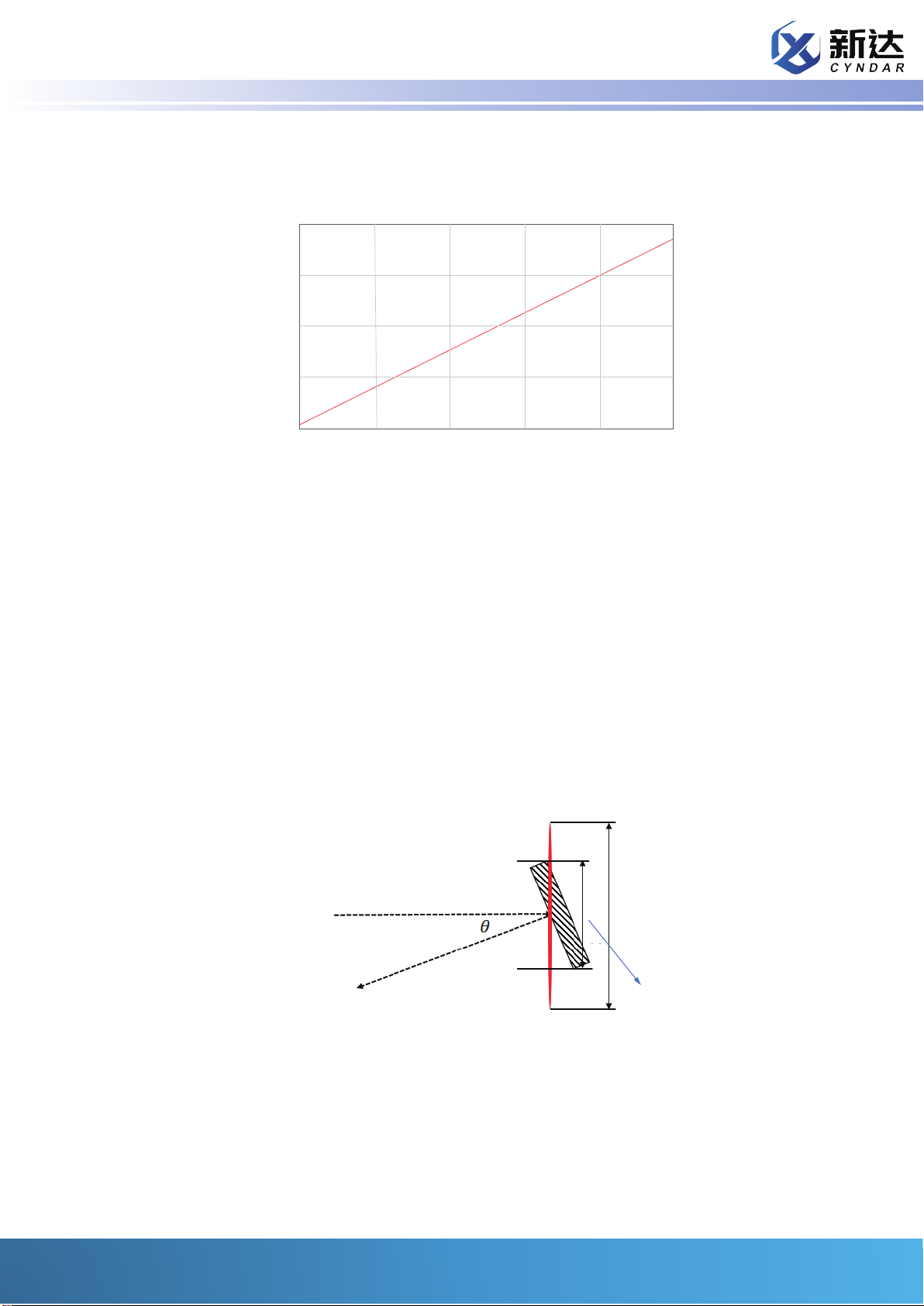

0.05-10m 10-15m 15-25m

20mm 20mm 35mm

15mm 20mm 30mm

Ranging error within different detection distances

1mm 1h

2mm 2h

3mm 3h No echo can be detected in this observation direction, and there is no

object that can be identified within the range.

4-50mm 4h-32h

50mm-500mm 32h—1F4h

500mm-

25000mm

1F4h—61A8

Ranging and scanning performance

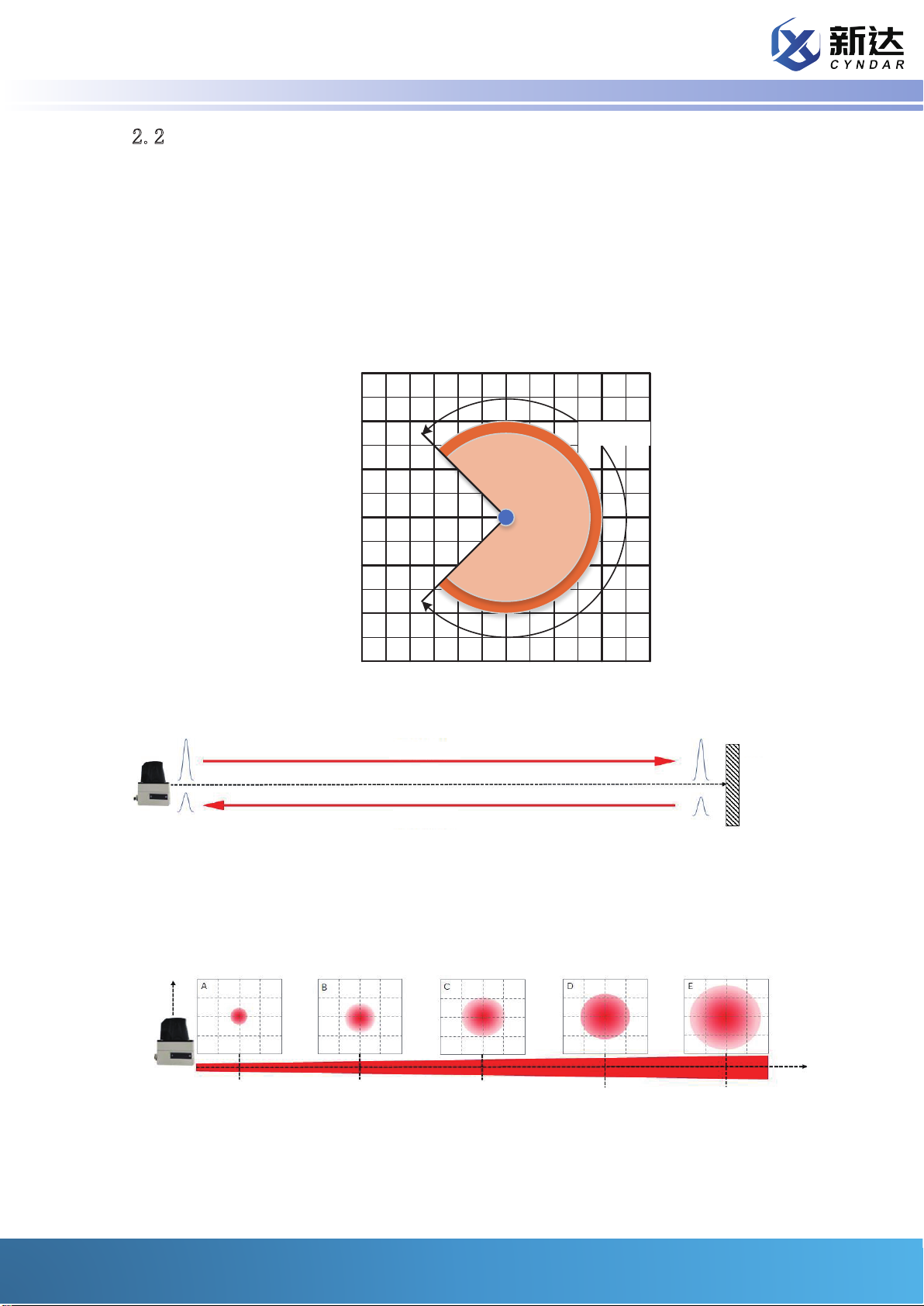

In this section, we will introduce the working mode, scanning mode and ranging performance of

XD-TOF-25 series in detail.

Within the measuring range, XD-TOF-25 can accurately measure the distance between the

object within the maximum range and the specified zero point. The measurement value

includes ranging error; in the process of continuous use, the measurement error at the same

detection distance presents a normal distribution. The following table gives the measurement

error of the statistical result at different detection distances and its standard deviation (specific

error And measurement).

Table 2-3 Ranging error within different detection distances

Ranging range

Ranging error

Standard deviation

of error distribution

The output range of XD-TOF-25 is 50mm-25000mm (the actual output is hexadecimal ASCII code,

1mm corresponds to 1h, ASCII code 30 30 30 31, 25000mm corresponds to 61A8h, ASCII code is 36

32 40 38, the specific format and details please (Refer to the section on data communication in

Section 4 Device Connection). For the ranging interval of 1-25000mm, our class has the following

division:

Table 2-4

Radar output Hex Significance

There are objects with too low reflectivity in this direction, the system cannot accurately identify

There are objects with too high reflectivity in this direction, the system cannot accurately identify

The diameter of the radar optics indicates that there is an object in the

observation direction, but the radar cannot clearly measure the

distance. Appeared in extremely special occasions, this option is to

avoid some physical conditions that we cannot understand that cause

the radar to fail to give accurate range values.

There is a certain fluctuating distance, with a maximum test relative

error of 5%. (Refer to test report)

Stable ranging distance, for normal reflectivity objects no more than

3cm ranging error